Académique Documents

Professionnel Documents

Culture Documents

ADEX Optimized Control of IKN Type Coolers - Cement - Industries - ADEX

Transféré par

Amr A. NaderTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ADEX Optimized Control of IKN Type Coolers - Cement - Industries - ADEX

Transféré par

Amr A. NaderDroits d'auteur :

Formats disponibles

6/21/12

ADEX Optimized Control of IKN Type Coolers | Cement | Industries | ADEX

C ontact Sitemap Espaol

Technology

Overview Energy Aerospace Petrochemical Water Cement Metallurgical Pulp & Paper Oil & Gas

Systems and Platforms

Products

Industries

About ADEX

Information Center

Home Industries Cement ADEX Optimized Control of IKN Type Coolers

ADEX Optimized Control of IKN Type Coolers

It is well known that the cooler control plays a fundamental role in the clinker process optimization due to its influence in the flow rate and the temperature of secondary air reentering the furnace. The first application of adaptive predictive control in the Gadors cement factory cooler meant an outstanding technological progress. Its success was exposed on the first Colloquium Cement and Concrete in the year 1991, and extended this solution to multiple cement plants. Later technological evolution introduced a new type of clinker cooler (IKN) (shown in the first figure), where the clinker coming from the furnace doesnt fall directly on the mobile grid of the cooler, instead it is dropped into a steady surface in which it forms a slope cooled by a fan acting directly on it, before it falls on to the mobile grid. This new clinker coolers arrangement brought, as pred ictable, a new control problem. The optimization of this process requires simultaneously a good control of the slopes size and a good control of the thickness of the clinkers bed on the mobile grid. Clinker IKN Cooler The clinker IKN cooler (shown at the left) must refrigerate the hot clinker coming from the furnace in order to allow subsequent transport and storage and recover heat energy introducing the hot air produced by the refrigeration process (called secondary air) into the furnace. Thus it is necessary to stabilize the flow rates of air in the fans and the thickness of the clinkers bed acting, both, on the speed of the fans and of the mobile grid.

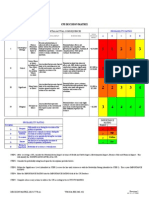

Problems associated to the IKN grid Two variables must be controlled, the size of the slope and the thickness of the clinkers bed on top of the grid, with only one control action: the grids movement speed. Of course, the process presents other difficulties: great changes on the dynamic behavior of the process, lack of a direct measurement of the clinkers bed thickness, strong non-measurable perturbations, etc. The figure at the left shows the most significant process variables in the plant before the ADEX solution was applied.

A DEX, S.L. 2007. Centro Empresarial "La A rboleda" Ctra. de Valencia, Km. 7,300 Madrid - 28031. SPA IN we b de ve lope d by lam anoazul

www.adexcop.com/industries/case-name/ikn-type-coolers-gador-holcim.html

1/1

Vous aimerez peut-être aussi

- Tank Cleaning MethodsDocument9 pagesTank Cleaning MethodsAmr A. Nader100% (1)

- Cement Plant Operation Handbook PDFDocument317 pagesCement Plant Operation Handbook PDFearthanskyfriends84% (25)

- Company Profile SMARTDocument21 pagesCompany Profile SMARTAmr A. NaderPas encore d'évaluation

- Cement Energy GuideDocument70 pagesCement Energy GuideAmr A. NaderPas encore d'évaluation

- PCCL Cement CourseDocument3 pagesPCCL Cement CourseAmr A. NaderPas encore d'évaluation

- CRP 2011.04 Clinker Module Page 1 of 2Document2 pagesCRP 2011.04 Clinker Module Page 1 of 2Amr A. NaderPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- What Is Architecture?Document17 pagesWhat Is Architecture?Asad Zafar HaiderPas encore d'évaluation

- Decision MatrixDocument12 pagesDecision Matrixrdos14Pas encore d'évaluation

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentxandercagePas encore d'évaluation

- Real Estate Regulatory Act (RERA) User ManualDocument29 pagesReal Estate Regulatory Act (RERA) User ManualprasadzinjurdePas encore d'évaluation

- Companies DatabaseDocument2 pagesCompanies DatabaseNIRAJ KUMARPas encore d'évaluation

- Digital Logic Design: Dr. Oliver FaustDocument16 pagesDigital Logic Design: Dr. Oliver FaustAtifMinhasPas encore d'évaluation

- Procedural Text Unit Plan OverviewDocument3 pagesProcedural Text Unit Plan Overviewapi-361274406Pas encore d'évaluation

- Significance of Vaiseshika's PragabhavaDocument5 pagesSignificance of Vaiseshika's Pragabhavavskanchi0% (1)

- Space Gass 12 5 Help Manual PDFDocument841 pagesSpace Gass 12 5 Help Manual PDFNita NabanitaPas encore d'évaluation

- I&C Engineer or Automation EngineerDocument3 pagesI&C Engineer or Automation Engineerapi-79304330Pas encore d'évaluation

- Barriers To Lifelong LearningDocument4 pagesBarriers To Lifelong LearningVicneswari Uma SuppiahPas encore d'évaluation

- 7 JitDocument36 pages7 JitFatima AsadPas encore d'évaluation

- A. Johnston - Naturalism and Anti NaturalismDocument47 pagesA. Johnston - Naturalism and Anti NaturalismaguiaradPas encore d'évaluation

- Structural Testing Facilities at University of AlbertaDocument10 pagesStructural Testing Facilities at University of AlbertaCarlos AcnPas encore d'évaluation

- Clinic Management System (24 PGS)Document24 pagesClinic Management System (24 PGS)pranithPas encore d'évaluation

- Process Validation Statistical ConfidenceDocument31 pagesProcess Validation Statistical ConfidenceSally PujaPas encore d'évaluation

- Консп 1Document48 pagesКонсп 1VadymPas encore d'évaluation

- Reich Web ADocument34 pagesReich Web Ak1nj3Pas encore d'évaluation

- Advance Control Systems LabDocument2 pagesAdvance Control Systems Labpadmajasiva100% (1)

- Applying Ocs Patches: Type Area Topic AuthorDocument16 pagesApplying Ocs Patches: Type Area Topic AuthorPILLINAGARAJUPas encore d'évaluation

- STAR Worksheet Interviewing SkillsDocument1 pageSTAR Worksheet Interviewing SkillsCharity WacekePas encore d'évaluation

- 3D Holographic Projection Technology SeminarDocument28 pages3D Holographic Projection Technology Seminarniteshnks1993Pas encore d'évaluation

- 10 1016@j Ultras 2016 09 002Document11 pages10 1016@j Ultras 2016 09 002Ismahene SmahenoPas encore d'évaluation

- 1 PDFDocument14 pages1 PDFPM JFPas encore d'évaluation

- ATP Draw TutorialDocument55 pagesATP Draw TutorialMuhammad Majid Altaf100% (3)

- HTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFDocument61 pagesHTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFZainul Fikri ZulfikarPas encore d'évaluation

- The Effect of Reward Practices on Employee Performance in Ethio TelecomDocument29 pagesThe Effect of Reward Practices on Employee Performance in Ethio TelecomZakki Hersi AbdiPas encore d'évaluation

- Two Monuments by C Mann 1493 Copy - PDF - OcredDocument23 pagesTwo Monuments by C Mann 1493 Copy - PDF - OcredStephania FrancoPas encore d'évaluation

- Conclusion For A Research Paper About BullyingDocument7 pagesConclusion For A Research Paper About Bullyingafnkjuvgzjzrgl100% (3)