Académique Documents

Professionnel Documents

Culture Documents

Kiln Shell Compressed 96 Dpi

Transféré par

Roderick Nieto MendezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kiln Shell Compressed 96 Dpi

Transféré par

Roderick Nieto MendezDroits d'auteur :

Formats disponibles

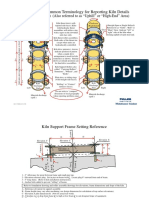

Rotary Kiln Maintenance Seminar

Kiln Shell

Kiln Shell

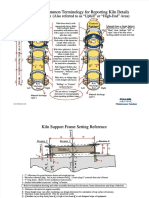

Shell Details

Kiln Crank Measuring Kiln Crank Heat Correction of Kiln Crank Shell Repair Shell Welding Submerged Arc Welding

Kiln Shell 2

Shell Details

Kiln Shell

Shell Details

Inlet Cone

Tire No. 3

Tire No. 2

Tire No. 1

Outlet Shroud

30 mm

40 mm (gear)

30 mm

30 mm

50 mm 75 mm (under tire)

40 mm 75 mm (under tire)

40 mm

80 mm (under tire)

40 mm

Typical shell plate thicknesses.

Kiln Shell

Kiln Crank

Kiln Shell

Kiln Crank

Kiln crank occurs when a kiln shell is not perfectly straight. As the shell turns, cyclical loads and stresses occur in the shell and the kiln supports.

Kiln Shell 6

Kiln Crank

Kiln crank can cause severe cyclical loads, leading to shell cracks and fatigue cracks in the roller shafts.

Kiln Shell

Kiln Crank

Kiln crank will result in gear misalignment which can destroy gear teeth.

Kiln Shell

Kiln Crank

Kiln crank can be temporary, as in the case of a rain warped shell, or permanent, as in the case of a shell damaged by heat blisters.

Kiln Shell 9

Kiln Crank

When a hot kiln is stopped during a heavy rainstorm, one side of the shell cools off and contracts, causing a concave up curvature.

Kiln Shell

10

Kiln Crank

When a hot kiln is stopped too long without rotation, heat will rise and the top of the shell will expand, causing a convex-up curvature.

Kiln Shell

11

Kiln Crank

Irregular coating formation or refractory wear can cause one side of the shell to heat up more than the other. The result is a temporary crank in the shell.

Kiln Shell 12

Kiln Crank

Damaged refractory will cause a hot spot in the shell.

Kiln Shell 13

Kiln Crank

A hot spot left unattended will wrinkle the shell and create a crank. Refractory bricks will no longer stay in place and the shell section will have to be replaced at great expense.

Kiln Shell 14

Heat Damaged Kiln Shell

A heat-wrinkled kiln shell will also shorten the kiln, causing tires to run off-center.

Kiln Shell 15

Kiln Crank

Kiln crank can be caused by poor alignment of kiln sections during assembly or repair.

Kiln Shell

16

Kiln Crank

Kiln crank can be caused by weld shrinkage at a temporary shell patch.

Kiln Shell 17

Measuring Kiln Crank

Kiln Shell

18

Measuring Kiln Crank

Kiln crank can be identified by measuring roller deflection. The load on the roller will change as the kiln turns and this results in bending of the roller shaft.

Kiln Shell 19

Measuring Kiln Crank

A roller that deflects cyclically with kiln rotation by over 0.3 mm typically indicates a crank in the shell that should be repaired.

Kiln Shell 20

Measuring Kiln Crank

Kiln crank can be measured by measuring shell runout. A polar diagram is generated on which the deviation from the true kiln center can be seen.

Kiln Shell 21

Measuring Kiln Crank

A series of polar diagrams gives a picture of the shell crank.

Kiln Shell 22

Heat Correction of Kiln Crank

Kiln Shell

23

Heat Correction of Kiln Crank

A kiln shell can sometimes be straightened by heat correction. Insulation is wrapped around the shell, allowing the shell steel to overheat. Shell stresses then diminish as the kiln sags into place on the rollers.

Kiln Shell 24

Heat Correction of Kiln Crank

Temperature sensors are installed to carefully monitor shell temperatures beneath the insulation during the correction process.

Kiln Shell 25

Heat Correction of Kiln Crank

Kiln Shell

26

Shell Repair

Kiln Shell

27

Shell Repair

Major shell defects are normally repaired by replacing the damaged section. The bandaid approach is at best a temporary solution.

Kiln Shell 28

Field Joint Hardware

New shell sections are joined with adjustable erection lugs.

Kiln Shell 29

Shell Alignment

By adjusting the erection lugs the shell sections are straightened until a perfect centerline is achieved.

Kiln Shell

30

Tire Handling

Kiln Shell

31

Shell Rigging

Kiln Shell

32

Shell Rigging

Kiln Shell

33

Shell Handling

Kiln Shell

34

Spider Bracing

Kiln Shell

35

Spider Bracing

Kiln Shell

36

Spider Bracing

Kiln Shell

37

Shell Stiffening Rings

Many older kilns had shell stiffening rings. These rings would eventually cause shell cracks due to heat expansion. Field-cutting expansion slots may help this problem.

Kiln Shell 38

Shell Welding

Kiln Shell

39

Joint Preparation

Prior to welding the shell plate ends are carefully prepared.

Kiln Shell

40

Weld Shrinkage

The 60 double V weld results in less shrinkage and less weld metal being required. Weld distortion is minimized, avoiding the gull-wing effect.

Kiln Shell 41

Weld Shrinkage

Kiln Shell

42

Shell Welding

Kiln Shell

43

Shell Welding

After completing the outside weld, the root pass is removed using carbon arc gouging.

Kiln Shell 44

Shell Welding

After gouging, the joint is carefully cleaned and inspected to ensure that no defects from the root pass remain.

Kiln Shell 45

Shell Welding

When welding is finished, the joint is inspected radiography or ultrasound. Defects are marked and then repaired.

Kiln Shell 46

Submerged Arc Welding

Kiln Shell

47

Submerged Arc Welding

Kiln Shell

48

Submerged Arc Welding

Kiln Shell

49

Submerged Arc Welding

Kiln Shell

50

Submerged Arc Welding

Kiln Shell

51

Submerged Arc Welding

The depth of penetration increases with increased current.

The depth of penetration is also dependant of the welding speed.

Kiln Shell

52

Submerged Arc Welding

The depth of penetration is high with the welding rod as PLUS POLE and law with the welding rod as MINUS POLE.

Kiln Shell

53

Submerged Arc Welding

Kiln Shell

54

Submerged Arc Welding

Kiln Shell

55

Submerged Arc Welding

Kiln Shell

56

Submerged Arc Welding

Kiln Shell

57

Submerged Arc Welding

Kiln Shell

58

Submerged Arc Welding

Kiln Shell

59

Submerged Arc Welding

Kiln Shell

60

Submerged Arc Welding

Kiln Shell

61

Submerged Arc Welding

Kiln Shell

62

Submerged Arc Welding

Kiln Shell

63

Submerged Arc Welding

Kiln Shell

64

Vous aimerez peut-être aussi

- Aprilia Pegaso 650 Strada Trail 1997-2005 Factory Service Repair Manual Download PDFDocument144 pagesAprilia Pegaso 650 Strada Trail 1997-2005 Factory Service Repair Manual Download PDFDavidPrasti100% (1)

- PDF Rotary Kiln Erection CompressDocument139 pagesPDF Rotary Kiln Erection CompressIqbal PT PKMPas encore d'évaluation

- AIS List of Automotive StandardDocument7 pagesAIS List of Automotive StandardPermeshwara Nand BhattPas encore d'évaluation

- CH 1 Cylinder Block Cylinder Head, GasketsDocument49 pagesCH 1 Cylinder Block Cylinder Head, GasketsBogdan Constantin CristeaPas encore d'évaluation

- Exemplary Hot Kiln Alignment ReportDocument82 pagesExemplary Hot Kiln Alignment ReportsamihakhanPas encore d'évaluation

- Kiln Migration and Its Effect On Brick LiningDocument3 pagesKiln Migration and Its Effect On Brick LiningJunaid Mazhar100% (2)

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderD'EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderPas encore d'évaluation

- Support Roller - AKSDocument31 pagesSupport Roller - AKSAnanth Iyer91% (11)

- Hot Kiln AlignmentDocument24 pagesHot Kiln AlignmentNael100% (2)

- Cylinder Liner TheoryDocument83 pagesCylinder Liner TheoryKamal Kumar100% (1)

- KilnDocument26 pagesKilnVishnu Vardhan . C100% (4)

- RollerDocument35 pagesRollergun100% (1)

- Kiln ShellDocument2 pagesKiln Shellfoxmancement100% (1)

- Function Description 9 Litre Engine With 5 CylindersDocument26 pagesFunction Description 9 Litre Engine With 5 CylindersCharlie RebañoPas encore d'évaluation

- Graphite Blocks - Gear Lubricant - Rotary Kilns - PKSEDocument7 pagesGraphite Blocks - Gear Lubricant - Rotary Kilns - PKSEliofasPas encore d'évaluation

- KILN TechnicalDocument37 pagesKILN TechnicalVisnu SankarPas encore d'évaluation

- Kiln Mechanics - (1.1) - ''Basic Notions''Document55 pagesKiln Mechanics - (1.1) - ''Basic Notions''Diego AlejandroPas encore d'évaluation

- 3 Rollers Skewing - ADocument9 pages3 Rollers Skewing - AFurqan ShabbirPas encore d'évaluation

- Kiln Mechanics - (1.3) - ''Design''.ppsDocument110 pagesKiln Mechanics - (1.3) - ''Design''.ppsDiego AlejandroPas encore d'évaluation

- Rotary Kiln ErectionDocument139 pagesRotary Kiln Erectionemadsabri100% (9)

- 2016 - 06 - PeG (Overhauling Report of MAAG Gear by Peter Gunsch)Document10 pages2016 - 06 - PeG (Overhauling Report of MAAG Gear by Peter Gunsch)AamirKhanPas encore d'évaluation

- Kiln MechanicsDocument59 pagesKiln Mechanicstricky77785% (13)

- Class 4 Frequent Asked Qs Shashwat000Document168 pagesClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- Mech Kiln InspectionDocument2 pagesMech Kiln InspectionMohamed ShehataPas encore d'évaluation

- JLG 450aj Parts ManualDocument490 pagesJLG 450aj Parts ManualGanapati Hegde100% (2)

- Comprehensive Alignment of Kiln PDFDocument95 pagesComprehensive Alignment of Kiln PDFAamirKhanPas encore d'évaluation

- Kiln DriveDocument20 pagesKiln DriveSamehibrahem100% (5)

- Phillips Kiln Tires ServicesDocument53 pagesPhillips Kiln Tires ServicesNael100% (14)

- Kiln Erection ProblemsDocument10 pagesKiln Erection Problemsmuhammad mujahidPas encore d'évaluation

- Phillips Kiln Kiln Alignment Gebhart 2006Document36 pagesPhillips Kiln Kiln Alignment Gebhart 2006mustaf100% (2)

- Combilift C4000 Operators ManualMDocument34 pagesCombilift C4000 Operators ManualMoleg796267% (3)

- Clinker Cooler SystemDocument69 pagesClinker Cooler SystemzementheadPas encore d'évaluation

- Rotary Kiln AlignmentDocument1 pageRotary Kiln AlignmentAnonymous YY2JbqyjMt100% (1)

- Aircraft TireDocument6 pagesAircraft TireBookMaggotPas encore d'évaluation

- HL770 9aDocument635 pagesHL770 9aAnonymous yjK3peI7100% (3)

- S.C.C. Kiln Inspection Fls 4-2005Document66 pagesS.C.C. Kiln Inspection Fls 4-2005Mohammed gPas encore d'évaluation

- What To Do When A Kiln Tire Stops MigratingDocument16 pagesWhat To Do When A Kiln Tire Stops MigratingVisnu Sankar100% (3)

- 1 Exemplary Technical Report 2012Document99 pages1 Exemplary Technical Report 2012MKPashaPashaPas encore d'évaluation

- Kiln ErectionDocument13 pagesKiln ErectionAkshay Kadbe67% (3)

- 4.kiln SupportsDocument74 pages4.kiln SupportsKayıhan Çağlar96% (23)

- Kiln Mechanics - (4.1) - ''Action Plan''Document5 pagesKiln Mechanics - (4.1) - ''Action Plan''Diego AlejandroPas encore d'évaluation

- Kiln Alignment AnalysisDocument32 pagesKiln Alignment Analysiszementhead100% (6)

- Msi 30 TDocument124 pagesMsi 30 TKiril AngelovPas encore d'évaluation

- 1.hornos RotatoriosDocument493 pages1.hornos RotatoriosRonald100% (4)

- Hot Kiln SurveyDocument2 pagesHot Kiln SurveyHenok Moges KassahunPas encore d'évaluation

- Watchmaking ExcerpDocument21 pagesWatchmaking Excerpharyantosumanto100% (4)

- The KilnDocument43 pagesThe Kilnraja ghoshPas encore d'évaluation

- Kiln LiningDocument39 pagesKiln LiningMUNNALURU UMAKANTHA RAO100% (1)

- Philips Kiln ServicesDocument20 pagesPhilips Kiln ServicesAbul Qasim QasimPas encore d'évaluation

- Rotary KilnDocument66 pagesRotary KilnAbiodun Ilori100% (4)

- 011-Repl of Kiln Shell Under TyreDocument32 pages011-Repl of Kiln Shell Under Tyremkpq100% (3)

- Kiln Mechanics 222222Document59 pagesKiln Mechanics 222222Said EL FakkoussiPas encore d'évaluation

- Cooler ETA Vs Grate JG (Document39 pagesCooler ETA Vs Grate JG (NaelPas encore d'évaluation

- Rotary Inclinometer Product DescriptionDocument8 pagesRotary Inclinometer Product DescriptionfetniPas encore d'évaluation

- Rotary Kiln: Compax CoolerDocument13 pagesRotary Kiln: Compax CoolerPablo SandovalPas encore d'évaluation

- FLS KilnAlign and ShellFlexDocument66 pagesFLS KilnAlign and ShellFlexMoud Sakly100% (5)

- Rotary Kiln PDFDocument49 pagesRotary Kiln PDFVictor Maruli100% (1)

- Rotary KilnDocument58 pagesRotary KilnFrancisco Uribe Parra100% (7)

- 2019 Mechanical Maintenance of Rotary Kilns and DryersDocument6 pages2019 Mechanical Maintenance of Rotary Kilns and DryersMario PuentePas encore d'évaluation

- Mechanical Maintenance of Rotary KilnDocument56 pagesMechanical Maintenance of Rotary KilnAnonymous 89ooer100% (1)

- Compax Installation, GeneralDocument21 pagesCompax Installation, GeneralPablo Sandoval100% (1)

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceAlbar Budiman100% (6)

- Diesel Engines 4Document4 pagesDiesel Engines 4Thiet PhamPas encore d'évaluation

- Pending Job of CPWDocument2 pagesPending Job of CPWvinodsnPas encore d'évaluation

- Pending Job of CPWDocument2 pagesPending Job of CPWvinodsnPas encore d'évaluation

- LGP REPORT #3 - SimpasaDocument15 pagesLGP REPORT #3 - SimpasaBeckham ChailePas encore d'évaluation

- Requirements For Checklists Before Putting A Forklift Into UseDocument11 pagesRequirements For Checklists Before Putting A Forklift Into UsekasivisanadhPas encore d'évaluation

- TM 5-2330-361-14P Hyster Hp15t-Mil TrailerDocument152 pagesTM 5-2330-361-14P Hyster Hp15t-Mil TrailerAdvocatePas encore d'évaluation

- Mil HDBK 695DDocument45 pagesMil HDBK 695Dfrank_jr_2Pas encore d'évaluation

- Titan-RTR (Ready To Run)Document34 pagesTitan-RTR (Ready To Run)caller10023Pas encore d'évaluation

- Basic Considerations For The Concepts of Wheeled Off-Road Vehicles PDFDocument8 pagesBasic Considerations For The Concepts of Wheeled Off-Road Vehicles PDFAnonymous ePcnZoBEPas encore d'évaluation

- 2009 01 0822 PC Crash Dolly Rollover AnalysisDocument13 pages2009 01 0822 PC Crash Dolly Rollover Analysisramadan1978Pas encore d'évaluation

- F 1806 - 97 r01 - Rje4mdytotdsmdeDocument6 pagesF 1806 - 97 r01 - Rje4mdytotdsmdeMorched TounsiPas encore d'évaluation

- Rovi X 3 Power Wheelchair User ManualDocument44 pagesRovi X 3 Power Wheelchair User ManualOsama QureshiPas encore d'évaluation

- Permobil c350Document68 pagesPermobil c350Laurent ColartPas encore d'évaluation

- Mio Amore - Aftermarket Tires and RimsDocument1 pageMio Amore - Aftermarket Tires and Rimsmotley crewzPas encore d'évaluation

- CPD4550F8 Li Ion en Brochure 1Document4 pagesCPD4550F8 Li Ion en Brochure 1Bersanz Srl100% (1)

- GARAGETECHNICCATALOGDocument55 pagesGARAGETECHNICCATALOGAbdurahimPas encore d'évaluation

- OSTDocument11 pagesOSTSreekalaPas encore d'évaluation

- Cub CadetDocument40 pagesCub CadetKen LangPas encore d'évaluation

- At Iva Gear Up CatalogueDocument12 pagesAt Iva Gear Up Cataloguewave umaPas encore d'évaluation

- ContourDocument35 pagesContourgenefusion0% (1)

- SW936K1 Brochure - May 2022 Edition-PERFILDocument9 pagesSW936K1 Brochure - May 2022 Edition-PERFILPablo GarnicaPas encore d'évaluation

- 47 - Sri Lanka Waste RubberDocument5 pages47 - Sri Lanka Waste RubberthisarisiriwardhanePas encore d'évaluation

- Wheel AlignmentDocument7 pagesWheel AlignmentJOIJODEPas encore d'évaluation

- Sains Y4Document24 pagesSains Y4AkuMrWPas encore d'évaluation

- 2015 TAG TAGUSA RulesDocument30 pages2015 TAG TAGUSA Rulesapi-284391570Pas encore d'évaluation

- Wheel Loader: Engine Power 66,0 KW / 88,5 HP at 2.350 RPM Operating Weight 6.875 - 7.180 KG Bucket Capacity 1,05 - 1,80 MDocument12 pagesWheel Loader: Engine Power 66,0 KW / 88,5 HP at 2.350 RPM Operating Weight 6.875 - 7.180 KG Bucket Capacity 1,05 - 1,80 MJimmyPas encore d'évaluation

- Marketplace - May 2010Document32 pagesMarketplace - May 2010Prime Creative MediaPas encore d'évaluation