Académique Documents

Professionnel Documents

Culture Documents

Air Pressure vs. Dry Performance: Lea Esta Página en Español

Transféré par

Priyadashini SamyrawDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Air Pressure vs. Dry Performance: Lea Esta Página en Español

Transféré par

Priyadashini SamyrawDroits d'auteur :

Formats disponibles

Air Pressure vs.

Dry Performance

Lea esta pgina en espaol Most drivers realize that tire load capacity is determined by tire size and inflation pressure. Larger tires and higher inflation pressures provide more load capacity, while smaller tires and lower tire pressures provide less. Correctly inflated tires receive appropriate support from the contained air pressure to provide an even distribution of load across the footprint and help stabilize the tire's structure. And while most drivers recognize that this has a significant impact on tire wear, rolling resistance and durability, only a few realize underinflation also has a noticeable influence on how quickly and precisely the tires respond to the driver's input. In order to evaluate the influence of inflation pressure on response and handling, the Tire Rack conducted a Performance Test Track Drive, comparing properly inflated tires to purposely underinflated tires. We used 2003 BMW 330Ci coupes, and installed P225/50R16 tires on 16x7.5" wheels. We tested new, full tread depth tires. We chose Goodyear Eagle GT-HR High Performance All-Season radials that were developed to blend good treadwear, responsive handling and dependable traction. One of the Eagle GT-HR's highlights is its internal construction that features Goodyear's RaceWrap Construction Technology developed for the Eagle Race tires used in NASCAR competition. RaceWrap Construction Technology brings a casing ply down the sidewall at a slight angle, wraps around the bead and returns it all of the way up the sidewall until it ends under the edge of the steel belts. This slightly angled, two-ply sidewall enhances steering response and handling stability. The tires installed on one of our BMW 330Ci test cars were inflated to the vehicle manufacturer's recommended inflation pressures of 29 psi front and 33 psi rear, while the other car had its tires inflated 30% lower (20 psi in the front and 23 psi in the rear). We chose 30% underinflation because it was the percentage of loss initially established by the US DOT at which passive pressure monitoring systems must warn the driver of low inflation pressure on future cars. The first part of the test was visual. We asked the drivers to look at the tires and decide which of the two vehicles was equipped with the underinflated tires. While perhaps this visual test might have been easier with taller tires of the past, today's low profile tires fitted to the BMWs demonstrated how difficult it has become. The drivers agreed that the tire appearance alone did not provide irrefutable confirmation of the tire pressure contained inside. You can't use your eyes as a tire pressure gauge. Can you easily identify which tire is 30% underinflated with your eyes? Here is what they would look like in the morning as you walked to your

car in the garage. (Roll your mouse across the pictures to confirm you were right)

The next test was run on our test course to confirm the influence of tire pressure on the tire's performance at its limit. While the drivers thought that the properly inflated tires provided responsiveness and predictable handling, they quickly realized that the same tires in an underinflated state left a lot to be desired. The underinflated tires required more steering input to initiate maneuvers and were slower to respond. The underinflated tires also felt out of sync during transitions; instead of moving in unison, the rear tires' reactions lagged behind the front tires, resulting in a detached sensation being transmitted to the drivers. The underinflated tires delivered acceptable steady-state cornering force once they stabilized on our test track's skid pad, but the car was uncooperative anytime it was asked to change directions. It proved to be over 2 seconds slower around our test course (2 seconds represents about a 7% loss of handling performance). In other words, the performance that tire manufacturers build in, low tire pressures can take away. Adjust your tire pressures as indicated on the vehicle tire placard or in the owner's manual. Check your inflation pressures at least once a month and before highway trips.

Air Pressure/Load Adjustment for High Speed Driving

Lea esta pgina en espaol

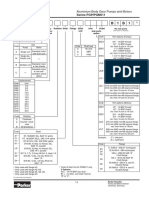

Driving at high speeds certainly helps make a trip go faster; just ask any driver who has gone "flat out" on the German Autobahn. However with the exception of events like the Silver State Classic's Open Road Rally or a driver's school on a racetrack, it's difficult to find a place that allows unlimited speeds! Remember, the tires on the vehicle should be properly sized, inflated and inspected if you plan to drive fast because the tires will be subjected to tremendous stresses. Because of the weight they bear, pneumatic tires' sidewalls bulge and their treads flatten as they roll into contact with the road. This results in dimensional difference between the tire's "unloaded" radius (i.e., between the center of the axle and the top of the tire) and its "loaded" radius (between the center of the axle and the road). The engineer's call the difference between the two radii "deflection." Increasing vehicle speed will cause the tires to deflect quicker and increasing vehicle load will cause the tires to deflect farther (if tire pressure isn't increased). Consider that a 225/45R17 91W Standard Load tire (with a 25-inch overall diameter) will roll about 835 times every mile. Although the number of tire revolutions per mile doesn't change significantly as speed climbs, the revolutions per second become daunting. While the 225/45R17 91W-sized tire rolls a rather comfortable 7 times per second at 30 mph, this same tire will roll about 16 times per second at 70 mph on an American Interstate and an amazing 35 times per second during a 150 mph cruise on the German Autobahn. Thirty-five tire revolutions per second means that the tire is transforming from its unloaded to loaded shape and back every 3/100th of a second. The European Tyre and Rim Technical Organization (ETRTO) establishes the standards for tires sold in Europe, and recognizes that the tire's deflection must be minimized and controlled in order to surpass high speed driving stresses. In order to accomplish this, the tire inflation pressure recommendations and the tire's rated load capacities are customized when speeds exceed 160 km/h (99 mph) for all tires up to and including a V-speed rating, and when speeds exceed 190 km/h (118 mph) for all tires that are Z-speed rated and above. The Autobahn's unlimited speed opportunities explain why many German vehicles identify alternate tire inflation pressures to accommodate higher than North American highway speeds and heavier than typical two-passenger loads. In order to accommodate higher speeds, the tire size and inflation pressure recommendations are tuned beyond what is branded on the tire's sidewalls. These increases in recommended tire pressure are usually determined by agreement between the vehicle and tire manufacturers. In the absence of such an agreement, apply the following: Beginning with the vehicle manufacturer's recommended tire pressure for normal highway conditions, tire inflation pressures are initially increased and then the tire's rated load capacities (branded on the sidewalls) are reduced as speeds climb. In our example shown below, the vehicle manufacturer's recommended 35 psi for a 225/45R17 91W Standard Load tire installed on a vehicle initially rises in 1.5 psi increments for every 10 km/h (6.2 mph) increase in speed until the inflation pressures max out with an increase of 7.5 psi when the vehicle's top speed has increased 50 km/h (31mph). Then as the vehicle's top speed continues to climb, the rated load capacity of the tire is reduced in 5% increments for every

additional 10 km/h until the vehicle's top speed has increased an additional 30 km/h (18.6 mph). In this case the 225/45R17 91W Standard Load size's rated load capacity of 1,477 lbs. is reduced to 1,255 lbs. when applied to a vehicle with a 270 km/h (168 mph) top speed.

Vous aimerez peut-être aussi

- Road & Track Iconic Cars: CamaroD'EverandRoad & Track Iconic Cars: CamaroLarry WebsterPas encore d'évaluation

- Self Inflating Tyre System.: AuthorsDocument17 pagesSelf Inflating Tyre System.: Authorsmicmech50% (2)

- TSSCC Test and Tune April 22, 2001 A Basic Guide To Dialing-In Your CarDocument10 pagesTSSCC Test and Tune April 22, 2001 A Basic Guide To Dialing-In Your CarAlbertoRodriguezPas encore d'évaluation

- Self Inflating Tyres ReportDocument26 pagesSelf Inflating Tyres ReportDebasish Padhy100% (5)

- Bridgestone Tyre Article 2009Document6 pagesBridgestone Tyre Article 2009David DominguezPas encore d'évaluation

- Technical Considerations For Plus SizingDocument31 pagesTechnical Considerations For Plus SizingEdward FoongPas encore d'évaluation

- Tire InfoDocument34 pagesTire InfoOliveira ManuelPas encore d'évaluation

- Automatic Tyre Inflation SystemDocument53 pagesAutomatic Tyre Inflation SystemMayur Salunke100% (1)

- F1-16 SetupManual PDFDocument24 pagesF1-16 SetupManual PDFVk3em100% (1)

- CSD 2 Wheel Tire BasicsDocument79 pagesCSD 2 Wheel Tire BasicsAlbert Sangalang BongalosPas encore d'évaluation

- Tubeless TyreDocument21 pagesTubeless Tyreujwaljaiswal100% (1)

- OTR Tires: Proper Air Pressure Per ApplicationDocument4 pagesOTR Tires: Proper Air Pressure Per ApplicationTriyonoPas encore d'évaluation

- Tyre Technology Pushes Boundaries: Run Flat TyresDocument4 pagesTyre Technology Pushes Boundaries: Run Flat TyresRahul JiPas encore d'évaluation

- Yokohama Tire and Wheel InfoDocument17 pagesYokohama Tire and Wheel InfoPramote SuPas encore d'évaluation

- Tire TipsDocument4 pagesTire TipsDennis Al GoPas encore d'évaluation

- Obtain The Best Results From Your TiresDocument34 pagesObtain The Best Results From Your TiresJosé Inés Bazán MotaPas encore d'évaluation

- Via VisionDocument8 pagesVia VisionTiagoAlbarranPas encore d'évaluation

- Wheel DiameterDocument9 pagesWheel DiameterHarshdeep SinghPas encore d'évaluation

- Tire Safety 110909Document7 pagesTire Safety 110909PherPas encore d'évaluation

- Final ReportDocument30 pagesFinal ReportSatish HSPas encore d'évaluation

- Tyre Sidewall Markings Explained SF R9 21.7.08Document2 pagesTyre Sidewall Markings Explained SF R9 21.7.08Andreas DelisPas encore d'évaluation

- Making It Stick Part 1Document10 pagesMaking It Stick Part 1Ben HallamPas encore d'évaluation

- Pat's Corner - Formula Student Tyres For DummiesDocument6 pagesPat's Corner - Formula Student Tyres For DummiesMohamed GhareebPas encore d'évaluation

- Wheel Assembly, SuspensionDocument7 pagesWheel Assembly, Suspensionkishan24812Pas encore d'évaluation

- 4WD Driver's Guide - Cooper TyresDocument16 pages4WD Driver's Guide - Cooper TyresJohn EvansPas encore d'évaluation

- Dunlop Tyres: Tyre Marking Details 1. Tyre Size and Tyre DescriptionDocument5 pagesDunlop Tyres: Tyre Marking Details 1. Tyre Size and Tyre DescriptionAitzazMurtazaPas encore d'évaluation

- Tire Pressure Inflation SystemDocument8 pagesTire Pressure Inflation SystemijrdtPas encore d'évaluation

- Automatic Tyre Inflation SystemDocument32 pagesAutomatic Tyre Inflation SystemSanjana Singh50% (2)

- Calculating Speed From RPMDocument3 pagesCalculating Speed From RPMTavi SharmaPas encore d'évaluation

- Tyresmanual Print PDFDocument14 pagesTyresmanual Print PDFBcorganPas encore d'évaluation

- My Project TyresDocument79 pagesMy Project Tyresmanoj1562Pas encore d'évaluation

- Why Inertia & Roll Diameter Are Important On A Chassis Dyno - Kinetic Motor WorksDocument1 pageWhy Inertia & Roll Diameter Are Important On A Chassis Dyno - Kinetic Motor Worksotokar2Pas encore d'évaluation

- Brake System and Upgrade SelectionDocument5 pagesBrake System and Upgrade SelectionMichael SerraPas encore d'évaluation

- Tyre Pressure Monitoring SystemDocument7 pagesTyre Pressure Monitoring SystemSrinivasa M Gowda SeenaPas encore d'évaluation

- Automatic Tyre Inflation SystemDocument61 pagesAutomatic Tyre Inflation SystemFikhriMaulanaSetiakuSatuHatiPas encore d'évaluation

- Basic Chassis SetupDocument3 pagesBasic Chassis SetupArifDarmawanPas encore d'évaluation

- F1 2016 Setup ManualDocument24 pagesF1 2016 Setup Manualdraq13Pas encore d'évaluation

- Quick Car Setup Guide Williams Toyota FW31Document8 pagesQuick Car Setup Guide Williams Toyota FW31maferioPas encore d'évaluation

- Effects of Tire Inflation Pressure and Cti On Road Life and Vehicle Stability WoodrooffeDocument19 pagesEffects of Tire Inflation Pressure and Cti On Road Life and Vehicle Stability Woodrooffeminh tranPas encore d'évaluation

- Bridgestone Firestone Canada Maint Safety Manual 05-12-17Document32 pagesBridgestone Firestone Canada Maint Safety Manual 05-12-17jacobpm2010Pas encore d'évaluation

- Goodyear Tyre ReadingDocument4 pagesGoodyear Tyre ReadingAttique TahirPas encore d'évaluation

- Tyre RetreadingDocument24 pagesTyre RetreadingRuksana BhanuPas encore d'évaluation

- MaiDireSetup Ver.1.1.2 EnglishDocument23 pagesMaiDireSetup Ver.1.1.2 EnglishMaiDireCamberPas encore d'évaluation

- Ecopia - AUS 120330 130715Document9 pagesEcopia - AUS 120330 130715Jimmy LoPas encore d'évaluation

- Handling Cornering Speed: 1) Tire's GripDocument17 pagesHandling Cornering Speed: 1) Tire's GripPushkin SaxenaPas encore d'évaluation

- Tires Tested: Plus-Size Models: Testing The Performance Effects of Upsizing Wheels and TiresDocument3 pagesTires Tested: Plus-Size Models: Testing The Performance Effects of Upsizing Wheels and TiresDavid AbrevasPas encore d'évaluation

- Chassis Newsletter 2010.8Document3 pagesChassis Newsletter 2010.8Ganesh ShanmugamPas encore d'évaluation

- Goodyear Ackerman Steering Effect On Tyre WearDocument7 pagesGoodyear Ackerman Steering Effect On Tyre WearpvekzPas encore d'évaluation

- Tire Final PresentationDocument20 pagesTire Final Presentationapi-267410481Pas encore d'évaluation

- Glossary of TermsDocument3 pagesGlossary of TermsBrader MisaiPas encore d'évaluation

- The Original: Cheap Tyres The Real CostDocument6 pagesThe Original: Cheap Tyres The Real CostAngelo LatinoPas encore d'évaluation

- Plus Sizing 0Document6 pagesPlus Sizing 0najouma2010Pas encore d'évaluation

- Automatic Tyre Pressure Inflation SystemDocument35 pagesAutomatic Tyre Pressure Inflation SystemmujeebPas encore d'évaluation

- Ackerman? Anti-Ackerman? or Parallel Steering?Document10 pagesAckerman? Anti-Ackerman? or Parallel Steering?Alija SirotanovićPas encore d'évaluation

- Rearend Gear GuideDocument18 pagesRearend Gear GuideJam BabPas encore d'évaluation

- Chapter Two: Tires & WheelsDocument143 pagesChapter Two: Tires & WheelsMisga Bekele100% (1)

- Braking System Suggested For The AtvDocument9 pagesBraking System Suggested For The AtvAkash SaxenaPas encore d'évaluation

- Breakdowns and Incidents: DVSA Safe Driving for Life SeriesD'EverandBreakdowns and Incidents: DVSA Safe Driving for Life SeriesPas encore d'évaluation

- Vehicle Dynamics and Damping: First Revised EditionD'EverandVehicle Dynamics and Damping: First Revised EditionÉvaluation : 4 sur 5 étoiles4/5 (2)

- Smart Care Program Comment Form: Tamiloda Uyarvom OrganisationDocument1 pageSmart Care Program Comment Form: Tamiloda Uyarvom OrganisationPriyadashini SamyrawPas encore d'évaluation

- The Impact of Family of Origin & EmotionalDocument26 pagesThe Impact of Family of Origin & EmotionalPriyadashini SamyrawPas encore d'évaluation

- In Current Generation Does A Student Gain MoreDocument7 pagesIn Current Generation Does A Student Gain MorePriyadashini SamyrawPas encore d'évaluation

- Detailed Design: From Systems To PartsDocument5 pagesDetailed Design: From Systems To PartsPriyadashini SamyrawPas encore d'évaluation

- Presentation Power PointDocument11 pagesPresentation Power PointPriyadashini SamyrawPas encore d'évaluation

- Propeller DesignDocument1 pagePropeller DesignKeerthana MaheswarlaPas encore d'évaluation

- Trade List 13 Mar 2019Document74 pagesTrade List 13 Mar 2019Bharat JainPas encore d'évaluation

- Ude My For Business Course ListDocument51 pagesUde My For Business Course ListShehroz BhuttaPas encore d'évaluation

- A Sample of Wet Soil Has A Volume of 0Document8 pagesA Sample of Wet Soil Has A Volume of 0eph0% (1)

- Using Dapper Asynchronously inDocument1 pageUsing Dapper Asynchronously inGiovani BrondaniPas encore d'évaluation

- Web 2.0: Dynamic Web PagesDocument12 pagesWeb 2.0: Dynamic Web PagesAra PantaleonPas encore d'évaluation

- Pioneer XDP - 30R ManualDocument213 pagesPioneer XDP - 30R Manualmugurel_stanescuPas encore d'évaluation

- Ultra Petronne Interior Supply Corp.: Manufacturer of Light Metal FramesDocument1 pageUltra Petronne Interior Supply Corp.: Manufacturer of Light Metal Framesjun vincint geleraPas encore d'évaluation

- Tharmal Analysis BasicsDocument56 pagesTharmal Analysis BasicsNetoPas encore d'évaluation

- Report On HACCP ManualDocument72 pagesReport On HACCP ManualRizwan KhanPas encore d'évaluation

- Korantin PPDocument4 pagesKorantin PPteddy garfieldPas encore d'évaluation

- Programming Bayes Rule OptionalDocument17 pagesProgramming Bayes Rule OptionalajuhaseenPas encore d'évaluation

- 2013 11 DUPLEX EasyDocument21 pages2013 11 DUPLEX EasyAnonymous HC0tWePas encore d'évaluation

- AHRLACDocument18 pagesAHRLACVictor Pileggi100% (1)

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Ofdma: LTE Air Interface CourseDocument63 pagesOfdma: LTE Air Interface CourseAkhtar KhanPas encore d'évaluation

- 4.10) Arch Shaped Self Supporting Trussless Roof SpecificationsDocument11 pages4.10) Arch Shaped Self Supporting Trussless Roof Specificationshebh123100% (1)

- ISO 9001:2015 Questions Answered: Suppliers CertificationDocument3 pagesISO 9001:2015 Questions Answered: Suppliers CertificationCentauri Business Group Inc.100% (1)

- Write An Algorithm and Flowchart For Computing The Average Number of The Default 4 NumbersDocument3 pagesWrite An Algorithm and Flowchart For Computing The Average Number of The Default 4 NumbersMark Jelan100% (1)

- An Introduction Into The Feynman Path Integral PDFDocument94 pagesAn Introduction Into The Feynman Path Integral PDFLivardy WufiantoPas encore d'évaluation

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Document7 pagesPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksPas encore d'évaluation

- Panel 01-Eldora-Grand-1500V-2021-R01 - G1Document2 pagesPanel 01-Eldora-Grand-1500V-2021-R01 - G1DHAVAL SHAHPas encore d'évaluation

- Coastal DefenceDocument112 pagesCoastal DefenceMorvin BudhanPas encore d'évaluation

- U042en PDFDocument12 pagesU042en PDFTatiya TatiyasoponPas encore d'évaluation

- Educational Solutions From Schneider ElectricDocument164 pagesEducational Solutions From Schneider ElectricfaneeeeeePas encore d'évaluation

- VB Script ReferenceDocument27 pagesVB Script ReferenceRajkumarPas encore d'évaluation

- 2019 All PDFDocument27 pages2019 All PDFvishesh bhatiaPas encore d'évaluation

- Semantic and Frames PDFDocument20 pagesSemantic and Frames PDFsyncasterPas encore d'évaluation

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiPas encore d'évaluation