Académique Documents

Professionnel Documents

Culture Documents

D10901 Retrofitting A Velocity Sensor To The Model 310

Transféré par

Brian McMorrisDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

D10901 Retrofitting A Velocity Sensor To The Model 310

Transféré par

Brian McMorrisDroits d'auteur :

Formats disponibles

Data Dolphin Tech Note

D10901

optinst.com viewdatanow.com datadolphin.com emailalarm.com

Retrofitting a Velocity Sensor to the Model 310

Introduction

While the internal harness of the Model 310 enclosure has wires dedicated to carrying the velocity sensor

signal, high-frequency components in the signal may be improperly attenuated if this internal harness is

used. This must be retrofitted so that the velocity sensor’s specially shielded cable will be routed directly

through the base of the enclosure to the Model 310 velocity port. The following tech note details this

procedure for retrofitting a velocity sensor to an existing Model 310 installation.

Figure 1. Velocity sensor with pre-installed strain relief gland

Required Tools

To complete the retrofit, the following tools will be necessary:

• ½” Conduit Unibit (to drill a 7/8” hole)

• An electric hand drill

• A set of large channel lock pliers

• 12” crescent wrench

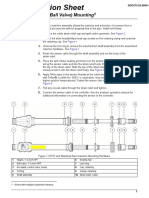

• A measuring tape Figure 2. 1/2" Conduit Unibit

• A pencil to mark the hole position.

• Electrical tape to mark the maximum depth on the Unibit

As the fiberglass material is subject to tearing if a regular drill bit is used, do not substitute the Unibit with

another type of drill bit.

Optimum Instruments Inc.

#201, 3124 Parsons Road, Edmonton, AB, Canada, T6N 1L6 1 of 3

For more info call (780) 450-0591 or FAX (780) 440-2515

Email: optimum@optinst.com 1000IE -09/02

D10901

Installation Procedure

Use the following procedure to route the velocity sensor cable through the bottom of the enclosure with a

water tight cable gland.

1. Open the enclosure and remove the battery and any objects that will interfere with drilling the hole

through the base of the enclosure.

2. Inspect the bottom of the case where the harness panel connectors are routed through the base of

the enclosure. From the right most panel connector (the two-wire wet sensor panel connector),

measure and mark a point approximately 2” on

center to the right. This point should also be inline

with the other three panel connectors.

3. As a helpful guide, mark the outside of the proposed

hole. A hole with a diameter of 7/8” (0.875”) is

required, so mark the edges of the hole at 7/16”

(0.4375”) from the center mark in step 2. 7/8”

4. Next, find and mark-off the maximum depth position

on the Unibit. This is done by marking the size just

above the 7/8” position with a piece of electrical

tape.

2”

5. Move all cables and wires clear and insert the Unibit

into the electrical drill’s chuck. Drill out the 7/8” hole

with the Unibit by drilling down to the position

marked on the Unibit with the electrical tape. Any slight Figure 3. Bored hole for strain gland, inside

tearing around the hole can be cleaned with #200 grit enclosure

sandpaper.

6. Next, remove jam nut from the strain relief gland on the

velocity sensor cable. Do not remove the ½” sealing ring.

7. Route approximately two feet of velocity sensor cable up into the inside of the enclosure through

the hole by loosening the sealing hub on the gland to slide the gland up the velocity sensor cable.

Push the threaded end of the gland up

through the hole. Bottom Top

8. Slide the jam nut over the connector end of (Underneath Enclosure) (Inside Enclosure)

the velocity cable and thread the jam nut

onto the end of the gland protruding into the

inside of the case. Be sure to have the jam nut

facing the correct way, with the securing feet on

the jam nut gripping the material of the

enclosure. Tighten as far as possible by hand.

9. Now tighten down the strain relief gland by

securing the jam nut with the channel lock pliers

on the inside of the case while rotating the throat Figure 4. Installed Gland

of the gland by turning on the nut built into it on

the outside of the case. Use a 12” crescent or 1 1/8” wrench. Tighten this very securely to

compress the sealing ring and make the gland seal against the outside of the enclosure.

10. Tighten down the outside hub with a large crescent or 1 1/8” wrench to compress the rubber seal

around the velocity sensor cable and make the gland watertight. Hold the nut built into the throat

of the gland to prevent it from rotating. Test the seal by tugging on the velocity sensor cable; it

should not slide or pull through the throat of the gland.

11. Unplug the harness connector from the velocity sensor port on the Model 310.

2 of 3 Retrofitting a Velocity Sensor to the Model 310

D10901

12. Finally, plug the velocity sensor connector into the velocity sensor port on the Model 310 and close

the enclosure to complete the installation.

Figure 5. Installed velocity sensor

Optimum Instruments Inc. makes no warranty for the use of its products, other than those expressly contained in the Company’s standard

warranty. The Company assumes no responsibility for any errors which may appear in this document, reserves the right to change devices or

specifications detailed herein at any time without notice, and does not make any commitment to update the information contained herein. No

licenses to patents or other intellectual property of Optimum are granted by the Company in connection with the sale of Optimum products,

expressly or by implication. Optimum’s products are not authorized for use as critical components in life support devices or systems.

Retrofitting a Velocity Sensor to the Model 310 3 of 3

Vous aimerez peut-être aussi

- Antenna Feeder System InstallationDocument24 pagesAntenna Feeder System InstallationAbdul RahimPas encore d'évaluation

- DD0304 Installing A Manhole Lid AntennaDocument2 pagesDD0304 Installing A Manhole Lid AntennaBrian McMorrisPas encore d'évaluation

- Sensor de Radiacion SolarDocument8 pagesSensor de Radiacion SolarCamilo PuertoPas encore d'évaluation

- DT436 500 Sq. MM PDFDocument3 pagesDT436 500 Sq. MM PDFHamedObaidPas encore d'évaluation

- Troubleshooting Manual, TS2712EN 04Document82 pagesTroubleshooting Manual, TS2712EN 04thibierozPas encore d'évaluation

- DG70 5423192Document31 pagesDG70 5423192Eliécer MeléndezPas encore d'évaluation

- BDA EN Analog Digital DOC2735290031Document6 pagesBDA EN Analog Digital DOC2735290031Agustín narroPas encore d'évaluation

- Magnet ExtensometerDocument12 pagesMagnet ExtensometerMandalay Pioneer Geoengineering Services (MPGS)Pas encore d'évaluation

- E4 Data SheetDocument3 pagesE4 Data SheetAyman ElotaifyPas encore d'évaluation

- Apex Locator Woodpex VHBZBSBDocument44 pagesApex Locator Woodpex VHBZBSBOmkar DavePas encore d'évaluation

- WEC SensorInstructions PDFDocument14 pagesWEC SensorInstructions PDFthouche007Pas encore d'évaluation

- Powercube1000 Installation and CommissioningDocument124 pagesPowercube1000 Installation and CommissioningHoda GaziaPas encore d'évaluation

- DTH Installation ProcedureDocument6 pagesDTH Installation Procedurenagbush2100% (2)

- 3.7 Meter ASC 208VAC Tedlar DP-7SSDocument36 pages3.7 Meter ASC 208VAC Tedlar DP-7SSpower kartoffelPas encore d'évaluation

- ETNSLB Operation and Installation ManualDocument12 pagesETNSLB Operation and Installation ManualsonotiumPas encore d'évaluation

- ZXSDR B8200 Outdoor Cabinet BC8910 PC891Document29 pagesZXSDR B8200 Outdoor Cabinet BC8910 PC891lankesha.ghnPas encore d'évaluation

- CCP700 Installation InstructionsDocument14 pagesCCP700 Installation Instructionsjaouad samnajiPas encore d'évaluation

- Installation Procedure For AntennaDocument8 pagesInstallation Procedure For AntennaAsraf AliPas encore d'évaluation

- 3100 Ultra Sonic Level Transmitter Install GuideDocument24 pages3100 Ultra Sonic Level Transmitter Install GuideHector Zenteno RodriguezPas encore d'évaluation

- EIC5000 Electronic Indicator Control Installation and Operation InstructionsDocument8 pagesEIC5000 Electronic Indicator Control Installation and Operation InstructionsАртемPas encore d'évaluation

- HELIAX Coaxial CableDocument8 pagesHELIAX Coaxial CablehernanoygPas encore d'évaluation

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaPas encore d'évaluation

- EVA Installation GuideDocument3 pagesEVA Installation GuidejeyalaljPas encore d'évaluation

- How To Install Hyport 8000 Series Medical Supply UnitDocument3 pagesHow To Install Hyport 8000 Series Medical Supply Unitofn gPas encore d'évaluation

- Doc enDocument11 pagesDoc enTina IvanovaPas encore d'évaluation

- ZXSDR B8200 Outdoor Cabinet BC8910+PC8910 Quick Install Guide R1.0 (V2010-12)Document29 pagesZXSDR B8200 Outdoor Cabinet BC8910+PC8910 Quick Install Guide R1.0 (V2010-12)AbrahamToscoPas encore d'évaluation

- Sptve: Electrical Installation and Maintenance (Eim) 9Document26 pagesSptve: Electrical Installation and Maintenance (Eim) 9Tade GaromaPas encore d'évaluation

- SPM6818 ManualDocument2 pagesSPM6818 ManualrenspurPas encore d'évaluation

- Wallbox 39Document24 pagesWallbox 39Larry WattsPas encore d'évaluation

- Installation and Use Guide for Bennett Premier XPT Trim Tab SystemDocument15 pagesInstallation and Use Guide for Bennett Premier XPT Trim Tab SystemPaul CharltonPas encore d'évaluation

- Network Mini Dome Cameras Quick Guide-V1.00Document13 pagesNetwork Mini Dome Cameras Quick Guide-V1.00pemerintahandesa palalangPas encore d'évaluation

- 15kV Front connector_KSU_500sq.mmDocument7 pages15kV Front connector_KSU_500sq.mmabd elmohsen saedPas encore d'évaluation

- Duct Installation of Fiber Optic Cable PDFDocument9 pagesDuct Installation of Fiber Optic Cable PDFnecmettinsengunPas encore d'évaluation

- Fireball Ignition PDFDocument14 pagesFireball Ignition PDFLucian LeontePas encore d'évaluation

- Digitilt Horizontal Probe Manual 2006Document17 pagesDigitilt Horizontal Probe Manual 2006Mahesh JalluPas encore d'évaluation

- Q1 Mod 3 EIM GRADE 12 NewDocument15 pagesQ1 Mod 3 EIM GRADE 12 NewRhenan LoseoPas encore d'évaluation

- Connector Service ManualDocument35 pagesConnector Service Manualleather_nunPas encore d'évaluation

- Operating Instructions Flow Monitors: SI6000 SI6100 SI6200Document17 pagesOperating Instructions Flow Monitors: SI6000 SI6100 SI6200harisPas encore d'évaluation

- M2 Antenna Systems, Inc. Model No: 222-5WL: SpecificationsDocument6 pagesM2 Antenna Systems, Inc. Model No: 222-5WL: SpecificationsAndhi AerosupplyPas encore d'évaluation

- Model 3051 Sensor Module Replacement: Safety MessagesDocument8 pagesModel 3051 Sensor Module Replacement: Safety MessagesSaeed VuPas encore d'évaluation

- Andrew Coaxial Cable Installation Instructions-Bulletin 17800BDocument8 pagesAndrew Coaxial Cable Installation Instructions-Bulletin 17800BMike FixPas encore d'évaluation

- AI316Document4 pagesAI316pvalverdea2014Pas encore d'évaluation

- Troubleshooting Guide QsonicaDocument8 pagesTroubleshooting Guide QsonicaarichePas encore d'évaluation

- Trango Antenna User Manual ADXX XX SX 1 and 2 FT DiamDocument14 pagesTrango Antenna User Manual ADXX XX SX 1 and 2 FT DiamhussainPas encore d'évaluation

- Luna Installation ManualDocument16 pagesLuna Installation Manualcmorley5057Pas encore d'évaluation

- Cable Gland Installation InstructionsDocument2 pagesCable Gland Installation InstructionsJairo WilchesPas encore d'évaluation

- Q1 Mod 5 EIM GRADE 12 LRMDSDocument16 pagesQ1 Mod 5 EIM GRADE 12 LRMDSRhenan LoseoPas encore d'évaluation

- Flexi Lite Quick Guide-0900d80580a0ba9f PDFDocument12 pagesFlexi Lite Quick Guide-0900d80580a0ba9f PDFAlex Enrique Chavez GonzalezPas encore d'évaluation

- DEC EC5 Manual - 751Document24 pagesDEC EC5 Manual - 751David Trejo CancinoPas encore d'évaluation

- MTS E-Beam Evaporator ManualDocument11 pagesMTS E-Beam Evaporator ManualMarco SalvatoriPas encore d'évaluation

- Antai Rail Solar Mounting Installation ManualDocument11 pagesAntai Rail Solar Mounting Installation ManualDiego EscobarPas encore d'évaluation

- Huawei OptiX RTN 950 IDU Quick Installation Guide (V100R006)Document46 pagesHuawei OptiX RTN 950 IDU Quick Installation Guide (V100R006)Thunder-Link.com100% (5)

- Traditional Sonar and DSI Sonar InstallationDocument22 pagesTraditional Sonar and DSI Sonar Installationgz770hPas encore d'évaluation

- Matrix FF InstallDocument22 pagesMatrix FF Installgcu93Pas encore d'évaluation

- sealey SMS2008Document3 pagessealey SMS2008cabuloPas encore d'évaluation

- ManualDocument16 pagesManualSean LancasterPas encore d'évaluation

- ELECTRICITYDocument70 pagesELECTRICITYJean Rose BalbontinPas encore d'évaluation

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationD'EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationPas encore d'évaluation

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationD'EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationPas encore d'évaluation

- Ultimate Guide: Wiring, 8th Updated EditionD'EverandUltimate Guide: Wiring, 8th Updated EditionÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- AMS 2Q 2009 10K FilingDocument21 pagesAMS 2Q 2009 10K FilingBrian McMorrisPas encore d'évaluation

- ICVGR Proceedings ColorDocument571 pagesICVGR Proceedings ColorBrian McMorris100% (2)

- GMO Grantham July 09Document6 pagesGMO Grantham July 09rodmorleyPas encore d'évaluation

- JP Morgan JPM Annual Report 2008Document240 pagesJP Morgan JPM Annual Report 2008Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook May - 09Document2 pagesBill Gross Investment Outlook May - 09Brian McMorris100% (2)

- JP Morgan JPM 10K 2008Document379 pagesJP Morgan JPM 10K 2008Brian McMorris100% (1)

- Bill Gross Investment Outlook Jun - 09Document3 pagesBill Gross Investment Outlook Jun - 09Brian McMorris100% (2)

- Bill Gross Investment Outlook Aug - 09Document3 pagesBill Gross Investment Outlook Aug - 09Brian McMorris100% (2)

- Bill Gross Investment Outlook Jul - 09Document3 pagesBill Gross Investment Outlook Jul - 09Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Jan - 09Document3 pagesBill Gross Investment Outlook Jan - 09Brian McMorrisPas encore d'évaluation

- Microsoft MSFT Annual Report 2008Document56 pagesMicrosoft MSFT Annual Report 2008Brian McMorrisPas encore d'évaluation

- GMO Ben Inker - Valuing Equities in An Economic Crisis - April 6 2009Document6 pagesGMO Ben Inker - Valuing Equities in An Economic Crisis - April 6 2009Brian McMorris100% (1)

- GGP 10-K Annual Report Filing 12-31-08Document142 pagesGGP 10-K Annual Report Filing 12-31-08Brian McMorrisPas encore d'évaluation

- 2008 AR Letter To ShareholdersDocument28 pages2008 AR Letter To Shareholdersfwallstreet100% (1)

- Bill Gross Investment Outlook Apr - 09Document4 pagesBill Gross Investment Outlook Apr - 09Brian McMorrisPas encore d'évaluation

- Microsoft MSFT Annual Report 2008Document56 pagesMicrosoft MSFT Annual Report 2008Brian McMorrisPas encore d'évaluation

- Ams 10K 2008Document80 pagesAms 10K 2008Brian McMorrisPas encore d'évaluation

- GGP 8K Bankruptcy Filing 04-16-09Document8 pagesGGP 8K Bankruptcy Filing 04-16-09Brian McMorrisPas encore d'évaluation

- Ams 10K 2006Document74 pagesAms 10K 2006Brian McMorrisPas encore d'évaluation

- Still River Systems in MIT Tech Review 9-5-2006Document3 pagesStill River Systems in MIT Tech Review 9-5-2006Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Nov - 02Document5 pagesBill Gross Investment Outlook Nov - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Aug - 01Document4 pagesBill Gross Investment Outlook Aug - 01Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Jul - 02Document4 pagesBill Gross Investment Outlook Jul - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Dec - 02Document5 pagesBill Gross Investment Outlook Dec - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Sep - 02Document8 pagesBill Gross Investment Outlook Sep - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Mar - 02Document5 pagesBill Gross Investment Outlook Mar - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Oct - 02Document5 pagesBill Gross Investment Outlook Oct - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Aug - 02Document5 pagesBill Gross Investment Outlook Aug - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook May - 02Document8 pagesBill Gross Investment Outlook May - 02Brian McMorrisPas encore d'évaluation

- Bill Gross Investment Outlook Feb - 02Document5 pagesBill Gross Investment Outlook Feb - 02Brian McMorrisPas encore d'évaluation

- Quiz and Answers - Group 2Document6 pagesQuiz and Answers - Group 2Paul Christian PerezPas encore d'évaluation

- Multi-Axis Drilling MachineDocument11 pagesMulti-Axis Drilling MachineJui KarmalkarPas encore d'évaluation

- Ngen Filament Post Processing GuideDocument6 pagesNgen Filament Post Processing GuidePDDELUCAPas encore d'évaluation

- Mac Pricelist 0810Document72 pagesMac Pricelist 0810rich475100% (1)

- Solga KatalogDocument40 pagesSolga KatalogMOHAMMEDPas encore d'évaluation

- Hass Programming Walk Through For MillsDocument22 pagesHass Programming Walk Through For MillsBiszopPas encore d'évaluation

- Titen HD Heavy-Duty Screw Anchor: FeaturesDocument17 pagesTiten HD Heavy-Duty Screw Anchor: FeaturesmrnaeemPas encore d'évaluation

- For Drifting and Tunneling: Sandvik RT300-seriesDocument6 pagesFor Drifting and Tunneling: Sandvik RT300-seriesДамир НазиповPas encore d'évaluation

- Carpentry Learning Activity Sheet 9Document16 pagesCarpentry Learning Activity Sheet 9Francisco LeaPas encore d'évaluation

- Drilling of Composite MaterialsDocument17 pagesDrilling of Composite Materialsrinu248Pas encore d'évaluation

- RZ - GTG - Produktkatalog-2021 - EN - Ansicht (1) - 22Document54 pagesRZ - GTG - Produktkatalog-2021 - EN - Ansicht (1) - 22Edson NhabetsePas encore d'évaluation

- AR 15 80 Tutorial Drill PressDocument11 pagesAR 15 80 Tutorial Drill PressBrian Bauman100% (2)

- Makita Acc-Cat 2019 20 View V1Document176 pagesMakita Acc-Cat 2019 20 View V1Himanshu GajjarPas encore d'évaluation

- 505 As Bas B 5052335Document11 pages505 As Bas B 5052335Bruno Alonso PachecoPas encore d'évaluation

- HILTI Anchors For Attachments To Hollow Core SlabDocument12 pagesHILTI Anchors For Attachments To Hollow Core SlabWenlei ZouPas encore d'évaluation

- 7 Use of Chip Breaker in MachiningDocument16 pages7 Use of Chip Breaker in MachiningPRASAD326100% (1)

- Mobile WorkbenchDocument5 pagesMobile Workbenchcfh666100% (3)

- Price List 2023 Ingco Hrs + HetDocument47 pagesPrice List 2023 Ingco Hrs + HetmimtechnPas encore d'évaluation

- 2012 Amana Tool CatalogDocument356 pages2012 Amana Tool CatalogCecilio ViverosPas encore d'évaluation

- Production EngineeringDocument15 pagesProduction EngineeringManav PriyadarshiPas encore d'évaluation

- Over Speed AlarmDocument36 pagesOver Speed AlarmJithinRajPas encore d'évaluation

- Fitting Workshop Manual2014Document35 pagesFitting Workshop Manual2014Sachi DhanandamPas encore d'évaluation

- FMDA DD17.2 Assembly TutorialDocument43 pagesFMDA DD17.2 Assembly TutorialArridhaios Buyesti100% (4)

- Build Your Own Electric GuitarDocument40 pagesBuild Your Own Electric GuitarMarko Aleksic100% (1)

- Benchwork Powerpoint PresentationDocument100 pagesBenchwork Powerpoint PresentationStewart StevenPas encore d'évaluation

- Dicorp - DiamantadosDocument40 pagesDicorp - DiamantadosSergei Sarmiento DuránPas encore d'évaluation

- Deep hole drilling systems MQL carbide toolsDocument2 pagesDeep hole drilling systems MQL carbide toolsarvinupPas encore d'évaluation

- Alupanel Brochure MULTIPANEL PDFDocument16 pagesAlupanel Brochure MULTIPANEL PDFjariasvazquezPas encore d'évaluation

- Klaw Bit BrosurDocument4 pagesKlaw Bit BrosurMus MualimPas encore d'évaluation

- Quick Hang Barn Door Without Backerboard Installation Instructions 2020 No Soft Close 1Document12 pagesQuick Hang Barn Door Without Backerboard Installation Instructions 2020 No Soft Close 1Brandon DeHartPas encore d'évaluation