Académique Documents

Professionnel Documents

Culture Documents

Material Handling

Transféré par

Agus Pahala SimbolonDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Material Handling

Transféré par

Agus Pahala SimbolonDroits d'auteur :

Formats disponibles

CASE STUDY

Material Handling System

Situation

Zuari Industries Limited has a big fertilizer plant in Goa which spans few kilometers in area. The plant has huge turn-over of raw materials required for building the fertilizer and shipping back the fertilizers to various states and cities. Intern, there is huge vehicle turn-over too. Goa government had put a mandate on all the plants to have minimum security/contingency measures in place in case of emergency in the plant. It is most important to know exact statistics of vehicles and inventory of all the materials to plan for evacuation in case of emergency. Zuari approached ICA and Aftek to build a solution which would track the material, end products as well as vehicles.

Expected Feature Set

Automatic identification of vehicles using weather-resistant, reliable and long-lasting RFID tags Automatic recording of entry and exit time for all vehicles Automatic recording of weights and printing of slip at weighbridges Alarm annunciation for over/under weight and overstay of vehicles Lightning-fast response time of less than 3 seconds to all events Dual, redundant servers for failsafe operation with near-instantaneous switchover (less than 2 seconds) Data exchange facilities with other EDP systems Ability to handle large amount of transactions with capacity limited only by physical disk-space

Solution

ICA and Aftek jointly conceptualized RFID based solution which had web-based GUI. Close coordination with Zuari staff was done. Aftek provided fully fault-tolerant and 24x7 system to cater to the need. Zuari had EDP System which kept information about material and end products. This solution had Web Service based integration done with EDP System for further analysis. Aftek executed the project with distinct phases with reviews from Zuari at necessary phases. Aftek deployed skilled personnel on-site for requirement gathering and analysis. PPT based screen layouts and flow was communicated for Zuari personnel to visualize the solution. Exhaustive architecture and detail design phase was carried out to come up with fully fault-tolerant system. Alpha and Beta testing (also called Factory Acceptance Test) was carried out before taking solution to production. ICA provided value addition in layout of hardware like RFID readers, signal posts etc. Interfacing was done at Programmable Logic Controller (PLC) level.

Benefits to the client

Open source technologies and Linux based solution saved deployment costs drastically. Zero pilferage by providing complete transparency of turn-over data in real-time. Online statistics of any vehicle and material in the plant. Hardware and EDP System integration zeroed down possibility of all manual errors in recording of information.

Afteks value-add

Conceptualized the complete software solution for Zuari Performance, Scalability and Reliability (PSR) ensured robust and scalable system Demonstrated seamless team integration across companies to deliver integrated solution Software simulators were developed to eliminate hardware dependency during development stage.

www.aftek.com

CASE STUDY

Material Handling System

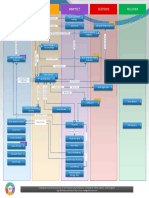

Architectural Overview

Server farm

Slave Server

With same components of Master Server

DB Purchase and Raw Material Department

H/W Network

Master Server

PLC Master PLC Master

Temporary Trucks

Replicator

PLC Communicator

PLC Communicator

Server

Permanent Trucks

Vehicles

O M R O N

HTTP

P L C

FINS

Browser

Sales Department

Event Event Queue

Alarms

Event

Web Application

Health Check

Print Server Print Server

Backend Process

RMI

Event Alarms

Action on Events

Java Client

Raw Material Product Turnover Information

Security Personnel

EDP Systems

DB

RFD Reader Traffic Signal Weighbridge Security Gate

Technology

RFID Tag J2EE (JSP, Servlet) OMRON FINS XML Web Service Oracle Postgres (PL/SQL)

www.aftek.com

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- OUTPUTDocument8 pagesOUTPUTKecamatan Bontang selatanPas encore d'évaluation

- Question Bank Unit 2 SepmDocument2 pagesQuestion Bank Unit 2 SepmAKASH V (RA2111003040108)Pas encore d'évaluation

- Icte 10073 Systems Administration and Maintenance 1Document132 pagesIcte 10073 Systems Administration and Maintenance 1christine villanuevaPas encore d'évaluation

- Detailed Scheduling Planning Board Technical HelpDocument6 pagesDetailed Scheduling Planning Board Technical Helpmanojnarain100% (1)

- Win32 Processes and ThreadsDocument168 pagesWin32 Processes and ThreadsAjit Kumar SinghPas encore d'évaluation

- DICTIONARIES NotesDocument42 pagesDICTIONARIES NotesmPas encore d'évaluation

- Kanban Course PresentationDocument125 pagesKanban Course Presentationaditya Nirmal100% (2)

- C Programming 7Document21 pagesC Programming 7CarabPas encore d'évaluation

- Important ABAP FunctionsDocument6 pagesImportant ABAP FunctionsHoney SwapnaPas encore d'évaluation

- Web 1Document36 pagesWeb 1Hana ʚĩɞPas encore d'évaluation

- HPE2-T36 by HP Actual Free Exam Questions and Answers8Document4 pagesHPE2-T36 by HP Actual Free Exam Questions and Answers8efrataPas encore d'évaluation

- FB01-Document Posting Based On Different Posting KeysDocument34 pagesFB01-Document Posting Based On Different Posting KeysThierry KempPas encore d'évaluation

- Nutanix ECA v6.5 DatasheetDocument5 pagesNutanix ECA v6.5 DatasheetIlavarasu c b sekarPas encore d'évaluation

- Important DBMS Questions For Final Exam: GgisolutionsDocument12 pagesImportant DBMS Questions For Final Exam: GgisolutionsDhirajBhaktaPas encore d'évaluation

- An Inter-Classes Obfuscation Method For Java ProgramDocument6 pagesAn Inter-Classes Obfuscation Method For Java ProgramPrajwal AtramPas encore d'évaluation

- Catchlogs - 2023-01-12 at 21-10-48 - 5.12.0.100 (1165) - .JavaDocument9 pagesCatchlogs - 2023-01-12 at 21-10-48 - 5.12.0.100 (1165) - .JavaCovoy gamingPas encore d'évaluation

- Java Fundamentals 4-2: Object and Driver Classes Practice ActivitiesDocument3 pagesJava Fundamentals 4-2: Object and Driver Classes Practice ActivitiesBellaaj Mohamed YassinePas encore d'évaluation

- 11 Uq Software SlidesDocument18 pages11 Uq Software SlidesVictor ArmegioiuPas encore d'évaluation

- Azure Security MapDocument1 pageAzure Security MapEnrico garfiaPas encore d'évaluation

- Vtu Network Security (10ec832) Unit-7 Notes.Document10 pagesVtu Network Security (10ec832) Unit-7 Notes.jayanthdwijesh h pPas encore d'évaluation

- Smart Schema Design-V1.0Document43 pagesSmart Schema Design-V1.0Shankar Narayanan0% (1)

- VPN Troubleshooting For Firepower Threat Defense: System MessagesDocument10 pagesVPN Troubleshooting For Firepower Threat Defense: System Messagesramadhian89Pas encore d'évaluation

- B Cisco Dna Center Admin Guide 2 3 5Document210 pagesB Cisco Dna Center Admin Guide 2 3 5andyo_uaPas encore d'évaluation

- Concepts and Techniques: Data MiningDocument58 pagesConcepts and Techniques: Data MiningSudhakar TripathiPas encore d'évaluation

- Master Direction Draft On Information Technology Governance Risk ControlsDocument15 pagesMaster Direction Draft On Information Technology Governance Risk Controlsabee narayanPas encore d'évaluation

- Project ReportDocument32 pagesProject ReportGowtham Kola0% (1)

- Apex Advanced Tutorials PDFDocument60 pagesApex Advanced Tutorials PDFDiganta Kumar GogoiPas encore d'évaluation

- Henrydizbanian ADBDocument2 pagesHenrydizbanian ADBPalak SaxenaPas encore d'évaluation

- Project 6 - Hangman ProjectDocument24 pagesProject 6 - Hangman Projectnubaid50% (2)

- Analysis of Web Application Penetration TestingDocument70 pagesAnalysis of Web Application Penetration TestingEngr. Md Yusuf MiahPas encore d'évaluation