Académique Documents

Professionnel Documents

Culture Documents

ConFloor Calculation

Transféré par

Gabor OlahDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ConFloor Calculation

Transféré par

Gabor OlahDroits d'auteur :

Formats disponibles

CF80/1.

ENV 1994-1-1 & ENV 1994-1-2

Page 1

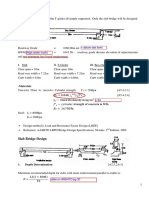

SCI Corus Panels and Profiles JOB REFERENCE: Lucrare de diploma DECK REFERENCE: CF 80 1.20 thk COMPANY NAME: CLIENT NAME: Universitatea Technica Cluj-Napoca FILENAME: Calcs by: Olah Gabor

Date: Time: Job No: Checked by:

8. 3 06-14-2012 1:16:20 PM

FULL OUTPUT NOTE: SECTION DESIGNED TO ENV 1994-1 Construction Stage: PASS Max Unity Factor = 0.21 Normal Stage: PASS Max Unity Factor = 0.36 Fire Condition: PASS Max Unity Factor = 0.57 Serviceability: SATISFACTORY Max Unity Factor = 0.18 *** SECTION ADEQUATE ***

FLOOR PLAN DATA : (unpropped composite construction with CF80/1.2 decking) Beam centres - equal 2.00 m Span type Beam or wall width 160 mm Propping PROFILE DATA : (CF80/1.2 decking. Grade S 450 GD ) Depth 80 mm Trough width 120 mm Nominal sheet thickness 1.20 mm Deck weight 0.15 kN/m

MULTIPLE NONE

Pitch of deck ribs Crest width Design sheet thickness Yield strength

300 mm 147.0 mm 1.16 mm 450 N/mm

CONCRETE SLAB : [Normal Weight Concrete ; Mesh : A142] ***NOTE: Nesting of mesh reinforcement and use of lacing bars at laps may be required for the construction of the slab Overall slab depth 140 mm Concrete class C25/30 Concrete wet density 2400 kg/m Modular ratio 10 Concrete dry density 2350 kg/m Bar reinforcement : Diameter 8 mm Yield strength 500 N/mm Distance from slab soffit 30 mm Mesh reinforcement : Mesh A142 Yield strength 460 N/mm Cover to Mesh 30 mm Account for End Anchorage NO Shear connectors per rib 0 Screeds NONE SECTION PROPERTIES : ***NOTE - 1: All values of inertia are expressed in steel units ***NOTE - 2: Average inertia is used for deflection calculations for the composite stage ***NOTE - 3: Cracked dynamic inertia is used for natural frequency calculations DECK PROFILE: Sagging Inertia, Ixx Hogging Inertia, Iyy COMPOSITE: Inertia, Ixx - Uncracked Average inertia Shear bond coefficients - m Concrete volume 234.100 cm4/m 0.000 cm4/m 2040 cm4/m 1628 cm4/m 84.60 0.096 m/m/m Area of profile (Net), Ap 1871 mm/m

Cracked Cracked inertia (dynamic) k

1216 cm4/m 1395 cm4/m 0.273861

LOADS ACTING ON SLAB : (ACTIONS) *** NOTE: Slab subjected to uniformly distributed loads (UDL) ONLY Imposed (occupancy) 3.00 kN/m Partitions Ceilings and services 0.80 kN/m Finishes Self weight of concrete slab (wet) 2.27 kN/m Self weight of decking Self weight of concrete slab (dry) 2.22 kN/m Screeds Construction load 2.3 kN/m

1.00 kN/m 3.78 kN/m 0.15 kN/m NONE

File Name: .pmd

Comdek V8. 3

CF80/1.2

ENV 1994-1-1 & ENV 1994-1-2

Page 2

LINE LOADS PERPENDICULAR TO DECK SPAN : (ACTIONS) None LINE LOADS PARALLEL TO DECK SPAN : (ACTIONS) None FIRE DATA : Design method FIRE ENGINEERING Non-permanent imposed loads 0.0 kN/m PARTIAL SAFETY FACTORS : Actions Permanent, gamma G Permanent - accidental, gamma GA Variable, gamma Q Combination factor - Fire, psi 1

Fire resistance period

60 mins

1.35 1.05 1.50 0.70

Materials Structural steel - elastic, gamma M0 Structural steel - buckling, gamma M1 Concrete, gamma C Reinforcement, gamma S

1.05 1.05 1.50 1.15

CONSTRUCTION STAGE

LOADINGS : Unfactored (kN/m) Self weight of decking 0.15 Self weight of concrete slab (wet) 2.27 Construction load (one span) 2.25 Construction load (adjacent span(s)) 0.75 Total factored load (maximum) Factored (kN/m) 0.20 3.06 3.38 1.13

= 0.20 + 3.06 + 0.00 + 3.38 = 6.64 kN/m

EFFECTIVE SPAN OF DECK : Effective span Le, is the smaller of 1) c/c of supports 2) clear span + deck depth Therefore Le SHEAR RESISTANCE CHECK : *** Check at first interior support position Applied shear Shear strength of decking, buckling Resistance, Pv Shear strength of decking, yielding Resistance, Pv Shear resistance of decking, Pv UNITY FACTOR

= 2.00 m = 1.84 + 80.0 / 1000 = 1.92 m = 1.92 m

= [1.10 * 0.20 + 1.20 * 3.06 + 2.50 * 3.38/3] * 1.92 / 2 = 6.44 kN/m = 191.5 N/mm = 115.2 kN/m = 259.8 N/mm = 156.3 kN/m = MIN(115.2, 156.3) = 115.2 kN/m = 0.06 PASS

WEB CRUSHING RESISTANCE CHECK : *** Check at first interior support position Applied reaction = 12.89 kN/m Web crushing resistance, Pw = 71.57 kN/m UNITY FACTOR = 0.18 PASS

File Name: .pmd

Comdek V8. 3

CF80/1.2

ENV 1994-1-1 & ENV 1994-1-2

Page 3

BENDING RESISTANCE CHECK : NOTE: *** a 30% redistribution of hogging moment is taken based on equilibrium of the continuous decking as the sagging moment does not exceed the design resistance SAGGING: Max applied moment Moment resistance, Mc UNITY FACTOR HOGGING: Max. applied moment Moment resistance, Mc UNITY FACTOR = [0.080 * 0.20 + 0.094 * 3.06 + 0.094 * 3.38] * 1.92^2 = 2.29 kNm/m = 23.10 kNm/m = 0.10 = [0.100 * 0.20 + 0.117 * 3.06 + 0.250 * 3.38/ 3] * 1.92^2 = 1.70 kNm/m = 19.40 kNm/m = 0.09 PASS PASS

INTERACTION OF BENDING MOMENT AND SHEAR : NOTE 1: *** Check at first interior support position NOTE 2: *** a 30% redistribution of hogging moment is taken based on equilibrium of the continuous decking as the sagging moment does not exceed the design resistance Applied shear Shear resistance, Pv Applied moment Moment resistance, Mc UNITY FACTOR = 6.44 kN/m = 115.22 kN/m = 1.70 kNm/m = 19.40 kNm/m = [6.44/115.22]^2 + [2.43/19.40]^2 = 0.01

PASS

INTERACTION OF BENDING MOMENT AND WEB CRUSHING : NOTE 1: *** Check at first interior support position NOTE 2: *** a 30% redistribution of hogging moment is taken based on equilibrium of the continuous decking as the sagging moment does not exceed the design resistance Applied reaction Web crushing resistance, Pw Applied moment Moment resistance, Mc UNITY FACTOR = 12.13 kN/m = 71.57 kN/m = 1.70 kNm/m = 19.40 kNm/m = 12.13/71.57 + 1.70/19.40 = 0.26 ( < 1.25 )

PASS

DEFLECTION CHECK : Allowable deflection max, is the smaller of 1) Effective span/180 (= 10.7 mm ), and 2) 20.0 mm ( absolute maximum value ), and 3) Slab depth/10 = ( 14.0 mm ) Max. self weight deflection = 0.0069 * 2.42 * (1.92* 1000 )^4 / (210*2341000 )/1000 = 0.46 mm ( < 10.67 mm ) SATISFACTORY ***NOTE: Deflection within code limits; ponding is not considered

File Name: .pmd

Comdek V8. 3

CF80/1.2

ENV 1994-1-1 & ENV 1994-1-2

Page 4

NORMAL STAGE

LOADINGS : (see construction load calculations for details): Unfactored (kN/m) Factored (kN/m) Dead 0.15 + 2.22 = 2.37 3.20 Imposed 3.00 + 1.00 = 4.00 6.00 Superimposed dead 0.80 + 3.78 + 0.00 = 4.58 6.18 Total EFFECTIVE SPAN : Effective span Le, is the smaller of 1) c/c of supports 2) clear span + slab overall depth Therefore Le SHEAR RESISTANCE CHECK : Maximum applied shear Shear stress in concrete, v Shear strength of concrete, vc Shear resistance UNITY FACTOR PUNCHING SHEAR CHECK : Not Applicable SHEAR BOND RESISTANCE CHECK : Shear span Applied shear Shear due to shear bond Tension in bar reinforcement Moment due to reinforcement Shear due to reinforcement Moment due to end anchorage Total shear resistance UNITY FACTOR = 10.95 kN/m 15.39 kN/m

= 2.00 m = 1.8 + 140.0 / 1000 = 1.98 m = 1.98 m

= 0.5 * 15.39 * 1.98 = 15.23 kN/m = 0.33 N/mm = 0.90 N/mm = 136.50 * 102.842 * 0.300 * 1.50 * (1.2 + 40 * 0.02) / 300.00 = 42.03 kN/m = 0.36 PASS

= 1.98 / 4 = 0.50 m = 15.2 - 1.0 * (0.15 + 2.22) * 0.5 * 2.0 * 1.0 = 12.88 kN/m = 1000 * 102.2/1.25 * [84.6 * 1871.0 / (1000 * 495.0) + 0.2739)] / 1000 = 48.53 kN/m (using m&k method) = 50.3/1.15 * 500.0 / 300.0 = 72.85 kN/m = 72.8 * (140.0 - 30.0 - 46.2 /2) / 1000 = 6.33 kNm/m = 6.33 / 0.50 = 12.79 kN/m Not Applicable = 48.53 + 12.79 = 61.32 kN/m = 0.21 PASS

File Name: .pmd

Comdek V8. 3

CF80/1.2

ENV 1994-1-1 & ENV 1994-1-2

Page 5

BENDING RESISTANCE CHECK : Applied bending moment

= 0.125 * 15.39 * 1.98^2 = 7.54 kNm/m Depth of concrete stress block = 46.19 mm NOTE: depth of concrete in compression may be limited to 0.45 ds Tension in decking = 654.29 kN/m Tension in bar reinforcement = 0.00 kN/m Depth to position of resultant tension = (0.0 * 110.0 + 654.3 * 102.2) / (0.0 + 654.3) = 102.19 mm Lever arm = 79.10 mm NOTE: lever arm may be limited to 0.95 ds Compression in concrete = 654.29 kN/m Moment resistance = 654.29 * 79.10/1000 = 51.75 kNm/m UNITY FACTOR FIRE RESISTANCE CHECK : Effective span in fire, is the greater of 1) c/c suppports - support width 2) c/c supports - 150 i.e effective span in fire Fire dead load Non-permanent fire imposed load Permanent fire imposed load Fire imposed load Fire free moment Moment resistance, sagging Moment resistance, Mr UNITY FACTOR = 0.15 PASS

= 2.00 - 160 / 1000 = 1.84 m = 2.00 - 150 / 1000 = 1.85 m = 1.85 m = 0.15 + 2.22 + 0.80 + 3.78 + 0.00 = 6.95 kN/m = 0.70 * 0.0 *3.00 = 0.0 kN/m = (1 - 0.0) *3.00 + 1.00 = 4.00 kN/m = 0.00 + 4.00 = 4.00 kN/m = 0.125 * ( 6.95 + 4.00 ) * 1.85^2 = 4.69 kNm/m = 8.16 kNm/m = 8.16 kNm/m = 0.57 PASS

DEFLECTION CHECK : Allowable deflection max-i under imposed loads, is the smaller of 1) Effective span/350 (= 5.7 mm ), and 2) 20.0 mm ( absolute maximum value ) Imposed load deflection = 5 / 384 * 4.00 * (1.98* 1000 )^4 / (210 *16280657 )/1000 = 0.2 mm ( < 5.7 mm ) SATISFACTORY

Allowable total deflection max-t, is the smaller of 1) Effective span/250 or 7.9 mm, and 2) 30.0 mm ( SCI recommended absolute maximum value ) Deflection due to imposed loads Additional deflection due to superimposed dead loads Total deflection = 0.2 mm (based on average inertia) = 0.3 mm (based on average inertia) = 0.2 + 0.3 = 0.5 mm ( < 7.9 mm ) SATISFACTORY

File Name: .pmd

Comdek V8. 3

CF80/1.2

ENV 1994-1-1 & ENV 1994-1-2

Page 6

DYNAMIC SENSITIVITY : *** NOTE: loads are dead + super-imposed dead + 10% imposed Dynamic inertia (cracked section) = 1395 cm4 Maximum deflection = 5 / 384 * 9.75 * (1.98* 1000 )^4 / (210 *13951030 )/1000 = 0.67 mm Frequency = 18 / sqr( 0.67 ) = 22.05 Hz ( greater than 4.00 Hz) SATISFACTORY

File Name: .pmd

Comdek V8. 3

Vous aimerez peut-être aussi

- ComFlor 46/1.2/S280 design calculationsDocument6 pagesComFlor 46/1.2/S280 design calculationsKawser HossainPas encore d'évaluation

- Slab Comflor60Document6 pagesSlab Comflor60ihpeterPas encore d'évaluation

- Bs5950 Calculation Decking SheetDocument6 pagesBs5950 Calculation Decking SheetKho C Ahl100% (1)

- Load Calculation For Air Compressor BuildingDocument27 pagesLoad Calculation For Air Compressor BuildingLandon Mitchell100% (1)

- Comflor - 60mm Steel DeckingDocument6 pagesComflor - 60mm Steel DeckingSyed AamerPas encore d'évaluation

- Materials: Slab Bridge DesignDocument13 pagesMaterials: Slab Bridge DesignephremPas encore d'évaluation

- Fin Glass 6Document6 pagesFin Glass 6EIWAA100% (1)

- Step by Step Design of PSC Girder by Working Stress MethodDocument50 pagesStep by Step Design of PSC Girder by Working Stress Methodpravin100% (3)

- Deck SlabDocument10 pagesDeck SlabArun EthirajPas encore d'évaluation

- CWR 3700KL R5Document10 pagesCWR 3700KL R5NitinShepurPas encore d'évaluation

- Continuous (One Way)Document7 pagesContinuous (One Way)scribd1991Pas encore d'évaluation

- Abut DesignDocument32 pagesAbut DesignSubir Kunda100% (2)

- Access Scaffolding CalculationDocument8 pagesAccess Scaffolding CalculationSarah HaiderPas encore d'évaluation

- Access Scaffolding CalculationDocument8 pagesAccess Scaffolding CalculationOsama Tahir100% (3)

- FORMWORK DESIGNDocument28 pagesFORMWORK DESIGNsubhananya50% (4)

- Bridge-Ch-5-Example On Slab Bridge EDITEDFINALDocument15 pagesBridge-Ch-5-Example On Slab Bridge EDITEDFINALkassahun kebede100% (1)

- 15m Brick Wall Frame 2021-08-21Document21 pages15m Brick Wall Frame 2021-08-21Jack WenPas encore d'évaluation

- Design of Compound WallDocument4 pagesDesign of Compound WallMaku Rajkumar100% (2)

- Design of StaircaseDocument5 pagesDesign of Staircasedavysol2015Pas encore d'évaluation

- Typical RCC Beam: Hand Calculation As Per IS-456:2000Document3 pagesTypical RCC Beam: Hand Calculation As Per IS-456:2000sanjusamsonPas encore d'évaluation

- Structural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-BDocument60 pagesStructural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-Bنصر عبدالسلامPas encore d'évaluation

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Tong TheDocument5 pagesTong TheBien Thuy TranPas encore d'évaluation

- Designs Design of Deck Slab (S1) : 1) Data: Overall Thickness 600 MMDocument11 pagesDesigns Design of Deck Slab (S1) : 1) Data: Overall Thickness 600 MMskumaraneeePas encore d'évaluation

- Durabilty and Fire ResistanceDocument6 pagesDurabilty and Fire ResistanceMohafisto SofistoPas encore d'évaluation

- Strip FootingDocument10 pagesStrip FootingKain Pasang Ruby IIPas encore d'évaluation

- Doka Large Formwork User ManualDocument21 pagesDoka Large Formwork User ManualNasir AryaniPas encore d'évaluation

- Composite floor slab design verificationDocument7 pagesComposite floor slab design verificationFong Pei TyngPas encore d'évaluation

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Jutpani SS20Document23 pagesJutpani SS20Suman NakarmiPas encore d'évaluation

- Composite Slab DesignDocument13 pagesComposite Slab Design_jesseca100% (2)

- Final Revised Box DesignDocument10 pagesFinal Revised Box Designabu bakkarPas encore d'évaluation

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama83% (12)

- 1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionDocument4 pages1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionMICHAEL MWONGAPas encore d'évaluation

- Design of Isolated Footing With Vertical Load Only - According To ACI-318-99Document3 pagesDesign of Isolated Footing With Vertical Load Only - According To ACI-318-993cesPas encore d'évaluation

- Column/Wall Punching Shear ReportDocument2 pagesColumn/Wall Punching Shear ReportWei ThienPas encore d'évaluation

- Example - Slab Bridge PDFDocument7 pagesExample - Slab Bridge PDFRefisa Jiru100% (3)

- RC Girder Bridge DesignDocument8 pagesRC Girder Bridge DesignIyœ MøsisæPas encore d'évaluation

- Structure Design Basis: Page - 1Document7 pagesStructure Design Basis: Page - 1MdShahbazAhmedPas encore d'évaluation

- 1.8 - Calc Febc-224 Water TankDocument8 pages1.8 - Calc Febc-224 Water TankAbdelrahman ElkhollyPas encore d'évaluation

- Combined FootingDocument15 pagesCombined FootingAnish NeupanePas encore d'évaluation

- JjSD211 PRACTICAL NO 2Document11 pagesJjSD211 PRACTICAL NO 2Leonard MwangokaPas encore d'évaluation

- Design of Free Standing WallsDocument12 pagesDesign of Free Standing Wallssaif.mulla0% (1)

- Retainingwall BS8110Document8 pagesRetainingwall BS8110Obet NegoPas encore d'évaluation

- Design of Isolated Footing With Vertical Load Only - According To ACIDocument1 pageDesign of Isolated Footing With Vertical Load Only - According To ACIFouad El ZanatyPas encore d'évaluation

- Design of One Way SlabDocument3 pagesDesign of One Way SlabRachanaPas encore d'évaluation

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Anchor Bolt and Shear Key DesignDocument3 pagesAnchor Bolt and Shear Key DesignsvgkraoPas encore d'évaluation

- Advanced Design of Steel Structure Composite Beam DesignDocument6 pagesAdvanced Design of Steel Structure Composite Beam DesignNaim YaqeenPas encore d'évaluation

- DESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m HeightDocument15 pagesDESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m Heightmsiddiq1100% (2)

- Combined Footing - FormatDocument9 pagesCombined Footing - FormatMikhail TabucalPas encore d'évaluation

- Bridge DesignDocument220 pagesBridge Designrochelleandgello100% (1)

- Pressuremeter Testing: Methods and InterpretationD'EverandPressuremeter Testing: Methods and InterpretationÉvaluation : 5 sur 5 étoiles5/5 (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportD'EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsD'EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerPas encore d'évaluation

- Materials Science and Technology of Optical FabricationD'EverandMaterials Science and Technology of Optical FabricationPas encore d'évaluation

- IMSLP458907 PMLP73098 Kayser - Opus 20 PDFDocument60 pagesIMSLP458907 PMLP73098 Kayser - Opus 20 PDFAntonio CicconePas encore d'évaluation

- IMSLP458907 PMLP73098 Kayser - Opus 20 PDFDocument60 pagesIMSLP458907 PMLP73098 Kayser - Opus 20 PDFAntonio CicconePas encore d'évaluation

- Industrial Buildings PDFDocument10 pagesIndustrial Buildings PDFGabor OlahPas encore d'évaluation

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Hacking Secrets To Becoming A Genius Hacker How To Hack Smartphones - Computers - Websites For BeginnersDocument55 pagesHacking Secrets To Becoming A Genius Hacker How To Hack Smartphones - Computers - Websites For BeginnersMarius Cenușă80% (15)

- Hacking Secrets To Becoming A Genius Hacker How To Hack Smartphones - Computers - Websites For BeginnersDocument55 pagesHacking Secrets To Becoming A Genius Hacker How To Hack Smartphones - Computers - Websites For BeginnersMarius Cenușă80% (15)

- Uputstvo Za Obijanje Brava (Englseki)Document18 pagesUputstvo Za Obijanje Brava (Englseki)Nermin SelicPas encore d'évaluation

- Example Composite Floor SlabDocument13 pagesExample Composite Floor SlabZamfira Octavian100% (2)

- Tekla - Steel Detailing - Basic Training DrawingDocument160 pagesTekla - Steel Detailing - Basic Training DrawingGabor OlahPas encore d'évaluation

- Column SpliceDocument22 pagesColumn SpliceGabor OlahPas encore d'évaluation

- The Structural Design of Petronas Twin TowerDocument18 pagesThe Structural Design of Petronas Twin Toweramirriyyah75% (4)

- ConSteel 6 Manual ENGDocument133 pagesConSteel 6 Manual ENGDumitru CandalePas encore d'évaluation

- Autodesk Robot Structural Analysis Professional 2010 - Training Manual (Metric Version)Document178 pagesAutodesk Robot Structural Analysis Professional 2010 - Training Manual (Metric Version)ericfgPas encore d'évaluation

- Slim Floor: Long Carbon Europe Sections and Merchant BarsDocument36 pagesSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongPas encore d'évaluation

- Foundation Design - 5110-P-001ABC - Rev 0Document11 pagesFoundation Design - 5110-P-001ABC - Rev 0Yatendra TyagiPas encore d'évaluation

- Material Requirements for Steel and Concrete StructuresDocument38 pagesMaterial Requirements for Steel and Concrete StructuresSimon LsmPas encore d'évaluation

- International Journal o F PlasticityDocument56 pagesInternational Journal o F PlasticityTrai NguyenPas encore d'évaluation

- AIJ Proposal (ACI SP123)Document19 pagesAIJ Proposal (ACI SP123)hbookPas encore d'évaluation

- Experimental investigation of soil-cement columns for ground improvementDocument8 pagesExperimental investigation of soil-cement columns for ground improvementCristina Andreea BitirPas encore d'évaluation

- Types of Deep FoundationsDocument98 pagesTypes of Deep FoundationsRuli Aprillianto67% (3)

- Concrete: Analyses Assumption Enviromental ParametersDocument5 pagesConcrete: Analyses Assumption Enviromental ParametersVarun VermaPas encore d'évaluation

- Structural Engineer - Issue 9 - 2010Document76 pagesStructural Engineer - Issue 9 - 2010ntatar90Pas encore d'évaluation

- Adapt Pt7 Manual Vol IIIDocument235 pagesAdapt Pt7 Manual Vol IIIapi-3730088100% (2)

- Challenging Foundations for Tall BuildingsDocument27 pagesChallenging Foundations for Tall BuildingsRENZZ IRVIN DELA TORREPas encore d'évaluation

- TB02 Bearing Capacity of Geopier Supported Foundations PDFDocument16 pagesTB02 Bearing Capacity of Geopier Supported Foundations PDFDavid Garces MesaPas encore d'évaluation

- ASME B31.3 2020 CambiosDocument10 pagesASME B31.3 2020 CambiosJosé Juan Jiménez AlejandroPas encore d'évaluation

- NA To BS EN 1993-1-1 2005Document14 pagesNA To BS EN 1993-1-1 2005afiq2697100% (1)

- Elasticity ProblemsDocument1 pageElasticity ProblemsjenibelPas encore d'évaluation

- Chapterwise Question bank-DSR-22502Document5 pagesChapterwise Question bank-DSR-22502soumyasonawane100% (1)

- Soil Slope Stability Analysis: 6, Chapter 13 JDocument35 pagesSoil Slope Stability Analysis: 6, Chapter 13 JgayathryPas encore d'évaluation

- Macromechanics of A LaminateDocument45 pagesMacromechanics of A LaminateAvinash ShindePas encore d'évaluation

- Reinforced Concrete Structural Design of Two Story Residential BuildingDocument2 pagesReinforced Concrete Structural Design of Two Story Residential BuildingJadrien Mark Imperial100% (1)

- RCC & PSC Class NotesDocument329 pagesRCC & PSC Class NotesVinod VadithyaPas encore d'évaluation

- Verification of Numerical and Analytical Methods of Analysis of TunnelDocument6 pagesVerification of Numerical and Analytical Methods of Analysis of TunnelAhmedPas encore d'évaluation

- Excavacion PDFDocument25 pagesExcavacion PDFLuis Alejandro Godoy OrdenesPas encore d'évaluation

- Design of FlyingWall To Box CulvertDocument6 pagesDesign of FlyingWall To Box CulvertVivek PremjiPas encore d'évaluation

- Foundation Design Chapter 11Document85 pagesFoundation Design Chapter 11ES JoandreyPas encore d'évaluation

- Earth Retaining Systems GuideDocument43 pagesEarth Retaining Systems GuideAmanPas encore d'évaluation

- Assam EQ Report 28apr2021Document3 pagesAssam EQ Report 28apr2021sdt4uxPas encore d'évaluation

- Bolt CapacityDocument2 pagesBolt Capacityerikaren85Pas encore d'évaluation

- Analisis Stabilitas Lereng Dengan Perkuatan Soil Nailing Menggunakan Program KomputerDocument7 pagesAnalisis Stabilitas Lereng Dengan Perkuatan Soil Nailing Menggunakan Program KomputerAULIA AGUSTINAPas encore d'évaluation

- Seismic Performance of Multi-Storey RCC Building With Floating ColumnsDocument12 pagesSeismic Performance of Multi-Storey RCC Building With Floating ColumnsSrinivas B VPas encore d'évaluation

- Structural ReportDocument85 pagesStructural ReportSravani PrabhalaPas encore d'évaluation

- Exit Model - Exams 2023Document39 pagesExit Model - Exams 2023Yosef GirmaPas encore d'évaluation