Académique Documents

Professionnel Documents

Culture Documents

Pipe Water Services

Transféré par

SamDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pipe Water Services

Transféré par

SamDroits d'auteur :

Formats disponibles

MECHANICAL COMMISSIONING STANDARD CHECKLIST SHEET STATION : NTPC - Ramagundam Stage III (1 X 500 MW) 01 OF 02 PLANT ITEM: PIPEWORK

- WATER SERVICES PLANT NOMENCLATURE : SYSTEM: UNIT NO : 7 ITEM 1 STATUS YES/NO General conditions satisfy the site Standing instructions as listed in the "Plant Item Comissioning Essential Pre-requisites". ( SCL MS1/1 ). The nameplate legend agrees with the approved NTPC Plant Nomenclature is clearly visible,securely fixed, durable and correleates with remote leabels. The installation is complete and correct in accordance with the latest drawings and specifications. Access for adjustments maintenance and repairs is satisfactory. Check that all bolts , flanges and tapping points are adequately provided. Check that all pipe falls to draining points satisfactory. Check that all fittings on the pipework comply to the requirements of the relevent Indian Standard for that system. Verify , if appropriate , that compression coupling have been inspected on site to confirm that coupling with drawing showing approved location. Check that all eqipment , fittings , temporary supports , anchors used during construction have been removed. Check that floor collars and wall boxes are of suficient size and the pipe suitably positioned to cater for pipe movement within the system constraints. Check that the pipework system,including supports is free to expand and contract within its constraints. Check that adequate venting and draining facilities have been provided for the pipe system. Check that all hose connections and fittings on fire Hydrant pipework are of the instantaneous coupling pattern. Check that all suppots are undamaged, fixed mounted vertically (except where design requires the support at a specified angle.) Check that all support loadings have been correctly set. ACTIVITY REMARKS

4 5

6 7

10

11

12

13

14

15

MECHANICAL COMMISSIONING STANDARD CHECKLIST SHEET 02 OF 02 STATION : NTPC - Ramagundam Stage III (1 X 500 MW) PLANT ITEM: PIPEWORK - WATER SERVICES PLANT NOMENCLATURE : SYSTEM: UNIT NO : 7 ITEM ACTIVITY STATUS REMARKS YES/NO 16 Confirm where possible, that there is a radial clearance between the pipe and the support clip. 17 18 Check that all temporary supports have been withdrawn. Check that all roller and sliding support are clean ,free to move and so constructed that dirt and water can not accumulate . Check that all thrust/anchor points are correctly installed. Confirm adequate support for small bore,horizontal pipes that may be stood upon (or adequate protection for pipes and support for system not strong enough to withstand additional loads). Verify that all valves in the system have been checked. Particularly NRV for correct direction of flow. Flush pipework through to open drain to ensure cleaniness and lack of debris in the lines . Hydraulic pressure test to the appropriate standard and ensure that system is leak free. Check that all temporary fittings,connections ,pades and blanks used for testing &cleaning have been removed ,and that all blanks still required in the system are adequately identified & recorded in the Blank Scedule. Ensure that ,where applicable ,commissioning strainers/filters have been removed and system strainer / filters fitted. During system Initial Operation /proving trails at full working pressure check for : (a) Leaks (b) System Vibration Check for proper painting of pipe line as per colour codes approved by NTPC. Name Signature Date

19 20

21

22

23

24

25

26

28

Elect. Mech. C&I BHEL Erec. BHEL Comg. NTPC Comg.

NTPC Erec.

Agency Elect. Mech. C&I

Vous aimerez peut-être aussi

- Water Circulation SystemDocument37 pagesWater Circulation SystemSam50% (2)

- Turbo GeneratorDocument92 pagesTurbo GeneratorArpit Kumar100% (1)

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- Introduction To Turbovisory InstrumentsDocument40 pagesIntroduction To Turbovisory InstrumentsSam0% (1)

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- Water Circulation SystemDocument37 pagesWater Circulation SystemSam50% (2)

- Recording, Reporting of OutputDocument30 pagesRecording, Reporting of OutputSam100% (3)

- Feedwater SystemDocument70 pagesFeedwater SystemishanpahwaPas encore d'évaluation

- L-03 Spring Loaded Foundation-PresentationDocument34 pagesL-03 Spring Loaded Foundation-PresentationSam100% (1)

- Generator ClassDocument93 pagesGenerator ClassSam100% (5)

- Equipment at HPSDocument60 pagesEquipment at HPSSam100% (1)

- Generator CommissioningDocument90 pagesGenerator CommissioningSam94% (18)

- Automatic Turbine Tester EeDocument17 pagesAutomatic Turbine Tester EeSam100% (1)

- KWU Turbine SystemDocument90 pagesKWU Turbine Systemvenukumare100% (6)

- Accident - Causes & FactorsDocument38 pagesAccident - Causes & FactorsSam100% (1)

- KWU Text GoverningDocument43 pagesKWU Text GoverningSam100% (2)

- DuctDocument100 pagesDuctSam100% (2)

- StartupDocument35 pagesStartupSam100% (1)

- Automatic Turbine TestorDocument26 pagesAutomatic Turbine TestorSam100% (2)

- Vertical Tube, Variable Pressure Furnace For Supercritical Steam BoilersDocument7 pagesVertical Tube, Variable Pressure Furnace For Supercritical Steam BoilersSamPas encore d'évaluation

- Boiler Erection PDFDocument44 pagesBoiler Erection PDFShankar Jha100% (1)

- Control TheoryDocument28 pagesControl TheorySamPas encore d'évaluation

- Vibration Measurement & AnalysisDocument48 pagesVibration Measurement & AnalysisSamPas encore d'évaluation

- Soot Blower Erosion: Typical Locations Corrective ActionDocument65 pagesSoot Blower Erosion: Typical Locations Corrective ActionSamPas encore d'évaluation

- Tube Fail 1Document29 pagesTube Fail 1Sam100% (1)

- Schemes TalcherDocument206 pagesSchemes TalcherSam100% (1)

- Vindh 9 CAVT ReportDocument20 pagesVindh 9 CAVT ReportSamPas encore d'évaluation

- Caustic Corrosion: Typical Locations Corrective ActionDocument33 pagesCaustic Corrosion: Typical Locations Corrective ActionSamPas encore d'évaluation

- Super Critical BoilerDocument78 pagesSuper Critical BoilerSam100% (2)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 3 Carbohydrates' StructureDocument33 pages3 Carbohydrates' StructureDilan TeodoroPas encore d'évaluation

- OZO Player SDK User Guide 1.2.1Document16 pagesOZO Player SDK User Guide 1.2.1aryan9411Pas encore d'évaluation

- of Thesis ProjectDocument2 pagesof Thesis ProjectmoonPas encore d'évaluation

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDocument1 092 pagesSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaPas encore d'évaluation

- Monergism Vs SynsergismDocument11 pagesMonergism Vs SynsergismPam AgtotoPas encore d'évaluation

- DP 2 Human IngenuityDocument8 pagesDP 2 Human Ingenuityamacodoudiouf02Pas encore d'évaluation

- The Indonesia National Clean Development Mechanism Strategy StudyDocument223 pagesThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaPas encore d'évaluation

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsDocument19 pagesHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraPas encore d'évaluation

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Organizational ConflictDocument22 pagesOrganizational ConflictTannya AlexandraPas encore d'évaluation

- 2021-03 Trophy LagerDocument11 pages2021-03 Trophy LagerAderayo OnipedePas encore d'évaluation

- MASONRYDocument8 pagesMASONRYJowelyn MaderalPas encore d'évaluation

- Mixed Up MonstersDocument33 pagesMixed Up MonstersjanePas encore d'évaluation

- Hole CapacityDocument2 pagesHole CapacityAbdul Hameed OmarPas encore d'évaluation

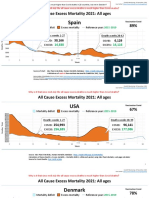

- Countries EXCESS DEATHS All Ages - 15nov2021Document21 pagesCountries EXCESS DEATHS All Ages - 15nov2021robaksPas encore d'évaluation

- Howard R700X - SPL - INTDocument44 pagesHoward R700X - SPL - INTJozsefPas encore d'évaluation

- Benevisión N15 Mindray Service ManualDocument123 pagesBenevisión N15 Mindray Service ManualSulay Avila LlanosPas encore d'évaluation

- Crown WF-3000 1.2Document5 pagesCrown WF-3000 1.2Qirat KhanPas encore d'évaluation

- Grade 7 ExamDocument3 pagesGrade 7 ExamMikko GomezPas encore d'évaluation

- Presentation 11Document14 pagesPresentation 11stellabrown535Pas encore d'évaluation

- Project ManagementDocument11 pagesProject ManagementBonaventure NzeyimanaPas encore d'évaluation

- Dialogue Au Restaurant, Clients Et ServeurDocument9 pagesDialogue Au Restaurant, Clients Et ServeurbanuPas encore d'évaluation

- From Philo To Plotinus AftermanDocument21 pagesFrom Philo To Plotinus AftermanRaphael888Pas encore d'évaluation

- Soosan Crane Training: (Principles)Document119 pagesSoosan Crane Training: (Principles)Boumediene CHIKHAOUIPas encore d'évaluation

- Android Developer PDFDocument2 pagesAndroid Developer PDFDarshan ChakrasaliPas encore d'évaluation

- Dalasa Jibat MijenaDocument24 pagesDalasa Jibat MijenaBelex ManPas encore d'évaluation

- Application of Graph Theory in Operations ResearchDocument3 pagesApplication of Graph Theory in Operations ResearchInternational Journal of Innovative Science and Research Technology100% (2)

- Playful Homeschool Planner - FULLDocument13 pagesPlayful Homeschool Planner - FULLamandalecuyer88Pas encore d'évaluation

- Chapter 1 To 5 For Printing.2Document86 pagesChapter 1 To 5 For Printing.2Senku ishigamiPas encore d'évaluation

- UC 20 - Produce Cement Concrete CastingDocument69 pagesUC 20 - Produce Cement Concrete Castingtariku kiros100% (2)