Académique Documents

Professionnel Documents

Culture Documents

Elective This Is It

Transféré par

Lyssawords DiamsayDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Elective This Is It

Transféré par

Lyssawords DiamsayDroits d'auteur :

Formats disponibles

JISHU HOZEN (Autonomous Maintenance) Jishu Hozen, which means autonomous or self-maintenance, promotes development of production operators to be able

to take care of small maintenance tasks, such as cleaning, inspecting, and lubricating their equipment, thus freeing the maintenance associates to spend time on more value-added activities and technical repairs.

Goals of Jishu Hozen: Uninterrupted operation of equipment Flexible operators who can operate and maintain other equipment Elimination of defects at the source through active employee participation Stepwise implementation of JH activities

Cleaning Clean machines are easier to operate, inspect, and maintain. When the machine is dirty and corroded problems cannot be seen.

The following steps outline the initial cleanup of machines: 1. Arrange all items needed for cleaning. 2. Clean equipment completely (with help from Maintenance, if necessary). 3. Remove dirt, dust, stains, oils, and grease. 4. Take care of any oil leaks, loose wires, loose nuts or bolts and worn parts.

After the initial cleanup of machines: 1. Note inaccessible machine areas and sources of contamination. 2. Categorize and tag problem areas. (Use white tags to note problems that operators can solve; red tags note the maintenance department is needed.) 3. Transfer tag contents to a database for a record.

Inspection Inspect the conditions of each part of equipment using the human senses of sight, hearing, smell, and touch to detect signs of equipment failure.

Inspection can be aided through the use of stickers affixed to the equipment to show which sense is to be used at which location.

Lubrication Prime movers transfer power so the equipment can do work. This involves a number of moving components, e.g., bearings, gears, shafts, spindles, sprockets, chains, levers, and slides. Without proper lubrication, ALL of these components WILL FAIL.

Proper lubrication involves using the proper type of lubricant in the proper amount at the proper time. Too much lubricant can cause problems including overheating the components; collecting dust, dirt, and debris; and causing slip hazards, etc.

Lubrication (Cont.) Each machine lubrication location is color coded to match the container used to dispense the lubricant. The storage container is color coded to match the dispenser. Equipment may also have color-coded lubrication labels. Always follow the lubrication instruction sheet. If you have any question about the instructions, ask your supervisor.

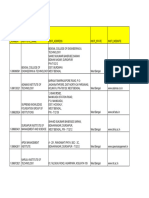

Steps in JISHU HOZEN: Initial cleanup of machines Take counter measures Fix tentative JH standards General inspection Autonomous inspection Standardization Autonomous management

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Workbook Group TheoryDocument62 pagesWorkbook Group TheoryLi NguyenPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Development Developmental Biology EmbryologyDocument6 pagesDevelopment Developmental Biology EmbryologyBiju ThomasPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Quarter 1 - Module 1Document31 pagesQuarter 1 - Module 1Roger Santos Peña75% (4)

- Lecture2 GranulopoiesisDocument9 pagesLecture2 GranulopoiesisAfifa Prima GittaPas encore d'évaluation

- Hidrl1 PDFDocument7 pagesHidrl1 PDFRajesh Kumar100% (1)

- Evolution Army 3 R DadDocument341 pagesEvolution Army 3 R DadStanisław DisęPas encore d'évaluation

- 2016 Closing The Gap ReportDocument64 pages2016 Closing The Gap ReportAllan ClarkePas encore d'évaluation

- Intellirent 2009 CatalogDocument68 pagesIntellirent 2009 Catalograza239Pas encore d'évaluation

- (Jones) GoodwinDocument164 pages(Jones) Goodwinmount2011Pas encore d'évaluation

- Rajiv Gandhi University of Health Sciences, Bengaluru, KarnatakaDocument9 pagesRajiv Gandhi University of Health Sciences, Bengaluru, KarnatakaNavin ChandarPas encore d'évaluation

- Out PDFDocument211 pagesOut PDFAbraham RojasPas encore d'évaluation

- Biography Thesis ExamplesDocument7 pagesBiography Thesis Examplesreneewardowskisterlingheights100% (2)

- Literatura Tecnica 3Document10 pagesLiteratura Tecnica 3Christian PerezPas encore d'évaluation

- Anemia in PregnancyDocument5 pagesAnemia in PregnancycfgrtwifhPas encore d'évaluation

- Quiz 140322224412 Phpapp02Document26 pagesQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriPas encore d'évaluation

- WBDocument59 pagesWBsahil.singhPas encore d'évaluation

- Journal of Biology EducationDocument13 pagesJournal of Biology EducationFarah ArrumyPas encore d'évaluation

- EqualLogic Release and Support Policy v25Document7 pagesEqualLogic Release and Support Policy v25du2efsPas encore d'évaluation

- SASS Prelims 2017 4E5N ADocument9 pagesSASS Prelims 2017 4E5N ADamien SeowPas encore d'évaluation

- Ra 9272Document6 pagesRa 9272janesamariamPas encore d'évaluation

- Bachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesDocument13 pagesBachelor of Arts in Theology: Christian Apologetics/ Seventh-Day Adventist Contemporary IssuesRamel LiguePas encore d'évaluation

- Z-Purlins: Technical DocumentationDocument11 pagesZ-Purlins: Technical Documentationardit bedhiaPas encore d'évaluation

- Pityriasis VersicolorDocument10 pagesPityriasis Versicolorketty putriPas encore d'évaluation

- Catedral de SevillaDocument28 pagesCatedral de SevillaAnonymous LkgNmKePas encore d'évaluation

- MCI Approved Medical College in Uzbekistan PDFDocument3 pagesMCI Approved Medical College in Uzbekistan PDFMBBS ABROADPas encore d'évaluation

- Siemens Make Motor Manual PDFDocument10 pagesSiemens Make Motor Manual PDFArindam SamantaPas encore d'évaluation

- ASHRAE Journal - Absorption RefrigerationDocument11 pagesASHRAE Journal - Absorption Refrigerationhonisme0% (1)

- ReadmeDocument2 pagesReadmechethan100% (1)

- Mosfet Irfz44Document8 pagesMosfet Irfz44huynhsang1979Pas encore d'évaluation

- Tesco True Results Casing Running in China Results in Total Depth PDFDocument2 pagesTesco True Results Casing Running in China Results in Total Depth PDF123456ccPas encore d'évaluation