Académique Documents

Professionnel Documents

Culture Documents

Composite Review

Transféré par

Tedy ThomasDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Composite Review

Transféré par

Tedy ThomasDroits d'auteur :

Formats disponibles

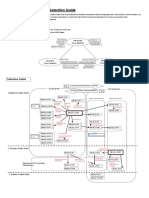

COMPOSITE MATERIALS

a material composed of two or more distinct phases (matrix phase and dispersed phase) properties are significantly different .

1. 2.

Based on matrix material MMC CMC PMC Based on reinforcing material structure

Particulate composites Fibrous composites Laminate composites

PMC- polymer matrix( thermoset -UP,EP/ thermoplast-PC,PVC,Nylon) + fibrous reinforcing dispersed phase(glass, carbon,steel,Kevlar fiber..)

High tensile strength High stiffness High fracture toughness Good abrasion resistance Good corrosion resistance Low cost fabrication Simple fabrication methods

Aerospace Automotive industry Sports goods Transportation & infrastructure

1.Mechanical properties of natural fibre reinforced polymer composites

A S SINGHA* and VIJAY KUMAR THAKUR Material Science Laboratory, National Institute of Technology, Hamirpur 177 005, India Methodology: 1. UF resin is prepared and its various properties have been studied 2. A new kind of green composite is synthesize and its property have been studied (UF resin + hibiscus sabdariffa) 3. Tensile, compressive, wear property were invesigated (utm,sem,wear & friction monitor) Observation: Composite having improved properties than resin

2. Magnetic properties of pmc filled with ferrite powders

J. Stabik a, A. Chrobak b, G. Haneczok c, A. Dybowska a,*Institute of Engineering Materials and Biomaterials, Silesian University of Technology, poland Aim: To study about the magnetic properties in pmc with varying amount of ferrite filler Methodology:

Epoxy resin filled with different amounts (15%, 25% and 35%vol.) of filler and 2 types of ferrite powders were prepared by gravitational casting Magnetic properties of polymeric composites were measured by SQUID magnetometer . Observation: Addition of ferrite powder to epoxy resin increases magnetic remanence

S. Sarkar*, Akhilesh Singh , Department of Metallurgical and Materials Engineering, National Institute of Technology, Rourkela, India. Methodology:

1.Iron ore+ molten Al, iron ore + Al Mg, Iron ore + Al si by vortex method. 2. As a result,Al2o3 ,mgo will be formed and iron dissolves in Al 3. Composite thus produced were cast in to cast iron die and mechanical properties are studied

Observation: The oxide particles and the un reacted particles of iron ore give sufficient improvement in strength and hardness of the composite The wear resistance has improved significantly by addition of iron ore.

Nuclear and Radiation Chemistry Division, Institute of Nuclear Science and Technology, Bangladesh Atomic Energy Commission, Dhaka, Bangladesh Methodology

2 different kinds of composites are fabricated by compression molding Poly propylene + short jute, poly propylene + short e glass fiber 2. Both of these composites have been tested for finding out its comparative mechanical properties Observation: based on number of test regarding tensile strength, tensile modulus, flexural modulus, impact strength it is came to know that short jute based composite is superior than short e glass fiber composite

1.

Ioannis G. Raftoyiannis , Department of Civil Engineering, National Technical University of Athens Methodology:

The primary aim of the project is to examine the mechanical properties of such panels for use in secondary structural members . Composite is fabricated from polyester resin + cotton fiber Observation The tensile strength and modulus increase with increasing fiber weight ratio up to a certain amount.

THANKS

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- NF P18 470NF P18 470 (E) - Specifications, Performance, Production and Conformity 29 July 2016Document94 pagesNF P18 470NF P18 470 (E) - Specifications, Performance, Production and Conformity 29 July 2016Leonardo100% (2)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Coil DesignDocument7 pagesCoil DesignSajal Kulshrestha100% (3)

- Product Design and DevelopmentDocument16 pagesProduct Design and DevelopmentTedy ThomasPas encore d'évaluation

- Product Design and DevelopmentDocument16 pagesProduct Design and DevelopmentTedy ThomasPas encore d'évaluation

- SHP CMPDocument1 pageSHP CMPTedy ThomasPas encore d'évaluation

- Automated Guided VehicleDocument17 pagesAutomated Guided VehicleTedy ThomasPas encore d'évaluation

- Automated Guided VehicleDocument13 pagesAutomated Guided VehicleTedy ThomasPas encore d'évaluation

- Damage Tolerance Assessment BookDocument174 pagesDamage Tolerance Assessment BooksemipurPas encore d'évaluation

- Polystyrene Properties&UsesDocument5 pagesPolystyrene Properties&UsesChandrachood SBPas encore d'évaluation

- Waste Glass: Table 5.1 Types of Glass and Their Main UsesDocument2 pagesWaste Glass: Table 5.1 Types of Glass and Their Main UsesGowri J BabuPas encore d'évaluation

- Chapter Viii: The Nano WorldDocument2 pagesChapter Viii: The Nano WorldCherry Ann OlasimanPas encore d'évaluation

- A1021Document4 pagesA1021Aleksei AvilaPas encore d'évaluation

- Hdpe Versus FRPDocument4 pagesHdpe Versus FRPAshok NarayanPas encore d'évaluation

- Gas Laws Simulation Lab: Experiment One: Constant VolumeDocument4 pagesGas Laws Simulation Lab: Experiment One: Constant Volumealan musselwhite100% (1)

- Fluoroelastomer DAIEL Selection Guide: Peroxide Cure SystemDocument1 pageFluoroelastomer DAIEL Selection Guide: Peroxide Cure Systemkyeong cheol leePas encore d'évaluation

- Materials and Jacketing TechniqueDocument5 pagesMaterials and Jacketing TechniqueHSY79Pas encore d'évaluation

- DNV RP-F201Document26 pagesDNV RP-F201Mr. EngineerPas encore d'évaluation

- Termal AnalysiiiisDocument5 pagesTermal AnalysiiiisSalman AshfaqPas encore d'évaluation

- RCE Slender ColumnDocument35 pagesRCE Slender ColumnWindi AstutiPas encore d'évaluation

- ConcDocument5 pagesConcDeep DebnathPas encore d'évaluation

- Chapter 5 - Welding of High-Alloy Steels, Corrosion PDFDocument19 pagesChapter 5 - Welding of High-Alloy Steels, Corrosion PDFEmad A.AhmadPas encore d'évaluation

- Engineering Alloys (307) Lecture 7 Titanium Alloys I: David DyeDocument15 pagesEngineering Alloys (307) Lecture 7 Titanium Alloys I: David DyeFelipe Perissé Duarte LopesPas encore d'évaluation

- CH 01Document72 pagesCH 01Shashi ShekharPas encore d'évaluation

- Beam&GridDocument32 pagesBeam&GridTejas DesaiPas encore d'évaluation

- Report FFFDocument2 pagesReport FFFamevaluacionesPas encore d'évaluation

- Root Cause Assessment - Fractured Girder Flanges: Transbay (Salesforce) Transit Center, San FranciscoDocument44 pagesRoot Cause Assessment - Fractured Girder Flanges: Transbay (Salesforce) Transit Center, San Franciscogulilero_yoPas encore d'évaluation

- Soil PlasticityDocument16 pagesSoil PlasticityYogeswaran RishanthanPas encore d'évaluation

- Moment Area MethodDocument9 pagesMoment Area MethodHammad RiazPas encore d'évaluation

- Seismic Design of Shallow Foundations PDFDocument40 pagesSeismic Design of Shallow Foundations PDFNicon Paul100% (1)

- Controversial Electro ProblemDocument16 pagesControversial Electro ProblemJorge AlcarazPas encore d'évaluation

- Estabilidad Pamoato PirantelDocument6 pagesEstabilidad Pamoato PirantelHéctor Fabio Leyton ArcosPas encore d'évaluation

- Lecture 2 - Particle Characterization & Size Reduction v2Document32 pagesLecture 2 - Particle Characterization & Size Reduction v2roxette100% (1)

- HW 2. ProblemsDocument5 pagesHW 2. ProblemsAruzhanPas encore d'évaluation

- 1D Elasticity 02 ElastodynamicsDocument17 pages1D Elasticity 02 Elastodynamics박남수Pas encore d'évaluation

- Science4 q3 St#2Document2 pagesScience4 q3 St#2Joelle Ann UbanaPas encore d'évaluation