Académique Documents

Professionnel Documents

Culture Documents

Mechanics of Materials II: UET, Taxila Lecture No.

Transféré par

danemsalDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mechanics of Materials II: UET, Taxila Lecture No.

Transféré par

danemsalDroits d'auteur :

Formats disponibles

Mechanics of Materials II

UET, Taxila

Lecture No. (2)

Tensile behavior of

different materials:

In a typical tensile test one tries

to induce uniform extension of

the gage section of a tensile

specimen.

The gage section of the

tensile specimen is

normally of uniform

rectangular or circular

cross-section.

The following figure shows a

typical dog-bone sample.

Gage length

P

P

P

P

The two ends are used for fixing

into the grips, which apply the

load. As can be seen from the

free-body diagram to the right,

the load in the gage section is

the same as the load applied

by the grips.

An extensometers are used

to measure the change of

length in the gage section

and load cells to measure

the load applied by the grips

on the sample.

By the means of this it is

possible to calculate the

axial strain and normal

stress (knowing the initial

gage length and cross-

sectional area of the gage

section).

The result is a stress-strain

diagram, a diagram of how

stress is changing in the

sample as a function of the

strain for the given loading. A

typical stress-strain diagram

for a mild steel is shown

below.

Mild Steel Stress-Strain Curve

Yield stress,

y

o

Ultimate stress,

u

o

Stress,

o

Strain,

c

The different regions of the area

response denoted by their

characteristics as follows

Yield stress,

y

o

Ultimate stress,

u

o

Stress, o

Strain,

c

1

2

3

4

5

1. Linear elastic: region of proportional elastic loading

2. Nonlinear elastic: up to yield

3. Perfect plasticity: plastic flow at constant load

4. Strain hardening: plastic flow with the increase of stress

5. Necking: localization of deformation and rupture

Brittle versus Ductile

behavior

Brittle materials fail at

small strains and in

tension. Examples of

such materials are glass,

cast iron, and ceramics.

Ductile materials fail at

large strains and in

shear. Examples of

ductile materials are mild

steel, aluminum and

rubber.

The ductility of a material

is characterized by the

strain at which the

material fails.

An alternate measure is

the percent reduction in

cross-sectional area at

failure.

Isometric of tensile test

specimen

Different types of

response:

Elastic response:

If the loading and unloading

stress-strain plot overlap each

other the response is elastic.

The response of steel below

the yield stress is considered to

be elastic.

Elastic Response (Linear &

Non-linear)

c

o

Linear

Elastic

Nonlinear

Elastic

After loading beyond the

yield point, the material no

longer unloads along the

loading path.

There is a permanent

stretch in the sample after

unloading.

The strain associated

with this permanent

extension is called the

plastic strain c

p

As shown in next figure,

the unloading path is

parallel to the initial

linear elastic loading

path (and not

overlapping).

c

o

Unl oadi ng

Loading

cp

Most plastics when loaded

deform over time even without

increasing the load. The

material continuous extension

under constant load referred to

as creep. If held at constant

strain, the load required to hold

the strain decreases with time.

Relaxation

The decrease in load

over time at constant

stretch is referred to

as relaxation.

Bearing Stress:

Even though bearing stress

is not a fundamental type of

stress, it is a useful concept

for the design of

connections in which one

part pushes against

another.

The compressive load

divided by a

characteristic area

perpendicular to it yields

the bearing stress which

is denoted by

b

.

Therefore, in form, the bearing

stress is no different from the

compressive axial stress and is

given by:

A

F

b

= o

Where:

F: is the compressive

load and

A: is a characteristic area

perpendicular to it.

F

cp

F

F

F

F

F

F

F

d

t

t

t

t

Cylindrical bolt or rivet

For example, if two

plates are connected by

a bolt or rivet as shown,

each plate pushes

against the side of the

bolt with load F.

It is not clear what the

contact area between the

bolt and the plate is since it

depends on the size of the

bolt and the shape of the

deformation that results.

Also, the distribution of the

load on the bolt varies from

point to point, but as a first

approximation one can use

the shown rectangle of

area A=td

This gives a representative

bearing stress for the bolt as:

td

F

b

= o

Linear-Elastic

Response and

Factor of Safety

Linear-elastic response:

Hookes law:

In the linear elastic portion of the

response of material one can

model the response by Hookes

law as follows

Hookes law for extension:

= E c

Hookes law for shear:

t = G

Where:

E is the elastic modulus (or

Youngs modulus), and

G is the shear modulus.

The elastic and shear moduli

are material constants

characterizing

the stiffness of the material.

Physical Meaning of E

(Stress Strain Curve)

c

o

E

1

Poissons Ratio:

Another material

parameter is Poissons

ratio that characterizes

the contraction in the

lateral directions when a

material is extended.

The symbol v (nu) is used for

the poison ration, which is

negative the ratio of the lateral

strain to axial strain.

a

t

c

c

v =

lo

do

l

d

o

o

t

d

d d

= c

o

o

a

l

l l

= c

The relation between the

elastic moduli:

For an isotropic elastic material

(i.e., an elastic material for which

the properties are the same

along all directions) there are

only two independent material

constants.

The relation between

the three moduli are

given by the following

equation:

Equation for the relation between the

elastic moduli:

) 1 ( 2 u +

=

E

G

Factor of safety:

The factor of safety

denoted by n is the ratio

of the load, the structure

can carry, divided by the

load it is required to take.

Factor of safety

strength Required

strength Actual

n =

Therefore, the factor of safety

is a number greater than unity

(n>1). The allowable stress for

a given material is the

maximum stress the material

can take (normally the ultimate

or yield stress) divided by the

factor of safety).

n

or

n

or

u y

allow

u y

allow

t t

t

o o

o

=

=

Vous aimerez peut-être aussi

- Mechanics of MachinesDocument79 pagesMechanics of MachinesSyed Waqar Ahmed100% (1)

- Mechanics of Materials IIDocument48 pagesMechanics of Materials IIsoulcivicPas encore d'évaluation

- Mechanics of Materials II: UET, TaxilaDocument61 pagesMechanics of Materials II: UET, TaxilaSyh TfkPas encore d'évaluation

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsD'EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsPas encore d'évaluation

- Material Properties ReportDocument8 pagesMaterial Properties ReportazizsaafanPas encore d'évaluation

- Chapter 1 Simple StressDocument13 pagesChapter 1 Simple Stressمصطفى احمد محيسنPas encore d'évaluation

- Mechanical Properties of MaterialsDocument33 pagesMechanical Properties of Materialsraghu_raman5364Pas encore d'évaluation

- Stress Strain Curve ExplanationDocument8 pagesStress Strain Curve ExplanationGptc Chekkanurani0% (1)

- Stress–Strain Curve: Material PropertiesDocument4 pagesStress–Strain Curve: Material PropertiesMartine CastroPas encore d'évaluation

- Mechanics of MachinesDocument79 pagesMechanics of MachinesTbos ThabisoPas encore d'évaluation

- Strength of Material CH-1 Ppt-1Document26 pagesStrength of Material CH-1 Ppt-1Nura Guyo67% (3)

- Strength of MaterialsDocument47 pagesStrength of MaterialsColorgold BirliePas encore d'évaluation

- MSM Unit No.2 NotesDocument39 pagesMSM Unit No.2 NotesPratik SaindanePatilPas encore d'évaluation

- Mechanical Properties of Materials - MechaniCalcDocument11 pagesMechanical Properties of Materials - MechaniCalcharieduidPas encore d'évaluation

- Chapter 1 - Stress and StrainDocument77 pagesChapter 1 - Stress and StrainIman Fitri IsmailPas encore d'évaluation

- Module-1 Stresses and StrainsDocument33 pagesModule-1 Stresses and StrainsC.E.M JEFFREYSPas encore d'évaluation

- Experiment of Rubber BlockDocument10 pagesExperiment of Rubber BlockM Zaid Akram50% (4)

- CH 2Document45 pagesCH 2Said EliasPas encore d'évaluation

- Lecture 4Document45 pagesLecture 4SAIF ULLAHPas encore d'évaluation

- CE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainDocument6 pagesCE 323/ BES 222 Mechanics of Deformable Bodies: Chapter 2 - StrainNadlor Gasco OzausPas encore d'évaluation

- Stress and Strain: Elastic ModulusDocument20 pagesStress and Strain: Elastic Moduluslaura sagePas encore d'évaluation

- Stress and StrainDocument17 pagesStress and StrainakshatbhargavaPas encore d'évaluation

- Stress Strain CurveDocument16 pagesStress Strain CurveMedakayala Nagasravanthi 20PHD7125Pas encore d'évaluation

- Stress and Strain: Elastic ModulusDocument10 pagesStress and Strain: Elastic Moduluslaura sagePas encore d'évaluation

- Mechanics of MaterialsDocument31 pagesMechanics of Materialsps4haris.ch3534Pas encore d'évaluation

- Stress and StrainDocument14 pagesStress and StrainEFRAIM CAMBEPas encore d'évaluation

- Mechanical Properties of MetalsDocument15 pagesMechanical Properties of MetalsLaurence Bande Del RosarioPas encore d'évaluation

- Young's Modulus, Shear Modulus, and Bulk Modulus Mechanical PropertiesDocument9 pagesYoung's Modulus, Shear Modulus, and Bulk Modulus Mechanical PropertiesBVoc AutomobilePas encore d'évaluation

- GET 208 Lecture Note 1Document6 pagesGET 208 Lecture Note 1Jehu RanyangPas encore d'évaluation

- ENCI 317 - LAB 1 - Lab MaterialDocument15 pagesENCI 317 - LAB 1 - Lab MaterialSherry YousafPas encore d'évaluation

- Mechanical Properties IntroductionDocument29 pagesMechanical Properties IntroductionHiwot DemissePas encore d'évaluation

- Instructional Material in Mechanics of Deformable Bodies (CE BSC 232b)Document15 pagesInstructional Material in Mechanics of Deformable Bodies (CE BSC 232b)Joshua John JulioPas encore d'évaluation

- MECHANICS OF DEFORMABLE BODIESDocument106 pagesMECHANICS OF DEFORMABLE BODIESVinayak PrabhuPas encore d'évaluation

- 4 - Mechanical Properties of MaterialsDocument28 pages4 - Mechanical Properties of MaterialsYusf ari jerjisPas encore d'évaluation

- Tensile properties testing and stress-strain curvesDocument4 pagesTensile properties testing and stress-strain curvesjontylee87Pas encore d'évaluation

- 6.0 Mechanical Properties of Materials: Tension Compression Shear TorsionDocument40 pages6.0 Mechanical Properties of Materials: Tension Compression Shear TorsionWilliams AkandiPas encore d'évaluation

- Flow Theory of Plasticity - Key ConceptsDocument6 pagesFlow Theory of Plasticity - Key ConceptsMohan ChandraPas encore d'évaluation

- Measuring Mechanical Properties of MaterialsDocument25 pagesMeasuring Mechanical Properties of MaterialsUmesh ChandraPas encore d'évaluation

- Mechanical PropertiesDocument25 pagesMechanical PropertiesUmesh ChandraPas encore d'évaluation

- Mechanic FractureDocument9 pagesMechanic Fracturehengki wibowoPas encore d'évaluation

- Stress Strain CurveDocument4 pagesStress Strain Curvekirandasi123Pas encore d'évaluation

- Mechanical Properties PDFDocument57 pagesMechanical Properties PDFvardhaPas encore d'évaluation

- STRENGTH OF MATERIALS EQUATIONSDocument7 pagesSTRENGTH OF MATERIALS EQUATIONSChristianPas encore d'évaluation

- HOME ASSIGNMENT 2 (AutoRecovered)Document15 pagesHOME ASSIGNMENT 2 (AutoRecovered)ATIF KHANPas encore d'évaluation

- Thermal StressDocument104 pagesThermal Stressmanishtopsecrets100% (1)

- Thermal StressDocument104 pagesThermal Stressgaspardo123100% (1)

- CET Ceng Wu's civil engineering materials lecture notesDocument11 pagesCET Ceng Wu's civil engineering materials lecture notesTolera GutuPas encore d'évaluation

- MD-I Lecture 04Document21 pagesMD-I Lecture 04Uzair NaeemPas encore d'évaluation

- Strain-Life Fatigue Analysis ToolDocument14 pagesStrain-Life Fatigue Analysis ToolKALIDASS DPas encore d'évaluation

- Strain Hardening Rheology. Rheology Is The Science of Deformation. This Science Poses ADocument8 pagesStrain Hardening Rheology. Rheology Is The Science of Deformation. This Science Poses Akhudhayer1970Pas encore d'évaluation

- Mechanical Properties of SolidsDocument8 pagesMechanical Properties of SolidsffyyhafxqefqobhaswPas encore d'évaluation

- Stress and StrainDocument60 pagesStress and StrainMuhammad Shafie100% (1)

- Unit IDocument8 pagesUnit IPurushothamPas encore d'évaluation

- Chapter 1 - STRESS AND STRAIN PDFDocument34 pagesChapter 1 - STRESS AND STRAIN PDFnurul eryn100% (1)

- Som ProjectDocument37 pagesSom ProjectVarun SinghPas encore d'évaluation

- Addis Ababa Institute of Technology: School of Mechanical and Industrial Engineering Materials Science and EngineeringDocument40 pagesAddis Ababa Institute of Technology: School of Mechanical and Industrial Engineering Materials Science and EngineeringColorgold BirliePas encore d'évaluation

- Strain Also Known As Unit Deformation, Strain Is The Ratio of The Change in Length Caused by The AppliedDocument3 pagesStrain Also Known As Unit Deformation, Strain Is The Ratio of The Change in Length Caused by The AppliedJomarie AlcanoPas encore d'évaluation

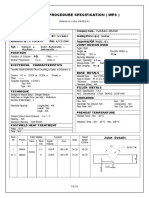

- 1999v05 Welding Requirements PDFDocument6 pages1999v05 Welding Requirements PDFdanemsalPas encore d'évaluation

- WPS Smaw1gDocument1 pageWPS Smaw1gDanem HalasPas encore d'évaluation

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDocument7 pagesWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalPas encore d'évaluation

- Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDocument7 pagesWelding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDanem HalasPas encore d'évaluation

- StructEngII Connections 276-327Document52 pagesStructEngII Connections 276-327danemsalPas encore d'évaluation

- ThickWalledCylinder and PressShrinkFit ShigDocument17 pagesThickWalledCylinder and PressShrinkFit ShigArooj WaniPas encore d'évaluation

- 4 1 Sirin ManuscriptDocument6 pages4 1 Sirin ManuscriptdanemsalPas encore d'évaluation

- ZorcDocument6 pagesZorcdanemsalPas encore d'évaluation

- Psrao Welding DefectsDocument35 pagesPsrao Welding DefectsdanemsalPas encore d'évaluation

- Ultrasonic SolutionDocument46 pagesUltrasonic Solutionsoumyadev86% (14)

- Yongxu Yang 2Document164 pagesYongxu Yang 2danemsalPas encore d'évaluation

- B Section 202 To 212Document11 pagesB Section 202 To 212joshua_tan_31Pas encore d'évaluation

- Παρουσίαση EC3 Connections Και ΙNSTANT Steel 2012Document28 pagesΠαρουσίαση EC3 Connections Και ΙNSTANT Steel 2012danemsalPas encore d'évaluation

- 208 4Document35 pages208 4danemsalPas encore d'évaluation

- Fundamentals - ValvesDocument52 pagesFundamentals - Valvesapi-3808778100% (2)

- Buried PipeDocument83 pagesBuried PipePlalvarezcelis100% (3)

- Bts Roc Methodes 2009Document31 pagesBts Roc Methodes 2009Med Ali MaatougPas encore d'évaluation

- Bts Roc Methodes 2002 PDFDocument36 pagesBts Roc Methodes 2002 PDFdanemsalPas encore d'évaluation

- CDC UP Test Plan TemplateDocument20 pagesCDC UP Test Plan TemplatedanemsalPas encore d'évaluation

- Calculate HVL Material Attenuation CoefficientDocument4 pagesCalculate HVL Material Attenuation CoefficientdanemsalPas encore d'évaluation

- Causes and Cures of Common Welding Defects: Blow HolesDocument12 pagesCauses and Cures of Common Welding Defects: Blow HolesDeepak GuptaPas encore d'évaluation

- A - SeriesDocument18 pagesA - SeriesdanemsalPas encore d'évaluation

- Psrao Welding DefectsDocument35 pagesPsrao Welding DefectsdanemsalPas encore d'évaluation

- Ultrasonic SolutionDocument46 pagesUltrasonic Solutionsoumyadev86% (14)

- Course Module 9Document10 pagesCourse Module 9danemsalPas encore d'évaluation

- 4 1 Sirin ManuscriptDocument6 pages4 1 Sirin ManuscriptdanemsalPas encore d'évaluation

- Welding Processes: Basic Ideas, Terminology, Properties of The Welding ArcDocument38 pagesWelding Processes: Basic Ideas, Terminology, Properties of The Welding ArcdanemsalPas encore d'évaluation

- A - SeriesDocument18 pagesA - SeriesdanemsalPas encore d'évaluation

- Arccosts PDFDocument27 pagesArccosts PDFharry_1981Pas encore d'évaluation

- B Section 202 To 212Document11 pagesB Section 202 To 212joshua_tan_31Pas encore d'évaluation