Académique Documents

Professionnel Documents

Culture Documents

671 1750 1 PB

Transféré par

WychSupaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

671 1750 1 PB

Transféré par

WychSupaDroits d'auteur :

Formats disponibles

110

Occupational Hazards among Operators in a Garment Manufacturing Units

Prof. Nila.A.Chotai, Assistant Professor, Acharayas Bangalore B- School, Dept of Management, Lingadheernahalli, Magadi Road, Bangalore-560091, Karnataka India

ABSTRACT: A comparative study on male and female workers between 30-35 years of age was conducted regarding occupational hazards in garment manufacturing units located in Bangalore. The total sample size was 110 which comprised of 55 men and 55 women. The finding shows that maximum (54.5 per cent) of male and (45.4 per cent) of female workers faced problems due to amount and intensity of light, majority of (49.0 per cent) male and (36.3 per cent) female get injured with machine needles. It was found that the poorly designed workstations, unsuitable furniture, lack of ventilation, inappropriate lighting, excessive noise and lack of personal protective equipment are main causes for occupational hazards. Keywords: Accidents, Apparel, Garment, Industry, Manufacturing Sewing, Tailors.

environments where predominantly women work. Occupational noise exposure commonly results in hearing loss and distortion. Edith (2001) revealed that quality and type of lighting can have a significant impact on our health and comfort. Noise related hearing loss may result in distortion of sound, including auditory perception of sound of co-workers speech. The work environment in a majority of these units is unsafe and unhealthy. These include poorly designed workstations, unsuitable furniture, lack of ventilation, inappropriate lighting, excessive noise and lack of personal protective equipment. People working in such poor or substandard environment are prone to occupational diseases. II. MATERIALS AND METHODS

I.

INTRODUCTION

A review of the textile industry quotes that it is the largest manufacturing sector in India accounting for around 20% of industrial output and 37% of total exports. Indias industrial output and 37% of total exports. Karnataka is major apparel sourcing destination for the global market with exports over Rs. 3000 crore in 2000-01 making it the second largest garments exporter in India. There 5777 factories in India employing 3, 27,397 personnel producing goods both for home markets and for export. There are 780 garments industries in Bangalore alone. Women form 80% of workforce in industry. The textile garment industry is at the forefront of the globalization process, where multinational investors continuously shift production from one part of the world to another in search of low wages and even more competitive locations. This has led to an increase in working hours and a substantial reduction in safety standards, especially in the newly industrialized countries. The occupational hazards are those hazards which are faced by the workers due to poor working environment. Parimalam et al. (2006) revealed that the congested work area, improper ventilation, dust, unergonomically designed workstation, excessive noise were the main constraints faced by the workers in garment manufacturing units. Noise and vibration are often found in textile settings, garment manufacturing units, and many other workplace

The present study was conducted in garment manufacturing units located in Bangalore. Total of 110 sewing machine operators, 55 men and 55 women of garment manufacturing units aged between 30-55 years were selected. Purposive sampling technique, semi structured interview schedule, observation technique and equipments like noise level meter and illuminometer was used to check the level of noise and intensity of noise respectively. III. RESULT AND DISCUSSION

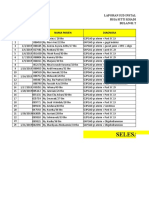

It is seen from table-1 that Maximum (54.5 per cent) of male and (45.4 per cent) of female workers faced problems due to amount and intensity of light, 14.5 per cent male and 20.0 per cent female workers faced problems due to too much of noise, 16.3 percent men and 14.5 per cent women reported dust problems due to improper ventilation system whereas 5.4 per cent men and 3.6 per cent women reported problems due to vibration.

www.theinternationaljournal.org > RJSSM: Volume: 01, Number: 10, Feb-2012

Page 110

111

TABLE 1. DISTRIBUTION OF WORKERS ACCORDING TO OCCUPATIONAL HAZARDS. RESPONDENTS 110 Occupation al Hazards Frequenc y (n=55) Heat 6 8 Occupation al Hazards Frequenc y (n=55) Vibration Ventilation Light None of Above It was revealed from the table-2 that intensity of light in the industry for men was more than that of women.. The average level of illumination in the stitching sections of both the units was of 411.1 and 331.1Lx respectively. This was found to be low when compared to the standard levels recommended by Grandjean, and Ghosal, which are 750 and 400 Lx respectively in cutting and sewing sections. TABLE 2 INTENSITY OF LIGHT IN GARMENT MANUFACTURING UNITS. SL. NO 1. 2. It is observed from the table-3 that level of noise in male industry was more than female industry. Some unions have set a noise level of 80 dB as safe standard to work. The level of noise in male manufacturing units was more than 93.8 dB and in women manufacturing units 87.01 dB which was more than the standard level of noise. MANUFACTURING UNITS MEN WOMEN MEAN INTENSITY LIGHT 411.1 Lx 331.1 Lx 30 5 54.5 9.1 25 4 45.4 7.2 3 9 5.4 16.3 2 8 3.6 14.5 Percenta ge 10.9 14.9 7 11 FEMALE WORKERS Frequenc y (n=55) Percenta ge 12.7 20.0 Percenta ge MALE WORKERS FEMALE WORKERS Frequenc y (n=55) Percenta ge

TABLE 3 NOISES IN GARMENT MANUFACTURING INDUSTRIES. SL. NO 1. 2. MANUFACTURING UNITS MEN WOMEN MEAN LEVEL OF NOISE 93.8Db 87.01dB

TABLE 4 DISTRIBUTIONS OF WORKERS ACCORDING TO ACCIDENTS DUE TO EQUIPMENTS USED AT WORKPLACE.

RESPONDENTS 110 Equipments at workplace Frequency (n=55) Electric Wires Piercing Needle Press (Burn) Scissors None of Above 12 8 21.8 14.5 16 8 29.0 14.5 6 10.9 4 5.4 25 49.0 20 36.3 4 5.4 Percentage Frequency (n=55) 7 12.7 Percentage MALE WORKERS FEMALE WORKERS

RESPONDENTS 110 MALE WORKERS

Table-4 shows that the accidents occurred due to equipments used at workplace. It is revealed that majority of 49.0 per cent men and 36.3 per cent women get injured with machine needles. Whereas 21.8 percent male and 29.0 per cent female got injured by scissors during cutting operations and some minor accidents 5.4 per cent each in both male and female workers respectively. Conclusion: Accidents are a common occurrence in the apparel manufacturing industry. Both workers and the managements should be made aware of the problems associated with accidents and on the correct and continuous use of personal protective equipments that are recommended for each task in the industry.

www.theinternationaljournal.org > RJSSM: Volume: 01, Number: 10, Feb-2012

Page 111

112

REFERENCES 1. Farkkila (1978) A study of portable vibrating tools in the relation to the clinical effects they produce. Br.J Ind. Med 4:141-63. 2. Karasch, B. (2005) Textbook of Occupational and Environmental Medicine. Philadelphia: W B Saunders, 356-364 3. Maier, E. (2009) Adaptive Lights can Monitor what Room Occupants Are Doing and Setting Lighting Accordingly. Science Daily; Pg- 35. 4. Sakakibara, D (1995), Overhead Work and Shoulder- neck pain in orchard farmers harvesting pears and apples. (Ergonomics, 38 (4), 700-706. 5. Sakurai and Matoba (1986), Vibration syndrome again. Br Med Journal 282: 1738-39. 6. Vikrunnen, H. (2005), Long working hours and health. Scandivian Journal of work, Environment and Health, Vol 29: 171-178. 7. Puliani S. The Factories Act, 1948 along with Karnataka Factories Rules 1969 and allied laws, 4th Edition Bangalore Karnataka Law Journal Publications 2000. 8. Pandita S. The plight of workers in Export Processing Zonein India. [monograph on the Internet] New Delhi: Society for Participatory Research In Asia (PRIA) and the American Centre for International Labour Solidarity (ACILS) [cited2004, Jul 28]. Available from : http://www.iimahd.ernet.in/partha/EPZ%20Study%20 report.htm

www.theinternationaljournal.org > RJSSM: Volume: 01, Number: 10, Feb-2012

Page 112

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Allocating Hospital Resources To Improve Patient ExperienceDocument6 pagesAllocating Hospital Resources To Improve Patient ExperienceMichael0% (1)

- Professional Review Industry Route Guidance NotesDocument10 pagesProfessional Review Industry Route Guidance NotesAnonymous TlYmhkPas encore d'évaluation

- Porter'S Five Forces Model-Telecommunication IndustryDocument19 pagesPorter'S Five Forces Model-Telecommunication IndustryWychSupaPas encore d'évaluation

- Style# Zipper Color Ykk Zipper Color Code Option 1Document4 pagesStyle# Zipper Color Ykk Zipper Color Code Option 1WychSupaPas encore d'évaluation

- BOM CI 100% Cotton Polo Men 17-01Document13 pagesBOM CI 100% Cotton Polo Men 17-01WychSupaPas encore d'évaluation

- Coh Community Snapshots Tataelxsi Tata InternationalDocument1 pageCoh Community Snapshots Tataelxsi Tata InternationalWychSupaPas encore d'évaluation

- CTA Apparels Private LimitedDocument2 pagesCTA Apparels Private LimitedWychSupaPas encore d'évaluation

- Civil 3d 2008 Top Benefits FinalDocument3 pagesCivil 3d 2008 Top Benefits FinalWychSupaPas encore d'évaluation

- SHARON SCHULTZ, ET AL. v. JANOS GUOTH, M.D. AND KHALED F. RABIE, M.D. (Parish of Rapides)Document18 pagesSHARON SCHULTZ, ET AL. v. JANOS GUOTH, M.D. AND KHALED F. RABIE, M.D. (Parish of Rapides)wstPas encore d'évaluation

- Department of Health & Human ServicesDocument6 pagesDepartment of Health & Human ServiceseduardoPas encore d'évaluation

- African National Congress: Department of Information and PublicityDocument9 pagesAfrican National Congress: Department of Information and PublicityeNCA.com100% (2)

- Proforma Curriculum VitaeDocument4 pagesProforma Curriculum VitaeSohail IqbalPas encore d'évaluation

- Risk Assessment - GardenDocument2 pagesRisk Assessment - GardenOlivia BrookesPas encore d'évaluation

- Body Image: Marika Tiggemann, Kristy HageDocument7 pagesBody Image: Marika Tiggemann, Kristy HageRachel VictorianaPas encore d'évaluation

- Effect of A Program of Physical Activity Motivated by Lipid Parameters of Patients With Obesity and or Overweight PDFDocument6 pagesEffect of A Program of Physical Activity Motivated by Lipid Parameters of Patients With Obesity and or Overweight PDFMarlio Andres Vargas PolaniaPas encore d'évaluation

- Tano Vs SocratesDocument3 pagesTano Vs SocratesNimpa PichayPas encore d'évaluation

- Meditation ScriptDocument9 pagesMeditation Scriptapi-361293242100% (1)

- Title Defense CapstoneDocument2 pagesTitle Defense CapstoneDelightful TinePas encore d'évaluation

- Reactive Hyperplastic Lesions of The Oral CavityDocument8 pagesReactive Hyperplastic Lesions of The Oral CavityMarïsa CastellonPas encore d'évaluation

- VF-VT AlgorithmDocument10 pagesVF-VT AlgorithmPuskesmas Pinang JayaPas encore d'évaluation

- Technology For Iron and Manganese Ion Removal From Groundwater A ReviewDocument15 pagesTechnology For Iron and Manganese Ion Removal From Groundwater A ReviewGlobal Research and Development Services100% (1)

- Practice Sheet Session 2 - 2021 - Student SheetDocument2 pagesPractice Sheet Session 2 - 2021 - Student SheetAlisa SayPas encore d'évaluation

- Chapter I Related Literature Teenage PreDocument12 pagesChapter I Related Literature Teenage PreWilkenn Tuazon100% (3)

- Form Lplpo Pustu Dan PoskesdesDocument3 pagesForm Lplpo Pustu Dan PoskesdesristiPas encore d'évaluation

- Sex Differences of Brain and Their Implications For Personalized TherapyDocument14 pagesSex Differences of Brain and Their Implications For Personalized TherapyMaria Isabel Montañez RestrepoPas encore d'évaluation

- Potsdam Village Police Dept. Blotter Sept. 10, 2017Document2 pagesPotsdam Village Police Dept. Blotter Sept. 10, 2017NewzjunkyPas encore d'évaluation

- 3M Disposable Filtering Facepiece Respirator Fitting Poster English and SpanishDocument2 pages3M Disposable Filtering Facepiece Respirator Fitting Poster English and SpanishTrunggana AbdulPas encore d'évaluation

- SHS 079 2021 - 12STEM C - Group9Document62 pagesSHS 079 2021 - 12STEM C - Group9NATIOLA HYTHAM XYRUS A.Pas encore d'évaluation

- Homoeopathic Perspective of Thyroid DisordersDocument20 pagesHomoeopathic Perspective of Thyroid DisordersSaurav AroraPas encore d'évaluation

- 3 Colinet Dustsampling PDFDocument21 pages3 Colinet Dustsampling PDFom pandeyPas encore d'évaluation

- Laporan Iud 2019Document91 pagesLaporan Iud 2019Yuli AntiPas encore d'évaluation

- 60 Substance Abuse Group Therapy ActivitiesDocument7 pages60 Substance Abuse Group Therapy ActivitiesHanes Labajos100% (1)

- Full Employee ReportDocument3 pagesFull Employee ReportXYZPas encore d'évaluation

- Dinup BSBMGT605Document41 pagesDinup BSBMGT605fhc munna100% (1)

- Ponr 1Document14 pagesPonr 1Jhade RelletaPas encore d'évaluation

- Registrars Manual On Band DDocument32 pagesRegistrars Manual On Band DkailasasundaramPas encore d'évaluation