Académique Documents

Professionnel Documents

Culture Documents

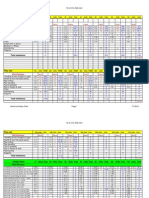

Piping Manhour Costing Estimate Sample

Transféré par

Methosalem HaincadtoDescription originale:

Copyright

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Piping Manhour Costing Estimate Sample

Transféré par

Methosalem HaincadtoDroits d'auteur :

Inch-Mtr (IM) & Inch-Dia (ID)

Inch-Mtr

When a Pipe oI 1 Inch Dia having a length oI 1

Mtr is installed, it is termed as 1 Inch-Mtr.

(Ex. 6 Inch Pipe, Length 5 Mtr 6 x 5 30 IM)

Inch-Dia

When a Pipe oI 1 Inch Dia Size is welded having 1

joint, it is termed as 1 Inch-Dia.

(Ex. 10 Inch Pipe, 4 Joints 10 x 4 40 ID)

ManHour, ManDay & ManMonth

ManHour

When 1 Worker works Ior 1 Hour, it is said 1 MH oI work.

(Ex. 2 Workers worked 8 Hrs 2 x 8 16 MH)

ManDay

When 1 Worker works Ior 1 Day, it is said 1 MD oI work

(Ex. 3 Workers worked 7 Days 3 x 7 21 MD)

ManMonth

When 1 Worker works Ior 1 Mth, it is said 1 MM oI work

(Ex. 8 Workers worked Ior 5 Mths 8 x 5 40 MM)

Piping Rates Quotation Basis

1) Per Mtr

2) Per Inch-Mtr

3) Per Inch-Dia

4) Per MT

5) Lumpsum

Piping Welding Productivity

Normal Figures as per the Average working oI

any Company, certain Norms are as below

a) Shop Floor 50 - 60 ID / Day / Welder

(Marking, Cutting, Grinding, Tacking etc..)

b) Erection at Site 25 - 30 ID / Day / Welder

(Laying, Fit-up, Welding, Testing etc..)

Piping Fabrication from Plates

Normally, above 30 Inch Size Pipes are

PreIabricated out oI Plates by Rolling &

Welding.

Plate Bending Machine is very much

important aspect in this Fabrication. It is

SpeciIied as Thk (mm) x Wiath (Mtr)

Related Piping Works

Pipe Supports Fabrication & Erection

Mitres Fabrication (Tee, Reducer, Elbow ..)

Insulation (Hot & Cold)

Sand Blasting (SA 2 )

Painting (Primer, Intermediate, Final)

Hydro Testing

Chemical Cleaning etc..

Jarious AD1 Requirements

Visual Inspection

Radiography (X Ray, Gamma Ray)

DP / MP Testing

Vacuum Box Testing

Ultrasonic testing (UT) etc..

Jarious Piping Materials

CS API 5L, A 106 Gr B (IBR, Non IBR)

LTCS A333 Gr 6

AS A335 Gr P1, P11, P22

SS 304, 304 L, 316, 316 L, 347 H

GI IS 1239

HDPE / Plastic

C.I. / Cement Pipes

Cement Lined

PIPIAC EREC1IOA 1YPES PIPIAC EREC1IOA 1YPES

a) Unit Piping

Involved within the plant mostly coming on Equipments & has more

number oI welding joints is reIerred as Unit Piping.

b) Offsite / Rack / Yara Piping

Involved within the plant mostly on Racks & across the plant, but has

less number oI welding joints is reIerred as OIIsite Piping.

c) Cross country Piping

Out oI plant mostly coming across the cities & has naturally less

number oI welding joints is reIerred as Cross-country Piping. (Oil,

Gas, Water)

a) Unaer Grouna Piping

Involved under the ground / buried may be within or outside the plant

& has less number oI welding joints is reIerred as Underground Piping

Ratio of Inch-Mtr to Inch-Dia (Appr.)

Unit Piping 1.5 to 2.0

OIIsite / Rack / Yard Piping 3.5 to 4.0

Cross-Country Piping 10.0 to 12.0

Under-Ground Piping 4.0 to 6.0

IM & ID Calculations from Isometrics

Piping Material wise Grouping

Sizewize Grouping

Number oI Fittings

Valves (Welded / Bolted)

Piping Cangs

a) Piping Prefabrication

Pipe Fabricator, Gas Cutter, Tack Welder,

Grinder, Helper

b) Piping Erection

Pipe Fitter, Tack Welder, Rigger, Helper

c) Piping Welaing

QualiIied Welder, Rigger, Helper

Weighted Inch-Dia

Piping involves various types oI Schedules. To estimate

Man-hours, Consumables etc.. Ior each Schedule, it is

really a tough task. Hence, all welding Inch-Dia are

converted to a 40 Schedule as a base. On this basis costing

is done, which becomes easier. This is callea Weighea

Inch-Dia.

Example

Si:e Sch Thk Actual ID Wightea ID

6 Dia 40 6 mm 100D 100D

6 Dia 120 18 mm 100D 300D

Direct Cost

Direct Labor

Direct Supervision

Consumables

R & M oI Tools / Tackles & Vehicles

Rental Charges oI Equipments

Power & Water consumption

Indirect Cost

Administrative StaII

Indirect Labor

Accommodation

Tools / Tackles & Vehicles Depreciation

Insurance

Preparatory Expenses

Travel

Bank Guarantees

General Expenses

Guarantee Obligation

1otal Price

Direct Expenses

Indirect Expenses +

Material Supplies +

Subcontracting Charges

Taxes & Duties

Agents Commission

Overheads

ProIits

Vous aimerez peut-être aussi

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisD'EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Piping Works EstimationDocument3 pagesPiping Works Estimationakg20041100% (5)

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (34)

- Cost Estimating Manual for Pipelines and Marine Structures: New Printing 1999D'EverandCost Estimating Manual for Pipelines and Marine Structures: New Printing 1999Évaluation : 5 sur 5 étoiles5/5 (2)

- Piping CostDocument33 pagesPiping CostAjay SastryPas encore d'évaluation

- Estimate Piping LabourDocument5 pagesEstimate Piping Labourandy100% (7)

- Estimator's General Construction Manhour ManualD'EverandEstimator's General Construction Manhour ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (20)

- 54 - Process Plant Piping Estimate DetailDocument57 pages54 - Process Plant Piping Estimate Detailstefax2010100% (3)

- Building Material Estimates and Rates Build Up: Second EditionD'EverandBuilding Material Estimates and Rates Build Up: Second EditionPas encore d'évaluation

- 630 Crew Manhour FactorsDocument112 pages630 Crew Manhour FactorsSatria Pinandita91% (11)

- Schedule for Sale: Workface Planning for Construction ProjectsD'EverandSchedule for Sale: Workface Planning for Construction ProjectsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- SS Pipe Fab & Erect CostsDocument5 pagesSS Pipe Fab & Erect Costswally55bear67% (3)

- CS Pipe Fab & Erect CostsDocument6 pagesCS Pipe Fab & Erect Costswally55bear69% (16)

- Piping ManhoursDocument32 pagesPiping ManhoursNejat Ababay75% (16)

- Piping EstimationDocument19 pagesPiping EstimationTitoFernandez86% (7)

- Resource Planning & ProductivityDocument19 pagesResource Planning & ProductivityVinit Kant Majumdar67% (3)

- Piping Manhours (Weight)Document25 pagesPiping Manhours (Weight)Nejat AbabayPas encore d'évaluation

- Piping EsitmlDocument92 pagesPiping Esitmlnbnb100% (3)

- Manhour StandardsDocument6 pagesManhour StandardsNaing Lin Cho56% (18)

- 2b Piping Estimate & Summary FormDocument14 pages2b Piping Estimate & Summary FormEK63100% (1)

- DACE Labour Productivity Norms The New Gulf CoastDocument25 pagesDACE Labour Productivity Norms The New Gulf Coastiplaruff0% (2)

- Man-Hour EstimateDocument1 pageMan-Hour EstimateImtinan Mohsin85% (20)

- Cost Centers & Unit ManhoursDocument161 pagesCost Centers & Unit ManhoursHammad100% (1)

- Labor Requirements For Construction M Aterials: Par T Il-Concrete Masonry UnitsDocument22 pagesLabor Requirements For Construction M Aterials: Par T Il-Concrete Masonry UnitsMohammed AffrozePas encore d'évaluation

- Standard Unit Work HoursDocument312 pagesStandard Unit Work HoursGino Alessandro PiazzaPas encore d'évaluation

- Cost Centers Vs ManhoursDocument166 pagesCost Centers Vs Manhoursguy88100% (1)

- Cost Estimation of Storage TankDocument2 pagesCost Estimation of Storage Tankmiteshmayur84% (19)

- Planning Norm Common WorkDocument6 pagesPlanning Norm Common WorkRidhwan Mad AliPas encore d'évaluation

- Technical Calculation and Estimator's Man-Hour Manual - Erection of Process or Chemical PlantsDocument241 pagesTechnical Calculation and Estimator's Man-Hour Manual - Erection of Process or Chemical PlantsJOHN67% (15)

- Technical Calculation and Estimators Man-Hour ManualDocument238 pagesTechnical Calculation and Estimators Man-Hour ManualN P Srinivasarao33% (12)

- Industrial Piping (Process Plant) Productivity StandardsDocument30 pagesIndustrial Piping (Process Plant) Productivity Standardsburerey100% (4)

- RIL Constn NormDocument29 pagesRIL Constn NormSubhojit Adhikary100% (3)

- Manhours Calculations MBDocument129 pagesManhours Calculations MBTalal Ahmed Khan100% (2)

- Technical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Document107 pagesTechnical Calculation and Estimator's Man Hour Manual - Marko Bulic's 20031Rezza Aditya47% (17)

- CS Pipes Installation CostDocument12 pagesCS Pipes Installation Costrajkamal_e100% (2)

- Estimation Man HourDocument241 pagesEstimation Man HourAnonymous ynJByUs52% (42)

- Welding Presentation by NoreastDocument78 pagesWelding Presentation by Noreastravi00098Pas encore d'évaluation

- 459-475 Hose AssembliesDocument17 pages459-475 Hose Assembliesrobertito101Pas encore d'évaluation

- Visit of CompanyDocument35 pagesVisit of CompanyMD Ishteyaque AhmadPas encore d'évaluation

- Company Profile - Sinai Engineering 07.09.2021Document49 pagesCompany Profile - Sinai Engineering 07.09.2021YOGESH PHALKEPas encore d'évaluation

- Casing DesignDocument71 pagesCasing DesignPeterMarkPas encore d'évaluation

- Piping Theory As Per ASME B31.3 PROCESS PIPINGDocument107 pagesPiping Theory As Per ASME B31.3 PROCESS PIPINGDeen first sdiPas encore d'évaluation

- 3D & 5D Pipe Bend For PipelineDocument6 pages3D & 5D Pipe Bend For PipelinemohammadazraiPas encore d'évaluation

- Internship Report of ISHAN EQUIPMENTS LTDDocument38 pagesInternship Report of ISHAN EQUIPMENTS LTDTapanPas encore d'évaluation

- Refrigerant Piping Work1Document13 pagesRefrigerant Piping Work1Le Manh HieuPas encore d'évaluation

- Data Rates-Tunnel Works 1Document20 pagesData Rates-Tunnel Works 1vpmohammed100% (2)

- Luciano Mantovano, Marcos Ponciano, Santiago Serebrinsky, Hugo Ernst, Teresa Pérez, Martin Valdez, Luis ChadDocument10 pagesLuciano Mantovano, Marcos Ponciano, Santiago Serebrinsky, Hugo Ernst, Teresa Pérez, Martin Valdez, Luis ChadMarcelo Varejão CasarinPas encore d'évaluation

- Project Report On Galvanised Nut & BoltDocument6 pagesProject Report On Galvanised Nut & BoltEIRI Board of Consultants and PublishersPas encore d'évaluation

- SoR 2015-16 (PART-IV)Document98 pagesSoR 2015-16 (PART-IV)Srinivasa KavitamPas encore d'évaluation

- Shop 49 - Pipe ShopDocument3 pagesShop 49 - Pipe ShopSahil JawaPas encore d'évaluation

- TFP1865 03 2013Document4 pagesTFP1865 03 2013Srikanth ShanmugamPas encore d'évaluation

- Satorp/Tr Interview Questionnare (Welding) : 1) What Is The Package Number and Explain?Document21 pagesSatorp/Tr Interview Questionnare (Welding) : 1) What Is The Package Number and Explain?RishiPas encore d'évaluation

- Welding InspectorDocument21 pagesWelding InspectorHamid MansouriPas encore d'évaluation

- Presentation Pipeline DesignDocument47 pagesPresentation Pipeline DesignEdy Erwanto100% (2)

- Weld CalculationsDocument13 pagesWeld CalculationsDries VandezandePas encore d'évaluation

- Rotor Clip Company - Wave Spring CalculatorDocument2 pagesRotor Clip Company - Wave Spring CalculatortstergioulasPas encore d'évaluation

- Aramco Interview Questions-4Document21 pagesAramco Interview Questions-4chandu666creator100% (4)

- Costing of PipelinesDocument15 pagesCosting of Pipelinesalex_caballero_12100% (1)

- Primavera P6 Project Management Refrence ManualDocument700 pagesPrimavera P6 Project Management Refrence ManualDebabrata Trivedi100% (8)

- Yo Have To UploadDocument1 pageYo Have To UploadMethosalem HaincadtoPas encore d'évaluation

- P6.7 - EPC Progress Calculation Percent Weight MethodDocument11 pagesP6.7 - EPC Progress Calculation Percent Weight MethodMethosalem Haincadto86% (7)

- Top Pull Down Menu PinoytoolbarDocument9 pagesTop Pull Down Menu PinoytoolbarMethosalem HaincadtoPas encore d'évaluation

- TopicsDocument1 pageTopicsMethosalem HaincadtoPas encore d'évaluation

- Stick Electrode Welding GuideDocument44 pagesStick Electrode Welding GuideTrajan AureliusPas encore d'évaluation

- Section Factors HPADocument16 pagesSection Factors HPATanmay GorPas encore d'évaluation

- Kraloy Catalogue 2018Document96 pagesKraloy Catalogue 2018Everth ValenciaPas encore d'évaluation

- Alloy 309Document3 pagesAlloy 309Branko FerenčakPas encore d'évaluation

- Ae Pu25Document3 pagesAe Pu25Shimmy AntonyPas encore d'évaluation

- Attachment 0Document32 pagesAttachment 0maría joséPas encore d'évaluation

- B0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WDocument1 pageB0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WNanang Cesc UttaPas encore d'évaluation

- Katalog CaravanDocument19 pagesKatalog CaravanOctavian GrecuPas encore d'évaluation

- Materials of Manav SadhnaDocument2 pagesMaterials of Manav SadhnaIshita JainPas encore d'évaluation

- Timber DesignDocument36 pagesTimber DesignKristine May Maturan100% (1)

- Masonry PDFDocument14 pagesMasonry PDFElmerPas encore d'évaluation

- MivanDocument15 pagesMivanMohammed rafeeq75% (4)

- MINUTO CARAFE Parts DiagramDocument8 pagesMINUTO CARAFE Parts DiagramBugsPas encore d'évaluation

- Corrodium Marine PDFDocument2 pagesCorrodium Marine PDFSutan Andreas Parlindungan HutaurukPas encore d'évaluation

- UK National Annex To EC2 - 1-1Document26 pagesUK National Annex To EC2 - 1-1David midland100% (1)

- A) Ordinary Portland Cement (OPC) - Also Known Simply As Portland Cement orDocument7 pagesA) Ordinary Portland Cement (OPC) - Also Known Simply As Portland Cement orRoberto AlvarezPas encore d'évaluation

- Concrete Beam DesignDocument3 pagesConcrete Beam Designheherson juanPas encore d'évaluation

- Sustainable Building TechnologiesDocument9 pagesSustainable Building TechnologiesprashuboyPas encore d'évaluation

- Mineral-Insulated Thermocouples According To DIN 43710 and DIN EN 60584Document11 pagesMineral-Insulated Thermocouples According To DIN 43710 and DIN EN 60584Veryco BudiantoPas encore d'évaluation

- Rubber CoatingDocument5 pagesRubber CoatingBalakrishna G SettyPas encore d'évaluation

- CBD Type Z1 PDFDocument10 pagesCBD Type Z1 PDFvtalexPas encore d'évaluation

- Kitz DJ E-234-03 PDFDocument16 pagesKitz DJ E-234-03 PDFYudi KurniawanPas encore d'évaluation

- 54 Ing 1240236698.06Document1 page54 Ing 1240236698.06Juan Alberto Mendoza VegaPas encore d'évaluation

- (MHD Catalogue) ME 2022 - V070722Document7 pages(MHD Catalogue) ME 2022 - V070722Chhenglong HengPas encore d'évaluation

- Steel Doors and Frames 2020 - LightDocument25 pagesSteel Doors and Frames 2020 - Lightchakacharlitch camposPas encore d'évaluation

- Power CoilDocument2 pagesPower CoilMirela VoiculescuPas encore d'évaluation

- VyaraBrochure TerrazzoDocument17 pagesVyaraBrochure TerrazzoHarshPas encore d'évaluation

- Installation and Maintenance Instructions: Resilient Seat Butterfly ValvesDocument12 pagesInstallation and Maintenance Instructions: Resilient Seat Butterfly ValvesBhargav PatelPas encore d'évaluation

- Drosibas Stiklu Klasifikacija PDFDocument2 pagesDrosibas Stiklu Klasifikacija PDFMārcis LukšēvicsPas encore d'évaluation

- Flexible Sprinkler Connection Type - Unbraided: Info@newage-India - in WWW - Newage-India - inDocument9 pagesFlexible Sprinkler Connection Type - Unbraided: Info@newage-India - in WWW - Newage-India - inAdmin NewAgePas encore d'évaluation

- Masdar Technical Supplies: Inspection and Test PlanDocument1 pageMasdar Technical Supplies: Inspection and Test PlanmaqboolPas encore d'évaluation

- Din 1693Document11 pagesDin 1693vitor7hugo100% (3)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)