Académique Documents

Professionnel Documents

Culture Documents

Chap12 Strain Measurements

Transféré par

upendra35Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chap12 Strain Measurements

Transféré par

upendra35Droits d'auteur :

Formats disponibles

Strain Measurements

Engineering calculations are often based on stress. If we want to do

experiments to confirm our theory, we need to measure the result of

stress rather than stress directly. Stress results in the deformation of

material, which is called strain. For most engineering materials, there

is a rather simple relationship between stress and strain.

o

a

= Ec

a

c

a

=

dL

L

~

L

2

L

1

L

1

=

AL

L

1

Lateral Strain, Poissons Ratio

If we stress a rod by pulling on it,

and is stretches axially as a result, it

will also get thinner. This behavior

is quantified by Poissons ratio:

v =

lateral strain

axial strain

=

c

L

c

a

This is a property of the material.

General Stress States

c

y

=

o

y

E

v

o

x

E

c

x

=

o

x

E

v

o

y

E

o

x

=

E c

x

+vc

y

( )

1v

2

o

y

=

E c

y

+v c

x

( )

1v

2

These equations relate the 2-D stress field to the

2-D strain field. I will assume that you already

know this.

We measure strain in one or more directions and infer the stress state

from that. In general, in order to know the 3-D stress state, we

would need 3 components of strain. In some cases (like pure axial

stress) we may be able to reduce the number of required

components. I will teach you more about the instrumentation side of

this topic, and it will be left to you to figure out how to get the stress

state from the measurements.

12.3 Electrical Resistance Strain Gage

Ruge, 1940s

Rosettes

Installation

The gauge length limits the spatial

resolution of the sensor.

Connection to the bridge is made

at the solder tabs.

The backing material needs to be

made of something that can:

Withstand the temperatures

encountered

Transmit strain but electrically

insulate

Accept the bonding adhesive

12.4 Metallic Gauges

R =

L

A

=

L

CD

2

If you have a conductor of resistivity , the resistance across that

conductor is

If you strain this conductor axially, its length will increase while its

cross sectional area will decrease. Taking the total differential of R,

dR =

cR

c

d +

cR

cL

dL +

cR

c CD

2

( )

d CD

2

( )

=

1

CD

2

Ld + dL 2L

dD

D

|

\

|

.

|

dR

R

=

dL

L

2

dD

D

+

d

Metallic Gauges

dR/ R

dL/ L

=12

dD/ D

dL/ L

+

d/

dL/ L

dR

R

=

dL

L

2

dD

D

+

d

c

a

=

dL

L

c

L

=

dD

D

v =

c

L

c

a

F

dR/ R

dL/ L

=

dR/ R

c

a

=1+ 2v +

d/

dL/ L

For most strain gauges, v = 0.3. If the resistivity is not a function of

strain, then F only depends on poissons ratio, and F ~ 1.6.

Gage factor

dR

R

=

dL

L

1+v

( )

+

d

t

1

=

1

E

d/

dL

1

/ L

dR/ R

dL/ L

=1+ 2v + t

1

E

Piezoresistance

Coefficient

Gage Factor

c =

1

F

AR

R

F

dR/ R

dL/ L

=

dR/ R

c

a

=1+ 2v +

d/

dL/ L

F and R are supplied by the

manufacturer, and we measure

AR.

Example

A typical strain gauge uses constantan (55% copper, 45% nickel)

which has a resistivity of 49 X 10

-8

Om. The strain gauge must be

120O nominally (why?). If the diameter is 0.025 mm, how long

does it need to be?

R =

e

L

A

c

L = 12 cm

12.5 Selection and Installation

Read on your own

12.6 Circuitry for Metallic Strain Gage

Most commercial strain gages are 120 O, have a gage factor near 2, and

can measure 1 microstrain (1 part in a million).

c =

1

F

AR

R

AR =12021E 6 = 0.00024O

Clearly, our work is cut out for us in terms of the measurement.

12.8 The Strain Gage Bridge Circuit

Ae

o

e

i

=

AR

1

/ R

4 + 2 AR

1

/ R

( )

c =

1

F

AR

R

Ae

o

=

e

i

Fc

4 + 2Fc

Ae

o

=

e

i

Fc

4 + 2Fc

If we assume some typical values for the excitation voltage (8V) and the

gage factor (2), then we can see that the second term in the denominator

is not significant:

Ae

o

=

16c

4 + 4c

Ae

o

=

e

i

Fc

4

so

12.8.1 Bridges with 2 and 4 strain gages

The bending strain on the top gage is equal

and opposite of the one on the bottom.

e

o

= e

i

R

2

R

1

+ R

2

R

4

R

3

+ R

4

|

\

|

.

|

make R

2

= R

4

= R

e

o

= e

i

R

R

1

+ R

R

R

3

+ R

|

\

|

.

|

e

o

= e

i

R

R

1

+1

R

R

3

1

|

\

|

.

|

e

o

e

i

= R

1

R

1

1

R

3

|

\

|

.

|

Multiple Gauge Bridge

Most strain gauge measurement systems allow us to make 1, 2, 3 or all 4

legs of the bridge strain gauges. There are many reasons to do this that

we will talk about now.

Going back to our fundamental bridge equations from chapter 6,

E

o

= E

i

R

1

R

1

+ R

2

R

3

R

3

+ R

4

|

\

|

.

|

Say that unstrained, all of these have the

same value. If they are then strained,

the resultant change is E

o

is

dE

o

=

cE

o

cR

i i=1

4

dR

i

E

o

Multiple Gauges

Make the following assumptions:

All gauges have the same nominal resistance (generally true)

All gauges have matched gauge factors (must be purchased as set)

Then:

AE

o

E

i

=

F

4

c

1

c

2

+c

4

c

3

( )

E

o

Apparent Strain and Compensation

Things like temperature can change the resistance of a gauge and our

system may interpret this as strain. Sometimes our gauge may be

subject to strains other than the one we are interested in.

Compensation is removing these effects by using multiple gauges. As

an example, say you have a beam under axial stress and a bending

moment, and you are interested in the axial stress only:

o

x

=12My/bh

3

+ F

N

/bh

The two gauges see the

same axial strain but

opposite bending

strains

Ae

o

e

i

=

F

4

c

1

+ c

4

( )

c

1

= c

a1

+ c

b1

c

4

= c

a4

c

b 4

Ae

o

e

i

=

F

2

c

a

( )

Temperature Compensation

The resistance of a strain gauge changes with temperature. In addition,

changing its temperature may cause strain in the gauge making it even

more sensitive to temperature.

Compensation

12.8.2 Bridge Constant

k =

A

B

k = the bridge constant

A = the actual bridge output

B = the output you would get with a single gage.

12.8.3 Lead-wire Error

Since we are looking at very small changes in resistance, the lead wires

can create significant errors. We handle this the same way we discussed

for RTDs.

We have wire especially made for strain gage

measurements which has three conductors

12.10 Temperature Compensation

R

1

R

2

=

R

3

R

4

R

1

+ AR

t

R

2

+ AR

t

=

R

3

R

4

If the temperature of the

specimen changes, then

both gages will change their

resistance similarly

12.11 Calibration

AR =

R

g

R

s

R

g

+ R

s

( )

R

g

=

R

g

2

R

g

+ R

s

( )

c =

1

F

AR

g

R

g

c

e

=

1

F

R

g

R

g

+ R

s

|

\

|

.

|

|

12.16.1

Multiple gages in series

12.17.1 Cross Sensitivity

e

L

=

K

t

c

L

/c

a

+v

po

( )

1v

po

K

t

100

Semiconductor Strain Gauges

The gauges we have been talking about are made of metal. We can

also make them out of semiconductors, which is how the strain

gauges in our pressure sensors are made. These are dominated by the

piezoresistive component of the change in resistance and have

several advantages and disadvantages:

Pros:

Very high gauge factors (up to 200)

Higher resistance

Longer fatigue life

Lower Hysteresis

Smaller

High frequency response

Cons:

Temperature sensitivity

Nonlinear output

More limited on maximum strain

Mostly used for construction of

transducers

Hysteresis of Strain Gauges

Vous aimerez peut-être aussi

- Mechanical Measurements ApplicationsDocument41 pagesMechanical Measurements Applicationsluis alanPas encore d'évaluation

- Electrical Resistance Strain Gage CircuitsDocument27 pagesElectrical Resistance Strain Gage CircuitsHareesha N GPas encore d'évaluation

- Strain Measurements: - Module GoalsDocument14 pagesStrain Measurements: - Module GoalspachieduPas encore d'évaluation

- Analytical Balance. Sensitivity Increases With L, But Decreases With The Weight of The ArmsDocument23 pagesAnalytical Balance. Sensitivity Increases With L, But Decreases With The Weight of The Armsupendra35Pas encore d'évaluation

- Electrical Resistance Strain Gages: MAE 244 Lab-1 A. 1Document10 pagesElectrical Resistance Strain Gages: MAE 244 Lab-1 A. 1kostas.sierros9374100% (1)

- Current Electricity DoneDocument36 pagesCurrent Electricity DonewhyreadPas encore d'évaluation

- Properties of Resistors Therm Is Tor CharacteristicsDocument12 pagesProperties of Resistors Therm Is Tor CharacteristicsRimsha AttikePas encore d'évaluation

- Strain and Pressure Sensors: PiezoresistivityDocument17 pagesStrain and Pressure Sensors: PiezoresistivitySaleha QuadsiaPas encore d'évaluation

- Unit 1: DC Circuits: Summary and Learning OutcomesDocument12 pagesUnit 1: DC Circuits: Summary and Learning OutcomesKevin CheePas encore d'évaluation

- Expt 5b.strain MeasurementsDocument7 pagesExpt 5b.strain Measurementsnikhil jaiswalPas encore d'évaluation

- BAB 3: PearuhDocument14 pagesBAB 3: PearuhhafizeijaPas encore d'évaluation

- Lecture Notes 15Document8 pagesLecture Notes 15Manish RajanakPas encore d'évaluation

- Applying The Wheatstone Bridge CircuitDocument36 pagesApplying The Wheatstone Bridge CircuitMichael Kang0% (1)

- EE-101 Electrical Technology) - 2012 Mech PDFDocument79 pagesEE-101 Electrical Technology) - 2012 Mech PDFPonteyoss KonjokelossPas encore d'évaluation

- Thermistor ArduinoDocument16 pagesThermistor ArduinoJaume Segura GarciaPas encore d'évaluation

- Mechatronics II Laboratory: Experiment #1: Force and Torque SensorsDocument6 pagesMechatronics II Laboratory: Experiment #1: Force and Torque SensorsGoran MiljkovicPas encore d'évaluation

- Experiment 09Document6 pagesExperiment 09Deepan AdakPas encore d'évaluation

- Bridge PPTDocument74 pagesBridge PPTKarthi ChowdaryPas encore d'évaluation

- Module IIDocument22 pagesModule IIKinoti Mugiira NtundaPas encore d'évaluation

- Strain Gages: DR R D D A ADocument21 pagesStrain Gages: DR R D D A ARitu KapoorPas encore d'évaluation

- Electrical EngineeringDocument12 pagesElectrical EngineeringColton SmithPas encore d'évaluation

- Strain MeasurementDocument6 pagesStrain MeasurementalmarfePas encore d'évaluation

- Force, Torque and StrainDocument22 pagesForce, Torque and StrainLungie MbathaPas encore d'évaluation

- D L M E C: Eriving Ife Ultipliers For Lectrolytic ApacitorsDocument2 pagesD L M E C: Eriving Ife Ultipliers For Lectrolytic ApacitorsTuấn Âm Thanh Hi-endPas encore d'évaluation

- MAE 212: Spring 2001 Module III: Material Property Characterization Using Strain Gage InstrumentationDocument7 pagesMAE 212: Spring 2001 Module III: Material Property Characterization Using Strain Gage InstrumentationChulbul PandeyPas encore d'évaluation

- Example 1Document5 pagesExample 1Neda SpasojevićPas encore d'évaluation

- Resistive Bridge Basics: Part One: Bridge Circuits, Bridges, Wheatstone Bridge, Sigma Delta, Sigma-Delta ConvertersDocument10 pagesResistive Bridge Basics: Part One: Bridge Circuits, Bridges, Wheatstone Bridge, Sigma Delta, Sigma-Delta ConvertersPu DuanPas encore d'évaluation

- Bagay Junee Bscpe Summative-1Document37 pagesBagay Junee Bscpe Summative-1Dylan CosepPas encore d'évaluation

- N.B.C.C. S.J.: Electricity and ElectronicsDocument5 pagesN.B.C.C. S.J.: Electricity and ElectronicsVy ThoaiPas encore d'évaluation

- Meter Bridge Experiment Using Wheatstone Bridge Principle PDFDocument12 pagesMeter Bridge Experiment Using Wheatstone Bridge Principle PDFOm Kumar100% (1)

- TransducersDocument24 pagesTransducersSania NowshinPas encore d'évaluation

- The Negative Temperature Coefficient (NTC) Thermistor and The Light Dependent ResistorDocument3 pagesThe Negative Temperature Coefficient (NTC) Thermistor and The Light Dependent ResistorAyman Mohamed Hashim100% (1)

- Electric Circuit Electric Circuit: It Is A Closed Path, Composed of Active and Passive ElementsDocument22 pagesElectric Circuit Electric Circuit: It Is A Closed Path, Composed of Active and Passive Elementsapi-141028293Pas encore d'évaluation

- Physics Lab Manual For ClassXII (2021-2022)Document33 pagesPhysics Lab Manual For ClassXII (2021-2022)Naveen PrakashPas encore d'évaluation

- Resistive Transducers: Instructor: DR Alivelu M ParimiDocument28 pagesResistive Transducers: Instructor: DR Alivelu M ParimiSaketh DahagamPas encore d'évaluation

- On AC ResistanceDocument4 pagesOn AC ResistancesreedharPas encore d'évaluation

- PTC Ee Tee 7 Us MPDocument4 pagesPTC Ee Tee 7 Us MPbmmostefaPas encore d'évaluation

- Lab 6Document7 pagesLab 6Bhupender SharmaPas encore d'évaluation

- Jntuk R13 Physics Lab Manual PDFDocument62 pagesJntuk R13 Physics Lab Manual PDFgaruda198250% (2)

- Ee-113 Basic Electrical Engineering - 2011Document86 pagesEe-113 Basic Electrical Engineering - 2011Imtiaz HussainPas encore d'évaluation

- XII Practical Lab Manual (2022 - 2023)Document29 pagesXII Practical Lab Manual (2022 - 2023)Kanishk KrishnanPas encore d'évaluation

- Bio Devices and Sensors HW 1: (Abeer U1135709)Document8 pagesBio Devices and Sensors HW 1: (Abeer U1135709)Sayed Abu SufyanPas encore d'évaluation

- Current Proportional Potential Difference Voltage ResistanceDocument32 pagesCurrent Proportional Potential Difference Voltage ResistanceSivaraj ChandrasekaranPas encore d'évaluation

- V Ir (1 Way) I V/R (2 Way) R V/I (3 Way)Document14 pagesV Ir (1 Way) I V/R (2 Way) R V/I (3 Way)bipotor149Pas encore d'évaluation

- Datarc eDocument5 pagesDatarc eAttar RahaPas encore d'évaluation

- Bridge MeasureDocument19 pagesBridge MeasureThanh Nhan LePas encore d'évaluation

- PEEI - Expt - Electrical EnggDocument13 pagesPEEI - Expt - Electrical EnggnickswapPas encore d'évaluation

- Exp 2 Resistors, Ohm's Law, Power Rating and I-V Caharacteristic (2012)Document10 pagesExp 2 Resistors, Ohm's Law, Power Rating and I-V Caharacteristic (2012)usmpowerlabPas encore d'évaluation

- EE131.1 LabDocument40 pagesEE131.1 LabMarc MontillaPas encore d'évaluation

- Principles of Measurement System-FormulaDocument8 pagesPrinciples of Measurement System-FormulaMahdi Imanian100% (1)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1D'EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Pas encore d'évaluation

- A Guide to Electronic Maintenance and RepairsD'EverandA Guide to Electronic Maintenance and RepairsÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Easy(er) Electrical Principles for General Class Ham License (2019-2023)D'EverandEasy(er) Electrical Principles for General Class Ham License (2019-2023)Pas encore d'évaluation

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10D'EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10Pas encore d'évaluation

- Easy(er) Electrical Principles for General Class Ham License (2015-2019)D'EverandEasy(er) Electrical Principles for General Class Ham License (2015-2019)Évaluation : 5 sur 5 étoiles5/5 (1)

- Complete Electronics Self-Teaching Guide with ProjectsD'EverandComplete Electronics Self-Teaching Guide with ProjectsÉvaluation : 3 sur 5 étoiles3/5 (2)

- 01 Beginers Guide To PneumaticsDocument57 pages01 Beginers Guide To Pneumaticsupendra35Pas encore d'évaluation

- 3.4) The Plc's InsideDocument2 pages3.4) The Plc's Insideupendra35Pas encore d'évaluation

- 17) Math InstructionDocument4 pages17) Math Instructionupendra35Pas encore d'évaluation

- Compressed Air-Quality Optimisation For Pneumatic Control SystemDocument19 pagesCompressed Air-Quality Optimisation For Pneumatic Control Systemupendra35Pas encore d'évaluation

- AutomationDocument2 pagesAutomationupendra35Pas encore d'évaluation

- Recorganising The HardwareDocument13 pagesRecorganising The Hardwareupendra35Pas encore d'évaluation

- Nptel - Iitm.ac - in PDF New-Semesterwise-Reading Comp EngineeringDocument4 pagesNptel - Iitm.ac - in PDF New-Semesterwise-Reading Comp Engineeringupendra35Pas encore d'évaluation

- 7) PLC RegistersDocument3 pages7) PLC Registersupendra35Pas encore d'évaluation

- Chapter 6 Induction Motor ConstructionDocument42 pagesChapter 6 Induction Motor Constructionupendra35Pas encore d'évaluation

- 16) Getting & Moving DataDocument5 pages16) Getting & Moving Dataupendra35Pas encore d'évaluation

- Auxillary Switch Terminal BlockDocument2 pagesAuxillary Switch Terminal Blockupendra35Pas encore d'évaluation

- Domestic AC Power Plugs and SocketsDocument34 pagesDomestic AC Power Plugs and Socketsupendra35Pas encore d'évaluation

- Seminar (PLC)Document29 pagesSeminar (PLC)upendra35Pas encore d'évaluation

- AC Inputs: Got A Shock? Be Careful) Typically, Ac Input Modules Are AvailableDocument3 pagesAC Inputs: Got A Shock? Be Careful) Typically, Ac Input Modules Are Availableupendra35Pas encore d'évaluation

- Electropneumatics Basic LevelDocument44 pagesElectropneumatics Basic Levelupendra35Pas encore d'évaluation

- Festo Electrical, Pneumatic and Logic SymbolsDocument1 pageFesto Electrical, Pneumatic and Logic SymbolsAvtomatika Kole Nehtenin50% (2)

- Chapter 6 Induction Motor ConstructionDocument42 pagesChapter 6 Induction Motor Constructionupendra35Pas encore d'évaluation

- Recorganising The HardwareDocument13 pagesRecorganising The Hardwareupendra35Pas encore d'évaluation

- Electric Motor PresentationDocument19 pagesElectric Motor Presentationupendra35Pas encore d'évaluation

- HelloDocument61 pagesHelloJapinder SinghPas encore d'évaluation

- PLCDocument33 pagesPLCupendra35Pas encore d'évaluation

- Snrs 2Document27 pagesSnrs 2www.otomasyonegitimi.comPas encore d'évaluation

- 01 Beginers Guide To PneumaticsDocument57 pages01 Beginers Guide To Pneumaticsupendra35Pas encore d'évaluation

- Electronic Soft Starters: How and Why They Work, and What They Can Do For YouDocument35 pagesElectronic Soft Starters: How and Why They Work, and What They Can Do For Youupendra35Pas encore d'évaluation

- Starter DrivesDocument9 pagesStarter Drivesupendra35Pas encore d'évaluation

- NLC #2Document8 pagesNLC #2aeilorv infantePas encore d'évaluation

- HuanYang 400Hz Setup PDFDocument71 pagesHuanYang 400Hz Setup PDFRadovan KnezevicPas encore d'évaluation

- T2159en MVD500-4701Document18 pagesT2159en MVD500-4701J KeigPas encore d'évaluation

- Long-Wavelength Infrared Semiconductor Lasers PDFDocument406 pagesLong-Wavelength Infrared Semiconductor Lasers PDFKunchur Narayan100% (1)

- Parallel Operation of Power MOSFETDocument7 pagesParallel Operation of Power MOSFETTaqi SyedPas encore d'évaluation

- Linear Technology: Application Note 87 November 2000Document124 pagesLinear Technology: Application Note 87 November 2000stm320% (1)

- 3 PHASE - OSC - A405701-233Document4 pages3 PHASE - OSC - A405701-233Dias AdrPas encore d'évaluation

- Poster Template PortraitDocument1 pagePoster Template PortraitTuanito NguyenPas encore d'évaluation

- Complete Manual For AVR Multi-Tester Version 1.12kDocument128 pagesComplete Manual For AVR Multi-Tester Version 1.12kBenjamin Dover100% (1)

- Micropower Supply Voltage Supervisors: FeaturesDocument38 pagesMicropower Supply Voltage Supervisors: FeaturesVysakh SharmaPas encore d'évaluation

- Trends in Electrical TransmissionDocument47 pagesTrends in Electrical TransmissionSumit Kumar DattaPas encore d'évaluation

- Unisonic Technologies Co., LTD: 2A, 600V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 2A, 600V N-CHANNEL Power Mosfetjsalinas78Pas encore d'évaluation

- PLD GDocument33 pagesPLD GPrince AlexisPas encore d'évaluation

- Module4.Etching - Ee143 f14.CtnDocument20 pagesModule4.Etching - Ee143 f14.CtnstansilawPas encore d'évaluation

- 64 Pixel RGB LED Display Another Arduino CloneDocument17 pages64 Pixel RGB LED Display Another Arduino CloneJúlio César SilveiraPas encore d'évaluation

- Lect ELCE 27 2022Document18 pagesLect ELCE 27 2022Accountfor YoutubePas encore d'évaluation

- Flex Sensor Patents PDFDocument7 pagesFlex Sensor Patents PDFhakam pranatagamaPas encore d'évaluation

- 79G Radar LeafletDocument2 pages79G Radar LeafletLê Đình TiếnPas encore d'évaluation

- Bien Doi DC-DC Ly ThuyetDocument82 pagesBien Doi DC-DC Ly ThuyetCỏ DươngPas encore d'évaluation

- A Hands-On Course in Sensors Using PDFDocument259 pagesA Hands-On Course in Sensors Using PDFeaeros100% (1)

- 12th Grade Physics by Byju'sDocument56 pages12th Grade Physics by Byju'sSoham ChakrabortyPas encore d'évaluation

- Ssd1803a 2 0Document69 pagesSsd1803a 2 0gem1144aaPas encore d'évaluation

- lm339 PDFDocument10 pageslm339 PDFMarcelo VasquezPas encore d'évaluation

- Preset Counters Electronic: 2 Presets, Totalizer and Batch Counter Display LED, 8-Digits, ProgrammableDocument4 pagesPreset Counters Electronic: 2 Presets, Totalizer and Batch Counter Display LED, 8-Digits, Programmablenabil160874Pas encore d'évaluation

- EXPERIMENT Capacitor RC CircuitDocument4 pagesEXPERIMENT Capacitor RC Circuitfaiz shukriPas encore d'évaluation

- 2005 Hill Laser Diode PresentationDocument17 pages2005 Hill Laser Diode PresentationSwapnil BhattacharyaPas encore d'évaluation

- Caddyt Arc 150i Caddyt Tig 150i Origot Tig 150i: Service ManualDocument66 pagesCaddyt Arc 150i Caddyt Tig 150i Origot Tig 150i: Service Manualr_cristiPas encore d'évaluation

- Final Year Project Report Writing GuidelinesV5.0Document8 pagesFinal Year Project Report Writing GuidelinesV5.0Ridzuan RahmanPas encore d'évaluation

- Basics of Electronic Components - Final Print ReadyDocument58 pagesBasics of Electronic Components - Final Print ReadyRodrigoFuenzalidaPas encore d'évaluation

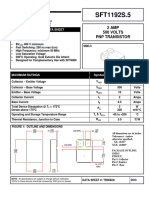

- SFT1192S.5: Solid State Devices, IncDocument2 pagesSFT1192S.5: Solid State Devices, IncIPUNK PURNOMOPas encore d'évaluation