Académique Documents

Professionnel Documents

Culture Documents

Modelling

Transféré par

Portia ShilengeDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Modelling

Transféré par

Portia ShilengeDroits d'auteur :

Formats disponibles

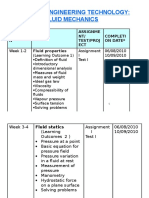

MATHEMATICAL

MODELING

1

OBJECTIVES:

Modeling principles.

Outline the procedure for developing a mathematical

model of a dynamic physical / chemical process using

fundamental laws.

Uses of Mathematical Modeling.

Derivations / development of mathematical models

2

INTRODUCTION

Modeling is used to study the dynamic behaviour, process

design, model-based control, optimization and predictions

of the processes.

It is the mathematical representation of a process intended

to promote understanding of a real process.

Suppose we have an experimental setup as shown below.

3

Experimental Setup

Input

Output

U

n

i

t

1

4

Input

Output

Mathematical

modelling

The same Output

U

n

i

t

1

Modelling principles

Dynamics models of chemical processes consist

of ODE (ordinary differential equations) and /

partial differential equations (PDE), plus related

algebraic equations.

For process control problems, dynamic models

are derived using unsteady state conservation

laws.

5

U

n

i

t

2

A systematic approach for developing

dynamic models

1. State the modelling objectives and the end use of the

model.

2. Draw the schematic diagram of the process and label

all process variables.

3. List all the assumptions involved in developing the

model.

4. Write appropriate conservation equation (mass,

component, energy, and so forth).

5. Introduce equilibrium relation and other algebraic

equation (from thermodynamics, transport phenomena,

chemical kinetics etc).

6

U

n

i

t

3

6. Perform degree of freedom.

7. Simplify the model. (Grouping of like terms).

8. Classify the inputs as the disturbance or manipulated

variables.

Conservation laws

Theoretical models of chemical processes are based on

conservation laws such as the conservation of mass and energy.

Conservation of Mass

Rate of mass accumulation = rate of mass in rate of mass out

7

U

n

i

t

4

Conservation of Component i

Conservation of Energy

8

consumed mass of rate -

generated mass of rate

out mass of rate - in mass of rate on accumulati mass

+

= of Rate

system on the performed work of rate

system the o addition t heat of rate net

out energy of rate - in energy of rate on accumulati Energy

net

of Rate

+

+

=

U

n

i

t

4

Uses of Mathematical Modeling

To improve understanding of the process

To optimize process design/operating

conditions

To design a control strategy for the process

To train operating personnel

9

U

n

i

t

5

Development of Dynamic Models

Liquid - level system

Example:

Two liquids are mixed together in a tank and the product is

removed through an exit stream at the bottom of a tank. We

know that changes in the feed stream flow rate can cause the

tank to overflow or completely drain, and this is undesirable.

out flow (F) is linearly related to the hydrostatic head of the

liquid level through the resistant (R).

Is it possible to modify the design of the tank to avoid

instability? How? Develop a model which will give a true

representation of this experimental setup.

10

U

n

i

t

6

Liquid - level system

Liquid - level system (steady state condition)

11

h

F

1

F

2

F

U

n

i

t

6

Changes in the feed stream flow rate causes the process to be

of a transient behaviour.

Liquid - level system (un-steady state condition)

12

H

V

F

1

F

2

F

U

n

i

t

6

Conservation of Mass

Rate of mass accumulation = rate of mass in rate of mass out

..(1)

..(2)

.(3)

(4)

13

out in

m m

dt

dM

- -

=

F F

dt

Ah d

+ =

2

1

F

) (

R

h

F F

dt

Adh

+ =

2 1

( ) ( )( ) R F F h

dt

dh

RA

2 1

+ = +

U

n

i

t

6

Class exercise

Consider an example of a man in a shower.

By making scenarios / design questions, follow the

procedure to design a control system which will help to

achieve the desired products. Develop a model

mathematical model to represent this process.

14

U

n

i

t

6

The Blending Process Revisited

Determine the component balance model

15

U

n

i

t

6

.........................1

The corresponding steady-state model

.....................................2

............................3

The Blending Process Revisited

For constant density, the transient process become:

16

( ) ( ) out mass of rate - in mass of rate

tank in the mass of

on accumulati of

=

|

|

.

|

\

|

rate

( )

w w w

dt

V d

+ =

2 1

w w w + =

2 1

0

x w x w x w + =

2 2 1 1

0

U

n

i

t

6

..4

5

Equation 5 can be simplified by expanding the accumulation term

using the chain rule for differentiation of a product:

..6

Substitution of (5) into (6) gives

..7

17

w w w

dt

dV

+ =

2 1

wx x w x w

dt

dVx

+ =

2 2 1 1

( )

dt

dV

x

dt

dx

V

dt

Vx d

+ =

wx x w x w

dt

dV

x

dt

dx

V + = +

2 2 1 1

U

n

i

t

6

Substitution of the mass balance in (7) for in (4) gives:

..8

After canceling common terms and rearranging (4) and (5) in

8, a more convenient model form is obtained:

18

( ) wx x w x w w w w x

dt

dx

V + = + +

2 2 1 1 2 1

( )

( ) ( ) x x

V

w

x x

V

w

dt

dx

w w w

dt

dV

+ =

+ =

2

2 1

2 1

1

1

U

n

i

t

6

Vous aimerez peut-être aussi

- HELYX-OS OpenFoam Tutorial - Rev1Document47 pagesHELYX-OS OpenFoam Tutorial - Rev1Carlos Silva Rocha0% (2)

- Chemical Engineering Process SimulationD'EverandChemical Engineering Process SimulationÉvaluation : 4 sur 5 étoiles4/5 (13)

- PiSo Vs Transient SimpleDocument33 pagesPiSo Vs Transient SimpleJaeHeung GillPas encore d'évaluation

- III Dynamic Process ModelDocument26 pagesIII Dynamic Process ModelIshita BhattacharyyaPas encore d'évaluation

- Solid-Liquid Separation by Leaching: ReportDocument11 pagesSolid-Liquid Separation by Leaching: ReportlauraPas encore d'évaluation

- Theoretical Models of Chemical ProcessesDocument21 pagesTheoretical Models of Chemical Processesstup_30100% (2)

- PCT 301T ModelingDocument21 pagesPCT 301T ModelingPortia ShilengePas encore d'évaluation

- Module - 1 - Models in Engineering and Equation FormsDocument29 pagesModule - 1 - Models in Engineering and Equation FormsG MahendraPas encore d'évaluation

- Computer Methods in Chemical EngineeringDocument247 pagesComputer Methods in Chemical Engineeringkris010100% (1)

- CEIC3000 Process Modelling and Analysis Week 1 Session 1, 2012Document17 pagesCEIC3000 Process Modelling and Analysis Week 1 Session 1, 2012Ben TanPas encore d'évaluation

- Optimal Control of A Hybrid Dynamical System: Two Coupled TanksDocument25 pagesOptimal Control of A Hybrid Dynamical System: Two Coupled TanksPhạm Ngọc HòaPas encore d'évaluation

- Course Code: KKEK 3152 Modeling of Chemical ProcessesDocument47 pagesCourse Code: KKEK 3152 Modeling of Chemical ProcessesRishi KumarPas encore d'évaluation

- Distillation Dynamics and Control Workbook 2006 PDFDocument18 pagesDistillation Dynamics and Control Workbook 2006 PDFEr Mayur PatilPas encore d'évaluation

- Integrate Process Simulation and Process Synthesis - DesbloqueadoDocument5 pagesIntegrate Process Simulation and Process Synthesis - DesbloqueadoVictor Heredia MattaPas encore d'évaluation

- CSTRCOM: Isothermal Reactor With Complex ReactionDocument7 pagesCSTRCOM: Isothermal Reactor With Complex ReactionBishal LamichhanePas encore d'évaluation

- Borelli Predictive Control PDFDocument424 pagesBorelli Predictive Control PDFcharlesPas encore d'évaluation

- Derivation 01Document2 pagesDerivation 01mbmonvillePas encore d'évaluation

- MPC BookDocument464 pagesMPC BookNilay SarafPas encore d'évaluation

- Material and Energy BalancesDocument9 pagesMaterial and Energy BalancesAbdulkudus AbdulshukurPas encore d'évaluation

- Lecture 4 - Simulation of Recycle StreamsDocument57 pagesLecture 4 - Simulation of Recycle StreamsKin Wai Cheah75% (4)

- Performances Comparison Between Real-Time Auto-Tuning PID and Conventional PID Controller For A Dairy Industrial Evaporation Process ControlDocument7 pagesPerformances Comparison Between Real-Time Auto-Tuning PID and Conventional PID Controller For A Dairy Industrial Evaporation Process ControlDuy Phan Lữ AnhPas encore d'évaluation

- Comparing Pressure Flow Solvers For Dinamic SimulationDocument24 pagesComparing Pressure Flow Solvers For Dinamic SimulationEdgar HuancaPas encore d'évaluation

- (E) 10.1.1.29.1494Document52 pages(E) 10.1.1.29.1494Moh InePas encore d'évaluation

- Computation PDFDocument28 pagesComputation PDFvermavermapoojaPas encore d'évaluation

- BBMbook Cambridge NewstyleDocument373 pagesBBMbook Cambridge Newstylejpvieira66Pas encore d'évaluation

- Hyss PDFDocument8 pagesHyss PDFEugenio Alejandro Pérez ReséndizPas encore d'évaluation

- Chap 03 Marlin 2002Document45 pagesChap 03 Marlin 2002Audrey Patrick KallaPas encore d'évaluation

- Simulation of Process Lines in Microsoft Excel - Nitric Acid ProductionDocument16 pagesSimulation of Process Lines in Microsoft Excel - Nitric Acid ProductionmanojPas encore d'évaluation

- Solid Gas Flow 4Document100 pagesSolid Gas Flow 4Anu MittalPas encore d'évaluation

- IADC/SPE 81636 Improvements in Dynamic Modeling of Underbalanced DrillingDocument8 pagesIADC/SPE 81636 Improvements in Dynamic Modeling of Underbalanced DrillingJohnSmithPas encore d'évaluation

- Case Study - 1 Report - 21BME081Document7 pagesCase Study - 1 Report - 21BME081krishnaPas encore d'évaluation

- Numerical Simulation in Statistical PhysicsDocument201 pagesNumerical Simulation in Statistical PhysicsMasamichi NogawaPas encore d'évaluation

- Integrate Process Simulation and Process SynthesisDocument6 pagesIntegrate Process Simulation and Process Synthesisjanota24Pas encore d'évaluation

- WQU - Econometrics - Compiled Content - Module5 PDFDocument46 pagesWQU - Econometrics - Compiled Content - Module5 PDFvikrantPas encore d'évaluation

- Model Predictive ControlDocument460 pagesModel Predictive ControlHarisCausevicPas encore d'évaluation

- Process Design and Optimization - 2Document24 pagesProcess Design and Optimization - 2zarar saleemPas encore d'évaluation

- Distillation Column ModelingDocument8 pagesDistillation Column ModelingMohamed GuenounePas encore d'évaluation

- Chemical Process DynamicsDocument19 pagesChemical Process DynamicsFarid Al-FansuriPas encore d'évaluation

- Practical Optimization Using Evolutionary MethodsDocument20 pagesPractical Optimization Using Evolutionary MethodsGerhard HerresPas encore d'évaluation

- CSM - Dhanwani (12 Dec 2020)Document9 pagesCSM - Dhanwani (12 Dec 2020)Harsh RavalPas encore d'évaluation

- Lecture Notes - Optimal Control (LQG, MPC)Document76 pagesLecture Notes - Optimal Control (LQG, MPC)mindthomasPas encore d'évaluation

- Thesis With LogoDocument71 pagesThesis With LogoAnonymous 5oTiSrPas encore d'évaluation

- 1501.applied Parameter Estimation For Chemical Engineers (Chemical Industries) by Peter Englezos (Cap 1)Document6 pages1501.applied Parameter Estimation For Chemical Engineers (Chemical Industries) by Peter Englezos (Cap 1)cegarcia0% (1)

- Dynamic Optimization of Bioreactors: A Review: Julio R. Banga, Eva Balsa-Canto, Carmen G. Moles and Antonio A. AlonsoDocument21 pagesDynamic Optimization of Bioreactors: A Review: Julio R. Banga, Eva Balsa-Canto, Carmen G. Moles and Antonio A. Alonsojmrozo3Pas encore d'évaluation

- Introduction To Chemical Engineering ProcessesDocument136 pagesIntroduction To Chemical Engineering ProcessesYen AdamsPas encore d'évaluation

- Chapter 2Document40 pagesChapter 2Halkawt G MuhammadPas encore d'évaluation

- Predictive Control: For Linear and Hybrid SystemsDocument458 pagesPredictive Control: For Linear and Hybrid SystemsSanthosh KumarPas encore d'évaluation

- Intro To Operations ResearchDocument47 pagesIntro To Operations Researchsiva86Pas encore d'évaluation

- Computational Methods for Process SimulationD'EverandComputational Methods for Process SimulationÉvaluation : 3 sur 5 étoiles3/5 (1)

- Integer Optimization and its Computation in Emergency ManagementD'EverandInteger Optimization and its Computation in Emergency ManagementPas encore d'évaluation

- Solutions Manual to Accompany Introduction to Quantitative Methods in Business: with Applications Using Microsoft Office ExcelD'EverandSolutions Manual to Accompany Introduction to Quantitative Methods in Business: with Applications Using Microsoft Office ExcelPas encore d'évaluation

- Discrete Event Systems in Dioid Algebra and Conventional AlgebraD'EverandDiscrete Event Systems in Dioid Algebra and Conventional AlgebraPas encore d'évaluation

- Multiple Models Approach in Automation: Takagi-Sugeno Fuzzy SystemsD'EverandMultiple Models Approach in Automation: Takagi-Sugeno Fuzzy SystemsPas encore d'évaluation

- Stochastic Modelling in Process TechnologyD'EverandStochastic Modelling in Process TechnologyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Stochastic Dynamic Programming and the Control of Queueing SystemsD'EverandStochastic Dynamic Programming and the Control of Queueing SystemsPas encore d'évaluation

- 7 Flow of Compressible FluidsDocument27 pages7 Flow of Compressible FluidsPortia ShilengePas encore d'évaluation

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 pagesConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengePas encore d'évaluation

- 4 Flow MeasurementsDocument19 pages4 Flow MeasurementsPortia ShilengePas encore d'évaluation

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengePas encore d'évaluation

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengePas encore d'évaluation

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengePas encore d'évaluation

- Preconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterDocument20 pagesPreconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterPortia ShilengePas encore d'évaluation

- 2014 Nua301t Assessment 1 - MemoDocument4 pages2014 Nua301t Assessment 1 - MemoPortia ShilengePas encore d'évaluation

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 pagesExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengePas encore d'évaluation

- 15 Johan MullerDocument22 pages15 Johan MullerPortia ShilengePas encore d'évaluation

- Milling Multotec ProjectDocument15 pagesMilling Multotec ProjectPortia ShilengePas encore d'évaluation

- Kroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFDocument32 pagesKroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFPortia ShilengePas encore d'évaluation

- Derrick Screen ProjectDocument15 pagesDerrick Screen ProjectPortia ShilengePas encore d'évaluation

- Ball Mills For Blue Ridge PDFDocument2 pagesBall Mills For Blue Ridge PDFPortia ShilengePas encore d'évaluation

- 17-Processing Iron Ore PDFDocument12 pages17-Processing Iron Ore PDFPortia Shilenge100% (1)

- 0204finalreportbrgm PDFDocument88 pages0204finalreportbrgm PDFPortia ShilengePas encore d'évaluation

- Mini Report of Duties Done in The Ug2 PlantDocument9 pagesMini Report of Duties Done in The Ug2 PlantPortia ShilengePas encore d'évaluation

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengePas encore d'évaluation

- Report in The Ug2 PlantDocument8 pagesReport in The Ug2 PlantPortia ShilengePas encore d'évaluation

- UAE University College of Engineering Training and Graduation Project UnitDocument100 pagesUAE University College of Engineering Training and Graduation Project UnitPortia ShilengePas encore d'évaluation

- Operation of A Centrifugal Oil PurifersDocument11 pagesOperation of A Centrifugal Oil PurifersIonescu GeorgePas encore d'évaluation

- HY22TJUYDocument2 pagesHY22TJUYJacob Lucas NiguidulaPas encore d'évaluation

- Chapter 07Document35 pagesChapter 07Hassan SaeedPas encore d'évaluation

- Astm A706Document4 pagesAstm A706croberperez10Pas encore d'évaluation

- Ultrasonic Thickness GagingDocument4 pagesUltrasonic Thickness Gagingcal2_uniPas encore d'évaluation

- Turbo ExpanderDocument47 pagesTurbo ExpanderJetul PatelPas encore d'évaluation

- Exercises Chapter29Document8 pagesExercises Chapter29Чего Хочешь?Pas encore d'évaluation

- De Super HeaterDocument12 pagesDe Super HeaternewprocessPas encore d'évaluation

- Basics NWP and ApplicationDocument20 pagesBasics NWP and ApplicationCasetome IdPas encore d'évaluation

- On The Resonances and Polarizabilities of Split Ring ResonatorsDocument9 pagesOn The Resonances and Polarizabilities of Split Ring ResonatorsNabil DakhliPas encore d'évaluation

- DistillationDocument103 pagesDistillationKrishnamoorthy VijayalakshmiPas encore d'évaluation

- Steering Column: Rolling Bearings and Components For Passenger Car ChassisDocument34 pagesSteering Column: Rolling Bearings and Components For Passenger Car ChassisDragoş SorinPas encore d'évaluation

- 3 Periodical Examination S.Y. 2018-2019 Science VI: Umingan Central Elementary SchoolDocument4 pages3 Periodical Examination S.Y. 2018-2019 Science VI: Umingan Central Elementary SchoolPrincis CianoPas encore d'évaluation

- Corrosion & Corrosion ControlDocument233 pagesCorrosion & Corrosion ControlMahmoud HagagPas encore d'évaluation

- Phonon Crystal VibrationsDocument331 pagesPhonon Crystal VibrationsV Sree Suswara Suswara100% (1)

- 3.2 The Acceleration FieldDocument1 page3.2 The Acceleration FieldLit Pao WongPas encore d'évaluation

- For Finals Practice ProblemsDocument13 pagesFor Finals Practice Problemsengr marcialawPas encore d'évaluation

- Au2-13, Deka2008Document11 pagesAu2-13, Deka2008ht117Pas encore d'évaluation

- Powder Metallurgy of Tungsten AlloyDocument2 pagesPowder Metallurgy of Tungsten AlloyTanzil ZaidiPas encore d'évaluation

- H2 Chemistry 9729 P3 - Section ADocument9 pagesH2 Chemistry 9729 P3 - Section AchuasioklengPas encore d'évaluation

- Bonding Types Lab #1: Ionic vs. Covalent Solids Teacher'sDocument3 pagesBonding Types Lab #1: Ionic vs. Covalent Solids Teacher'sEsther SparksPas encore d'évaluation

- Chemistry An Introduction To General Organic and Biological Chemistry 12th Edition Timberlake Test BankDocument23 pagesChemistry An Introduction To General Organic and Biological Chemistry 12th Edition Timberlake Test Bankrobertrandallsmweqgpyzc100% (27)

- Design of A Three-Storey Commercial Building: I. Description of The StructureDocument8 pagesDesign of A Three-Storey Commercial Building: I. Description of The StructureShōya Ishida100% (1)

- Dual High StrengthDocument8 pagesDual High StrengthAhmed El-SaiedPas encore d'évaluation

- Spe 52157Document30 pagesSpe 52157budiPas encore d'évaluation

- The Causes and Effects of EarthquakesDocument4 pagesThe Causes and Effects of EarthquakesKarma AkabanePas encore d'évaluation

- Elastic Beams in Three Dimensions: Lars Andersen and Søren R.K. NielsenDocument104 pagesElastic Beams in Three Dimensions: Lars Andersen and Søren R.K. NielsenAnonymous hprsT3WlPPas encore d'évaluation

- Foundation Science For EngineersDocument7 pagesFoundation Science For EngineersZaid HadiPas encore d'évaluation

- Grand Viva QuestionsDocument9 pagesGrand Viva Questionsbaniya is herePas encore d'évaluation