Académique Documents

Professionnel Documents

Culture Documents

Novolac Screed

Transféré par

md_kureshiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Novolac Screed

Transféré par

md_kureshiDroits d'auteur :

Formats disponibles

Dr.

Fixit Novolac Mortar

3 K C H E M I C A L & H E AT R E S I S TA N T N O V O L A C E P OX Y M O R TA R

Description

Dr. Fixit Novolac mortar is a three component, high solids amine hardener cured Novolac epoxy resin based mortar resistant to chemicals, solvent & temperature. It is composed of novolac epoxy resin, modified amine hardener, inert silica filler & additives. After curing it produces a tough screed with strong adhesion to primed surface. Dr. Fixit Novolac Mortar

Areas of Application

}} }} }} }} }} }} }} }} }} }}

Aggressive chemical tank linings. Secondary chemical containment. Industrial floors. Battery charge rooms / stations. Chemical processing industries. Chemical storage godowns. Extremely harsh chemical spillage areas. Pulp & paper industries. Pharmaceutical industries. Water & waste water storages.

Features & Benefits

}} }} }} }} }} }} }} }} }} }}

Easy to trowel. Sand finish. Fast curing. Low odour. Low VOC. Excellent resistance to mineral & organic acids, alkalies & solvents. High solids yields durable surface. Strong bond to concrete surface. Can be applied in running industry. Can be used in immersion service upto 120c & non immersion (dry) service upto 150c.

Method of Application The quality & performance of final coating is dependent on the substrate & material / application temperature. The recommended substrate temperature shall be min 5 c & max 35 c

1 S U R FAC E P R E PA R AT I O N

The new concrete surface must be atleast 28 days cured & should have moisture content less than 5% before priming.

}}

Clean the surface thorough by wire brushing & cleaning of dust by air blower or compressed oil free air. Clean the old concrete surface by sand / grit blasting to remove laitance & loosely bonded materials. Completely remove the oil & grease if present by degreasing using solvents like Toluene or Xylene Degreased surface shall be high pressure water washed, acid etched if required & high pressure water washed again. Substrate should be sound & free from contamination of mortar, paint splashes & curing compound. Coated surface shall be abrasive blasted & clean. Remove all the contaminations that could affect the bond to concrete. If possible wash the surface with clean water & allow it to dry completely before priming. Weak & damaged concrete must be removed & replaced with a suitable polymer modified or epoxy mortar. The surface defects should be repaired.

}} }} }}

}} }}

Dr. Fixit Novolac Mortar

INDUSTRIAL FLOORINGS

Dr. Fixit Novolac Mortar

3 K C H E M I C A L & H E AT R E S I S TA N T N O V O L A C E P OX Y M O R TA R

2 PRIMING

}}

3 MIXING

}} }} }}

Mix Part A & Part B in their individual containers to uniform consistency & appearance. Transfer Part A & Part B components into a clean & dry mixing vessel. Mix together using a slow speed (200 rpm) drill with a spiral mixing head to a homogeneous & uniform mix. Scrape the sides & bottom of the mixing container during mixing. Start addition of Part C, filler component into the liquid mix in parts under continuous stirring. Mix to a uniform & homogeneous thick mortar consistency.

}} }}

4 APPLICATION

}}

Spread mixed material over primed surface by trowel. Compact the spread mortar by steel trowel to a uniform & leveled surface.

5 CLEANING

}}

Clean tools & equipments immediately after use with solvents like Acetone, Methyl Ethyl Ketone or Toluene.

Precautions & Limitations

}}

Theoretical thickness given is based on measurement over smooth & non porous surface. The actual coverage & thickness of the coating will vary depending upon the field substrate texture, roughness& evenness. It is the responsibility of the applicator to apply sufficient material to achieve minimum dry film thickness. The containers must be tightly closed when not in use. Avoid naked flames, use flame proof electrical appliances. No smoking during use.

}} }} }}

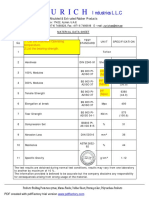

Technical Information

PROPERTIES SPECIFICATION RESULTS

Nature Mixing Ratio, parts by weight (Part A : Part B : Part C) Specific Gravity at 30c, grams / litre Pot life, at 30c minutes Over coating time, at 30c hours Foot traffic time, at 30c hours Mechanical Properties of cured material System Hardness Shore D Compressive strength, MPa, 7 Days Flexural strength, MPa, 7 Days Tensile strength, MPa, 7 Days Impact resistance Direct Mtr. Kg, 7 Days Indentation Bond strength to concrete MPa, 7 Days Abrasion resistance ASTM D 4541 ASTM D 4226 MIL- D 3134 F ASTM D 2240 ASTM D 695 ASTM C 580 ASTM D 638

Three component. 11.67 : 5 : 83.33 1.9 2.0 45 8 12 67 70 80 70 80 40 50 30 35 1.8 2.0 No indentation > 1.75, Concrete fails

Dr. Fixit Novolac Mortar

Apply one coat of Dr. Fixit Novolac EP primer. Allow it to dry for 8 12 hrs before application of Dr. Fixit Novolac Mortar. Dr. Fixit Novolac Mortar

INDUSTRIAL FLOORINGS

Dr. Fixit Novolac Mortar

3 K C H E M I C A L & H E AT R E S I S TA N T N O V O L A C E P OX Y M O R TA R

CS17, 1 Kg, 1000 cycles, mg loss Water absorption, (24 hr immersion) % Service temperature, c Chemical resistance Water, alkalies & mineral acids Organic acids & solvents Flammability pH range withstands Packing

17 kg

ASTM C 501 ASTM C 570

30 Max 0.1 120 150 Excellent V. Good

Dr. Fixit Novolac Mortar

ASTM D 635

self extinguishing 1 13.5

Coverage*

2.5 3 Sq. mt / 17 kg / 3 mm

* Coverage depends upon surface profile of the substrate.

Shelf Life & Storage

Shelf life is pf 1 year from date of manufacturing when stored in a cool & dry place (at + 10c to + 30c & 50 % RH) in unopened condition.

Health & Safety Precautions

}}

Skin Contact : Wash skin with soap & water. remove contaminated clothes. See medical attention if irritation persists. Do not use solvent. Eye Contact: Immediately flush eyes with plenty of water for at least 15 minutes. Eye lids should be held away from the eye ball to ensure thorough rinsing. Consult Physician if irritation persists. Inhalation: Move the subject to fresh air. if breathing is difficult or not breathing, give artificial respiration. obtain medical attention. Ingestion: Do not induce vomitting. never give anything by mouth to an unconscious person. call a Physician. Note To Physician: There is no specific antidote. Treatment should be given symptomatically on the clinical conditions. Fire Extinguishing Media: Both materials are combustible. Use foam, Dry chemical Powder or CO2 to extinguish the fire. Thermal Decomposition Product: These products may be toxic. may yield acrid smoke and irritating gases with oxides of carbon and other toxic vapours. Special Fire Fighting Procedure: It is advisable to use self contained breathing apparatus or equivalent [MSHA/ NIOSH approved] with full protective clothing. Unusual Fire And Explosion Hazards: Use water spray to cool the containers. material can form explosive mixture with air in hot condition.

}}

}}

}} }} }} }}

}}

}}

Other Product Categories Available

DR. FIXIT has wide range of Waterproofing & Construction chemicals which includes,

} } } }

Waterproofing Products Repair Products Sealants Flooring Products

} } } }

Exterior Coating Products Tile Fixing Range Concrete Admixtures Grouts

Dr. Fixit Novolac Mortar

INDUSTRIAL FLOORINGS

Dr. Fixit Novolac Mortar

3 K C H E M I C A L & H E AT R E S I S TA N T N O V O L A C E P OX Y M O R TA R

Dr. Fixit Novolac Mortar

Pidilite Industries Limited

Construction Chemicals Division Ramkrishna Mandir Road Post Box No. 17411 Andheri (E) Mumbai 400059 INDIA Tel +91-22-2835 7000 Fax +91-22-2835 7008 website www.doctor-fixit.com E-mail drfixit@pidilite.com

Toll Free No.: 1800-22-5502

DISCLAIMER The product information & application details given by the company & its agents has been provided in good faith & meant to serve only as a general guideline during usage. Users are advised to carry out tests & take trials to ensure on the suitability of products meeting their requirement prior to full scale usage of our products. Since the correct identification of the problems, quality of other materials used and the on-site workmanship are factors beyond our control, there are no expressed or implied guarantee / warranty as to the results obtained. The company does not assume any liability or consequential damage for unsatisfactory results, arising from the use of our products.

Dr. Fixit Novolac Mortar

INDUSTRIAL FLOORINGS

Vous aimerez peut-être aussi

- Advances in Aerogel Composites for Environmental RemediationD'EverandAdvances in Aerogel Composites for Environmental RemediationAftab Aslam Parwaz KhanPas encore d'évaluation

- Bio ShieldDocument3 pagesBio ShieldVimal GopalakrishnanPas encore d'évaluation

- Drip SealDocument4 pagesDrip Seal9236162548Pas encore d'évaluation

- Damp FreeDocument3 pagesDamp FreeblaqhaqarPas encore d'évaluation

- Fast FlexDocument3 pagesFast FlexManoj Kumar SinghPas encore d'évaluation

- Hexamine 1Document4 pagesHexamine 1Yousuck Donny ChandraPas encore d'évaluation

- Method Statement For Anti-Termite TreatmentDocument4 pagesMethod Statement For Anti-Termite TreatmentPEng. Tech. Alvince KoreroPas encore d'évaluation

- Guide Specifications For Portland Cement PlasterDocument5 pagesGuide Specifications For Portland Cement PlasterUmang sharmaPas encore d'évaluation

- Granite Tiles Unit: Profile No.: 245 NIC Code:13939Document13 pagesGranite Tiles Unit: Profile No.: 245 NIC Code:13939Sanyam BugatePas encore d'évaluation

- Concrete Technology Notes 2Document10 pagesConcrete Technology Notes 2Munir HalimzaiPas encore d'évaluation

- Anti Termite TreatmentDocument8 pagesAnti Termite TreatmentMYTHRI INFRA VIZAGPas encore d'évaluation

- Providing and Laying Integral Cement Based Water Proofing Treatment IncDocument5 pagesProviding and Laying Integral Cement Based Water Proofing Treatment IncEr R RamanPas encore d'évaluation

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Document6 pagesExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- Specifications of Painting WorksDocument7 pagesSpecifications of Painting WorksSiddharth Gamare100% (1)

- Water Proofing of Terrace: Specification: Part1: Sealing of Pipe InsertsDocument3 pagesWater Proofing of Terrace: Specification: Part1: Sealing of Pipe InsertsJayashree nPas encore d'évaluation

- Integral Colour ConcreteDocument1 pageIntegral Colour ConcretektbaluPas encore d'évaluation

- RIPSTAR 49v5Document4 pagesRIPSTAR 49v5Ankita Baban GavadePas encore d'évaluation

- ESTOP TDS - Estogard CS Lining R002.i.21Document2 pagesESTOP TDS - Estogard CS Lining R002.i.21Dewi OktoraPas encore d'évaluation

- Damp FreeDocument2 pagesDamp FreeShashi Bhushan SinghPas encore d'évaluation

- Asian Filling PuttyDocument2 pagesAsian Filling PuttyAhmad ShakeelPas encore d'évaluation

- MasterSeal 380 TDSDocument2 pagesMasterSeal 380 TDSEngTamerPas encore d'évaluation

- Paint Calculation: Factor To Consider AreDocument1 pagePaint Calculation: Factor To Consider AreKalyanasundaram ThirugnanasambandamPas encore d'évaluation

- Polymer Modified Mortars and CementDocument9 pagesPolymer Modified Mortars and CementKunwar Apoorv Singh Parihar100% (1)

- High Grade Mix ConcreteDocument12 pagesHigh Grade Mix Concretevishal banaPas encore d'évaluation

- Melamine Polyimide Composite Fire Resistant Intumescent Coatings (Repaired)Document26 pagesMelamine Polyimide Composite Fire Resistant Intumescent Coatings (Repaired)Satish GuptaPas encore d'évaluation

- MTC For ThermocolDocument2 pagesMTC For ThermocolhariprasadPas encore d'évaluation

- RSCF Method Statement Terrace WaterproofingDocument2 pagesRSCF Method Statement Terrace WaterproofingSagar ParabPas encore d'évaluation

- Furan C - Product Information Sheet PDFDocument2 pagesFuran C - Product Information Sheet PDFAnuradhaPatraPas encore d'évaluation

- Co 34Document10 pagesCo 34Baskar Srinivas SPas encore d'évaluation

- ConcreteDocument3 pagesConcreteTran DtrungPas encore d'évaluation

- Renderoc PlugDocument3 pagesRenderoc Plugtalatzahoor100% (1)

- S# Item C Waterproofing On SurfacesDocument8 pagesS# Item C Waterproofing On SurfacesDeepa Junnarkar Degwekar100% (1)

- CT PPTS - 1Document333 pagesCT PPTS - 1tahir khanPas encore d'évaluation

- Supplying, Jointing and Fixing G.I Water Pipe and FittingDocument8 pagesSupplying, Jointing and Fixing G.I Water Pipe and FittingUmesh joshiPas encore d'évaluation

- Sieve Analysis of Fine and Coarse Aggregate: Test Procedure ForDocument5 pagesSieve Analysis of Fine and Coarse Aggregate: Test Procedure Forzulaffan zairifliPas encore d'évaluation

- Dr. Rizwan ThesisDocument168 pagesDr. Rizwan ThesisSufian AhmadPas encore d'évaluation

- 9510 Bitumen MasticDocument21 pages9510 Bitumen MasticAbhinandan Guwahati VmcPas encore d'évaluation

- Cement Test Methods High AluminaDocument22 pagesCement Test Methods High AluminaSaragadam DilsriPas encore d'évaluation

- University College Accessibility India Design Manual Svayam AICTE Guidelines ModifiedDocument39 pagesUniversity College Accessibility India Design Manual Svayam AICTE Guidelines ModifiedVaishnavi JayakumarPas encore d'évaluation

- ECMAS Terrace Waterproofing SolutionsDocument8 pagesECMAS Terrace Waterproofing SolutionsLokesh DvPas encore d'évaluation

- Concrete TechnologyDocument36 pagesConcrete Technologyshalu R FPas encore d'évaluation

- Chemical AdmixtureDocument9 pagesChemical AdmixtureShenbagaraja PandianPas encore d'évaluation

- Pamphlet On Quality Assurance For Cement PlasteringDocument4 pagesPamphlet On Quality Assurance For Cement PlasteringD V BHASKARPas encore d'évaluation

- DR Fixit Powder WaterproofDocument2 pagesDR Fixit Powder Waterprooflokeshras12Pas encore d'évaluation

- Mathematical Modeling and Manufacturing of Hdpe/pp Bricks Using Different Fillers by Continuous Extrusion ProcessDocument65 pagesMathematical Modeling and Manufacturing of Hdpe/pp Bricks Using Different Fillers by Continuous Extrusion ProcessEkta ChaturvediPas encore d'évaluation

- Drfixit Torchshield PDFDocument4 pagesDrfixit Torchshield PDFshashiPas encore d'évaluation

- Water ProfoofingDocument8 pagesWater ProfoofingShruti VermaPas encore d'évaluation

- Cements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersDocument8 pagesCements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersjaimePas encore d'évaluation

- Slump LossDocument4 pagesSlump LossAman SahadeoPas encore d'évaluation

- Final Aac PDFDocument7 pagesFinal Aac PDFindrajit sodhaPas encore d'évaluation

- Developing Together. Building With Each Other.: We Create Chemistry For Advanced ConstructionDocument5 pagesDeveloping Together. Building With Each Other.: We Create Chemistry For Advanced ConstructionAlex Paye AncoPas encore d'évaluation

- Hyper CreteDocument2 pagesHyper CretedjgiumixPas encore d'évaluation

- PBS Stephen Miranda May2014 S Jet ArticleDocument4 pagesPBS Stephen Miranda May2014 S Jet ArticlejojibaPas encore d'évaluation

- Enhancing White and Colored Concrete With MetaMaxDocument3 pagesEnhancing White and Colored Concrete With MetaMaxm.shahbaghiPas encore d'évaluation

- PHASE 1 PPT CRCTDDocument14 pagesPHASE 1 PPT CRCTDSudhira ShettyPas encore d'évaluation

- Anquamine 731Document4 pagesAnquamine 731Cloudy DayPas encore d'évaluation

- Building Materials Final Solution After Cor.Document64 pagesBuilding Materials Final Solution After Cor.TarunPas encore d'évaluation

- 2918 Mapeproof 1k Turbo UkDocument4 pages2918 Mapeproof 1k Turbo UkFloorkitPas encore d'évaluation

- ICAR Rheometer: Eric Koehler W.R. Grace & CoDocument34 pagesICAR Rheometer: Eric Koehler W.R. Grace & CoHafiezul HassanPas encore d'évaluation

- Damp GuardDocument3 pagesDamp GuardManmohan SinghPas encore d'évaluation

- AAS Questions: Year 12 ChemistryDocument2 pagesAAS Questions: Year 12 ChemistryKhalidOfqirPas encore d'évaluation

- Role of RDF in SDGsDocument16 pagesRole of RDF in SDGsAPas encore d'évaluation

- Calibration Curve: Kathleen Faith C. Briones Hope Louis Simbrio BS in Chemistry III Experiment No. 9Document6 pagesCalibration Curve: Kathleen Faith C. Briones Hope Louis Simbrio BS in Chemistry III Experiment No. 9Kat Chavez BrionesPas encore d'évaluation

- Chapter 22 Problems 1,, Straightforward, IntermediateDocument12 pagesChapter 22 Problems 1,, Straightforward, Intermediatecobalt boronPas encore d'évaluation

- Roleof Gravity ConcentrationDocument10 pagesRoleof Gravity ConcentrationDEGAGA AMENUPas encore d'évaluation

- Light Genertaing ConcreteDocument14 pagesLight Genertaing ConcreteGaurav JainPas encore d'évaluation

- Carl Sagan - Definitions of LifeDocument4 pagesCarl Sagan - Definitions of LifejacobmohPas encore d'évaluation

- Tank and Pressure Vessel MaintenanceDocument30 pagesTank and Pressure Vessel MaintenancePandu Satrio100% (2)

- DPWH-QMSF-49 Rev00 Worksheet On Testing of Emulsified Asphalt-2Document2 pagesDPWH-QMSF-49 Rev00 Worksheet On Testing of Emulsified Asphalt-2Myrna FielPas encore d'évaluation

- Method StatementDocument5 pagesMethod StatementbecpavanPas encore d'évaluation

- 17 de Thi Hoc Ki 1 Mon Hoa Hoc Lop 10Document379 pages17 de Thi Hoc Ki 1 Mon Hoa Hoc Lop 10cclatrumPas encore d'évaluation

- IB 2 HL - Nuclear Physics - 2Document5 pagesIB 2 HL - Nuclear Physics - 2Jessica GuyPas encore d'évaluation

- Frictioanal WeldingDocument17 pagesFrictioanal WeldingNibras KPas encore d'évaluation

- (Richard C. Alkire, Dieter M. Kolb, Jacek LipkowskDocument281 pages(Richard C. Alkire, Dieter M. Kolb, Jacek LipkowskYanpiero BalladoresPas encore d'évaluation

- USP Monographs - PiroxicamDocument2 pagesUSP Monographs - Piroxicamaqeel1970Pas encore d'évaluation

- Teflon MDSDocument1 pageTeflon MDSSajir ThiyamPas encore d'évaluation

- BenzaldehydeDocument9 pagesBenzaldehydeMichelle AngelaPas encore d'évaluation

- Solutions Thermal Light ExerciseDocument4 pagesSolutions Thermal Light Exerciseblabla137Pas encore d'évaluation

- Cold Shut DefectsDocument3 pagesCold Shut Defectsvivek1312Pas encore d'évaluation

- Nanofabrication NIL PDFDocument59 pagesNanofabrication NIL PDFMoiz AmirPas encore d'évaluation

- LIFE Hymemb - Technical GuidelinesDocument30 pagesLIFE Hymemb - Technical GuidelinesMichaelPas encore d'évaluation

- CF1FR v2.0 OnlineDocument2 pagesCF1FR v2.0 OnlineAnonymous 3VAQ9SNxl7Pas encore d'évaluation

- Examen de Evaluación API 571Document18 pagesExamen de Evaluación API 571berray2007100% (2)

- Drawbacks of Open Chain StructureDocument7 pagesDrawbacks of Open Chain StructureRahul DubeyPas encore d'évaluation

- Drug MetabolismDocument52 pagesDrug MetabolismUsman AkhtarPas encore d'évaluation

- Z Energy Limited: Safety Data SheetDocument11 pagesZ Energy Limited: Safety Data SheetRajeshPas encore d'évaluation

- Rheomix 125: Binder 5Document3 pagesRheomix 125: Binder 5Raven James Angelo IgnacioPas encore d'évaluation

- ChevronDocument4 pagesChevronanon_464848664Pas encore d'évaluation

- Learning Activity Sheets: Ganilyn D. Ponciano. Stem 12 - A General Chemistry 2Document7 pagesLearning Activity Sheets: Ganilyn D. Ponciano. Stem 12 - A General Chemistry 2Ganilyn Ponciano0% (3)

- Amino Acid CatabolismDocument7 pagesAmino Acid CatabolismAhmed Ali Mohammed AlbashirPas encore d'évaluation