Académique Documents

Professionnel Documents

Culture Documents

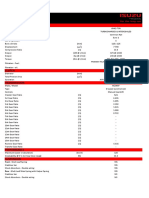

Transmission System

Transféré par

thekla21_971383176Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Transmission System

Transféré par

thekla21_971383176Droits d'auteur :

Formats disponibles

TRANSMISSION

It is the mechanism through which the driving torque of the engine is transmitted to the driving wheel of the vehicle so that the motor vehicle can move on the road. The reciprocating motion of the piston turns a crankshaft rotating the flywheel through the connecting rod. The circular motion of the crank shaft is now to be transmitted to the rear wheels. It is transmitted through the clutch, gear box, universal joints, propeller shaft or drive shaft, differential & axles extending to the wheels. The application of engine power to the driving wheels through all these parts is called POWER TRANSMISSION. The power system is usually the same on all modem passenger cars & trucks, but its arrangement may vary according to the method of drive & type of the transmission units.

HOW TRANSMISSION SYSTEM WORKS? Fig. shows the power transmission system of an automobile. The motion of the crankshaft is transmitted through the clutch to the gear box transmission, which consists of a set of gears to change the speed. From gear box the motion is transmitted to the propeller shaft through an universal joint. Universal joint is used where the two rotating shafts are connected at an angle for power transmission. Finally, the power is transmitted to the rear wheels through rear axles. The differential provides relative motion to the two rear wheels while vehicle is taking turn, thus the power developed inside the cylinder is transmitted to the rear wheels through a system of transmission.

THE PURPOSE OF TRANSMISSION ARE 1. It enables the engine to be disconnected from the driving wheels. 2. It enables the running engine to be connected to the driving wheel smoothly & without shock. 3. It enables the leverage between the engine & the driving wheels to be varied. 4. It enables the reduction of engine speed in the ratio of 4:1. In case of passenger cars & in a greater ratio in case of lorries. 5. It enables the turning of drive through 90o 6. It enables the driving wheels to be driven at different speeds. 7. It enables the relative movement betwccn the enginc & the driving wheel is due to flexing of the road springs.

TYPES OF TRANSMISSION SYSTEMS The various types of transmission system are classified into three main types as under:1) Mechanical transmission. 2) Hydraulic transmission a) Hydrodynamic b) Hydrostatic 3) Electrical & electromagnetic. Out of the above three types, mechanical type transmission is the most common. Numerous types of mechanical transmission are used in different types of automobiles. They can be classified into three types as under, a) Clutch, gear box & Live axle transmission. b) Clutch, gear box & dead axle transmission. c) Clutch, gear box & axle less transmission. Different parts of the power transmission system will be discussed in the following chapters.

CLUTCH Clutch is a device used in the transmission system of a motor vehicle to engage and disengage the engine to the transmission. Thus the clutch is located between the engine & the transmission.

REQUIREMENTS OF CLUTCH 1) Torque transmission :- The clutch should be able to transmit maximum torque of the engine. 2) Gradual Engagement :- The clutch should engage gradually to avoid sudden jerks. 3) Heat dissipation :- The clutch should be able to dissipate large amount of heat which is generated during the clutch operation due to friction., 4) Dynamic balancing :- Clutch should be dynamically balanced particularly required in case of high speed engine clutches. 5) Vibration damping :- Suitable mechanism should be incorporated within the clutch, to eliminate noise produced in the transmission. 6) Size The clutch should be as small as possible in size so that it will occupy minimum space. 7) Free pedal play :- The clutch should have free pedal plag in order to reduce effective load on the carbon thrust bearing & wear on it. 8) Easy in operation :- The clutch should be easy to operate requiring as little exertion as possible on the part of drive. 9) Lightness :- The driven member of the clutch should be made as light as possible so that it will not continue to rotate for any length of time after the clutch has been disengaged.

MAIN PARTS OF A CLUTCH :- The main parts of a clutch are divided into three groups. 1) Driving members 2) Driven members 3) Operating members Driving Members :- It consists of a flywheel mounted on the engine crankshaft. The flywheel is bolted to covers which carries a pressure plate or driving disc, pressure springs & releasing levers. This entire assembly of flywheel & cover rotate all the times. Driven members :- Consists of a disc or plate called the clutch plate which carries friction material on both of its surface. Operating members :- Consists of a foot pedal, linkage release or thrown-out bearing. Release levers & the springs necessary to insure proper operation of clutch.

TYPES OF FRICTION MATERIALS:- The friction materials of the clutch plate are generally of three types. 1) Mill board type. 2) Moulded type. 3) Woven type. Mill board type includes asbestos sheet treated with different types of impregnats, Cheap & quite satisfactory in operation. Moulded type friction materials are made from a matrix of asbestos fiber & starch or any other suitable binding material. Woven type facing materials are made by impregnating a cloth with certain binders or by wearing threads of brass or copper wires covered with long fibers asbestos & cotton. The woven sheet treated with binding solution are baked & rolled. The most common friction materials are: 1) Leather :- Co-efficient of friction ( ji ) = 0.27 2) Cork :- Co-efficient of friction ( t) = 0.32 3) Fabric :- Co-efficient of friction ( i) = 0.40 4) Asbestos:-Co-efficient of friction ( t) = 0.20 5) Reybestos & Ferado :- Co-efficient of friction ( i) = 0.20

PROPERTIES OF GOOD CLUTCH LINING :- OR ( FACING) Good wearing properties. High Co-efficient of friction. High resistance to heat. Good binder in it. Cheaper & easy to manufacture.

TYPES OF CLUTCHES 1) Friction clutch a) Single plate clutch b) Multiplate clutch i) wet ii) dry c) Cone clutch i) external ii) internal 2) Centrifugal clutch 3) Semi-centrifugal clutch 4) Conical spring clutch or diaphragm clutch a) Tapered finger type b) crown spring type 5) Positive clutch- Dog & spline clutch 6) Hydraulic clutch 7) Electro-magnetic clutch

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Group 0.001A Engine Conversion Packages: Chevrolet 60° V6Document5 pagesGroup 0.001A Engine Conversion Packages: Chevrolet 60° V6Jackson LaRosePas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 008 - CAT-6040 - RH170B - Travel SystemDocument28 pages008 - CAT-6040 - RH170B - Travel SystemJorby Cuadros100% (1)

- (Ebook) The BG Tuning ManualDocument72 pages(Ebook) The BG Tuning ManualMuhammad Akbar PradiptaPas encore d'évaluation

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- Part Bookpc200 6Document370 pagesPart Bookpc200 6M Ramzi100% (3)

- Competitive Analysis Motorcycle Repair Service (San Francisco)Document5 pagesCompetitive Analysis Motorcycle Repair Service (San Francisco)Ivan LockePas encore d'évaluation

- Fuction1 MANAGE THE OPERATION OF PROPULSION PLANT UPDATEDocument4 pagesFuction1 MANAGE THE OPERATION OF PROPULSION PLANT UPDATEAdii100% (1)

- EH1700 Hydraulic Training Manual - HTT1700!10!1007Document82 pagesEH1700 Hydraulic Training Manual - HTT1700!10!1007Jacques Van Niekerk100% (2)

- LHB Handbook On Maintof Air Brake System in LHB Coaches (FTIL Type)Document120 pagesLHB Handbook On Maintof Air Brake System in LHB Coaches (FTIL Type)Rakesh Jainwal100% (4)

- 1994-2002-Audi A8 and S8 Fuse Box DiagramDocument11 pages1994-2002-Audi A8 and S8 Fuse Box DiagramAlberto MiglinoPas encore d'évaluation

- Ingersoll-Rand Compressors 15T2Document2 pagesIngersoll-Rand Compressors 15T2Dedi Mulyana100% (1)

- Batteries-Types of Baterries, Principle and Construction of Lead Acid BatteryDocument3 pagesBatteries-Types of Baterries, Principle and Construction of Lead Acid BatterypriyaPas encore d'évaluation

- 01 Motor Engine ADocument67 pages01 Motor Engine AFranky FernandezPas encore d'évaluation

- Verificare Bujii IncandescenteDocument1 pageVerificare Bujii IncandescentemihaimartonPas encore d'évaluation

- Ingles 2T Nivel 4Document4 pagesIngles 2T Nivel 4ciclobasicohuergoPas encore d'évaluation

- HUFFY Bicycle Multispeed - ManualDocument44 pagesHUFFY Bicycle Multispeed - ManualottuserPas encore d'évaluation

- Sail NB Diesel MY15 28287957Document212 pagesSail NB Diesel MY15 28287957L Pampana100% (1)

- 0010 - Check Sheet PS PC400-7 KOMATSU 2Document2 pages0010 - Check Sheet PS PC400-7 KOMATSU 2sahruna japurPas encore d'évaluation

- Duplex Oil FilterDocument2 pagesDuplex Oil Filterbenjir shuvoPas encore d'évaluation

- European - JE Pistons AudiDocument2 pagesEuropean - JE Pistons AudivepsmotorsportPas encore d'évaluation

- OilChange DV6Document1 pageOilChange DV6ismael23Pas encore d'évaluation

- 981-0259 Onan HDCAA HDCAB (Spec A-D) Diesel Mobile Genset Parts Manual (10-2013)Document68 pages981-0259 Onan HDCAA HDCAB (Spec A-D) Diesel Mobile Genset Parts Manual (10-2013)Granville BarkerPas encore d'évaluation

- PRA - SR HAWKJAW - Part Replacement RecommendationDocument5 pagesPRA - SR HAWKJAW - Part Replacement RecommendationAnggoroPas encore d'évaluation

- S I L 9 8 - 9 C: Service Information LetterDocument4 pagesS I L 9 8 - 9 C: Service Information Lettertuandede03Pas encore d'évaluation

- 2 Variable Valve TimingDocument30 pages2 Variable Valve TimingAlex Mariei100% (1)

- MCQDocument5 pagesMCQSathis Kumar67% (12)

- This Is Your New Orca Aero M10Iltd: Ref: M137Ttcc SIZE: 55Document6 pagesThis Is Your New Orca Aero M10Iltd: Ref: M137Ttcc SIZE: 55Derrek KangPas encore d'évaluation

- Engine: Front: Multi Leaf SpringDocument3 pagesEngine: Front: Multi Leaf SpringKasidinPas encore d'évaluation

- Price Forvolvo 940 Spare PartDocument15 pagesPrice Forvolvo 940 Spare Partaswad97Pas encore d'évaluation

- GS80 Parts ManualDocument248 pagesGS80 Parts ManualUbaldo Enrique Caraballo EstradaPas encore d'évaluation