Académique Documents

Professionnel Documents

Culture Documents

SnaptiteHoseCatalog1 Page25

Transféré par

axelrose10 évaluation0% ont trouvé ce document utile (0 vote)

21 vues1 pageSnap-tite's exclusive "dura-cote(tm)" hose treatment is a nitrile / latex (emulsified rubber) material. The resultant protective layer gives superior abrasion, heat and chemical resistance. Brasion resistance increased 10 times over uncoated hose a lame resistance increased 5 times.

Description originale:

Titre original

SnaptiteHoseCatalog1.Page25

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSnap-tite's exclusive "dura-cote(tm)" hose treatment is a nitrile / latex (emulsified rubber) material. The resultant protective layer gives superior abrasion, heat and chemical resistance. Brasion resistance increased 10 times over uncoated hose a lame resistance increased 5 times.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues1 pageSnaptiteHoseCatalog1 Page25

Transféré par

axelrose1Snap-tite's exclusive "dura-cote(tm)" hose treatment is a nitrile / latex (emulsified rubber) material. The resultant protective layer gives superior abrasion, heat and chemical resistance. Brasion resistance increased 10 times over uncoated hose a lame resistance increased 5 times.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Hose Friction Loss

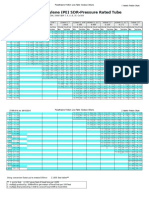

HOSE FRICTION LOSS (PSI per 100 FT)

1-1/2" 1-3/4" 60 70 80 90 100 120 140 150 8.6 11.8 15.4 19.4 24.0 34.6 47.0 54.0 4.9 6.6 8.6 10.9 13.5 5.0 19.4 10.0 26.5 15.0 30.4 16.0 54.0 25.0 84.4 31.0 2" 2.2 2.9 3.8 4.9 6.0 3.0 8.6 4.0 11.8 9.0 13.5 10.0 24.0 18.0 37.5 24.0 54.0 49.0 77.8 96.0 2-1/2" 3" 4" 5" 60 70 80 90 100 120 140 150 8.0 12.5 18.0 16.2 24.5 32.0 26.0 40.3 30.0 5.0 7.2 9.8 12.8 16.0

HOSE FRICTION LOSS (PSI per 100 FT)

1-3/4" 3.5 2" 1.4 2-1/2" 0.5 3" 4" 5" 6"

FLOW RATE (GPM)

250 300 350 400 500 750 1000 1500 2000

FLOW RATE (GPM)

200

200 250 300 350

9.6 15.1 21.3 40.0 84.0

4.0 6.2

1.3 2.0

8.9 16.0 37.5 54.0 77.8 96.0

2.9 3.2 12.5 18.0 24.5 32.0 1.7 5.0 7.2 9.8 12.8 20.0 45.0 3.2 5.0 11.4 19.2 43.2 76.8 1.1 1.7 3.7 6.6 14.9 26.4 0.6 0.9 1.9 2.6 7.3 10.4

3.2 5.0 5.0 11.4 9.0 19.2 11.9 43.2 27.5 76.8 48.8

1.1 1.7 0.5 3.7 2.5 6.6 4.1 17.0 9.0 32.0 16.0

400 500 750 1000 1500 2000

CONQUEST as Compared to

Typical Woven Hose

Typical Extruded Rubber Hose

Dura-Cote Hose Treatment

Snap-tites exclusive Dura-Cote hose treatment is a nitrile/latex (emulsified rubber) material that is force applied (not sprayed) and cross-linked during a high temperature curing process to build a virtually impenetrable shield in your choice of seven vibrant colors. The resultant protective layer gives superior abrasion, heat and chemical resistance, far surpassing the minimal standards or MIL-H-24606B. Compared to competitive coatings of urethane and acrylic, nitrile/latex has remarkably better flexibility and ultra low temperature maneuverability. brasion resistance increased 10 times over uncoated hose A lame resistance increased 5 times F Resistant to solvents, oil and other hydrocarbons revents water pick-up no need for drying P mmune to fungal damage I .V. and Ozone resistant U

Dura-Cote Makes Great Hose Even Better

M-25

Vous aimerez peut-être aussi

- Leadership Games and ActivitiesDocument38 pagesLeadership Games and ActivitiesWilliam Oliss100% (1)

- ST 36Document4 pagesST 36ray72roPas encore d'évaluation

- Measurements, Sizes, Shafts, KeywaysDocument91 pagesMeasurements, Sizes, Shafts, KeywaysVenkat DoraPas encore d'évaluation

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Document29 pages10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- Aluminium Alloy - Wikipedia, The Free EncyclopediaDocument12 pagesAluminium Alloy - Wikipedia, The Free EncyclopediaAshishJoshi100% (1)

- Accsap 10 VHDDocument94 pagesAccsap 10 VHDMuhammad Javed Gaba100% (2)

- Goulds Residential Pump Guide PDFDocument44 pagesGoulds Residential Pump Guide PDFSyed Muztuza Ali100% (1)

- Hollow Bar ChartDocument1 pageHollow Bar Charthornet121Pas encore d'évaluation

- Pipe ScheduleDocument1 pagePipe ScheduleLevi LeonardsPas encore d'évaluation

- WashPipe Data SheetDocument1 pageWashPipe Data SheetAman Aayra Srivastava100% (4)

- The Joy Luck Club Book 1Document12 pagesThe Joy Luck Club Book 1loronalicelPas encore d'évaluation

- Method Statement For Cable Trays & Cable Ladders InstallationDocument7 pagesMethod Statement For Cable Trays & Cable Ladders InstallationJamal Budeiri0% (1)

- Tesla Magazine Vol4Document48 pagesTesla Magazine Vol4jonathan100% (1)

- 09 Passport 7K 15K Performance Guidelines PCR 3 0Document44 pages09 Passport 7K 15K Performance Guidelines PCR 3 0thed719Pas encore d'évaluation

- Fama Fraternitatis Rosae Crucis PDFDocument2 pagesFama Fraternitatis Rosae Crucis PDFJudy50% (2)

- Flange: 규격표 (ANSI Code)Document12 pagesFlange: 규격표 (ANSI Code)aliPas encore d'évaluation

- Toshiba Rotary Compressor Tech Specs PDFDocument1 pageToshiba Rotary Compressor Tech Specs PDFcalvin.bloodaxe4478100% (2)

- Technical DataDocument40 pagesTechnical DataCristian Cachique QuitoPas encore d'évaluation

- Pipe Loss ChartsDocument4 pagesPipe Loss ChartscashloverPas encore d'évaluation

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument17 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicstasingenieriaPas encore d'évaluation

- Valve Face-to-Face FTF Dimension - HABONIM - 2017Document4 pagesValve Face-to-Face FTF Dimension - HABONIM - 2017compas.oeilPas encore d'évaluation

- Working of Breather Valve Working On TanksDocument4 pagesWorking of Breather Valve Working On Tanks54045114Pas encore d'évaluation

- Toyo R888RDocument3 pagesToyo R888RRonen MarkoPas encore d'évaluation

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaPas encore d'évaluation

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaPas encore d'évaluation

- MS-Maneurop Catalogue PDFDocument8 pagesMS-Maneurop Catalogue PDFMacSparesPas encore d'évaluation

- Marmon Keystone Catalog Carbon Pipe TubeDocument22 pagesMarmon Keystone Catalog Carbon Pipe TubeLarry GolladayPas encore d'évaluation

- ZR36KC PFJ 522Document2 pagesZR36KC PFJ 522أبو زينب المهندسPas encore d'évaluation

- Goulds PumpsDocument44 pagesGoulds PumpsCarlos Sagrit100% (1)

- Toshiba Rotary Compressor Tech SpecsDocument1 pageToshiba Rotary Compressor Tech Specscalvin.bloodaxe447880% (5)

- Rhodia Polyamide Poster AutoDocument10 pagesRhodia Polyamide Poster AutoRafa SorianoPas encore d'évaluation

- Fit Current 25c 4Document2 pagesFit Current 25c 4xuyen tranPas encore d'évaluation

- Air Motors PDFDocument6 pagesAir Motors PDFBe HappyPas encore d'évaluation

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaPas encore d'évaluation

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaPas encore d'évaluation

- TecData SD40-2 SD150Document1 pageTecData SD40-2 SD150Air Repair, LLCPas encore d'évaluation

- Pumpcal Polyethylene-Pump Power CalculatorDocument21 pagesPumpcal Polyethylene-Pump Power CalculatorVuong BuiPas encore d'évaluation

- Compresor Scroll Tech. Residential and Light Commercial, 50 HZ R407C - R22 - R410ADocument8 pagesCompresor Scroll Tech. Residential and Light Commercial, 50 HZ R407C - R22 - R410AArnulfo Rafael Álvarez OliverosPas encore d'évaluation

- Ukuran Nominal Nominal OD Tebal Dinding (T) S.8 S.10 S.12,5 S.16 S.20 S.25 MM Inch MM MM MM MM MM MM MMDocument15 pagesUkuran Nominal Nominal OD Tebal Dinding (T) S.8 S.10 S.12,5 S.16 S.20 S.25 MM Inch MM MM MM MM MM MM MMpipaswallowPas encore d'évaluation

- Flange Ansi B 16.5 - 300lbsDocument1 pageFlange Ansi B 16.5 - 300lbsZdenko MahacekPas encore d'évaluation

- T6DC ValveDocument13 pagesT6DC ValveQuangĐạoPas encore d'évaluation

- A 15Document4 pagesA 15Prem SharmaPas encore d'évaluation

- A 9Document4 pagesA 9Prem SharmaPas encore d'évaluation

- Goulds Pump PDFDocument44 pagesGoulds Pump PDFgad480100% (1)

- KirloskerDocument36 pagesKirloskerArup NathPas encore d'évaluation

- P30-31-50-51-75-76Gear PumpDocument18 pagesP30-31-50-51-75-76Gear PumpElverth TorresPas encore d'évaluation

- Data SheetDocument5 pagesData SheetselocaPas encore d'évaluation

- MM To Inch TableDocument1 pageMM To Inch TableManju BirjePas encore d'évaluation

- Din en 853 2Sn / Sae 100R2AtDocument1 pageDin en 853 2Sn / Sae 100R2Atafrizal ardityawanPas encore d'évaluation

- Transmit Tube Comparison ChartDocument3 pagesTransmit Tube Comparison Chartbellscb100% (2)

- For Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Document4 pagesFor Uses in Water, Gas, Steam and Air Line Conforming To IS: 1239 (PT I) - 2004, Equivalent To BS - 1387 / 1985Prem SharmaPas encore d'évaluation

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaPas encore d'évaluation

- L I G H TDocument4 pagesL I G H TPrem SharmaPas encore d'évaluation

- 2013 CatalogueDocument45 pages2013 Cataloguesyamsudin2006Pas encore d'évaluation

- 14800Document1 page1480045saulPas encore d'évaluation

- API Flanges Brochure PDFDocument10 pagesAPI Flanges Brochure PDFguru4lifegmailcomPas encore d'évaluation

- Seal Friction Parker SealsDocument6 pagesSeal Friction Parker SealsChristian MavarezPas encore d'évaluation

- Balflex Din en 853 2Sn / Sae 100R2AtDocument1 pageBalflex Din en 853 2Sn / Sae 100R2AtJuan Alberto Mendoza VegaPas encore d'évaluation

- Flow MeterDocument6 pagesFlow MeterYvoSteentjes100% (1)

- Dipole CheatSheetDocument2 pagesDipole CheatSheetMarshall DiasPas encore d'évaluation

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaPas encore d'évaluation

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- United States Census Figures Back to 1630D'EverandUnited States Census Figures Back to 1630Pas encore d'évaluation

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsD'EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsÉvaluation : 5 sur 5 étoiles5/5 (1)

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- TS SR Chemistry Imp Questions PDFDocument5 pagesTS SR Chemistry Imp Questions PDFUnknown Khan100% (3)

- Aircraft Design Course PhillStocking 4.2Document48 pagesAircraft Design Course PhillStocking 4.2ugurugur1982Pas encore d'évaluation

- Ge Fairchild Brochure PDFDocument2 pagesGe Fairchild Brochure PDFDharmesh patelPas encore d'évaluation

- Multiple Choice Enzymes Plant and Animal NutritionDocument44 pagesMultiple Choice Enzymes Plant and Animal Nutritionliufanjing07Pas encore d'évaluation

- Guidelines For The Management of Brain InjuryDocument26 pagesGuidelines For The Management of Brain InjuryfathaPas encore d'évaluation

- Unnatural Selection BiologyDocument2 pagesUnnatural Selection BiologyAlexa ChaviraPas encore d'évaluation

- Brief Summary of Catalytic ConverterDocument23 pagesBrief Summary of Catalytic ConverterjoelPas encore d'évaluation

- Tabel Gsi, RMR, RmiDocument4 pagesTabel Gsi, RMR, RmiPup BooPas encore d'évaluation

- Antoine Constants PDFDocument3 pagesAntoine Constants PDFsofiaPas encore d'évaluation

- Of The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestDocument4 pagesOf The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestBaydaa QaidyPas encore d'évaluation

- LighthouseDocument4 pagesLighthousejaneborn5345Pas encore d'évaluation

- Army Aviation Digest - Nov 1978Document52 pagesArmy Aviation Digest - Nov 1978Aviation/Space History Library100% (1)

- Updated SAP Cards Requirement JalchdDocument51 pagesUpdated SAP Cards Requirement Jalchdapi-3804296Pas encore d'évaluation

- TranscriptDocument1 pageTranscriptapi-310448954Pas encore d'évaluation

- Differential Geometry of Curves and Surfaces 3. Regular SurfacesDocument16 pagesDifferential Geometry of Curves and Surfaces 3. Regular SurfacesyrodroPas encore d'évaluation

- Pineapple in JohorDocument6 pagesPineapple in JohorHaiqal AzizPas encore d'évaluation

- Imbinari Teava Fibra de Sticla PDFDocument1 pageImbinari Teava Fibra de Sticla PDFplex015Pas encore d'évaluation

- ME 352 Design of Machine Elements: Lab ReportDocument5 pagesME 352 Design of Machine Elements: Lab ReportKeshav VermaPas encore d'évaluation

- DNA Mutation and Its Effect To An Individual (w5)Document6 pagesDNA Mutation and Its Effect To An Individual (w5)Cold CoockiesPas encore d'évaluation

- PAG7.1 Student The Effects of Antibiotics On Microbial Growth - v0.3Document3 pagesPAG7.1 Student The Effects of Antibiotics On Microbial Growth - v0.3Habib UddinPas encore d'évaluation