Académique Documents

Professionnel Documents

Culture Documents

Rotary Kiln Surya Engineering Co

Transféré par

boson k12Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rotary Kiln Surya Engineering Co

Transféré par

boson k12Droits d'auteur :

Formats disponibles

SURYA ENGINEERING CO. SURYA ENGINEERING CO.

BOSE PARK, T.N. BANERJEE ROAD. PO: SUKCHAR, KOLKATA- 700115. Ph: 033 25632032, 033 25443898, 9830217654,9830091468.Fax:(033) 28430370.

Email: surya_engg12@yahoo.co.in ; Web : www.suryamachinery.com;

ROTARY KILN

The Rotary Kiln is used for calcination of different type of materials at required Temperatures. SHELL : Made of. thick B.Q. Plate as per IS 2002 Gr. B or of equivalent quality, electrically welded, Cylindrical type, 2 sets of Tyres are fixed with the Kiln at the both ends of the shell which rotates on 4 Nos. Rollers, fixed with the shaft, Bearings in water cooled Bearing Blocks. The shell thickness below the Tyre section and below Gear section will be of Thicker B.Q plate The shell of the kiln is rolled to maximum tolerance with high precision & is sufficiently Strong to accept reasonable overloads and thermal Stresses. At the feeding end of the Shell, a Conical shell made of B.Q. Plate is fixed for easy Flow of Flue. The Kiln of the Shell is mounted on a heavy Duty sturdy. Base Frame with 4 Nos. supporting Rollers, Bearings and Bearing Housings supporting 2 Nos of steel Tyres & Thrust Rollers.

The Firing End of the Rotary Kiln. The Burner is fixed at this end.

RIDING RING : There are 2 Nos. riding rings (Tyres) fitted on the Kiln Shell. It is designed for full floating and are machined all over the surfaces. The inside diameter of the riding ring & outside diameter of the riding ring pads are designed to have sufficient clearance so that when the kiln becomes hot, the riding rings will snug fit and adjust the expansion of the material. The riding rings are made of Alloy Steel Castings as per IS1030, Gr. I.

Rotary Kiln Foundation

SUPPORTING ROLLER : Made of Alloy Steel properly machined. Alloy steel shaft (Forged EN- 8) is fitted with the Roller. Each roller is fitted with two water cooled C.I. Housing Blocks which are fitted with the Phosphorus Bronze Bush. The Bush of the Bearings are well lubricated by self Oil Lubricating system in the Bush housing. Custom made Roller Bearing are also supplied if requested by the Customer.

GIRTH GEAR & PINION : Made of Alloy Steel as per IS 1030, Gr.1 properly Machined. The teeth of the Gear are properly hardened and Heat Treated. The Gear is fitted on the outside diameter of the kiln shell.

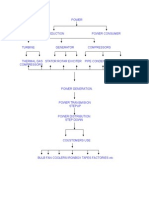

DRIVE & POWER TRANSMISSION : A Girth gear is fitted on the shell and the Pinion is fitted with the Radicon (GREAVES) make three stage Helical Gear Box. The Driving shaft rotates through Chain, Sprocket and Power is transmitted by the Motor. The Motor is fitted with Gear Box through a Heavy Duty Resilient Spring Grid Coupling.

Vous aimerez peut-être aussi

- Plans For Steam Marine EngineDocument5 pagesPlans For Steam Marine EngineGeorge LunguPas encore d'évaluation

- Heat Straightening ProcedureDocument3 pagesHeat Straightening ProcedurerzsoltPas encore d'évaluation

- 07 Connecting Rod & Cross HeadDocument18 pages07 Connecting Rod & Cross Headnaresh100% (1)

- Ceramic Tile Manufacturing ProcesssDocument20 pagesCeramic Tile Manufacturing ProcesssMike Cajes AsiadoPas encore d'évaluation

- Mini Project ReportDocument19 pagesMini Project ReportSan DeliriousPas encore d'évaluation

- Manufacturing Process of Rolling Element Bearing NewDocument26 pagesManufacturing Process of Rolling Element Bearing NewRamakanth P JoshiPas encore d'évaluation

- Friction Stir Welding: Figure 1 WheelsDocument16 pagesFriction Stir Welding: Figure 1 WheelsMashooq JainPas encore d'évaluation

- Billet Making ProcessDocument5 pagesBillet Making Processrameshrangachari2008Pas encore d'évaluation

- GeneratorDocument71 pagesGeneratorDhanesh VyasPas encore d'évaluation

- Coil Springs1Document8 pagesCoil Springs1Abhishek ShindePas encore d'évaluation

- PDF Public Desc GalvDocument4 pagesPDF Public Desc GalvRoxana LazarPas encore d'évaluation

- Cylinder Liners & Piston RingsDocument16 pagesCylinder Liners & Piston RingsMr.Babu TPas encore d'évaluation

- Background: Ball BearingDocument14 pagesBackground: Ball Bearing666mimi999Pas encore d'évaluation

- Bed Plate Main Engine BedplateDocument52 pagesBed Plate Main Engine BedplateSuhas KassaPas encore d'évaluation

- University of The East College of Engineering: Plate No. 2 Rolling MillDocument17 pagesUniversity of The East College of Engineering: Plate No. 2 Rolling MillJOHNEDERSON PABLOPas encore d'évaluation

- Engineering Vol 56 1893-11-03Document33 pagesEngineering Vol 56 1893-11-03ian_newPas encore d'évaluation

- Summer Training PresentationDocument18 pagesSummer Training Presentationnufaza97Pas encore d'évaluation

- CCM Equipment Detail For ClearanceDocument5 pagesCCM Equipment Detail For ClearancesmithPas encore d'évaluation

- Chapter-3 Cylinder Heads, Cylinders & LinersDocument18 pagesChapter-3 Cylinder Heads, Cylinders & LinersdearsaswatPas encore d'évaluation

- Ltps ElectricalDocument19 pagesLtps ElectricalVikash MaheshwariPas encore d'évaluation

- Quotation - Hind Rectifiers ...Document4 pagesQuotation - Hind Rectifiers ...dppl.mepPas encore d'évaluation

- ArmorDocument7 pagesArmorRecep VatanseverPas encore d'évaluation

- 08 PistonDocument40 pages08 PistonnareshPas encore d'évaluation

- Hardened Steel Housing, Retaining Ring Design With Rubber GrommetDocument2 pagesHardened Steel Housing, Retaining Ring Design With Rubber GrommetLuis G. Sànchez VeraPas encore d'évaluation

- Unit of Dispersing Solid Particles Into Molten Al-Alloys: Preparation and Casting of The CompositesDocument7 pagesUnit of Dispersing Solid Particles Into Molten Al-Alloys: Preparation and Casting of The CompositesMahmoud KaramPas encore d'évaluation

- Reaction VesselDocument4 pagesReaction VesselArunkumar MyakalaPas encore d'évaluation

- Generator Testing Project ReportDocument95 pagesGenerator Testing Project ReportSindhu ManchukondaPas encore d'évaluation

- Construction Materials For Marine Diesel EnginesDocument5 pagesConstruction Materials For Marine Diesel EnginesVijay APas encore d'évaluation

- Manufacturingsystemspring Howitsmade 171012152800Document15 pagesManufacturingsystemspring Howitsmade 171012152800Jeny Ferdiana LiemPas encore d'évaluation

- File 1418103136 PDFDocument2 pagesFile 1418103136 PDFAnonymous 4sL6BXUPas encore d'évaluation

- 2-Pole Turbine Generators: WEG GroupDocument12 pages2-Pole Turbine Generators: WEG GroupVasudev AgrawalPas encore d'évaluation

- 1.power Frame: Pinion ShaftDocument3 pages1.power Frame: Pinion ShaftJason PalmerPas encore d'évaluation

- Electrical Machines Block 2Document23 pagesElectrical Machines Block 2Aravind PadhiPas encore d'évaluation

- 1973 BACKER Shaped Heat 20111009Document50 pages1973 BACKER Shaped Heat 20111009Hank MarvinPas encore d'évaluation

- Karma Steels Product PhotosDocument49 pagesKarma Steels Product PhotosKirti KamdarPas encore d'évaluation

- Chapter-3 Cylinder Heads, Cylinders & LinersDocument18 pagesChapter-3 Cylinder Heads, Cylinders & LinersRam KumarPas encore d'évaluation

- NBC (NEI) : National Engineering Industries LimitedDocument9 pagesNBC (NEI) : National Engineering Industries LimitedAnupamPas encore d'évaluation

- DIY Plans - Model Steam Marine EngineDocument5 pagesDIY Plans - Model Steam Marine Enginemigss107483% (6)

- Salient Features of Generators Stage-1Document12 pagesSalient Features of Generators Stage-1raghavendran raghu100% (1)

- Generator Testing Project ReportDocument51 pagesGenerator Testing Project Reportsudheer0% (1)

- Piston of Large Marine EngineDocument3 pagesPiston of Large Marine EngineRuwan SusanthaPas encore d'évaluation

- The Pickling Process: Continuous OperationDocument2 pagesThe Pickling Process: Continuous Operationm daneshpourPas encore d'évaluation

- 2P TG Stator ConstructionDocument2 pages2P TG Stator ConstructionChathura DalugodaPas encore d'évaluation

- Street Light PoleDocument2 pagesStreet Light Polejagdish prabhuPas encore d'évaluation

- Us 20040158969Document5 pagesUs 20040158969dgfhjsdg hfsdhyjPas encore d'évaluation

- ALUMINIUMTECHNOLOGIES Week10Document110 pagesALUMINIUMTECHNOLOGIES Week10NhocSkyzPas encore d'évaluation

- Basics of Foundry LadlesDocument9 pagesBasics of Foundry LadlesArpan DasPas encore d'évaluation

- Piston: Parts, Types, Working, Piston Clearance, Shape and MoreDocument12 pagesPiston: Parts, Types, Working, Piston Clearance, Shape and MoreAndre RichardPas encore d'évaluation

- Manufacturing Process of A BearingDocument4 pagesManufacturing Process of A Bearingalif hasyimPas encore d'évaluation

- Metal BenderDocument6 pagesMetal Benderbula10100% (1)

- Calculation of Possibility For Parameter Design in Changing Central Cooling System To Revolver Cooling System For Continuous Casting RollersDocument6 pagesCalculation of Possibility For Parameter Design in Changing Central Cooling System To Revolver Cooling System For Continuous Casting RollersThaiminh VoPas encore d'évaluation

- SKF TMBRDocument24 pagesSKF TMBRjricpelPas encore d'évaluation

- Plans For Bench GrinderDocument2 pagesPlans For Bench GrinderFernando Morocho100% (1)

- NIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssDocument162 pagesNIS Bearing Units Cataloguexsx BgsssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssssEsca Dwi Nugroho33% (3)

- Double Disc Gate ValveDocument12 pagesDouble Disc Gate Valveshafeeqm3086Pas encore d'évaluation

- Quotation - Hindustan ControlsDocument3 pagesQuotation - Hindustan Controlsdppl.mepPas encore d'évaluation

- Crankshaft 1Document14 pagesCrankshaft 1Shweta NarayanPas encore d'évaluation

- Quotation - Hindustan Controls - ...Document4 pagesQuotation - Hindustan Controls - ...dppl.mepPas encore d'évaluation

- Manufacturing and Assembling of Stator and Rotor Inturbo GeneratorsDocument4 pagesManufacturing and Assembling of Stator and Rotor Inturbo GeneratorsAshfiya YazdaniPas encore d'évaluation

- The Boy Mechanic: Volume 1 700 Things for Boys to DoD'EverandThe Boy Mechanic: Volume 1 700 Things for Boys to DoPas encore d'évaluation

- Firing Deformation in Large Size Porcelain Tiles. Effect of Compositional and Process VariablesDocument15 pagesFiring Deformation in Large Size Porcelain Tiles. Effect of Compositional and Process Variablesmap vitcoPas encore d'évaluation

- Vip STUBNADocument4 pagesVip STUBNAIS AAPas encore d'évaluation

- Chinese Pottery and PorcelainDocument510 pagesChinese Pottery and PorcelainPuiu Vasile Chiojdoiu50% (2)

- Ceramic TileDocument9 pagesCeramic TileNazanin SabetPas encore d'évaluation

- Kiln Inlet Lamella Seal FLSDocument2 pagesKiln Inlet Lamella Seal FLSamir100% (3)

- Rectified Ceramic TilesDocument8 pagesRectified Ceramic TilesGyl DimpasPas encore d'évaluation

- Pottery: Global Action Programme On Education For All Youth ProjectDocument28 pagesPottery: Global Action Programme On Education For All Youth ProjectJoao DuartePas encore d'évaluation

- Lechner StephanDocument9 pagesLechner StephanleekiangyenPas encore d'évaluation

- A Dynamic Mathematical Model of The Complete Grate/Kiln Iron-Ore Pellet Induration ProcessDocument10 pagesA Dynamic Mathematical Model of The Complete Grate/Kiln Iron-Ore Pellet Induration Processdavibraga8041Pas encore d'évaluation

- Charcoal Production Kilns StudyDocument26 pagesCharcoal Production Kilns StudyJOHN100% (1)

- Teks 1Document10 pagesTeks 1raidenPas encore d'évaluation

- Electric Kiln Firing TechDocument13 pagesElectric Kiln Firing TechStefan Van CleemputPas encore d'évaluation

- Literature Survey For Energy Audit On Brick FactoryDocument15 pagesLiterature Survey For Energy Audit On Brick FactoryShalom AbebawPas encore d'évaluation

- Spotlighting Ultramarine PigmentsDocument9 pagesSpotlighting Ultramarine PigmentsAshutosh GuptaPas encore d'évaluation

- 1 Fixed Chimney Bulls Trench Kiln (FCBTK)Document4 pages1 Fixed Chimney Bulls Trench Kiln (FCBTK)Mian IrfanPas encore d'évaluation

- Eco Blac BricksDocument21 pagesEco Blac BricksShashankSharma0% (1)

- TGK GT 4050.general ManualDocument17 pagesTGK GT 4050.general ManualbhizartPas encore d'évaluation

- Study On Auto Bricks Bangladesh Perspect PDFDocument26 pagesStudy On Auto Bricks Bangladesh Perspect PDFMohiminul Khan100% (1)

- Internship Report On Simpolo CeramicsDocument46 pagesInternship Report On Simpolo CeramicsChintan RamnaniPas encore d'évaluation

- A. Introduction: 3. Poor LimeDocument28 pagesA. Introduction: 3. Poor LimeYenPas encore d'évaluation

- Accident Prevention Check List - Storing and Transportation of ExplosivesDocument22 pagesAccident Prevention Check List - Storing and Transportation of ExplosivesAftab ZafarPas encore d'évaluation

- Clay - Decomposed Granite RockDocument6 pagesClay - Decomposed Granite Rockcarolynet1294Pas encore d'évaluation

- PROCESSDocument25 pagesPROCESSPhương NguyễnPas encore d'évaluation

- Ceramics Monthly (June 1959)Document44 pagesCeramics Monthly (June 1959)Wade MacMorrighan100% (1)

- Coal Pyrolysis in A Rotary Kiln Part I MDocument10 pagesCoal Pyrolysis in A Rotary Kiln Part I MpashaPas encore d'évaluation

- ST315A Kiln Temperature ControllerDocument2 pagesST315A Kiln Temperature ControllerDave WalkerPas encore d'évaluation

- Wood Seasoning 2Document12 pagesWood Seasoning 2adasdaPas encore d'évaluation

- Wooden in Food IndustryDocument27 pagesWooden in Food Industryaudrey78838649Pas encore d'évaluation

- SonexDocument13 pagesSonexMarwah 55Pas encore d'évaluation