Académique Documents

Professionnel Documents

Culture Documents

221 08

Transféré par

a..all1Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

221 08

Transféré par

a..all1Droits d'auteur :

Formats disponibles

146

Liquid-Liquid Extraction (LLX)

Extraction is a liquid-liquid operation. It is a process of

transferring a solute from one

liquid phase to another immiscible

or partially miscible liquid in

contact with the first. The two

phases are chemically quite

different, which leads to a

separation of the components

according to their distribution or

partition between the two phases,

normally one organic and one

water. This is different from

distillation, in which the liquid is

partially vaporized to create

another (vapor) phase, but the two

phases are similar chemically.

147

Equilibrium Relations in Extraction

1. Phase rule.

In a liquid-liquid system, the minimum number of

components is three and we have two phases in

equilibrium. For a ternary system, the number of degrees

of freedom is three, as calculated by the phase rule (F = C

- P + 2 = 3 - 2 + 2 = 3). We have six variables:

temperature, pressure, and four concentrations. If the

pressure and temperature are specified, then setting one

concentration will fix the system. The other three

concentrations must be calculated from the phase

equilibrium.

2. Triangular coordinates and equilibrium data.

Since we have three components, the equilibrium data are

often expressed in equilateral triangular coordinates. This

is shown in the following figure.

Figure 1. Coordinates for a triangular diagram.

148

The three corners represent three pure components, A, B

and C. The point M is a mixture. The perpendicular

distance from the point M to any base line is the mass

fraction of the component at the corner opposite to that

base line. For example, the distance from M to base AB

is the mass fraction of C (x

C

= 0.40).

A com

Fig 2

misci

The tw

envel

separ

equili

also p

which

one p

Figur

The

curve

exper

and S

we c

mixtu

point

mixtu

equili

and Q

mmon p

, where

ble, an

wo pha

lope. A

ate into

ibrium

plotted

h is cal

phase re

re 2. Li

co

equili

e is

riments

S are

can ch

ure liqu

D in

ure is s

ibrium

Q.

phase d

e a pai

nd liqu

ase regi

An ori

o two c

tie line

d. The

lled the

egion.

iquid-li

ompone

ibrium

obtaine

s. If com

partiall

hoose

uid of B

n Fig.

separat

liquid

diagram

ir of co

id C d

ion is i

iginal m

conjuga

e throu

e two p

e Plait

iquid p

ents A a

solu

ed thr

mponen

ly mis

any b

B and S

3.

ed into

d phase

149

m is Typ

ompone

dissolve

include

mixture

ate pha

ugh poi

phases

point.

phase di

and B a

ubility

rough

nts B

cible,

binary

S, say

This

o two

es, P

Fig.3

ype I sy

ents A

es com

d insid

e of co

ases a a

int M.

are id

Outsi

iagram

are par

. Exper

ystem a

and B

mpletely

de below

omposi

and b w

Other

dentical

ide the

m where

rtially m

rimenta

and sho

are par

y in A

w the c

ition M

which a

tie line

l at po

envelo

e

miscible

al solub

wn in

rtially

or B.

curved

M will

are on

es are

int P,

ope is

e.

bility.

150

Under constant temperature, if we add component A into

this binary mixture drop by drop, the composition of the

ternary mixture will change along line DA. The ratio of

B/S is constant while the amount of A is changing. When

the amount of A is just to make the mixture from two

phases to one single homogeneous phase, the composition

is represented by the point D. By repeating this

procedure for other binary mixtures with compositions of

E, F, G, we obtain the points E, F, G. The curve links

the points PDEFGQ is the equilibrium solubility curve.

If B and S are completely immiscible, the two end points

P and Q on the solubility curve will superimpose to the

top points B and S, respectively.

Conjugate line. As far as some equilibrium tie lines are

available, other tie lines can be obtained by interpolation

with the help of conjugate curve. Assuming the tie lines

E

1

R

1

, E

2

R

2

, E

3

R

3

, E

4

R

4

are known, we draw a vertical line

from E

1

, which

intersects the

horizontal line from

R

1

at point F.

Similary, the vertical

lines from E

2

, E

3

, E

4

,

intersects the

horizontal lines from

R

2

, R

3

, R

4

at points G,

H and J. The curve

joining FGHJ and the

plait point P is called

the conjugate line.

151

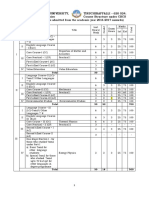

Example E1: Ternary acetic acid-benzene-water mixture.

The liquid-liquid equilibrium data at 25

o

C is given in the

following table. In the right-angled triangle, illustrate

(1) Solubility curve

(2) Tie lines for experiments of Nos. 2, 3, 4, 6, 8

(3) Plait point and conjugate line

No.

Benzene phase (mass %) Water phase (mass %)

acetic

acid

benzene water acetic

acid

benzene water

1 0.15 99.85 0.001 4.56 0.04 95.4

2 1.4 98.56 0.04 17.7 0.20 82.1

3 3.27 96.62 0.11 29.0 0.40 70.6

4 13.3 86.3 0.4 56.9 3.3 39.8

5 15.0 84.5 0.5 59.2 4.0 36.8

6 19.9 79.4 0.7 63.9 6.5 29.6

7 22.8 76.35 0.85 64.8 7.7 27.5

8 31.0 67.1 1.9 65.8 18.1 16.1

9 35.3 62.2 2.5 64.5 21.1 14.4

10 37.8 59.2 3.0 63.4 23.4 13.2

11 44.7 50.7 4.6 59.3 30.0 10.7

12 52.3 40.5 7.2 52.3 40.5 7.2

(1)The data points are plotted in the right-angled triangle

coordinates, joining the points gives the solubility curve.

(2) The experiments of Nos. 2, 3, 4, 6, 8 are shown as

points R

1

, E

1

, R

2

, E

2

, R

3

, E

3

, R

4

, E

4

, R

5

, E

5

. The tie lines

are the straight lines R

1

E

1

, R

2

E

2

, R

3

E

3

, R

4

E

4

, R

5

E

5

.

152

(3) The last set of data have the same composition in the

two phases, which is the plait point. The auxiliary curve

is obtained by drawing vertical lines from E

1

, E

2

, E

3

, E

4

,

E

5

, which intersect the horizontal lines from R

1

, R

2

, R

3

,

R

4

, R

5

at points G, H, I, J, L. Joining GHIJLP gives the

conjugate line.

153

Example E2: For the ternary system of example E1 at

25

o

C, a mixture is separated into two liquid phases after

settling. One phase contains 15% acetic acid, 0.5% water

and the rest being benzene (all mass %). Use the

conjugate line in example E1 to determine the

composition of the other conjugate liquid phase and draw

the tie line.

Solution: The solubility and conjugate curves are given.

1. Find the composition of 15% acetic acid, 0.5% water

as point R.

2. Draw a horizontal line from R to intersect the

conjugate line at Q.

3. Draw a vertical line from Q to intersect the

solubility curve at E, which is the composition of the

other conjugate phase, 59% acetic acid, 37% water,

4% benzene.

4. Join RE to obtain the tie line.

154

3. Equilibrium data on rectangular coordinates.

Because of the special coordinates, the triangular diagram

is not convenient. The liquid-liquid phase equilibrium is

more often presented in rectangular coordinates, which is

shown in Fig. 4 for acetic acid (A) - water (B) - isopropyl

ether solvent (C).

Figure 4. Acetic acid (A)-Water (B)-Isopropyl ether (C)

liquid-liquid phase diagram at 293 K (20

o

C).

The solvent pair B and C are partially miscible. The

concentration of A is plotted on the horizontal axis and

that of C on the vertical axis. The concentration of B is

calculated from the following equation

155

x x x

B A C

= 10 . y y y

B A C

= 10 .

A tie line gi is shown connecting the water-rich layer i,

called the raffinate layer, and the ether-rich solvent layer

g, called the extract layer. The raffinate composition is

designated by x, and the extract by y. Hence, the mass

fraction of C is designated as y

C

in the extract laywer and

as x

C

in the raffinate layer. To construct the tie line gi

using the equilibrium y

A

-x

A

plot below the phase diagram,

vertical lines to g and i are drawn.

Example E3: Material balance for equilibrium layers

An original mixture weighing 100 kg and containing 30

kg of isopropyl ether (C), 10 kg of acetic acid (A), and 60

kg water (B) is equilibrated and the equilibrium phases

separated. What are the compositions of the two

equilibrium phases.

Solution: The composition of the original mixture is

x

C

= 0.30, x

A

= 0.10, x

B

= 0.60

This composition is plotted as point h on Fig. 4. The tie

line gi is obtained through point h by trial and error. The

composition of the extract (ether) layer at g is y

A

= 0.04,

y

C

= 0.94, and y

B

= 1 0.04 0.94 = 0.02 mass fraction.

The raffinate (water) layer composition at i is x

A

= 0.12,

x

C

= 0.02, and x

B

= 1 0.12 0.02 = 0.86 mass fraction.

156

In the above system (Fig. 4) the solvent pair B and C are

partially miscible, while A is totally soluble in B or C. It

is also common for some other systems that both pairs, A

and C, and B and C are partially miscible. This is Type II

system and shown in figure 5.

Figure 5. Liquid-liquid phase diagram where the

solvent pairs A-C and B-C are partially miscible.

Examples are the systems of Styrene (A) -Ethylbene (B) -

Diethylene Glycol (C), and Chlorobenzene (A) -

Methylethyl Ketone (B) -Water (C).

157

Single-Stage Equilibrium Extraction

In an extraction process we have two entering streams (L

kg and V kg) which are NOT in equilibrium, as shown in

Fig. 6. The solvent, as stream V

2

, enters and the stream

L

0

enters from the other side. The two entering streams

are mixed and equilibrated and then exit as streams L

1

and V

1

, which are in equilibrium with each other. To find

the final product compositions in the two phases, it is

required to know the mixture total mass and composition

(point M). This can be obtained by material balances.

After the point M is identified, the product composition

can be found by the equilibrium tie line.

158

Figure 6. Single-stage Liquid-liquid extraction:

(a) process flow diagram, (b) phase diagram.

Material balances:

Overall: L V L V M

0 2 1 1

+ = + = (1)

(A): L x V y L x V y Mx

A A A A AM 0 0 2 2 1 1 1 1

+ = + = (2)

(C): L x V y L x Vy Mx

C C C C CM 0 0 2 2 1 1 1 1

+ = + = (3)

Since x

A

+ x

B

+ x

C

= 1 , an equation for B is not needed.

because L

0

and V

2

are known, values of M, x

AM

, and x

CM

,

can be found from Eqs. (1) to (3). L

1

and V

1

are obtained

by drawing a tie line through point M.

159

Derivation of lever-arm rule for graphical addition.

In Figure 7 we have two streams (L & V) mixed to give a

resulting mixture stream M kg total mass.

((b)

(b)

Figure 7. Graphical addition and lever-arm rule:

(a) process flow, (b) graphical addition.

By doing material balances, we have

Overall: V L M + = (4)

(A): Lx Vy Mx

A A AM

+ == (5)

(C): Lx Vy Mx

C C CM

+ == (6)

Combining Eqs. (4) & (5), and (4) & (6), we have

L

V

x y

x x

AM A

A AM

=

(7)

L

V

x y

x x

CM C

C CM

=

(8)

Equating Eqs. (7) & (8) and rearranging,

x x

x x

x y

x y

C CM

A AM

CM C

AM A

(9)

The left side is the slope of line LM and the right side is

the slope of line MV. Because the two slopes are the

same and the two lines have a common point M, the three

160

points L, M, and V must be on a straight line. The lever-

arm rule is

L

V

VM

LM

= &

L

M

VM

LV

= (10)

Example E4: Amount of phases in solvent extraction

The compositions of the two equilibrium layers in

example E1 are:

for the extract layer (V),

y

A

= 0.04, y

B

= 0.02, y

C

= 0.94

for the raffinate layer (L),

x

A

= 0.12, x

B

= 0.86, x

C

= 0.02

The original mixture contained 100 kg and x

AM

= 0.10.

Determine the amounts of V and L.

Solution: The overall material balance is

V + L = M = 100 kg

The material balance of A is

V(0.04) + L(0.12) = 100(0.10)

Hence,

V = 75 kg, L = 25 kg

Alternatively, using the lever-arm rule, the distance hg in

Fig. 4 is measured as 4.2 units and gi as 5.8 units. Then

L

N

=

L

1uu

=

hg

g

=

4.2

S.8

Solving, L = 72.5 kg and V = 27.5 kg, which is in

reasonable close agreement with the material balance

method.

161

Countercurrent Multistage Extraction

162

1. Countercurrent process and overall balances

A countercurrent multistage process is shown in Fig. 8.

Figure 8. Countercurrent multistage extraction process

flow diagram

The overall balance on all N stages is

L V L V M

N N 0 1 1

+ = + =

+

(11)

where M is the total mass (kg/h) and is a constant, L

0

the

inlet feed flow rate (kg/h), V

N+1

the inlet solvent flow rate

(kg/h), V

1

the exit extract stream, and L

N

the exit raffinate

stream. Material balance on C gives

L x V y L x V y Mx

C N C N N C N C CM 0 0 1 1 1 1

+ = + =

+ + , ,

(12)

x

CM

is obtained By solving Eqs. (11) & (12)

x

L x V y

L V

L x V y

L V

CM

C N C N

N

N CN C

N

=

+

+

=

+

+

+ +

+

0 0 1 1

0 1

1 1

1

,

(13)

A similar balance on component A gives

x

L x V y

L V

L x V y

L V

AM

A N A N

N

N AN A

N

=

+

+

=

+

+

+ +

+

0 0 1 1

0 1

1 1

1

,

(14)

So the point M, which ties together the two entering

streams (usually known) and the two exit streams, can be

located. The desired exit composition x

AN

is often set,

which is on the equilibrium curve (phase boundary). Then

the line L

N

M is extended to intersect the phase boundary

of the extract phase to give V

1

composition.

163

Example E5: Pure solvent isopropyl ether (C) at the rate

of V

N+1

= 600 kg/h is being used to extract an aqueous

solution of L

0

= 200 kg/h containing 30 wt % acetic acid

(A) and 70 wt % water (B) by countercurrent multistage

extraction. The desired exit acetic acid concentration in

the aqueous phase is 4%. Calculate the compositions and

amounts of the ether extract V

1

and the aqueous raffinate

L

N

. The equilibrium data at 20

o

C, 1 atm, are given and

plotted below.

Water phase

(mass fraction)

isopropyl ether phase

(mass fraction)

acetic

acid

(x

A

)

Water

(x

B

)

isopropyl

ether (x

C

)

acetic

acid

(y

A

)

Water

(y

B

)

isopropyl

ether

(y

C

)

6.9e-3 0.9810 0.0120 1.8e-3 5.0e-3 0.9930

0.0141 0.9710 0.0150 3.7e-3 7.0e-3 0.9890

0.0289 0.9550 0.0160 7.9e-3 8.0e-3 0.9840

0.0642 0.9170 0.0190 0.0193 0.0100 0.9710

0.1330 0.8440 0.0230 0.0482 0.0190 0.9330

0.2550 0.7110 0.0340 0.1140 0.0390 0.8470

0.3670 0.5890 0.0440 0.2160 0.0690 0.7150

0.4430 0.4510 0.1060 0.3110 0.1080 0.5810

0.4640 0.3710 0.1650 0.3620 0.1510 0.4870

164

Solution:

The given values are

Pure solvent inlet:

V

N+1

= 600, y

A,N+1

= y

B,N+1

= 0, y

C,N+1

= 1,

Feed:

L

0

= 200, x

A0

= 0.3, x

B0

= 0.7, x

C0

= 0,

Raffinate:

x

AN

= 0.04.

V

N+1

and L

0

are located by the compositions.

Since L

N

is on the phase boundary of the raffinate phase,

it can be plotted at x

AN

= 0.04 & we find x

CN

= 0.017.

165

The composition of the mixture, x

CM

and x

AM

, are

calculated by Eqs. (13) & (14) as 0.75 & 0.075 and used

to plot point M. V

1

is located by drawing a line from L

N

through M & extending it until it intersects the phase

boundary in the extract phase. This gives y

A1

= 0.08 &

y

C1

= 0.90.

By solving Eqs. (11) & (12), L

N

= 136 kg/h & V

1

= 664

kg/h.

2.Stage-to-stage calculation for countercurrent extraction

The next step is to go stage by stage to determine the

concentrations at each stage and the total number of

stages N needed to reach L

N

in the process.

Making a total balance on stage 1 and then on stage n,

L V L V

0 2 1 1

+ = + (15)

L V L V

n n n n +

+ = +

1 1

(16)

The above equations can be rearranged as

L V L V L V L V

n n N N 0 1 1 2 1 1

= = = = =

+ +

...

(17)

The value of is constant for all stages. The coordinates

of the operating point can be obtained by material

balances on A, B or C:

166

L x V y L x V y x

A A N AN N A N A 0 0 1 1 1 1

= = =

+ +

...

,

(18)

L x V y L x V y x

C C N CN N C N C 0 0 1 1 1 1

= = =

+ +

...

,

(19)

x

L x V y

L V

L x V y

L V

A

A A

N AN N A N

N N

+ +

+

0 0 1 1

0 1

1 1

1

,

(20)

Similar Eqs. for x

B

& x

C

can be obtained. This point

is located either by its coordinates as calculated by Eq.

(20) or graphically as the intersection of lines L

0

V

1

and

L

N

V

N+1

. The method to locate V

1

has been discussed in

example E5. All the operating lines (L

0

V

1

, L

1

V

2

,

L

n

V

n+1

, ... , L

N

V

N+1

) must pass through the common point

.

To graphically determine the number of stages, follow the

procedures below.

(1) locate L

0

, V

N+1

and L

N

by their compositions.

(2) draw a line L

0

V

N+1

, and locate the mixture point M

by Eq. (13) or (14).

(3) draw a line from L

N

through M & extend it until it

intersects the phase boundary, where is V

1

.

(3) extend lines L

0

V

1

, and L

N

V

N+1

, which will intersect

at the common operating point .

(4) start at L

0

and draw a line L

0

which intersects the

phase boundary at V

1

.

(5) draw an equilibrium tie line through V

1

to locate L

1

.

(6) draw a line L

1

to give V

2

at the phase boundary.

(7) a tie line from V

2

gives L

2

. This is continued until

the desired L

N

is reached.

167

Alternately, the point can firstly be located using Eq.

(20). Then we start at L

0

and draw a line L

0

to locate V

1

.

Then an equilibrium tie line through V

1

locates L

1

. Line

L

1

is drawn to give V

2

. A tie line from V

2

gives L

2

.

This is continued until the desired L

N

is reached.

168

Example E6: Number of stages in countercurrent extraction

Pure isopropyl ether (C) of 450 kg/h is being used to

extract an aqueous solution of 150 kg/h with 30 wt %

acetic acid (A) and 70 wt % water (B) by countercurrent

multistage extraction. The exit acid concentration in the

aqueous phase is 10 wt %. Calculate the number of

stages required.

Solution: draw a diagram,

Known values:

Pure solvent from N+1:

V

N+1

= 450 kg/h

y

A,N+1

= y

B,N+1

= 0

y

C,N+1

= 1.0,

Feed:

L

0

= 150 kg/h

x

A0

= 0.3

x

B0

= 0.7

x

C0

= 0

Exit in water phase:

x

AN

= 0.1.

L

N

must be in the raffinate solubility line.

The points V

N+1

, L

0

, and L

N

are plotted.

169

x

A

, y

A

0.0 0.1 0.2 0.3 0.4 0.5

x

C

,

y

C

0.0

0.2

0.4

0.6

0.8

1.0

A (acetic acid)

B

(water)

C (isopropyl ether)

L

0

L

N

V

1

V

N+1

The mixture points are found by Eqs. (13) & (14), x

CM

=

0.75, x

AM

= 0.075. The point V

1

is located as the

intersection of line L

N

M with the phase boundary in the

extract phase, y

A1

= 0.072, y

C1

= 0.895.

170

Then lines L

0

V

1

, and L

N

V

N+1

is drawn to locate the point

.

x

A

, y

A

-0.1 0.0 0.1 0.2 0.3 0.4 0.5

x

C

,

y

C

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

A (acetic acid)

B

(water)

C (isopropyl ether)

L

0

L

N

V

1

V

N+1

171

Starting at L

0

we draw a line L

0

to locate V

1

. Then an

equilibrium tie line through V

1

locates L

1

. Line L

1

is

drawn to give V

2

. A tie line from V

2

gives L

2

. A final tie

line gives L

3

, which is beyond the desired L

N

. Hence,

about 2.5 theoretical stages are needed.

172

3. McCabe-Thiele method

Stepping off many stages on a triangular diagram can be

difficult and inaccurate. More accurate calculations can

be done with a McCabe-Thiele diagram. Here we focus

on the concentration of solute in the extract and raffinate

phases. The diagram does not show the concentration of

the diluents in the extract or the concentration of solvent

in the raffinate. These minor components of both phases

are accounted for in determining the total flow of extract

and raffinate, which affects the position of the operating

line.

In the McCabe-Thiele diagram, the equilibrium data are

shown on a rectangular graph, where the mass fraction of

solute in the extract (V) phase, y

A

, is plotted as the

ordinate and the mass fraction of solute in the raffinate (L)

phase, x

A

, as the abscissa. The conversion of equilibrium

tie line in the triangle diagram to the y-x digram is shown

below.

173

174

Since the total flow rates are not constant, the triangular

diagram and the point are used to plot a curved

operating line on the McCabe-Thiele diagram. This

construction is illustrated in the following figure for a

single point.

The two end points of the operating line are already given

in example E6. (x

AN

= 0.1, y

A,N+1

= 0), and (x

A0

= 0.3, y

A1

= 0.072).

For any arbitrary operating line (must go through ), the

values of the extract and raffinate concentrations of A are

determined from the phase diagram using the common

point and transferred to the y-x diagram, as shown in

the following figure.

The number of stages is then calculated by stepping off

the triangles with the operating and equilibrium lines,

which is about 2 in this case.

175

176

4. Minimum solvent rate

If a solvent rate V

N+1

is selected at too low a value, a

limiting case will be reached with an operating line

through and a tie line being the same. Then an infinite

number of stages will be needed to reach the desired

separation. The minimum amount of solvent is reached.

For actual operation a greater amount of solvent must be

used.

The procedure to obtain

this minimum solvent rate

is as follows and shown in

the right figure. Firstly

line L

N

V

N+1

is extended,

then all tie lines between

L

0

and L

N

are drawn to

intersect the extended line

L

N

V

N+1

. The intersection

farthest from V

N+1

(if is

in the L

N

side, which is the

case in the figure) or

nearest V

N+1

(if is on

the V

N+1

side) is the

min

point for minimum solvent.

The actual position of

must be farther from V

N+1

(if on the L

N

side) or nearer to V

N+1

(if on the V

N+1

side)

for a finite number of stages. The larger the amount of

solvent, the fewer the number of stages.

Minimum solvent for

countercurrent extraction.

177

This is proved as below.

If is in the L

N

side,

L

N

- V

N+1

=

L

N

= V

N+1

+

According to lever arms

rule:

(v

N+1

)v

N+1

L

N

= L

N

=( L

N

- V

N+1

) L

N

= L

N

L

N

- V

N+1

L

N

v

N+1

=

L

N

L

N

v

N+1

L

N

+L

N

=

L

N

V

N+1

L

N

AL

N

+1

Since L

N

and v

N+1

L

N

are constant, V

N+1

will achieve its

maximum when the length of L

N

is at its maximum.

178

If is in the V

N+1

side,

(v

N+1

)v

N+1

= L

N

L

N

v

N+1

=

L

N

L

N

v

N+1

= L

N

L

N

v

N+1

+v

N+1

v

N+1

= L

N

(1 +

L

N

V

N+1

V

N+1

A

)

Since L

N

and v

N+1

L

N

are constant, V

N+1

will achieve its

maximum when the length of v

N+1

is at its minimum.

Vous aimerez peut-être aussi

- 005251Document3 pages005251a..all1Pas encore d'évaluation

- Homogeneous LiquidDocument1 pageHomogeneous Liquida..all1Pas encore d'évaluation

- P&ID DiagramDocument6 pagesP&ID DiagramMejdi Sylas ToudjiPas encore d'évaluation

- TessDocument6 pagesTessa..all1Pas encore d'évaluation

- TessDocument6 pagesTessa..all1Pas encore d'évaluation

- TessDocument6 pagesTessa..all1Pas encore d'évaluation

- TessDocument6 pagesTessa..all1Pas encore d'évaluation

- Ac102 ch7Document22 pagesAc102 ch7Mohammed OsmanPas encore d'évaluation

- Handout 3Document6 pagesHandout 3a..all1Pas encore d'évaluation

- Liquid Liquid ExtractionDocument40 pagesLiquid Liquid ExtractionMohsin Ehsan100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- DYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994Document27 pagesDYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994saurabhchandrakerPas encore d'évaluation

- Said DissertationDocument129 pagesSaid DissertationSaeed AzarPas encore d'évaluation

- Technorama Hausprospekt enDocument42 pagesTechnorama Hausprospekt enSriheri DeshpandePas encore d'évaluation

- Chemical Solution Density & ViscosityDocument18 pagesChemical Solution Density & ViscosityLee JianPas encore d'évaluation

- Gauge Mechanics-SardanashvilyDocument358 pagesGauge Mechanics-SardanashvilyJazon Bryan100% (1)

- 1603 Physics Paper With Ans Sol EveningDocument8 pages1603 Physics Paper With Ans Sol EveningRahul RaiPas encore d'évaluation

- EE305 Lecture 2 Instrument TypesDocument22 pagesEE305 Lecture 2 Instrument TypesFrank WhitePas encore d'évaluation

- Sample Problems 6717 PDFDocument10 pagesSample Problems 6717 PDFnagham radiPas encore d'évaluation

- Basic Electrical Engineering: BY R. Sivaprasad, Lecturer in Eee, Govt. Polytechnic, SatyaveduDocument77 pagesBasic Electrical Engineering: BY R. Sivaprasad, Lecturer in Eee, Govt. Polytechnic, Satyavedurathina4careerPas encore d'évaluation

- Buoyancy 100806114902 Phpapp02Document11 pagesBuoyancy 100806114902 Phpapp02saryPas encore d'évaluation

- MSL Technical Guide 18 Resistance Measurement For ThermometryDocument5 pagesMSL Technical Guide 18 Resistance Measurement For ThermometrydlonguinhoPas encore d'évaluation

- HW 3Document2 pagesHW 3Purusharth SemwalPas encore d'évaluation

- Basic Electronics 2Document19 pagesBasic Electronics 2Miss WorldPas encore d'évaluation

- Chemical KineticsDocument37 pagesChemical KineticsM H Alif HossainPas encore d'évaluation

- Thesis W QuakDocument178 pagesThesis W Quakdr_kh_ahmedPas encore d'évaluation

- Notes LT3Document16 pagesNotes LT3osmanfıratPas encore d'évaluation

- Lectures PDFDocument137 pagesLectures PDFFrancis Clinton Prashanth100% (1)

- Modeling and Analysis of Soil-Pile InteractionDocument21 pagesModeling and Analysis of Soil-Pile InteractionLhester NavascaPas encore d'évaluation

- Structure & Bonding - IONIC BONDINGDocument23 pagesStructure & Bonding - IONIC BONDINGTrishana GreenPas encore d'évaluation

- Thermal Physics - Rod in CylinderDocument5 pagesThermal Physics - Rod in CylinderLUIS HUMBERTO MARTINEZ PALMETHPas encore d'évaluation

- Axially Loaded Members PDFDocument50 pagesAxially Loaded Members PDFCharbel Saad SaadPas encore d'évaluation

- Lelm 316Document20 pagesLelm 316neerajPas encore d'évaluation

- Seminar Lesson PlanDocument18 pagesSeminar Lesson PlanNo one KnowsPas encore d'évaluation

- Siemens Vacumm Contactor 3tl6Document15 pagesSiemens Vacumm Contactor 3tl6Yong Ee VonnPas encore d'évaluation

- Solidworks Flow Simulation Project Report: (Company Logo Here)Document9 pagesSolidworks Flow Simulation Project Report: (Company Logo Here)zarzosa rabanalPas encore d'évaluation

- ORS SystemDocument4 pagesORS SystemlaxmanPas encore d'évaluation

- Bharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSDocument27 pagesBharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSSarjithPas encore d'évaluation

- Relativistic precession of planetary orbitsDocument5 pagesRelativistic precession of planetary orbitsdavePas encore d'évaluation

- Lateral Earth PressureDocument122 pagesLateral Earth PressureEric DelunaPas encore d'évaluation