Académique Documents

Professionnel Documents

Culture Documents

Fert

Transféré par

augus1982Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fert

Transféré par

augus1982Droits d'auteur :

Formats disponibles

VOL. 4, NO.

4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

ENERGY ANALYSIS FOR PRODUCTION OF POWDERED AND PELLETISED ORGANIC FERTILIZER IN NIGERIA

D. A. Fadare, O. A. Bamiro and A. O. Oni

Department of Mechanical Engineering, University of Ibadan, Ibadan, Oyo State, Nigeria E-Mail: fadareda@yahoo.com

ABSTRACT Energy study was conducted in an organic fertilizer plant in Ibadan, Nigeria, to determine the energy requirement for production of both powdered and pelletised organic fertilizer. The energy consumption patterns of the unit operations were evaluated for production of 9,000 kg of the finished products. The analysis revealed that eight and nine defined unit operations were required for the production of powder and pellets, respectively. The electrical and manual energy required for the production of powdered fertilizer were 94.45 and 5.55% of the total energy, respectively, with corresponding 93.9 and 5.07% for the production of pelletised fertilizer. The respective average energy intensities were estimated to be 0.28 and 0.35 MJ/kg for powder and pellets. The most energy intensive operation was identified as the pulverizing unit with energy intensity of 0.09 MJ/kg, accounting for respective proportions of 33.4 and 27.0% of the total energy for production of powder and pellets. Optimisation of the pulverizing process is suggested to make the system energy efficient.

Keywords: organic fertilizer, production, energy requirement, unit operations, Nigeria.

1. INTRODUCTION Energy is one of the most critical input resources in the manufacturing industries. In most cases, energy cost out weighs the costs of other resources such as raw material, personnel, depreciation and maintenance [1]. Hence, energy utilization efficiency constitutes a major determinant in the overall unit cost of production. Therefore, energy audit is an important management tool required for economic utilization of energy resources in any manufacturing outfit. Inefficient energy utilization could lead to huge economic losses. Excessive energy consumption adds to the costs of goods produced especially in the energy intensive industries. In view of this, attempts should be made for higher efficiency of utilization of fuel, electricity, thermal energy and labour, these being the major components of manufacturing cost. In Nigeria, the major sources of industrial energy are fossil fuel, natural gas, coal and electricity generated by thermal and hydro power station. The supply of electricity in the country is in acute shortage due in part to the dearth of underlying power generation technology and old facilities of the power stations, and also due to the problems in the transmission and the distribution of the energy. Consequently, most companies in the country now rely mainly on the use of heavy-duty generating plant for the supply of their electrical energy which is used for operations such as air conditioning, lighting and some machining processes [2]. The increasing energy demands coupled with the finite energy resources, the rising cost of fossil fuels and the considerable environmental impacts connected with their exploitation necessitate the needs to understand the mechanisms, which degrade the quality of energy and energy systems. The processes that degrade the quality of energy resources can only be identified through a detailed analysis of the whole system [2]. This account for the extensive work that has been done on energy auditing system of many manufacturing operations with the aim of

improving the design and performance of energy transfer systems. Although extensive literature exists concerning the energy audit of many manufacturing processes such as rice processing [3], sunflower oil expression [4], palmkernel oil processing [5,6], cashew nut processing [7], poultry processing [8], cassava-based foods [9], milk processing [10], and sugar production [11], limited work has been reported on energy audit of fertilizer processing operations. The energy requirements for the production, packaging, transportation, and application of inorganic fertilizers have been reported by Helsel [12]. The study revealed that the energy intensities required for production of Nitrogen, Phosphate and Potash fertilizers were 69.5, 7.7 and 6.4 MJ/kg, respectively. This thus indicates inorganic fertilizer production as an energy intensity operation. The adoption of modern manufacturing techniques has led to significant improvement in the energy efficiency for Nitrogen fertilizer production from a threshold value of about 400 MJ/kg (1910) to theoretical minimum of 40 MJ/kg (2000) [13]. Gellings and Parmenter [14] reported the energy requirements for transportation and application of inorganic and organic fertilizers. The study revealed that higher energy values were required for the transportation and application of organic fertilizer compared to inorganic fertilizers. However, the study did not quantify the energy requirement for the production of organic fertilizer. To the best of the authors knowledge no work has been conducted on the energy requirement and energy cost analysis of organic fertilizer manufacturing operations. The average annual fertilizer usage of 12.8 kg/hectare in Nigeria is very low compared with Zimbabwe and Western Europe with respective values of 57.1 and 231.4 kg/hectare [15]. The acute shortage in fertilizers required to maintain about 21 million hectares of farmland in Nigeria has been reported by Obigbesan [16]. The fertilizer requirement of Nigeria was 1.2 million

75

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com metric tonnes per annum for the period of 1985-1987. The demand has continued to increase since then, while the countrys total fertilizer supply increased from 750,000 tonnes in 1988 to 1.65 million tonnes in 1994, the supply drastically reduced to 835,000 tonnes in 1995. Of this total, only about 313,190 metric tonnes (37.5%) was produced locally and the trend has continued to increase [16]. The removal of 30% fertilizer subsidies by the government of Nigeria, the subsequent ban on importation of chemical fertilizers and constant breakdown of the existing five inorganic fertilizer manufacturing plants in the country have created scarcity leading to unaffordable prices of chemical fertilizer. Thus, making inorganic fertilizers to be beyond the reach of peasant farmers. The high cost of chemical fertilizer and the current global shift toward organic farming have led to increase in the demand for organic-based fertilizers. Therefore, many composting plants are springing up in different parts of the country [1]. The high organic content of the solid waste generated and the acute stortage in fertilizer requirement in the country favours the composting option as a sustainable and cost effective management strategy for solid waste and soil fertility. The use of organic based fertilizers has been found to increase crop yield, improve the quality of product, control soil-borne diseases, improve soil properties and conserve soil moisture [17]. The advantages of organic fertilizers over the inorganic fertilizers are: ability to supply the required plant nutrients, enhancement of the soil organic matter content, good water holding capacity, improved physical quality of the soil and cost effectiveness [15]. Development of various indigenous processing plants for organic fertilizer production has made business very important and on the forefront of various researches works [1]. Organic fertilizer production involves the conversion of organic wastes by aerobic or anaerobic microbial degradation. The basic operations involved in the production process include operations such as collection of the organic waste stocks, transportation, sorting, shredding, composting and curing, drying, screening, pulverising, mixing, pelleting and bagging. These operations require high and steady energy supply to function. Hence, there is need for efficient energy management strategy for production of organic-based fertilizer. The aim of this study was therefore to analyse the energy consumption pattern of the various unit operations required for the production of organic based fertilizer in Nigeria. The essence of the study is to identify the energy inefficiencies in the unit operations as a step towards the optimisation of the system. 2. MATERIALS AND METHODS 2.1 Process description An organic fertilizer processing plant located in Ibadan, Southwestern Nigeria was selected for this study. The plant was developed locally and installed in 1996 [1]. The plant, sited in a typical municipal market, produces both powdered and pelletised organo fertilizer using market refuse and animal intestinal waste. The types of energy sources utilized in the production system were electrical and manual energy. Electrical energy was the major source of energy used during production. Due to inconsistency in power from the National grid, a standby generating set with a capacity of 135 kV A was used as an alternative source for electrical power supply. There were nine defined unit operations in the production process for pelletised fertilizer, while eight unit operations were involved for production of powdered fertilizer. The process flow chart of the production system is shown in Figure-1. Refuse and animal intestinal waste were collected by the State Waste Management Authority and transported to the plant with a truck. The wastes were received, weighed and stored in different storage chambers for about 3 days before processing commenced. The storage chambers were made of rectangular concrete walls with a capacity of about fifteen thousand tonnes. The processing began by sorting manually the non biodegradable components of the market refuse such as iron, nylon, metal, glass, etc consisting of about 13.5% by weight of the total and 29.0% by volume. In order to facilitate the rate of decomposition during the composting process, the sorted bio-degradable component of market refuse was shredded with a shredding machine to reduce the particle size. The shredded market refuse and abattoir waste were then cocomposted aerobically with ratio of 3 to 1 by wet weight, respectively, inside open windrows for about 60 days. The organic wastes were piled up in layers and turned manually and sprinkled with water once a week. The compost was then cured for another 60 days and dried in a rotary dryer at low temperature to reduce the moisture content before the processing was continued. After composting and curing, the compost was screened with a mechanically operated separator fitted with a sieve of 15 mm in order to remove large, undegraded part of the compost, which was returned to the windrow and mixed with fresh compost, while the degraded part was conveyed via screw conveyor to the pulveriser. Other extraneous component like iron was removed by magnetic separator. The screened compost was then milled to fine powder using a hammer mill with a sieve size of 3 mm. Mineral additives such as Urea and rock phosphate were added and mixed with the milled compost. For the production of pellets, kaolin was added as artificial binding agent. Water was also added to increase the moisture content to about 15% on wet basis before bagging of the powdered fertilizer. The moisture content was increased to about 20% for the production of pellets. The milled and fortified compost was compacted mechanically with an extrusion pelletiser into 10 mm diameter pellets. The finished products (powder or pellet) were then bagged in 50 kg nylon laminated bags. The bagging process included the following operations such as, loading, weighing and sewing. The units operations were carried out on batch process. The energy input into each of these unit operations was accounted for by noting and quantifying the type of energy used, which were either one or a

76

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com combination of electrical and manual energy. All electric motors in the plant were identified, and the amperage and horsepower rating, number of phases and voltage were noted to enable the estimation of electrical energy. 2.2 Data collection The primary energy resources utilized in the plant were electrical and/or manual energy. An inventory of the electrical motors, power rating of the machines, heaters, number of personnel involved, time required for production, and material flow In each of the unit operation was made. The power rating of the electrical devices and capacity of each unit were collected from the plants manager. The production processes were monitored and data collected over a period of 2 months. The measuring quantities used in the course of the data acquisition include: (i) a stopwatch for measuring the time spent in each unit, (ii) a measuring cylinder for measuring the amount of water and (iii) a weighing balance for measuring the quantity of materials used. The data for the time and energy input into each of the unit operations are presented in Table-1. 2.3 Estimation of energy input into each unit operation The energy components (electrical and manual) for each of the unit operation were calculated for the production of 9,000 kg of finished fertilizer for both powdered and pelletised fertilizer. The following procedures were used: 2.3.1. Electrical energy The electrical energy usage by the equipment was obtained as the product of the rated power of each motor and the number of hours of operation. A motor efficiency of 80% was assumed to compute the electrical inputs [4]. This was calculated mathematically as: Ep = Pt (1) Where Ep is the electrical energy consumed in kW h, P is the rated power of motor in kW, t the hours of operation in hours and the power factor (assumed to be 0.8). 2.3.2. Manual energy This was estimated based on the values recommended by Odigboh [18]. According to him, at the maximum continuous energy consumption rate of 0.30kW and conversion efficiency of 25%, the physical power output of a normal human labourer in tropical climates is approximately 0.075kW sustained for an 810 h workday. This was calculated mathematically as: Em = 0.075 Nt (2) where Em is the manual energy in kW h, 0.075 is the average power of a normal human labour in kW, N is the number of persons involved in an operation and t the useful time spent to accomplish a given task in hours. Figure-1. Flow chart of the organic fertilizer processing operations.

77

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

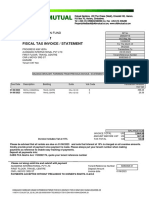

www.arpnjournals.com Table-1. Required parameters for evaluating energy in organic fertilizer plant. Operation Sorting Shredding Required Parameters Time taken for sorting (h) Number of persons involved in sorting Electrical power (kW) Time taken for shredding (h) Number of persons involved in shredding Composting Drying Time taken for sorting (h) Number of persons involved in sorting Electrical power (kW) Time taken for drying (h) Number of persons involved in drying Screening Pulverising Mixing Pelleting Electrical power (kW) Time taken for screening (h) Electrical power (kW) Time taken for pulverising (h) Electrical power (kW) Time taken for mixing (h) Electrical power (kW) Time taken for pelleting (h) Number of persons involved in pelleting Bagging Electrical power (kW) Time taken for bagging (h) Number of persons involved in bagging 3. RESULTS AND DISCUSSIONS The time and energy used for the production of 9,000 kg of both powdered and pelletised products are given in Tables-2 and 3. The energy consumption data obtained provides useful information on the sources of energy requirement of each processing unit. The data revealed that the total energy requirement for the production of powder and pellets were found to be 2,523.68 and 3,151.18 MJ, respectively. The total energy intensities were estimated to be 0.20 and 0.35 MJ/kg for the production of powdered and pelletised fertilizer, respectively. The estimated energy intensities for production of both powdered (0.20 MJ/kg) and pelletised (0.35MJ/kg) organic fertilizer were considerably lower compared to the energy intensities required for production of Nitrogen (69.5 MJ/kg), Phosphate (7.7 MJ/kg), and Potash (6.4 MJ/kg) fertilizers [12]. The electrical energy intensities were 0.27 and 0.33 MJ/kg for the production of powdered and pelletised products, respectively. The corresponding manual energy intensities were 0.016 and 0.018 MJ/kg. These clearly indicated that the pelletised product consumed more energy than the powdered product. The manual energy consumption for both Value 8.0 5 11.25 9.0 2 7.0 5 5.25 9.0 2 15.00 9.0 26.25 9.0 7.13 9.0 18.75 9.0 2 5.63 9.0 4

powdered and pelletised fertilizer represented proportions lower than 6% of the total energy consumption. It was observed that all the unit operations required electrical energy except for composting and sorting that was done manually. However, screening, pulverizing and mixing utilised only electrical energy and do not involve manual energy. The most energy intensive operating unit in the production system was identified as the pulverising unit with 850.50 MJ of energy, accounting for 33.4 and 26.99% of total energy required for the production of powder and pellets, respectively. To optimize the energy consumption of the pulverising unit, process and/or machine design modifications will be required. The process modification option will involve a change of process, the wet grinding method is suggested because of the low energy input requirement and drying can then be effected after the wet grinding process. The design modification option will involve increasing the capacity of the pulverising unit in order to increase the rate of production of the unit. Additional cost of investment will be required for the process modification option, while minimal additional cost may be required for the machine design modification option. Therefore, in terms of cost

78

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com effectiveness, the machine design modification considered to be the most feasible option. is

Table-2. Time and energy requirement for the production of powdered fertilizer. Production time (h) 8 9 7 9 9 9 9 9 Electrical energy Epi (MJ) 365.50 325.62 486.00 850.50 230.85 162.00 Manual energy Emi (MJ) 38.88 17.50 34.02 17.50 34.40 Total energy Et i (MJ) 38.80 383.00 29.16 343.12 486.00 850.50 230.85 182.25 Percentge energy ( Et i / Et tt )*100 (%) 1.53 15.06 1.15 13.5 19.11 33.4 9.08 7.17 100.00

# 1 2 3 4 5 6 7 8 Total

Process Sorting Shredding Composting/Curing Drying Screening Pulverizing Mixing Bagging

Eptt = 2420.47

94.45

8 8 8

Emtt = 142.30

5.55

Et tt = 2523.68

100.00

Percentage of total (%)

Ep tt = Epi , Emtt = Emi , Et tt = Et i

i =1 i =1 i =1

Table-3. Time and energy requirement for the production of pelletised organic fertilizer. Production time (h) 8 9 7 9 9 9 9 9 9 Electrical energy Epi (MJ) 365.50 325.62 486.00 850.50 230.85 540.00 162.00 Manual energy Emi (MJ) 38.88 17.50 34.02 17.50 17.50 34.40 Total energy Et i (MJ) 38.80 383.00 29.16 343.12 486.00 850.50 230.85 607.50 182.25 Percentage energy ( Et i / Et tt ) *100 (%) 1.23 12.15 0.93 10.89 15.42 26.99 7.33 19.28 5.78 100.00

# 1 2 3 4 5 6 7 8 9 Total

Process Sorting Shredding Composting/ Curing Drying Screening Pulverizing Mixing Pelleting Bagging

Eptt = 2,960.47

93.95

9 9 9

Emtt = 159.80

5.07

Et tt =

3,151.18 100.00

Percentage of total (%)

Ep tt = Epi , Emtt = Emi , Et tt = Et i

i =1 i =1 i =1

The energy and mass flow diagrams for the production of powdered and pelletised products are shown in Figures 2 and 3, respectively, using the modified form of energy accounting symbol presented by Singh [19]. The

electrical and manual energy consumption together with the material mass flow was assigned to each unit operations. The pelletised product involves nine defined

79

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com unit operation while the powdered production unit involves eight units.

Figure-2. Energy and mass flow diagram for the production of powdered organic fertilizer.

80

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Mass Flow (kg) Manual Energy (MJ) Electrical Energy (MJ) Unit Operation

Maket Refuse 12,531

Cow dung 4,177

Production System

38.88

Nonbiodegradable Refuse 1,048

Sorting 12,531

17.50 365.50

Shredding 11,483

Water 1,000 34.02 Water, Leachate & Gas 4,000

Composting/Curing 16,628

17.50 325.62

Water 6,000

Drying 12,628

468.00

Reject 1,657 Water, Additives& Binder 715

Screening 6,628

850.50

Pulverising 8,285

230.85

Mixing 9,000

17.50 540.00

Pelleting 9,000

34.40 162.00

Bagging 9,000

Pelletised organic fertilizer 9,000

Figure-3. Energy and mass flow diagram for the production of pelletised organic fertilizer. The two primary sources of electrical energy utility in the plant were the National grid and generating set. The acute energy crisis in the country often necessitated the use of power generator for most of the production time. 4. CONCLUSIONS The energy analysis for production of powdered and pelletised organic fertilizer in Ibadan, Nigeria suggested that: Eight defined unit operations were required for the production of powdered organic fertilizer, while nine unit operations were required for production of pelletised organic fertilizer; Electrical and manual energy were the two major sources of energy input in the production of organic fertilizer; The estimated energy intensities for production of powdered and pelletised organic fertilizer were 0.28 and 0.35 MJ/kg, respectively; and The most energy intensive operation was the pulveriser, which accounts for 27.0% of the total energy for production of pellets and 33.4% for powdered fertilizer.

81

VOL. 4, NO. 4, JUNE 2009

ISSN 1819-6608

ARPN Journal of Engineering and Applied Sciences

2006-2009 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com REFERENCES [1] D.A. Fadare. 2003. Development of an organomineral fertilizer processing plant. A Ph.D. thesis of Department of Mechanical Engineering, University of Ibadan. Ibadan, Nigeria. [2] M.A. Waheed, S.O Jekayinfa., J. O. Ojediran., O. E. Imeokparia. 2008. Energetic analysis of fruit juice processing operations in Nigeria. Energy. 33: 35-45 [3] G.O.I. Ezeike. 1981. Energy consumption in rice processing operations in Nigeria: selected case studies. J Agric Mech Asia Africa Latin Am.18 (1): 33-40. [4] A. Farsaie, M.S. Singh. 1985. Energy models for sunflower oil expression. Trans Am Soc Agric Engrs. 85: 275-85. [5] S.O. Jekayinfa, A.I. Bamgboye. 2004. Energy requirements for palm kernel oil processing operations. Nutr Food Sci. 34(4): 166-73. [6] S.O. Jekayinfa, A.I.Bamgboye. 2006. Development of equations for predicting energy requirements of palmkernel oil processing operations. J Food Eng. 79(1): 322-9. [7] S.O. Jekayinfa, A.I. Bamgboye. 2006. Estimating energy requirement in cashew (Anacardium occidentale L.) nut processing operations Energy. 31(8): 1305-20. [8] S.O. Jekayinfa. 2007. Energetic analysis of poultry processing operations. Leonardo J. Sci. 10(1): 77-92. [9] S.O. Jekayinfa, J.O. Olajide. 2007. Analysis of energy usage in the production of three selected cassavabased foods in Nigeria. J Food Eng. 82(2): 217-26. [10] E.J. Miller. 1986. Energy management in milk processing. In: Singh RP, editor. Energy in food processing, energy in World agriculture. Amsterdam: Elsevier. pp. 137-153. [11] T. Tekin, M. Bayramoglu. 1998. Exergy loss minimization analysis of sugar production process from sugar beet. Trans. I. Chem. E. 76: 149-154. [12] Z.R. Helsel. 1992. Energy and alternatives for fertilizer and pesticide use. In: Fluck R.C. (Ed.). Energy in Farm Production, Volume 6, New York: Elsevier. pp. 177-201. [13] Anundskas. 2000. Technical improvements in mineral nitrogen fertilizer production. In: Harvesting energy with fertilizers. European Fertilizer Manufacturers Association. [14] C.W. Gellings, K.E. Parmenter. 2004. Energy efficiency in fertilizer production and use. In: Gellings CW and Blok K [Eds.]. Efficient use and conservation of energy. In Encyclopedia of Life Support Systems (EOLSS), Developed under the auspices of the UNESCO, EOLSS Publishers, Oxford, UK. pp. 1-15. [15] J.A.I. Omueti, M.K.C. Sridhar, G.O. Adeoye, O.A. Bamiro, D.A. Fadare. 2000. Organic fertilizer use in Nigeria: our experience. In: Akoroda MO. (Ed.) Agronomy in Nigeria, University of Ibadan. pp. 208215. [16] G.O. Obigbesan.1999. Fertilizer: Nigerian Farmers Dilemma, Inaugural lecture delivered at University of Ibadan. pp. 1-23. [17] W.T. Chiu. 2001. Quality control of organic fertilizer (compost). FFTC Workshop, Suweon, Korea. pp. 6-9. [18] E.U. Odigboh. 1997. Machines for crop production. In: Stout BA, editor. Handbook of agricultural engineering-plant production engineering. American Society of Agricultural Engineers. [19] R.P. Singh. 1998. Energy accounting in food process operation. Food Technol. 32(4): 40-46.

82

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- AC Quanti Review 2 CC NO AnsDocument5 pagesAC Quanti Review 2 CC NO AnsRoda Gayle RañadaPas encore d'évaluation

- EisenDocument2 pagesEisenaugus1982Pas encore d'évaluation

- Life Cycle Analysis of AA Alkaline Batteries - 2020 - Procedia ManufacturingDocument8 pagesLife Cycle Analysis of AA Alkaline Batteries - 2020 - Procedia Manufacturingaugus1982Pas encore d'évaluation

- Smart Elevator SystemsDocument14 pagesSmart Elevator Systemsaugus1982100% (1)

- Finite Element Modeling of High Speed Milling 7050 T - 2020 - Procedia ManufactuDocument8 pagesFinite Element Modeling of High Speed Milling 7050 T - 2020 - Procedia Manufactuaugus1982Pas encore d'évaluation

- Advert - CEIRD Material Science Scholarships FinalDocument2 pagesAdvert - CEIRD Material Science Scholarships Finalaugus1982Pas encore d'évaluation

- Jun 2023 110874Document1 pageJun 2023 110874augus1982Pas encore d'évaluation

- General Notes 2022Document1 pageGeneral Notes 2022augus1982Pas encore d'évaluation

- Module 3 - Diagnosis of TBDocument76 pagesModule 3 - Diagnosis of TBaugus1982Pas encore d'évaluation

- Ether and AldehydeDocument112 pagesEther and Aldehydejhapindra adhikariPas encore d'évaluation

- 1.8 3 PVDF Hmwpe CableDocument1 page1.8 3 PVDF Hmwpe CableRobert LiraPas encore d'évaluation

- Environmental Education and ManagementDocument8 pagesEnvironmental Education and ManagementArhann Anthony Almachar AdriaticoPas encore d'évaluation

- Butyl Acylate 29161210 Sty. Monomer 29025000 Sty. Monomer 29025000 Butyl Acylate 29161210Document9 pagesButyl Acylate 29161210 Sty. Monomer 29025000 Sty. Monomer 29025000 Butyl Acylate 29161210raj123987Pas encore d'évaluation

- 19.8 Reduction of Aldehydes and Ketones To Alcohols: Cyclobutanone Lithium Aluminum Hydride CyclobutanolDocument5 pages19.8 Reduction of Aldehydes and Ketones To Alcohols: Cyclobutanone Lithium Aluminum Hydride CyclobutanolHimanshu Panchal100% (1)

- Solved Example: 1. The Final Product Obtained in The ReactionDocument43 pagesSolved Example: 1. The Final Product Obtained in The ReactionHardik SharmaPas encore d'évaluation

- Aditi VosDocument154 pagesAditi VosPatricio AcuñaPas encore d'évaluation

- Unit 6 & 7 Cell EnergyDocument17 pagesUnit 6 & 7 Cell EnergyRut ChristinePas encore d'évaluation

- Understandings, Applications and Skills (This Is What You Maybe Assessed On)Document14 pagesUnderstandings, Applications and Skills (This Is What You Maybe Assessed On)Big CinemaPas encore d'évaluation

- High Efficiency Transformation of Escherichia Coli With PlasmidsDocument6 pagesHigh Efficiency Transformation of Escherichia Coli With PlasmidsAnthony TeePas encore d'évaluation

- NabumetoneDocument2 pagesNabumetonePapaindoPas encore d'évaluation

- ADEKA Surfactants-productsList 1111 PDFDocument16 pagesADEKA Surfactants-productsList 1111 PDFichsanPas encore d'évaluation

- Soil Amendments and Fertilizers 2Document8 pagesSoil Amendments and Fertilizers 2FxPas encore d'évaluation

- Mcat Aamc Practice FLDocument7 pagesMcat Aamc Practice FLDSPas encore d'évaluation

- q2 Nucleic AcidsDocument5 pagesq2 Nucleic AcidsPaul TinarwoPas encore d'évaluation

- Fabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionDocument16 pagesFabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionAbdul Kani Ahamed MPas encore d'évaluation

- Chitooligosaccharides Prevention and Control of Diseases (Se-Kwon Kim (Ed) ) PDFDocument352 pagesChitooligosaccharides Prevention and Control of Diseases (Se-Kwon Kim (Ed) ) PDFGustavo RuizPas encore d'évaluation

- PasPapers and RevisionDocument5 pagesPasPapers and RevisionKii X TiiPas encore d'évaluation

- CochleamyciDocument4 pagesCochleamyciOscar Martin OrdoñezPas encore d'évaluation

- Narayana - 20!06!2022 - Outgoing SR - Jee Main Model Gtm-15 - SolDocument18 pagesNarayana - 20!06!2022 - Outgoing SR - Jee Main Model Gtm-15 - SolShreyas VedantiPas encore d'évaluation

- Physical-Science - 11 - Q1 - 07 Biological-Macromolecules-revised - 08082020Document18 pagesPhysical-Science - 11 - Q1 - 07 Biological-Macromolecules-revised - 08082020Joseph Arnido Jr100% (10)

- Ohana Circle (F4) / Fresh N Dash (F5) Sultanah Bahiyah National Secondary School Form 4Document7 pagesOhana Circle (F4) / Fresh N Dash (F5) Sultanah Bahiyah National Secondary School Form 4Hafizuddin KamarudinPas encore d'évaluation

- Lesson-16 Procedures For DNA RAN and Mitochondria DemonstrationDocument6 pagesLesson-16 Procedures For DNA RAN and Mitochondria DemonstrationSasa AbassPas encore d'évaluation

- Kromatogram Mimyak JintanDocument2 pagesKromatogram Mimyak JintanPutri ElafifahPas encore d'évaluation

- Riasorb Uv-1577 TDSDocument1 pageRiasorb Uv-1577 TDSparijat patelPas encore d'évaluation

- Y3 Module5Document78 pagesY3 Module5Quee Nnie0% (1)

- CHAPTER 3: Genetic Control of Protein Synthesis, Cell Function, and Cell ReproductionDocument4 pagesCHAPTER 3: Genetic Control of Protein Synthesis, Cell Function, and Cell ReproductionMan DejeloPas encore d'évaluation

- Fatty AlcoolDocument16 pagesFatty AlcoolAnamaria UrsuPas encore d'évaluation

- Biochemistry Practical WorkbookDocument130 pagesBiochemistry Practical WorkbookNaomiKerryaThompsonPas encore d'évaluation