Académique Documents

Professionnel Documents

Culture Documents

Vibration Mill

Transféré par

Aprilla FauzyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Vibration Mill

Transféré par

Aprilla FauzyDroits d'auteur :

Formats disponibles

Vibration Mill Operating principles: Under the state of high-frequency vibrations of shocker (or vibration motor) with high

speed, grinding medias (rods, sticks and balls)in grinding cavity launch strongly, rotate quickly and revolve with a low speed, making feed materials impacted, rubbed and sheared strongly, as a result of superfine particles distributed evenly. Performances and features Suitable for hard and soft materials with Mohs` hardness Compared to ball mill, air-stream mill and impacting mill, it has low investment cost, low energy consumption, simple flow, high efficiency and reasonable price. Particle size can be changed by adjusting quantities of feed materials, amplitude of vibration and grinding media`s grades. To form series connection with classifier to get products with narrower size of distribution. Grinding Medias and scale-board are made of high manganese steel, high cadmium steel stainless steel, Al2O3, ZrO2 and quartz materials. Wear-resistance and no pollution. To crush heat- sensitive and low melting point materials by the method of water cooling or strong refrigeration system. To use single machine to change products` nature and finish its mixture during crushing. According to materials` nature, to adopt dry mill, wet mill, continuous mill or intermittent mill. According to GMP, used in dugs, herbal medicine, food, health-care, or research institutes and Lab. To adopt air spring or rubber spring instead of hard spring. Long life, good vibration absorbing results and low noises.

Pharmaceutical Multi Mill We are providing highly efficient pharmaceutical multi mill, which is a self controlled portable unit. Our multi mills are suitable for high speed granulating, pulverizing, mixing, shredding and chopping of a range of wet and dry material without any special attachments.

To manage the size reduction of the material, the pharmaceutical multi mill uses all the principles of variable force such as grinding, compression, impact and shearing in an effective manner in its functions. Our multi mills give higher output with process uniformity. Following are the industries where our multi mills are

used:

Chemical Pharmaceutical Cosmetics Ceramics Dyestuff Food Pesticides Fertilizers

Smita Industries, Mumbay

Ball_Mill Operating principles: Under the state of high-frequency vibrations of shocker (or vibration motor) with high speed, grinding medias (rods, sticks and balls)in grinding cavity launch strongly, rotate quickly and revolve with a low speed, making feed materials impacted, rubbed and sheared strongly, as a result of superfine particles distributed evenly. Performances and features Suitable for hard and soft materials with Mohs` hardness Compared to ball mill, air-stream mill and impacting mill, it has low investment cost, low energy consumption, simple flow, high efficiency and reasonable price. Particle size can be changed by adjusting quantities of feed materials, amplitude of vibration and grinding media`s grades. To form series connection with classifier to get products with narrower size of distribution. Grinding Medias and scale-board are made of high manganese steel, high cadmium steel stainless steel, Al2O3, ZrO2 and quartz materials. Wear-resistance and no pollution. To crush heat- sensitive and low melting point materials by the method of water cooling or strong refrigeration system. To use single machine to change products` nature and finish its mixture during crushing. According to materials` nature, to adopt dry mill, wet mill, continuous mill or intermittent mill. According to GMP, used in dugs, herbal medicine, food, health-care, or research institutes and Lab. To adopt air spring or rubber spring instead of hard spring. Long life, good vibration absorbing results and low noises.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Device Turns Air Pollution Into InkDocument2 pagesDevice Turns Air Pollution Into InkAnonymous izrFWiQPas encore d'évaluation

- Cryogenic TurboexpandersDocument9 pagesCryogenic TurboexpandersDwinaRahmayaniPas encore d'évaluation

- Acyclic HydrocarbonsDocument14 pagesAcyclic Hydrocarbonsvishal_kalraPas encore d'évaluation

- Admira Fusion - VC-84-002750-GB PDFDocument10 pagesAdmira Fusion - VC-84-002750-GB PDFkomanjoePas encore d'évaluation

- Bactericidal Activity of Silver Nanoparticles - A Mechanistic ReviewDocument14 pagesBactericidal Activity of Silver Nanoparticles - A Mechanistic ReviewCristianPas encore d'évaluation

- Precipitation TitrationDocument7 pagesPrecipitation Titrationadnan nuravifPas encore d'évaluation

- CB-8491 Heat Recovery BrochureDocument8 pagesCB-8491 Heat Recovery Brochurekats2404Pas encore d'évaluation

- Alphabetic List of Iran Refinery Plant PDFDocument108 pagesAlphabetic List of Iran Refinery Plant PDFBambang Kardito100% (1)

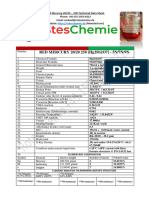

- Red Mercury 2020 Technical Data SheetDocument2 pagesRed Mercury 2020 Technical Data SheetThe UniversPas encore d'évaluation

- 2nd COTdetailedDocument6 pages2nd COTdetailedfe delgadoPas encore d'évaluation

- UNIT VDocument23 pagesUNIT VDhilsanth SLPas encore d'évaluation

- Chapter 2.1. Conduction Heat TransferDocument16 pagesChapter 2.1. Conduction Heat TransferDayanidiPas encore d'évaluation

- Sci8-Qtr3-Lesn2-Part1-Atomic StructureDocument21 pagesSci8-Qtr3-Lesn2-Part1-Atomic StructureDaniel LorioPas encore d'évaluation

- GEE ElectrodeDocument17 pagesGEE ElectrodeSatyamEngPas encore d'évaluation

- Pharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)Document13 pagesPharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)wangzahPas encore d'évaluation

- Gasha International School Homework PolicyDocument12 pagesGasha International School Homework PolicyOmar KhidhirPas encore d'évaluation

- State Wise Distribution of Units Registered Under Factories Act, 1948Document6 pagesState Wise Distribution of Units Registered Under Factories Act, 1948api-19850688Pas encore d'évaluation

- Units Earned Exam % No. of Test Items: ST NDDocument1 pageUnits Earned Exam % No. of Test Items: ST NDkenneth senadosPas encore d'évaluation

- HW 3Document2 pagesHW 3Christina HillPas encore d'évaluation

- A Brief Review On Optical Properties of Polymer Composites - Insights Into Light-Matter Interaction From Classical To Quantum Transport Point of ViewDocument28 pagesA Brief Review On Optical Properties of Polymer Composites - Insights Into Light-Matter Interaction From Classical To Quantum Transport Point of Viewomkar BembalgePas encore d'évaluation

- Calculation of Liquid Heat Capacity of Petroleum Distillate FuelsDocument3 pagesCalculation of Liquid Heat Capacity of Petroleum Distillate Fuelsdennise8Pas encore d'évaluation

- Computational Modelling in Drug DiscoveryDocument44 pagesComputational Modelling in Drug DiscoverySalna Susan AbrahamPas encore d'évaluation

- 2007 - Shellac in PolymerDocument43 pages2007 - Shellac in PolymerAnonymous x7VY8VF7Pas encore d'évaluation

- Basics of RadiobiologyDocument61 pagesBasics of RadiobiologyLikhon Amin AponPas encore d'évaluation

- FergDocument16 pagesFergSwetha SharmaPas encore d'évaluation

- Sika Igasol - 17: High Build, Bituminous Emulsion CoatingDocument3 pagesSika Igasol - 17: High Build, Bituminous Emulsion CoatingAhmed AbdallahPas encore d'évaluation

- Physics of Electromagnetic Calorimeters Based On Crystal ScintillatorsDocument49 pagesPhysics of Electromagnetic Calorimeters Based On Crystal ScintillatorsVigneshRamakrishnanPas encore d'évaluation

- Astm C 1202 - 2022Document8 pagesAstm C 1202 - 2022Mohammed AliPas encore d'évaluation

- AssociationDocument2 pagesAssociationRichmond EresmasPas encore d'évaluation