Académique Documents

Professionnel Documents

Culture Documents

Activity Based Costing

Transféré par

hiralpoonaterCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Activity Based Costing

Transféré par

hiralpoonaterDroits d'auteur :

Formats disponibles

ACTIVITY BASED COSTING

Meaning

Activity-Based Costing is a methodology that assigns resources to activities, and activities to cost objects based on a cause-and-effect relationship. ABC is that costing in which costs are first traced to activities and then to the products. It is a costing system which focuses on activities performed to produce products. Activities are responsible for incurrence of Costs.

Provide Quality of information to design a cost system. Distinction between cost behavior patterns which are volume, diversity, events & time. Cost driver need to be identified

Identify activities Determine cost for each activity Determine cost drivers Collect activity data Calculate product cost

Benefits / Advantages of ABC

Focus attention on Activities Most accurate product / service costs Managers manage activities and not products ABC focuses on cause and effect relationship ABC highlights problem areas easily

Limitations / Weakness of ABC

ABC fails to encourage managers to think about changing work processes ABC does not conform to GAAP Costly for long run ABC does not encourage the identification and removal of constraints creating delays and excesses

Difference between ABC and Absorption Costing

abc

absorption

costing

1. Overheads are first related to the 1. Overheads are first related to the activities or grouped into cost pools. various production and service departments. 2. Activity cost drivers can be used to 2. Overhead rates are used determine the cost of the cost objects. ascertain cost of products only. to

3. It portrays more realistic cost 3. Since the overheads are related to the behavior since the overheads are cost centre, a realistic picture of the related to the cost drivers. cost behavior is not portrayed 4. All levels of activities in the 4. Only two levels of activity, i.e. facility manufacturing cost hierarchy i.e. unit level and level are identified. level, batch level, product level and facility level are identified.

Examples of Activity and its Cost Drivers

Machine Set-up Purchase Materials Warehousing Material Handling Inspection Quality Testing Receiving Material Packing Store Delivery Line Item Ordering No. of Production Runs No. of orders Placed Items in Stock No. of Parts Inspection per Item Hours of Test Time No. of Receiving Orders No. of Packing Orders No. of Store Delivers No. of Line Items

Vous aimerez peut-être aussi

- Lone Pine CafeDocument4 pagesLone Pine CafeRahul TiwariPas encore d'évaluation

- Inland Fish Farming URDUDocument17 pagesInland Fish Farming URDUbaloch75100% (4)

- Activity Based CostingDocument29 pagesActivity Based CostingNaga Manasa KPas encore d'évaluation

- Abc CostingDocument27 pagesAbc CostingprasanthmctPas encore d'évaluation

- SC Licensing HandbookDocument75 pagesSC Licensing HandbookYff DickPas encore d'évaluation

- Costing SLE Roll No KFPMCAA030 Dev Shah Mcom Part 1 Sem 3 2022-2023Document19 pagesCosting SLE Roll No KFPMCAA030 Dev Shah Mcom Part 1 Sem 3 2022-2023Dev ShahPas encore d'évaluation

- ABC MethodologyDocument17 pagesABC MethodologyakeeraPas encore d'évaluation

- University of Education Winneba: School of Business Department of Accounting Cost Accounting Lecture SlidesDocument15 pagesUniversity of Education Winneba: School of Business Department of Accounting Cost Accounting Lecture SlidesPrince Nanaba EphsonPas encore d'évaluation

- Steps in Activity Based CostingDocument17 pagesSteps in Activity Based CostingYeshwanth ChordiaPas encore d'évaluation

- Chapter 3 Activity Based Costing - RevisedDocument75 pagesChapter 3 Activity Based Costing - RevisedJaiThra T JamesPas encore d'évaluation

- Sim Dae-Acc213Document99 pagesSim Dae-Acc213Danica Kaye MorcellosPas encore d'évaluation

- Big Picture A - ULOb - ABC and ABMDocument11 pagesBig Picture A - ULOb - ABC and ABMDaisy GuiralPas encore d'évaluation

- Activity-Based Costing and ManagementDocument30 pagesActivity-Based Costing and ManagementKalkidan ZerihunPas encore d'évaluation

- Chapter 6 Cost and Management AcctDocument8 pagesChapter 6 Cost and Management AcctDebebe DanielPas encore d'évaluation

- ABC Lecture NotesDocument8 pagesABC Lecture Notessudeis omaryPas encore d'évaluation

- Activity Based Costing (ABC)Document43 pagesActivity Based Costing (ABC)Snn News TubePas encore d'évaluation

- In Traditional Costing System Below Are The StepsDocument7 pagesIn Traditional Costing System Below Are The StepsNikhil KumarPas encore d'évaluation

- Activity Based Costing (ABC) /value Chain Analysis/ Target Costing/ Life Cycle CostingDocument21 pagesActivity Based Costing (ABC) /value Chain Analysis/ Target Costing/ Life Cycle Costingsonu sah0% (1)

- Lecture 8 and 9 MbaDocument48 pagesLecture 8 and 9 MbaMai Atef DabourPas encore d'évaluation

- Additional Aspect of Product Costing SystemDocument11 pagesAdditional Aspect of Product Costing SystemKris TinePas encore d'évaluation

- Management Accounting 2: MANG2005 Activity-Based Costing (ABC)Document22 pagesManagement Accounting 2: MANG2005 Activity-Based Costing (ABC)万博熠Pas encore d'évaluation

- Activity Based Costing FinalDocument27 pagesActivity Based Costing FinalNamrata KamrushiPas encore d'évaluation

- Activity Based CostingDocument17 pagesActivity Based Costingvinati100% (2)

- Roikhanatun Nafi'Ah, Activity Based Costing SummaryDocument3 pagesRoikhanatun Nafi'Ah, Activity Based Costing SummaryRoikhanatun Nafi'ahPas encore d'évaluation

- 20 & 22 Session Activity Based Costing.Document10 pages20 & 22 Session Activity Based Costing.ribuPas encore d'évaluation

- CHP 19 - Ab&tcDocument18 pagesCHP 19 - Ab&tcjayrjoshiPas encore d'évaluation

- Chapter 18 Activity Based CostingDocument28 pagesChapter 18 Activity Based CostingKağan GrrgnPas encore d'évaluation

- Activity Based CostingDocument24 pagesActivity Based Costingmehnaz kPas encore d'évaluation

- ABC Costing PDFDocument33 pagesABC Costing PDFDrpranav SaraswatPas encore d'évaluation

- Activity Based Costing Is An Accounting MethodologyDocument10 pagesActivity Based Costing Is An Accounting MethodologyNidhi MehrotraPas encore d'évaluation

- Chapter Three PDFDocument33 pagesChapter Three PDFSum AïyahPas encore d'évaluation

- Activity Based and Target CostingDocument18 pagesActivity Based and Target CostingAnupama MenonPas encore d'évaluation

- 11 - AbcDocument27 pages11 - AbcAllen FoureverPas encore d'évaluation

- HMCost2e PPT Ch02Document26 pagesHMCost2e PPT Ch02Nurul Meutia SalsabilaPas encore d'évaluation

- Activity Based Costing - ITL - GROUP 8Document9 pagesActivity Based Costing - ITL - GROUP 8Sanat MohantyPas encore d'évaluation

- 5 - Activity-Based CostingDocument26 pages5 - Activity-Based CostingCharisse Ahnne TosloladoPas encore d'évaluation

- Unit - 3 Activity Based CostingDocument32 pagesUnit - 3 Activity Based CostingHARSHIT KUMAR GUPTA 1923334Pas encore d'évaluation

- Chapter 5 Activity Based CostingDocument48 pagesChapter 5 Activity Based CostingAtif SaeedPas encore d'évaluation

- Cost Accounting Chpater 1Document14 pagesCost Accounting Chpater 1cwarekhaPas encore d'évaluation

- ABC CostingDocument46 pagesABC Costingdon number onePas encore d'évaluation

- Actuvity Based CostingDocument10 pagesActuvity Based Costingbablu159Pas encore d'évaluation

- Chapter 7 AbcDocument5 pagesChapter 7 AbcAyu FaridYaPas encore d'évaluation

- Chapter Five Lecture NoteDocument15 pagesChapter Five Lecture NoteAbrha636Pas encore d'évaluation

- Lesson 3. Abc Costing TheoryDocument27 pagesLesson 3. Abc Costing TheoryChengg JainarPas encore d'évaluation

- Activity Based CostingDocument22 pagesActivity Based CostingClaudette ClementePas encore d'évaluation

- Cost Accounting Traditions and Innovations: Activity-Based Cost Systems For ManagementDocument27 pagesCost Accounting Traditions and Innovations: Activity-Based Cost Systems For ManagementBambang HaryadiPas encore d'évaluation

- Cost Accounting Foundations and Evolutions: Activity-Based Management and Activity-Based CostingDocument48 pagesCost Accounting Foundations and Evolutions: Activity-Based Management and Activity-Based CostingPaolo Angel De VeraPas encore d'évaluation

- Activity Based CostingDocument23 pagesActivity Based CostingVivek KumarPas encore d'évaluation

- Activity Based Costing 2Document28 pagesActivity Based Costing 2Maricon BerjaPas encore d'évaluation

- Activity Based CostingDocument10 pagesActivity Based CostingTejasvi BodkePas encore d'évaluation

- Cost Accounting Foundations and Evolutions: Activity-Based Management and Activity-Based CostingDocument48 pagesCost Accounting Foundations and Evolutions: Activity-Based Management and Activity-Based CostingPaolo Angel De VeraPas encore d'évaluation

- Activity - Based Costing (ABC)Document9 pagesActivity - Based Costing (ABC)May AbiaPas encore d'évaluation

- Elements of TQM:: Process ManagementDocument59 pagesElements of TQM:: Process ManagementJulie Rose DimatatacPas encore d'évaluation

- Activity Based CostingDocument30 pagesActivity Based CostingGwenn VillamorPas encore d'évaluation

- Activity Based CostingDocument9 pagesActivity Based CostingAmitPas encore d'évaluation

- Chapter 24 Activity-Based Costing (ABC) PDFDocument10 pagesChapter 24 Activity-Based Costing (ABC) PDFmaklovesPas encore d'évaluation

- Lesson H - 3 Ch10 Substantive Test of Exp. Cycle Acct.Document21 pagesLesson H - 3 Ch10 Substantive Test of Exp. Cycle Acct.Blacky PinkyPas encore d'évaluation

- Ma2 - Acca - Chapter 1Document24 pagesMa2 - Acca - Chapter 1leducPas encore d'évaluation

- ABC System ConceptsDocument9 pagesABC System ConceptsMaria Lourdes Reynoso VenegasPas encore d'évaluation

- Chapter 7 - Process StrategyDocument56 pagesChapter 7 - Process StrategyVirgo StorePas encore d'évaluation

- Cost Management: A Case for Business Process Re-engineeringD'EverandCost Management: A Case for Business Process Re-engineeringPas encore d'évaluation

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1D'EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Évaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Module 3 - Overhead Allocation and ApportionmentDocument55 pagesModule 3 - Overhead Allocation and Apportionmentkaizen4apexPas encore d'évaluation

- Executive Summary: Sources and Application of FundsDocument6 pagesExecutive Summary: Sources and Application of FundsJimmy DagupanPas encore d'évaluation

- 2023 Mock Paper 1 BRD HL IB Business Management Copy 2Document4 pages2023 Mock Paper 1 BRD HL IB Business Management Copy 2pandasniper567Pas encore d'évaluation

- Essay Writing Traditional Marketing vs. Digital Marketing PDFDocument1 pageEssay Writing Traditional Marketing vs. Digital Marketing PDFAminPas encore d'évaluation

- Annual Report 2011Document41 pagesAnnual Report 2011Moinul HasanPas encore d'évaluation

- 05 Pricing MBADocument42 pages05 Pricing MBAABHIJEET BHUNIA MBA 2021-23 (Delhi)Pas encore d'évaluation

- 1JQS Poultry Farm Chapters 1 4Document41 pages1JQS Poultry Farm Chapters 1 4Alyssa TordesillasPas encore d'évaluation

- CPP PPT Gr-13 FinalDocument21 pagesCPP PPT Gr-13 FinalChetan SonawanePas encore d'évaluation

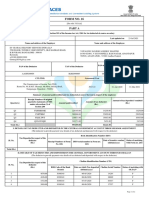

- Form No. 16: Part ADocument6 pagesForm No. 16: Part AVinuthna ChinnapaPas encore d'évaluation

- Ch5 MSA-Making-the-Franchise-Decision-WorkbookDocument95 pagesCh5 MSA-Making-the-Franchise-Decision-Workbookนายชัยสิทธิ์ เพชรรังษีPas encore d'évaluation

- ACCA Membership To ICPAPDocument4 pagesACCA Membership To ICPAPMian Muhammad Talha MehmoodPas encore d'évaluation

- OligopolyDocument15 pagesOligopolySS CreationsPas encore d'évaluation

- OPM555 - Assignment 1 - NUR FATMA SYAZANA MOHD HILMI - 2018808652Document11 pagesOPM555 - Assignment 1 - NUR FATMA SYAZANA MOHD HILMI - 2018808652Nur Fatma Syazana Mohd HilmiPas encore d'évaluation

- Session6 - OD InterventionDocument4 pagesSession6 - OD InterventionPriyam BatraPas encore d'évaluation

- Annual Report 2022Document169 pagesAnnual Report 2022Yahia MustafaPas encore d'évaluation

- Fin AcctgDocument9 pagesFin AcctgCarl Angelo0% (1)

- A Descriptive Analysis of Consumer'S Adoption of E-WalletsDocument19 pagesA Descriptive Analysis of Consumer'S Adoption of E-WalletsAndrea TugotPas encore d'évaluation

- Competitive Intelligence On The InternetDocument4 pagesCompetitive Intelligence On The Internetprofthadaskew4433Pas encore d'évaluation

- Bus Fin - QTR 2 Week 3 - Personal FinanceDocument33 pagesBus Fin - QTR 2 Week 3 - Personal FinanceSheila Marie Ann Magcalas-GaluraPas encore d'évaluation

- Investor Presentation MARCH 2011: A Global Leader in Integrated Clean Air Solutions For IndustryDocument33 pagesInvestor Presentation MARCH 2011: A Global Leader in Integrated Clean Air Solutions For IndustrymynameisvinnPas encore d'évaluation

- Ifs GMP Checklist Pac enDocument9 pagesIfs GMP Checklist Pac enCevdet BEŞENPas encore d'évaluation

- Miguel Angel Ariza SalazarDocument3 pagesMiguel Angel Ariza SalazarGreen InkPas encore d'évaluation

- Tax Collector Correspondence4210107211917Document2 pagesTax Collector Correspondence4210107211917Amsal Asif Kasbati0% (1)

- Notice Inviting Tender (NIT) For Empanelment of Survey Agencies For Conducting Surveys On Households and EnterprisesDocument56 pagesNotice Inviting Tender (NIT) For Empanelment of Survey Agencies For Conducting Surveys On Households and Enterprisesssat111Pas encore d'évaluation

- Lecture 3 MoodleDocument29 pagesLecture 3 MoodlepisicutzaaPas encore d'évaluation

- List of Accredited Agents Training Institutes in Nothern Zone Approved by The Authority - As Per Data Received Upto 31/07/2006Document118 pagesList of Accredited Agents Training Institutes in Nothern Zone Approved by The Authority - As Per Data Received Upto 31/07/2006arbaz khanPas encore d'évaluation

- Activity 1 Venn Diagram of Financial Market and Financial InstitutionsDocument1 pageActivity 1 Venn Diagram of Financial Market and Financial InstitutionsBea3Pas encore d'évaluation