Académique Documents

Professionnel Documents

Culture Documents

Dr. A. Aziz Bazoune: Mechanical Engineering Department

Transféré par

Vikram BorkhediyaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dr. A. Aziz Bazoune: Mechanical Engineering Department

Transféré par

Vikram BorkhediyaDroits d'auteur :

Formats disponibles

Dr. A.

Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Dr. A. Aziz Bazoune

King Fahd University of Petroleum & Minerals

Mechanical Engineering Department

CH-18 LEC 30 Slide 1

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

18-1 Introduction .922

18-2 Geometric Constraints .927

18-3 Strength Constraints .933

18-4 Strength Constraints Additional Methods .940

18-5 Shaft Materials .944

18-6 Hollow Shafts .944

18-7 Critical Speeds (Omitted) .945

18-8 Shaft Design .950

CH-18 LEC 30 Slide 2

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

18-1 Introduction .922

18-2 Geometric Constraints .927

18-3 Strength Constraints .933

CH-18 LEC 30 Slide 3

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 4

Neglecting axial loads because they are comparatively very small at critical

locations where bending and torsion dominate. Remember the fluctuating

stresses due to bending and torsion are given by

Fatigue Analysis of shafts

a m

a f m f

a m

a fs m fs

M C M C

K K

I I

T C T C

K K

J J

o o

t t

= =

= =

M

m

: Midrange bending moment,

m

: Midrange bending stress

M

a

: alternating bending moment,

a

: alternating bending stress

T

m

: Midrange torque,

m

: Midrange shear stress

T

a

: alternating torque,

m

: Midrange shear stress

K

f

: fatigue stress concentration factor for bending

K

fs

: fatigue stress concentration factor for torsion

CH-18 LEC 30 Slide 4

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 5

For solid shaft with round cross section, appropriate geometry terms can be

introduced for C, I and J resulting in

Fatigue Analysis of shafts

32 32

16 16

a m

a f m f

a m

a fs m fs

M M

K K

I I

T T

K K

J J

o o

t t

= =

= =

M

m

: Midrange bending moment,

m

: Midrange bending stress

M

a

: alternating bending moment,

a

: alternating bending stress

T

m

: Midrange torque,

m

: Midrange shear stress

T

a

: alternating torque,

m

: Midrange shear stress

K

f

: fatigue stress concentration factor for bending

K

fs

: fatigue stress concentration factor for torsion

CH-18 LEC 30 Slide 5

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

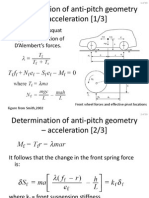

Fatigue Analysis of shafts

2 2 1/2 3 2 2 1/2 3

2 2 1/2 3 2 2 1/2 3

' 3 16/ 4( ) 3( ) 16 /

' 3 16/ 4( ) 3( ) 16 /

xya

xym

a

xa f a fs a

m

xm f m fs m

d K M K A T d

d K M K T d B

o o t t t

o o t t t

( (

= + = + =

( (

= + = + =

Combining these stresses in accordance with the DE failure theory the von-

Mises stress for rotating round, solid shaft, neglecting axial loads are given by

2 2 2

3 3

' ' 16 16

1

a m a m

e ut e ut e ut

S S n n nA nB

S S S S d S d S

o o

t t

| | | | | |

+ = + = + =

| | |

\ . \ . \ .

The Gerber fatigue failure criterion

(18-12)

where A and B are defined by the radicals in Eq. (8-12) as

2 2 1/2

2 2 1/2

4( ) 3( )

4( ) 3( )

f a fs a

f m fs m

A K M K T

B K M K T

(

= +

(

= +

CH-18 LEC 30 Slide 6

CH-18 LEC 30 Slide 6

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Fatigue Analysis of shafts

1/3

1/2

2

2 8

1 1

e

e ut

BS nA

d

S AS t

(

| |

(

= + +

` |

(

\ .

)

(18-13)

The critical shaft diameter is given by

or, solving for 1/n, the factor of safety is given by

1/2

2

3

2 1 8

1 1

e

e ut

BS A

n d S AS t

(

| |

(

= + +

` |

(

\ .

)

(18-14)

CH-18 LEC 30 Slide 7

CH-18 LEC 30 Slide 7

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Fatigue Analysis of shafts

(18-15)

where

CH-18 LEC 30 Slide 8

2 2

2 2

4( ) 3( )

4( ) 3( )

'

'

f a fs a

f m fs m

a

m

A K M K T

B K M K T

A

r

B

o

o

= +

= +

= =

CH-18 LEC 30 Slide 8

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

2

3

f a

fs m

A K M

B K T

=

=

Particular Case

Critical Shaft

Diameter

CH-18 LEC 30 Slide 9

Fatigue Analysis of shafts

1/3

1/2

2

16

1 1 3

f a fs m e

e f a ut

nK M K T S

d

S K M S t

(

| |

(

= + +

|

`

|

(

\ .

)

(18-16)

Safety Factor

1/2

2

3

16

1

1 1

f a fs m e

e f a ut

K M K T S

n d S K M S t

(

| |

(

= + +

|

`

|

(

\ .

)

(18-17)

For a rotating shaft with constant bending and torsion, the

bending stress is completely reversed and the torsion is

steady. Previous Equations can be simplified by setting M

m

= 0 and T

a

= 0, which simply drops out some of the terms.

CH-18 LEC 30 Slide 9

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 10

2

'

'

3

f a

a

m

fs m

K M

r

K T

o

o

= =

(18-18)

Fatigue Analysis of shafts

CH-18 LEC 30 Slide 10

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 11

Shaft Diameter Equation for the DE-Elliptic

Criterion

2 2 1/2 3 2 2 1/2 3

2 2 1/2 3 2 2 1/2 3

' 3 16/ 4( ) 3( ) 16 /

' 3 16/ 4( ) 3( ) 16 /

xya

xym

a

xa f a fs a

m

xm f m fs m

d K M K A T d

d K M K T d B

o o t t t

o o t t t

( (

= + = + =

( (

= + = + =

Remember

2 2 2

2 2 2

3 3

' ' 16 16

1

a m a m

e y e y e y

S S n n nA nB

S S S S d S d S

o o

t t

| | | | | |

| | | | | |

+ = + = + =

| | |

| | |

| | |

\ . \ . \ .

\ . \ . \ .

The Elliptic fatigue-failure criterion is defined by

(18-12)

where A and B are defined by

2 2 1/2

2 2 1/2

4( ) 3( )

4( ) 3( )

f a fs a

f m fs m

A K M K T

B K M K T

(

= +

(

= +

CH-18 LEC 30 Slide 11

CH-18 LEC 30 Slide 11

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 12

Shaft Diameter Equation for the DE-Elliptic

Criterion

Substituting for A and B gives expressions for d, 1/n and r:

(18-19)

Critical Shaft Diameter

1/3

1

2

2 2

2

/2

4 3 3

16

4

f m fs f a fs a

e e

m

y y

K M K T

S S

K M

S

n

K T

S

d

t

| | | |

+

| |

(

(

| | | |

+

| |

\ .

| |

\ . \ .

= +

`

(

)

\ .

Safety Factor

2

/2

2 2

1

2

3

4

6

4 3 3

1 1

f m fs m

y

a

e y

f fs a

e

K M K T

S S

K M K T

d S S n t

|

| | | |

+

| |

| |

\ . \ .

(

(

= +

| | |

+

| |

\ . \

(

.

(18-20)

CH-18 LEC 30 Slide 12

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 13

Shaft Diameter Equation for the DE-Elliptic

Criterion

( ) ( )

( ) ( )

2 2

2 2

4 3

'

'

4 3

f a fs a

a

m

f m fs m

K M K T

A

r

B

K M K T

o

o

+

= = =

+

CH-18 LEC 30 Slide 13

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Shaft Diameter Equation for the DE-Elliptic

Criterion

CH-18 LEC 30 Slide 14

2

3

f a

fs m

A K M

B K T

=

=

Particular Case

Critical Shaft Diameter (18-21)

Safety Factor

(18-22)

1/3

1/2

2

2

4

6

3

1

f a f

y e

s m

K T

n

d

K M

S S t

| |

| |

|

\ .

(

(

= +

`

|

|

\ .

(

)

1

2

/2

3

2

16

4

1

3

fs m

y

f a

e

K M

S n

T

d

K

S t

|

| |

(

(

= +

(

|

|

|

.

.

\

\

|

For a rotating shaft with constant bending and torsion,

the bending stress is completely reversed and the

torsion is steady. Previous Equations can be simplified

by setting M

m

= 0 and T

a

= 0, which simply drops out

some of the terms.

CH-18 LEC 30 Slide 14

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Shaft Diameter Equation for the DE-Elliptic

Criterion

CH-18 LEC 30 Slide 15

( )

( )

2

2

4

2

'

'

3

3

f a

f a

a

m

fs m

fs m

K M

K M

A

r

B

K T

K T

o

o

= = = =

At a shoulder Figs. A-15-8 and A-15-9 provide information about K

t

and

K

ts

.

For a hole in a solid shaft, Figs. A-15-10 and A-15-11 provide about K

t

and

K

ts

.

For a hole in a solid shaft, use Table A-16

For grooves use Figs. A-15-14 and A-15-15

CH-18 LEC 30 Slide 15

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Shaft Diameter Equation for the DE-Elliptic

Criterion

CH-18 LEC 30 Slide 16

The value of slope at which the load line intersects the junction of

the failure curves is designated r

crit

.

It tells whether the threat is from fatigue or first cycle yielding

If r > r

crit

, the threat is from fatigue

If r < r

crit

, the threat is from first cycle yielding.

CH-18 LEC 30 Slide 16

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Shaft Diameter Equation for the DE-Elliptic

Criterion

CH-18 LEC 30 Slide 17

For the Gerber-Langer intersection the strength components S

a

and

S

m

are given in Table 7-10 as

2

2

2

1 1 1

2

1

y

ut e

m

e ut e

a y m

y m y

a

crit

m m m

S

S S

S

S S S

S S S

S S S

S

r

S S S

(

| | | |

(

= +

| |

(

\ . \ .

=

= = =

(18-23)

CH-18 LEC 30 Slide 17

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

Shaft Diameter Equation for the DE-Elliptic

Criterion

CH-18 LEC 30 Slide 18

For the DE-Elliptic-Langer intersection the strength components S

a

and S

m

are given by

2

2 2

2

y e

a

e y

m y a

a a

crit

m y a

S S

S

S S

S S S

S S

r

S S S

=

+

=

= =

(18-24)

CH-18 LEC 30 Slide 18

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 19

Note that in an analysis situation in which the diameter is known and the

factor of safety is desired, as an alternative to using the specialized equations

above, it is always still valid to calculate the alternating and mid-range

stresses using the following Eqs.

and substitute them into the one of the equations for the failure criteria ,

Eqs. (7-48) to (7-51) and solve directly for n.

CH-18 LEC 30 Slide 19

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 20

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 21

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

In a design situation, however, having the equations pre-solved for

diameter is quite helpful.

It is always necessary to consider the possibility of static failure in

the first load cycle.

The Soderberg criteria inherently guards against yielding, as can

be seen by noting that its failure curve is conservatively within the

yield (Langer) line on Fig. 727, p. 348.

The ASME Elliptic also takes yielding into account, but is not

entirely conservative throughout its range. This is evident by

noting that it crosses the yield line in Fig. 727.

The Gerber and modified Goodman criteria do not guard against

yielding, requiring a separate check for yielding. A von Mises

maximum stress is calculated for this purpose.

CH-18 LEC 30 Slide 22

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 23

To check for yielding, this von Mises maximum stress is compared to the

yield strength, as usual

For a quick, conservative check, an estimate for

max

can be obtained by

simply adding

a

and

m

. (

a

+

m

) will always be greater than or equal

to

max

, and will therefore be conservative.

CH-18 LEC 30 Slide 23

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 24

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 25

Example

Solution

7-

20

7-

20

CH-18 LEC 30 Slide 25

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 26

Figure 7-20

Figure 7-21

CH-18 LEC 30 Slide 26

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 27 CH-18 LEC 30 Slide 27

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 28

18-

22

18-

14

18-

24

Sold

erbe

rg

CH-18 LEC 30 Slide 28

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 29

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 30 CH-18 LEC 30 Slide 30

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 31

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 32

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 33

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 34

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 35

Dr. A. Aziz Bazoune Chapter 18: Axles and Shafts

ME 307

Machine

Design I

CH-18 LEC 30 Slide 36

Vous aimerez peut-être aussi

- Aci 530 11 Masonry Wall 002Document4 pagesAci 530 11 Masonry Wall 002thanzawtun1981Pas encore d'évaluation

- Stamping Design GuidelineDocument13 pagesStamping Design GuidelineVikram Borkhediya100% (1)

- Storage Tank DesignDocument42 pagesStorage Tank Designronavanessa70% (10)

- Machine DesignDocument76 pagesMachine DesignTerenz Calangi67% (3)

- 425-Doubly Reinforced Beam Design-S11Document45 pages425-Doubly Reinforced Beam Design-S11Kaye MamisaoPas encore d'évaluation

- Design of Precast and Prestressed Double Tee Beam CalculationDocument20 pagesDesign of Precast and Prestressed Double Tee Beam CalculationLim Wee BengPas encore d'évaluation

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocument10 pagesDesign Aid For Triangular Bracket Plates Using AISC Specificationsmaroco1098100% (7)

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainD'EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainPas encore d'évaluation

- Steel and Timber Report Compiled (Aaa) PDFDocument42 pagesSteel and Timber Report Compiled (Aaa) PDFLee Chen ChoonPas encore d'évaluation

- 16 Suspension 3Document37 pages16 Suspension 3Sunilkumar ReddyPas encore d'évaluation

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsD'EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikPas encore d'évaluation

- ME307-11 Tutorial 9Document9 pagesME307-11 Tutorial 9Mohammed A IsaPas encore d'évaluation

- Owners Manual Activa 5G EnglishDocument83 pagesOwners Manual Activa 5G EnglishVikram Borkhediya50% (2)

- MTE 119 STATICS HOMEWORK SOLUTIONS FORCE REACTIONS TRUSSESDocument19 pagesMTE 119 STATICS HOMEWORK SOLUTIONS FORCE REACTIONS TRUSSESAmy TrevinoPas encore d'évaluation

- ATR 72 - Flight ManualDocument490 pagesATR 72 - Flight Manualmuya78100% (1)

- Shigley Mechanical Engineering DesignDocument18 pagesShigley Mechanical Engineering DesignNishanth MudkePas encore d'évaluation

- Homework Labs Lecture01Document9 pagesHomework Labs Lecture01Episode UnlockerPas encore d'évaluation

- Common Rail Fuel Injection Technology in Diesel EnginesD'EverandCommon Rail Fuel Injection Technology in Diesel EnginesPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Pressure Vessel and Stacks Field Repair ManualD'EverandPressure Vessel and Stacks Field Repair ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- X 09 CDX 09 High Security LocksDocument8 pagesX 09 CDX 09 High Security LocksBenoit CarrenandPas encore d'évaluation

- HES5320 Solid Mechanics, Semester 2, 2011, Practical Lab On Thick-Walled Cylinder by Stephen BongDocument17 pagesHES5320 Solid Mechanics, Semester 2, 2011, Practical Lab On Thick-Walled Cylinder by Stephen BongStephenPYBong100% (5)

- Chapter09 (Shaft)Document70 pagesChapter09 (Shaft)Ganesh DongrePas encore d'évaluation

- Design and Analysis of Centrifugal CompressorsD'EverandDesign and Analysis of Centrifugal CompressorsPas encore d'évaluation

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentDocument30 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentIsmail DoğanPas encore d'évaluation

- LEC 31 CH-18 Shafts and AxlesDocument34 pagesLEC 31 CH-18 Shafts and AxlesJoe Hosny100% (1)

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering DepartmentDocument34 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & Minerals Mechanical Engineering Departmentashray_111Pas encore d'évaluation

- Presentation Shaft and AxlesDocument21 pagesPresentation Shaft and AxlesAfiq BobbyPas encore d'évaluation

- ME 307 Machine Design I Shaft DesignDocument28 pagesME 307 Machine Design I Shaft Designganesh dongrePas encore d'évaluation

- RC Beam Torsion DesignDocument33 pagesRC Beam Torsion Design2011kumarPas encore d'évaluation

- Interpretation of CIU TestDocument7 pagesInterpretation of CIU TestAnonymous hhdd4mOmOhPas encore d'évaluation

- ARO Final Review SessionDocument48 pagesARO Final Review SessionZenon CortezPas encore d'évaluation

- Moment Curvature Relation (6-10)Document26 pagesMoment Curvature Relation (6-10)Nicholas ThompsonPas encore d'évaluation

- INTERPRET CIU TESTDocument7 pagesINTERPRET CIU TESTGnabBangPas encore d'évaluation

- Deflections PDFDocument9 pagesDeflections PDFChristopher SingletonPas encore d'évaluation

- Me307 Formula Sheet5423Document19 pagesMe307 Formula Sheet5423Gazi FıratPas encore d'évaluation

- E702 2Document15 pagesE702 2werdubob8944Pas encore d'évaluation

- Machine Design I Chapter 5 Fasteners and JointsDocument59 pagesMachine Design I Chapter 5 Fasteners and JointsShitnu SuwanPas encore d'évaluation

- 5 1 (Compression Members)Document30 pages5 1 (Compression Members)yugoingPas encore d'évaluation

- f13 Ce470ch4ftb CompDocument10 pagesf13 Ce470ch4ftb CompAulia Rahma AzisPas encore d'évaluation

- Reinforced Concrete Section PropertiesDocument10 pagesReinforced Concrete Section PropertiesJose MLPas encore d'évaluation

- Solution Tutorial - 1Document2 pagesSolution Tutorial - 1Akash FuryPas encore d'évaluation

- Chap06 Fatigue PDFDocument30 pagesChap06 Fatigue PDFAlex IskandarPas encore d'évaluation

- Optimum design of stiffened plates for different loads and shapes of ribsDocument15 pagesOptimum design of stiffened plates for different loads and shapes of ribsluke636250Pas encore d'évaluation

- Chapter11 Prob01Document13 pagesChapter11 Prob01imranakhtarPas encore d'évaluation

- Yield Line in Rectangular Slab PDFDocument6 pagesYield Line in Rectangular Slab PDFimanbillyPas encore d'évaluation

- Hw1 Sol Fall 2015Document8 pagesHw1 Sol Fall 2015Ong Kok Meng100% (1)

- Diseño de Atiesador TriangularDocument10 pagesDiseño de Atiesador TriangularMauricio SierraPas encore d'évaluation

- Compression MemberDocument45 pagesCompression MemberSatyasapath RoyPas encore d'évaluation

- 4.1 Rectangular Tied Columns: CHAPTER 4: Reinforced Concrete ColumnsDocument12 pages4.1 Rectangular Tied Columns: CHAPTER 4: Reinforced Concrete ColumnsRigobertoGuerraPas encore d'évaluation

- Mechanical Engineering Beam Force Diagram SolutionsDocument13 pagesMechanical Engineering Beam Force Diagram SolutionsAlberto RamirezPas encore d'évaluation

- Mechanics of Materials Solutions For Some ProbsDocument5 pagesMechanics of Materials Solutions For Some ProbsChirag AnandPas encore d'évaluation

- Lecture 17 Shaft Loading PDFDocument26 pagesLecture 17 Shaft Loading PDFAndrew Tan100% (1)

- Mechanics of MachineDocument25 pagesMechanics of Machinecarthik_rajaPas encore d'évaluation

- Unit 4 Flywheel: StructureDocument21 pagesUnit 4 Flywheel: StructureShivam Gupta0% (2)

- Fatigue of Textile and Short Fiber Reinforced CompositesD'EverandFatigue of Textile and Short Fiber Reinforced CompositesPas encore d'évaluation

- Dynamic Damage and FragmentationD'EverandDynamic Damage and FragmentationDavid Edward LambertPas encore d'évaluation

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsD'EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsPas encore d'évaluation

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignD'EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignPas encore d'évaluation

- Logical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeD'EverandLogical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universePas encore d'évaluation

- 218 ECAB4 D 01Document114 pages218 ECAB4 D 01Vikram BorkhediyaPas encore d'évaluation

- QpmeDocument16 pagesQpmeSandeep PandeyPas encore d'évaluation

- Mechanical Engineering Job Interview Preparation GuideDocument25 pagesMechanical Engineering Job Interview Preparation Guidenage_scribdPas encore d'évaluation

- Common Engineering TermsDocument23 pagesCommon Engineering TermsAitazaz Ahsan0% (1)

- Design Manual Provides Safety Guidance for Timing Belt ApplicationsDocument141 pagesDesign Manual Provides Safety Guidance for Timing Belt ApplicationsVikram BorkhediyaPas encore d'évaluation

- Mechanical Engineering Job Interview Preparation GuideDocument25 pagesMechanical Engineering Job Interview Preparation Guidenage_scribdPas encore d'évaluation

- Hero PleasureDocument4 pagesHero PleasureVikram BorkhediyaPas encore d'évaluation

- Kitchen WorkstationDocument15 pagesKitchen WorkstationVikram BorkhediyaPas encore d'évaluation

- Maintenance Manual - Hero ScooterDocument3 pagesMaintenance Manual - Hero ScooterVikram BorkhediyaPas encore d'évaluation

- Ojas Dekor - Plywood, Veener, Laminates, Alluminium, Wood, MDF, Wooden FlooringDocument2 pagesOjas Dekor - Plywood, Veener, Laminates, Alluminium, Wood, MDF, Wooden FlooringVikram BorkhediyaPas encore d'évaluation

- Sai Machine Tool LTD CapabilitiesDocument10 pagesSai Machine Tool LTD CapabilitiesVikram BorkhediyaPas encore d'évaluation

- Patwari 2017 CutoffDocument66 pagesPatwari 2017 CutoffVikram BorkhediyaPas encore d'évaluation

- Book Arab Spring West AsiaDocument172 pagesBook Arab Spring West AsiaVikram BorkhediyaPas encore d'évaluation

- Guide To Buying A HouseDocument57 pagesGuide To Buying A HouseVikram BorkhediyaPas encore d'évaluation

- Casting Details and CavitiesDocument14 pagesCasting Details and CavitiesVikram BorkhediyaPas encore d'évaluation

- Indore Illigal ColoneyDocument7 pagesIndore Illigal ColoneyVikram BorkhediyaPas encore d'évaluation

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyVikram BorkhediyaPas encore d'évaluation

- Fundamentals of Casting ProcessesDocument18 pagesFundamentals of Casting ProcessesKasinathan JeevaPas encore d'évaluation

- Shafts and Axles Chapter 29Document28 pagesShafts and Axles Chapter 29Vikram BorkhediyaPas encore d'évaluation

- Sheetmetal Design GuidelinesDocument5 pagesSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- 2 - Design BasicsDocument26 pages2 - Design BasicsVikas TiwariPas encore d'évaluation

- Gadget Notification of MP Education DepartmentDocument9 pagesGadget Notification of MP Education DepartmentVikram BorkhediyaPas encore d'évaluation

- Automobile BrakesDocument36 pagesAutomobile BrakesVikram BorkhediyaPas encore d'évaluation

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsVikram BorkhediyaPas encore d'évaluation

- Mechanical Engineering SyllabusDocument3 pagesMechanical Engineering SyllabusVikram BorkhediyaPas encore d'évaluation

- Ae53 Ac53 At53Document4 pagesAe53 Ac53 At53M Taher BamyaniPas encore d'évaluation

- Structural Geology From Barmer Basin (India)Document12 pagesStructural Geology From Barmer Basin (India)Sankhajit SahaPas encore d'évaluation

- SE Unit - 1Document30 pagesSE Unit - 1Sanketh KanuguPas encore d'évaluation

- Appendix B DAX ReferenceDocument174 pagesAppendix B DAX ReferenceTomislav Mališ100% (1)

- Matrix Assisted Laser Desorption Ionization Mass Spectrometry Maldi-Tof MsDocument4 pagesMatrix Assisted Laser Desorption Ionization Mass Spectrometry Maldi-Tof MsElizabeth Katherine Aigaje EspinosaPas encore d'évaluation

- AtmegaDocument22 pagesAtmegaMUKILANPas encore d'évaluation

- Atht Model Ques 2017Document1 pageAtht Model Ques 2017Jeyakumar VenugopalPas encore d'évaluation

- Compression Test/ Group 1/ Material & Science Eng'GDocument6 pagesCompression Test/ Group 1/ Material & Science Eng'GNiaz KilamPas encore d'évaluation

- SMD Meter User's ManualDocument2 pagesSMD Meter User's ManuallucianoPas encore d'évaluation

- Innovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemDocument8 pagesInnovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemRakesh BiswasPas encore d'évaluation

- Solubility of Caso: Major Concepts and Learning GoalsDocument6 pagesSolubility of Caso: Major Concepts and Learning GoalsNacorn PanchanawapornPas encore d'évaluation

- Chapter 1. Griffiths-Vector Analysis - 1.1 1.2Document24 pagesChapter 1. Griffiths-Vector Analysis - 1.1 1.2Hazem TawfikPas encore d'évaluation

- Lecture 10 - Dry Etching PDFDocument7 pagesLecture 10 - Dry Etching PDFSiddhant ModiPas encore d'évaluation

- AP+Bio 013+Photosynthesis++Respiration+Worksheet WLDocument2 pagesAP+Bio 013+Photosynthesis++Respiration+Worksheet WLVincent SuarezPas encore d'évaluation

- PSAB Product ManualDocument4 pagesPSAB Product ManualArnold StevenPas encore d'évaluation

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDocument4 pages19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RPas encore d'évaluation

- MCQ Metrology (CCCM & CCCT) PDFDocument21 pagesMCQ Metrology (CCCM & CCCT) PDFSahil Gauhar67% (3)

- A Tour Through Mathematical Logic: Robert S. WolfDocument4 pagesA Tour Through Mathematical Logic: Robert S. WolfUrahara JefPas encore d'évaluation

- Full Text 01Document110 pagesFull Text 01GumbuzaPas encore d'évaluation

- Install and Set Up Heavy Duty Plate Cutting MachineDocument14 pagesInstall and Set Up Heavy Duty Plate Cutting MachineJorn StejnPas encore d'évaluation

- ES Q2 Mod8Document26 pagesES Q2 Mod8maacovsPas encore d'évaluation

- Spread of Virus ModelledDocument2 pagesSpread of Virus ModelledDouglas TanPas encore d'évaluation

- Coreldraw 12 Hotkeys - Keyboard ShortcutsDocument6 pagesCoreldraw 12 Hotkeys - Keyboard ShortcutsRais AhmadPas encore d'évaluation

- Border Security Using Wireless Integrated Network Sensors (WINS)Document18 pagesBorder Security Using Wireless Integrated Network Sensors (WINS)Pradeep CheekatlaPas encore d'évaluation

- Test Automation Design PrinciplesDocument15 pagesTest Automation Design PrinciplesSujay KumarPas encore d'évaluation