Académique Documents

Professionnel Documents

Culture Documents

Guide To Fillet Welding

Transféré par

Peter KyawDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Guide To Fillet Welding

Transféré par

Peter KyawDroits d'auteur :

Formats disponibles

ABN 69 003 696 526

A Guide for the Welding, Assessment and Inspection of Fillet and Tee Butt Welds

TGN-RT-05 Rev: 0 Date: 31 May 2006 Pages: 5

1. Introduction Fillet welds are the predominant arc welded joint in Australia. They are straightforward to inspect and, because they are incomplete penetration welds, they are easy to weld. Tee Butt welds are complete penetration welds where full strength is achieved by complete penetration of the vertical member. In addition to fillet welds and tee butt welds a third category of Deep Penetration fillet welds is available. Known as Compound welds, these achieve full strength (but not necessarily complete penetration) by a combination of fillet weld and butt weld. It is important to be able to differentiate between these weld types as shown in Figure 1.

Throat Thickness

Leg Length 1a) Fillet Weld 1b) Tee Butt Weld 1c) Compound Tee weld

Throat Thickness 1d) Deep Penetration Fillet welds

Figure 1 Fillet, Tee Butt, Compound and Deep Penetration Fillet Welds

a) b) c) d)

Fillet Weld Incomplete Penetration, generally not a full strength weld Tee Butt Weld Complete Penetration full strength weld Compound Tee Weld more than strong enough Deep Penetration Fillet Incomplete Penetration (generally) full strength weld

2. Structural Integrity The load bearing capacity of a fillet weld is based on its throat thickness depicted in Figure 1(a). Indeed in some countries the size of a fillet weld is given in terms of throat thickness. In Australia the size of a fillet weld is given in terms of leg length. For an equal leg length fillet weld, Throat Thickness = Leg length / 1.41 = 0.71 x Leg Length Even though fillet welds are incomplete penetration welds they can be designed to provide full strength load bearing capacity. Two fillet welds are required each with leg lengths at least 70% of the thickness of the vertical member (total 141%). Such welds are relatively large so they are seldom used. Generally, when full strength welds are required, tee butt welds or deep penetration welding techniques are used. Those methods reduce the weld volume needed, Figures 1(b) and 1(d). AS/NZS 1554 Structural steel welding - Welding of steel structures only allows the design to take advantage of this extra strength if the welding is fully automatic. 3. Measurement of Fillet Leg Length

The size of the fillet leg length is the side of the largest triangle which can be inscribed inside the fillet weld. Generally this is a right angle triangle. This triangle is reduced in size if there is a root gap (See Figure 2). Special tools are available to measure fillet leg length (and throat thickness) although an engineers ruler and straight edge can also be used. Fillet welds made with manual or semi-automatic welding methods

will vary somewhat from the design leg length. For a nominal leg length of x mm, expect leg length measurements to vary locally from x 1 to x + 1 mm. However 90% of measurements should be at

Page 1 of 5

least equal to x. Automated and mechanized welding systems provide more consistent leg length dimensions. The welding specification (eg AS 1554.1) will have specific requirements for the size tolerance of fillet welds. When checking leg length of concave welds, use an appropriate gauge as in Fig 3d. 4. Pre-weld check

Throat thickness (measured from triangle reduced in size because of gap) Design throat thickness

Design throat thickness Throat thickness measured from triangle reduced in size because of overroll

Gap

Fig 2a Effect of gap on throat thickness Fig 2b Effect of overroll on throat thickness

Any gap between the two parts to be joined effectively reduces the throat thickness of the weld and the load bearing capacity, Figure 2. Most codes have limits on the maximum gap permissible for fillet welds. Note that the gap is not apparent when checking the leg length of a completed fillet weld. It is thus important to ensure control of gap is maintained during fabrication.

12 mm 12 mm

3(a, b) Measurement of one leg at a time. 12 mm 12 mm

3(c) Unequal leg length.

3(d) Concave weld.

Figure 3 Measurement of leg length on convex fillet welds One leg at a time, equal or unequal leg lengths and a different gauge for concave welds.

Page 2 of 5

5. Non Destructive Testing of Fillet Welds Because fillet welds are incomplete penetration welds they have inherent lack of fusion between the two parts. For this (and other) reasons neither ultrasonic nor radiographic testing are generally carried out. Magnetic Particle Inspection (MPI) is occasionally carried out on ferritic steel fillet welds where there are concerns about Hydrogen Assisted Cold Cracking (HACC). Such cracking which will manifest itself as under-bead cracking or toe cracking. Only use MPI when HACC is an identified threat. Dye Penetrant Testing may occasionally be carried out on Aluminium welds where there is risk of hot cracking although such cracking is generally visible with naked eye. 6. Confirming structural integrity of fillet welds Destructive tests In addition to measuring the leg length it is necessary to confirm that there is full fusion between the fillet weld and parts to be joined. This achieved by carrying out weld macro tests (AS 2205.5.1) or mechanical testing (various parts of AS 2205) at three stages of fabrication; a) Welding Procedure Qualification As part of the procedure qualification process a weld macro would likely have been carried out to demonstrate that the welding procedure can provide the necessary fusion. For each welding process there is an upper limit on fillet weld sizes that can be reliably achieved in one pass. Care is required to avoid trying to produce a fillet weld in one pass that is too large for the process. For welds requiring more than one pass the size of the individual passes must be optimized to produce the desired weld size in a minimum of passes. b) Welder Qualification During welder qualification weld macros are carried out to demonstrate the welder is capable of achieving the necessary fusion. The applicable welding codes provide requirements for welder qualification. c) In-process Macros Confirmation that full fusion is being achieved during production can be demonstrated by performing macros at the ends of the welds in situations where the weld runs to the end of the structure. Alternatively, test pieces can be welded together using the production procedure to confirm fusion is being achieved. Visual inspection of the weld may not provide an indication of internal fusion. However welds should exhibit a good profile; achieve the required throat thickness without excessive convexity, and have a smooth transition from the weld toes to the parent metal with an absence of overroll (Fig 2b). d) Mechanical Tests In addition to macro tests, fracture tests performed either on run-off/run-on tabs or test pieces can be used to demonstrate full fusion between the weld and parent metal. When subjected to fracture tests there should be no fractures or tears associated with the fusion line. 7. Welding Thick Sections As the thickness of the parts to be joined increases cooling rates increase and the tendency for lack of fusion also increases. This is the case for steel and particularly for aluminium. When developing fillet weld procedures be sure to test them on the thickest parts to be joined. Also note that increased preheats are often required when welding thicker sections this applies to aluminium as well. 8. Deep Penetration Fillet Welds Since fillet weld strength is based on throat thickness, advantage can be made of deep penetration welding processes such as submerged arc welding, fig 1(d). Where such deep penetration welds are incomplete penetration welds it is necessary to confirm penetration depth using macro tests throughout the fabrication process. Inspection of these welds includes a measurement of the depth to

Page 3 of 5

width ratio of the weld bead to ensure the risk of hot cracking is avoided. There will be a tendency for hot cracking if the depth to width ratio of the weld bead exceeds its width. AS 1554.1 Clause 5.6 refers. 9. Special Cases 9.1 I-Beams An incomplete or complete penetration weld used to join webs to flanges can be a compound weld for the purpose of smooth transition from the web to the flange. The fillet here does not need to be equal to the height of the weld face. For example, a 32 mm thick web would only need fillets 12 mm in size. 9.2 Lamellar Tearing Fillet welding can be preferred to butt welding in steels which are prone to Lamellar Tearing. For example modification of beams and columns in buildings in Australia built before 1960. In this case fillet welding is preferred because it widens out the area of high through-thickness shrinkage stress. A root gap is also preferred in these cases. A soft wire to which is compressible to allow weld contraction is also recommended in such a root gap. 9.3 Tee Butt Welds Tee butt welds require complete penetration between the two members. Macro tests are needed to qualify the welding procedure and the welder. Production macro tests also provide assurance of complete penetration. However for full fusion welds, ultrasonic inspection can be used to confirm full fusion by utilization of compression probes on the reverse side of the flange, fig 4.

Compression probe being used to detect lack of fusion along dotted line between web and flange

Fig 4 Ultrasonic Testing of Tee Butt using Compression Probe

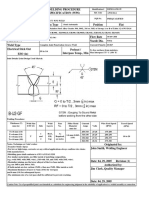

10. Designing and Fabricating Tee Butt Welds No matter what the welding process is, Tee Butt welds need to be carefully designed to ensure full fusion is consistently obtained. When producing Tee Butt welds by welding from both sides (recommended for arc welding processes) the land and bevel angle need to be designed so that the welding process can consistently achieve 70 80% penetration of the land from one side, Figure 5.

Figure 5. Designing bevel and land dimensions to achieve penetration overlap during welding.

Page 4 of 5

Note that thicker parts will require more arc energy heat input in order to provide full fusion. A complete penetration butt weld designed for welding a 10mm web to a 20mm flange will not necessarily work for welding the same 10mm web to a 40mm flange. The 40mm flange provides more of a heat sink and therefore higher heat inputs will be required. Again thicker sections may require increased pre-heat to maintain penetration. Additionally variations in root gap will affect the amount of penetration achieved. For ease of fabrication it is recommended to have no root gap whenever possible. When producing full penetration Tee Butt welds it is imperative to: a) Control the size of the land to close tolerances; b) Control the size and angle of the bevel when required; c) Achieve consistent fit-up every time (preferably zero root gaps); d) Use mechanized welding processes that can replicate amperage, voltage and travel speed; e) Maintain constant contact tip to work distances; f) Use a consistent pre-heat temperature; g) Ensure the power source can operate at 100% duty cycle at the nominated current and voltage. 11. Designing and Fabricating Fillet welds and Deep Penetration Fillet Welds The same principles that apply to Tee Butt welds are applicable to Fillet and Deep Penetration Fillet welds. Both these weld types are classed as incomplete penetration welds so full fusion of the web is not required. However with deep penetration welding techniques it is necessary to demonstrate that the required throat thickness is being consistently achieved. This can only be verified with a production macro test. Sophisticated NDT techniques by experienced operators can confirm throat thickness or adequate side wall fusion when incomplete penetration welding is being employed. 12. Conclusion Deep penetration fillet welds provide a way of making efficient Tee joints with a minimum of added weld metal. Visual inspection needs to be augmented with macro tests when producing fillet welds and deep penetration fillet welds. Welding procedure development should be carried out on the thickest parts to be joined in production in order to ensure the required strength has been achieved. AS/NZS 1554 only allows the design to take advantage of this extra strength if the welding is fully automatic.

DISCLAIMER: While every effort has been made and all reasonable care taken to ensure the accuracy of the material contained herein, the authors, editors and publishers of this publication shall not be held to be liable or responsible in any way whatsoever and expressly disclaim any liability or responsibility for any injury or loss of life, any loss or damage costs or expenses, howsoever incurred by any person whether the reader of this work or otherwise including but without in any way limiting any loss or damage costs or expenses incurred as a result of or in connection with the reliance whether whole or partial by any person as aforesaid upon any part of the contents of this publication. Should expert assistance be required, the services of a competent professional person should be sought.

PO Box 6165, Silverwater NSW 1811 Unit 50, 8 The Avenue of the Americas, Newington NSW 2127 Ph: +61 (0) 2 9748 4443 Fx: +61 (0) 2 9748 2858 Email: info@wtia.com.au Webpage: www.wtia.com.au

Page 5 of 5

NDNP TECHNOLOGY DIFFUSION ACTIVITY # 27

ABN 69 003 696 526

NATIONAL DIFFUSION NETWORKS PROJECT TECHNOLOGY QUESTIONNAIRE

Document No: 9.4.5QR-0003 Revision No: Rev 0 Page 1 of 2 Date: 22 May 2006

Road Transport Industry Group Guidance on Fillet and Tee Butt Welding

As part of the WTIA National Diffusion Networks Project, the Road Transport Industry Sector has identified the need for guidance in designing, making and testing fillet welds and Tee butt welds in steel structures. The WTIA has prepared a Technical Guidance Note A Guide for the Welding, Assessment and Inspection of Fillet and Tee Butt Welds. As a valued technology expert in this area we would like you to be part of the Technology Expert Group to review this note. Please complete this questionnaire so that we can gauge the success of meeting this need.

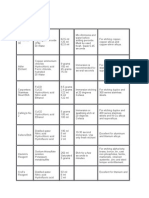

Objective 1: Identify the need for guidance on fillet and Tee butt welding.

Fillet welds are the most common weld in Australian construction. This guidance note is intended to provide the steel fabrication industry with guidance on designing, making and testing fillet welds and Tee butt welds in steel structures. How well does the document explain this subject? poor Comments: average good very good

Objective 2: Identify appropriate technology receptors in the Road Transport Industry

This document was written for designers, fabricators and inspectors. Are these people the appropriate individuals we should be targeting? yes no

What other types of companies and/or personnel do you suggest we target?

Objective 3: Identify current best practice for fillet and Tee butt welding?

The document was written to reflect current best practice for fillet and Tee butt welding? Do you envisage opportunities for the use of this technology in the industry? yes no

If yes, what and where, if no why not?

Objective 4: Is the information provided clear, concise and accurate?

yes If not, why? no

Objective 5: Broad dissemination of technology to the Road Transport Industry

Please indicate how best to disseminate this Technical Guidance Note to the appropriate Road Transport Industry Recipients Free Website Download If poster, what size? A1 Poster A2 A3 Pocket Guide Laminated Pamphlet What selling price? $

If a pocket guide, what selling price? $ Other format?

G:\USERS\guidance-notes\Questionnaires\RT05 Guide to Fillet Welding Questionnaire.doc

NDNP TECHNOLOGY DIFFUSION ACTIVITY # 27

ABN 69 003 696 526

NATIONAL DIFFUSION NETWORKS PROJECT TECHNOLOGY QUESTIONNAIRE

Document No: 9.4.5QR-0003 Revision No: Rev 0 Page 2 of 2 Date: 22 May 2006

Road Transport Industry Group Guidance on Fillet and Tee Butt Welding Objective 6: Continuous Improvement

Please Identify areas where the document can be improved or return the document with your recommended additions/amendments. Alternatively, please use the area below to provide any additional comments.

Respondents Name: Fax:

Company: Email:

Phone: Date:

Please Fax (02 9748 2858) or E-mail (b.gross@wtia.com.au) your response. Your prompt response is appreciated.

The WTIA has joined forces with industry and government to create a 3.5 million dollar Technology Support Centres Network. This network will assist industry to identify and exploit worlds best technology and manufacturing methods to establish a vibrant Australian industry beyond 2006. Together we will be implementing a step by step process which will lead to ongoing viability and greater profitability for all concerned: (1) (2) (3) Determine your technological and manufacturing needs; Identify worlds best practice; Draw upon the network to implement worlds best practice at your site

G:\USERS\guidance-notes\Questionnaires\RT05 Guide to Fillet Welding Questionnaire.doc

Vous aimerez peut-être aussi

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpPas encore d'évaluation

- Apollo Heat Exchanger Welding Defect GuideDocument77 pagesApollo Heat Exchanger Welding Defect GuideQC apollohx100% (1)

- Weld SymbolDocument3 pagesWeld SymbolMahesh Gohel50% (2)

- Consider Penetration When Determining Fillet Weld SizeDocument3 pagesConsider Penetration When Determining Fillet Weld SizedavidemolPas encore d'évaluation

- Guidelines For Fabrication Error PDFDocument99 pagesGuidelines For Fabrication Error PDFBUDAPESPas encore d'évaluation

- A WPS Is A Document That Describes How Welding Is To Be Carried Out in ProductionDocument3 pagesA WPS Is A Document That Describes How Welding Is To Be Carried Out in Productionukavathekar100% (1)

- Spiral Welded Steel PipeDocument11 pagesSpiral Welded Steel PipeAmelindaKusumaPas encore d'évaluation

- GN12 WTIA Comparison of Welding Inspector Qualifications and Certifications PDFDocument4 pagesGN12 WTIA Comparison of Welding Inspector Qualifications and Certifications PDFHoa Nguyen ThaiPas encore d'évaluation

- Fillet Welded Joints - A Review of The Practicalities - Job Knowledge 66Document4 pagesFillet Welded Joints - A Review of The Practicalities - Job Knowledge 66Anuj ShahiPas encore d'évaluation

- Pipelines Welding HandbookDocument64 pagesPipelines Welding HandbookSixto GerardoPas encore d'évaluation

- Documents - Tips - Cswip 322 Questions PDFDocument37 pagesDocuments - Tips - Cswip 322 Questions PDFJithuJohn83% (6)

- Fillet WeldingDocument36 pagesFillet WeldingDaria D'souzaPas encore d'évaluation

- Comp MechDocument235 pagesComp Mechgopvij1Pas encore d'évaluation

- Fillet WeldsDocument17 pagesFillet Weldssoroush1111Pas encore d'évaluation

- DesignDocument15 pagesDesignMuhammed Sulfeek100% (1)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- TGN-D-02 Fatigue Improvement of Welded StructuresDocument10 pagesTGN-D-02 Fatigue Improvement of Welded StructuresakuntayPas encore d'évaluation

- Weld Joint Detail PDFDocument9 pagesWeld Joint Detail PDFKosit WongpinkaewPas encore d'évaluation

- Welding Gauges PDFDocument4 pagesWelding Gauges PDFsopan kharchePas encore d'évaluation

- 1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016Document64 pages1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016ivan sulistianPas encore d'évaluation

- Astm A 227 A227m 2006Document4 pagesAstm A 227 A227m 2006Aadhya engineering ServicesPas encore d'évaluation

- Aa 036007 001Document1 pageAa 036007 001narutothunderjet216Pas encore d'évaluation

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Introduction To GMAWDocument63 pagesIntroduction To GMAWRumman Ul AhsanPas encore d'évaluation

- Welding Procedure SpecificationsDocument14 pagesWelding Procedure SpecificationsBasavaraj KaraningPas encore d'évaluation

- WTIA IIW IWE Face-to-Face Training Modules and ExaminationsDocument2 pagesWTIA IIW IWE Face-to-Face Training Modules and ExaminationsRizwan NazirPas encore d'évaluation

- 1 WELDING INSPECTION - STEELSDocument115 pages1 WELDING INSPECTION - STEELSrahim_335162856100% (3)

- Mild Steel to Stainless Steel Welding Materials CatalogDocument334 pagesMild Steel to Stainless Steel Welding Materials CatalogTran Chi Binh DDC100% (1)

- UIC Rail Steel RecommendationsDocument4 pagesUIC Rail Steel RecommendationsReepak guptaPas encore d'évaluation

- Butt JointsDocument21 pagesButt JointsRaj1-23Pas encore d'évaluation

- Weld Fit Up ToleranceDocument2 pagesWeld Fit Up Tolerancesatrahe100% (2)

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungPas encore d'évaluation

- Bruce Stewart Field Heat Treatment TrainingDocument40 pagesBruce Stewart Field Heat Treatment Trainingnguyen100% (1)

- Gmaw & Fcaw-MsmeDocument73 pagesGmaw & Fcaw-MsmemilindPas encore d'évaluation

- Guide to Fillet Welded JointsDocument4 pagesGuide to Fillet Welded Jointsjocelyn beltranPas encore d'évaluation

- Metallurgy-Investigatory Project PDFDocument20 pagesMetallurgy-Investigatory Project PDFAbhishek yadav80% (5)

- Alloys: FerrousDocument10 pagesAlloys: FerroussunsirPas encore d'évaluation

- Stress Corrosion Cracking PDFDocument48 pagesStress Corrosion Cracking PDFPako RosasPas encore d'évaluation

- Welding terminology guideDocument18 pagesWelding terminology guidemahi1437100% (1)

- Cracks and welding imperfectionsDocument39 pagesCracks and welding imperfectionsAnonymousPas encore d'évaluation

- Welded Joint Design FundamentalsDocument16 pagesWelded Joint Design FundamentalsEngr Arfan Ali DhamrahoPas encore d'évaluation

- FCAW Procedure PDFDocument110 pagesFCAW Procedure PDFsolserengsaPas encore d'évaluation

- List of Etchant For MetallographyDocument3 pagesList of Etchant For Metallographyniraj_hwbPas encore d'évaluation

- Welding Process and ConsumableDocument64 pagesWelding Process and Consumablenizar_ikmps100% (1)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12Pas encore d'évaluation

- Corrosion On WeldmentDocument5 pagesCorrosion On Weldmentprabuharan89100% (1)

- Comparison of NDT Methods and Their CostsDocument11 pagesComparison of NDT Methods and Their Costskailash100% (1)

- Weld Defects Incomplete Root PenetrationDocument4 pagesWeld Defects Incomplete Root PenetrationMuhammed SulfeekPas encore d'évaluation

- TGN-M-04 Weld Procedure Comparison Struc SteelDocument5 pagesTGN-M-04 Weld Procedure Comparison Struc Steelmanoj983@gmail.comPas encore d'évaluation

- Weld GaugesDocument15 pagesWeld Gaugesraobabar21100% (1)

- CWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsDocument2 pagesCWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsStephen TilleyPas encore d'évaluation

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasPas encore d'évaluation

- WELDING CONSUMABLE CHARTDocument2 pagesWELDING CONSUMABLE CHARTAfetPas encore d'évaluation

- In-Service Welding of Pipelines Industry Action PlanDocument13 pagesIn-Service Welding of Pipelines Industry Action Planعزت عبد المنعم100% (1)

- Basic Weld MetallurgyDocument34 pagesBasic Weld Metallurgydaha333Pas encore d'évaluation

- Difference between weldolet and sockoletDocument3 pagesDifference between weldolet and sockoletWaqas Waqas100% (3)

- MOTS-12 Welding and NDE of WeldsDocument1 pageMOTS-12 Welding and NDE of Weldsryan.sPas encore d'évaluation

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.Pas encore d'évaluation

- Selection of Welding ConsumablesDocument13 pagesSelection of Welding ConsumablesbassemaePas encore d'évaluation

- MIG Welding Aluminum Guide: Equipment, Settings & TechniquesDocument8 pagesMIG Welding Aluminum Guide: Equipment, Settings & TechniquesHandri YantoPas encore d'évaluation

- The Heat Affected ZoneDocument24 pagesThe Heat Affected ZoneRatan PanditPas encore d'évaluation

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedPas encore d'évaluation

- Weld Penetration Procedure NewDocument4 pagesWeld Penetration Procedure NewJm VenkiPas encore d'évaluation

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Job Knowledge 68Document8 pagesJob Knowledge 68Mehmet Soysal100% (1)

- Design Part 2 - TWIDocument9 pagesDesign Part 2 - TWIFreddie KooPas encore d'évaluation

- Avinash PanchalDocument92 pagesAvinash PanchalDhyey KalariyaPas encore d'évaluation

- Boiler Pressure Parts - Straight TubesDocument2 pagesBoiler Pressure Parts - Straight TubesLTE002Pas encore d'évaluation

- Ebara DSZDocument5 pagesEbara DSZflaviusgrozaPas encore d'évaluation

- Everything You Need to Know About Steel StructuralsDocument42 pagesEverything You Need to Know About Steel StructuralsJosh Jaymes MassePas encore d'évaluation

- Ain Shams Engineering Journal: Yousef R. Alharbi, Aref A. Abadel, Nourhan Elsayed, Ola Mayhoub, Mohamed KohailDocument7 pagesAin Shams Engineering Journal: Yousef R. Alharbi, Aref A. Abadel, Nourhan Elsayed, Ola Mayhoub, Mohamed KohailMAHESH A VPas encore d'évaluation

- Foundations Bill of QuantitiesDocument40 pagesFoundations Bill of QuantitiesAnonymous 7ZYHilDPas encore d'évaluation

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedPas encore d'évaluation

- SumergiblesDocument108 pagesSumergiblesSergio S. Zegarra TumiPas encore d'évaluation

- BCsectionDocument71 pagesBCsectionAmir WassimPas encore d'évaluation

- Yg-1 Combo Tap Yu Ct21Document24 pagesYg-1 Combo Tap Yu Ct21Nurul AtikahPas encore d'évaluation

- Crafting Strong Relationships in SteelDocument15 pagesCrafting Strong Relationships in SteelOnkar DograPas encore d'évaluation

- Descripción General Del Material para Bombas Sumergibles EléctricasDocument13 pagesDescripción General Del Material para Bombas Sumergibles EléctricasCeleste ZapataPas encore d'évaluation

- APEX CATALOGUE FinalDocument48 pagesAPEX CATALOGUE FinalLuito78Pas encore d'évaluation

- Ugiweb 913082Document128 pagesUgiweb 913082psychedelic_lullabyPas encore d'évaluation

- Preface PDFDocument2 pagesPreface PDFOscar Espinosa BonillaPas encore d'évaluation

- 21Document10 pages21Ashwani KansaraPas encore d'évaluation

- Strength of MaterialsDocument5 pagesStrength of MaterialsKumar SubramanianPas encore d'évaluation

- Master list of Cirebon power plant equipmentDocument1 658 pagesMaster list of Cirebon power plant equipmentZaki FauzanPas encore d'évaluation

- Li. ASPN of Austenitic Stainless Steel. Surface Engineering 18 No. 6 (2002) 453-458 PDFDocument6 pagesLi. ASPN of Austenitic Stainless Steel. Surface Engineering 18 No. 6 (2002) 453-458 PDFNgọc Minh LêPas encore d'évaluation

- Smaw NC 2 Shop LayoutDocument1 pageSmaw NC 2 Shop Layoutjanrel sedorifaPas encore d'évaluation

- 10131tolleranze Dimensionali5Document4 pages10131tolleranze Dimensionali5John BarrowPas encore d'évaluation

- KVX Wear BarDocument2 pagesKVX Wear BarAli OsorioPas encore d'évaluation