Académique Documents

Professionnel Documents

Culture Documents

Ni - PPT

Transféré par

haroub_nasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ni - PPT

Transféré par

haroub_nasDroits d'auteur :

Formats disponibles

Nickel and nickel based alloys are chosen because of their: corrosion resistance heat resistance and high

temperature properties low temperature properties

Material types trade names such as Inconel and Hastelloy

solid solution alloys precipitation hardened alloys. (solution treatment plus ageing) produce a fine distribution of hard particles in a nickel rich matrix.

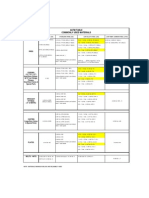

Solid solution alloys Nickel 200, Monel alloy 400 series, Inconel alloy 600 series, Incoloy alloy 800 series, Hastelloys and some Nimonic alloys (such as 75, and PE13). These alloys are readily fusion welded, normally in the annealed condition. As the heat affected zone (HAZ) does not harden, heat treatment is not usually required after welding.

Precipitation hardening alloys Monel alloy 500 series, Inconel alloy 700 series, Incoloy alloy 900 series and most of the Nimonic alloys (such as 80,90,263 and PE16). These alloys may susceptible to post-weld heat treatment cracking.

Weldability Most nickel alloys can be fusion welded using gas shielded processes like TIG or MIG. Of the flux processes, MMA is frequently used SAW process is restricted to solid solution alloys (Nickel 200, Inconel alloy 600 series and Monel alloy 400 series) and is less widely used. Solid solution alloys - normally welded in the annealed condition [ precipitation hardened alloys in the solution treated condition

Preheating is not necessary unless there is a risk of porosity from moisture condensation. It is recommended that material containing residual stresses be solution-treated before welding to relieve the stresses. Post-weld heat treatment is not usually needed to restore corrosion resistance but thermal treatment may be required for precipitation hardening or stress relieving purposes to avoid stress corrosion cracking.

Filler alloys Filler composition normally matches the parent metal. However, most fillers contain a small mount of titanium, aluminium and/or niobium to help minimise the risk of porosity and cracking.

Filler metals for gas shielded processes are covered in BS 2901: Pt 5 and in the USA by AWS A5.14.

Imperfections and degradation essential that the surface is cleaned immediately before welding. The normal method of cleaning is to degrease the surface, remove all surface oxide by machining, grinding or scratch brushing and finally degrease.

porosity oxide inclusions and lack of inter-run fusion weld metal solidification cracking microfissuring Additionally, precautions should be taken against post-welding imperfections such as: post-weld heat treatment cracking stress corrosion cracking

Porosity Porosity can be caused by oxygen and nitrogen from air entrainment and surface oxide or by hydrogen from surface contamination. Careful cleaning of component surfaces and using a filler material containing deoxidants (aluminium and titanium) will reduce the risk. When using argon in TIG and MIG welding, attention must be paid to shielding efficiency of the weld pool including the use of a gas backing system. In TIG welding, argon-H2 gas mixtures which provide a slightly reducing atmosphere are particularly effective.

Oxide inclusions and lack of inter-run fusion As the oxide on the surface of nickel alloys has a much higher melting temperature than the base metal, it may remain solid during welding. Oxide trapped in the weld pool will form inclusions.

In multi-run welds, oxide or slag on the surface of the weld bead will not be consumed in the subsequent run and will cause lack of fusion imperfections.

Before welding, surface oxide, particularly if it has been formed at a high temperature, must be removed by machining or abrasive grinding; it is not sufficient to wire brush the surface as this serve only to polish the oxide. During welding, surface oxide and slag must be removed between runs.

Weld metal solidification cracking Weld metal or hot cracking results from contaminants concentrating at the centreline and an unfavourable weld pool profile. Too high a welding speed produces a shallow weld pool which encourages impurities to concentrate at the centreline and, on solidification, generates sufficiently large transverse stresses to form cracks. This risk can be reduced by careful cleaning of the joint area and avoiding high welding speeds.

Similar to austenitic stainless steel, nickel alloys are susceptible to formation of liquation cracks in reheated weld metal regions or parent metal HAZ.

This type of cracking is controlled by factors outside the control of the welder such as grain size or content impurity. Some alloys are more sensitive than others.

For example, the extensively studied Inconel 718 is now less sensitive than some cast superalloys which cannot be welded without inducing liquation cracks.

Post-weld heat treatment cracking This is also known as strain-age or reheat cracking. It is likely to occur during post-weld ageing of precipitation hardening alloys but can be minimised by pre-weld heat treatment. Solution annealing is commonly used but overageing gives the most resistant condition. Inconel 718 alloy was specifically developed to be resistant to this type of cracking. Stress corrosion cracking Welding does not normally make nickel alloys susceptible to weld metal or HAZ corrosion. However, when the material will be in contact with caustic soda, fluosilicates or HF acid, stress corrosion cracking is possible. After welding, the component or weld area must be given a stress-relieving heat treatment to prevent stress corrosion cracking.

Vous aimerez peut-être aussi

- Nickel and Nickel Alloys: Weldability and Joining of MaterialsDocument4 pagesNickel and Nickel Alloys: Weldability and Joining of MaterialsMehmet SoysalPas encore d'évaluation

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Welding of Nickel AlloysDocument4 pagesWelding of Nickel AlloysMuhammed SulfeekPas encore d'évaluation

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkD'EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkPas encore d'évaluation

- Aluminium Alloys: Weldability and Joining of MaterialsDocument5 pagesAluminium Alloys: Weldability and Joining of MaterialsMehmet SoysalPas encore d'évaluation

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- Aluminium Alloys: Weldability of Materials Job Knowledge 21Document3 pagesAluminium Alloys: Weldability of Materials Job Knowledge 21kevin herryPas encore d'évaluation

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksD'EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksPas encore d'évaluation

- Weldability of Material TWIDocument4 pagesWeldability of Material TWIRaviTeja BhamidiPas encore d'évaluation

- Farm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalD'EverandFarm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalPas encore d'évaluation

- Welding Steels GuideDocument5 pagesWelding Steels GuideJlkKumarPas encore d'évaluation

- Job Knowledge 19Document5 pagesJob Knowledge 19Mehmet SoysalPas encore d'évaluation

- Weldability of Materials - Carbon Manganese and Low Alloy SteelsDocument6 pagesWeldability of Materials - Carbon Manganese and Low Alloy SteelsmanimaranPas encore d'évaluation

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghPas encore d'évaluation

- Weldability and Joining of Materials: Titanium and Titanium AlloysDocument4 pagesWeldability and Joining of Materials: Titanium and Titanium AlloysMehmet SoysalPas encore d'évaluation

- YintroDocument6 pagesYintroJoshua StrykrPas encore d'évaluation

- Weldability of Aluminium Alloys GuideDocument3 pagesWeldability of Aluminium Alloys Guidebrijesh kinkhabPas encore d'évaluation

- Welding DefectsDocument30 pagesWelding DefectsSane ShajanPas encore d'évaluation

- Welding of AuminumDocument62 pagesWelding of AuminumMalik AlsaadiPas encore d'évaluation

- Aluminium Alloys: Weldability of Materials: Alloy Designation Chemical Designation Classificatio N Filler ApplicationDocument7 pagesAluminium Alloys: Weldability of Materials: Alloy Designation Chemical Designation Classificatio N Filler ApplicationMuhammad WaseemPas encore d'évaluation

- Weldability of MaterialsDocument5 pagesWeldability of MaterialsclnPas encore d'évaluation

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekPas encore d'évaluation

- Aluminum SolderingDocument14 pagesAluminum SolderingChris De La TorrePas encore d'évaluation

- Weldability of SteelsDocument20 pagesWeldability of SteelsMuhammed SulfeekPas encore d'évaluation

- Guide Cast Iron Welding TechniquesDocument8 pagesGuide Cast Iron Welding TechniquesAgustine SetiawanPas encore d'évaluation

- Welding of Titanium and Its AlloysDocument3 pagesWelding of Titanium and Its AlloysMuhammed SulfeekPas encore d'évaluation

- WOWLibrary Preheating of Materials ConsumablesDocument4 pagesWOWLibrary Preheating of Materials ConsumableshreerPas encore d'évaluation

- Weldability of Materials - Nickel and Nickel AlloysDocument5 pagesWeldability of Materials - Nickel and Nickel AlloysmanimaranPas encore d'évaluation

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainPas encore d'évaluation

- Ajp Module-2Document75 pagesAjp Module-2Naveen S BasandiPas encore d'évaluation

- Welding Definition: by S K MondalDocument26 pagesWelding Definition: by S K MondalSaajal SharmaPas encore d'évaluation

- Welding Complete PPT With QuestionDocument50 pagesWelding Complete PPT With QuestionKBSMANITPas encore d'évaluation

- 2 Unit 2 - Brazing, Soldering and Adhesive BondingDocument13 pages2 Unit 2 - Brazing, Soldering and Adhesive BondingAditya KumarPas encore d'évaluation

- ProjectDocument34 pagesProjectSTAR PRINTINGPas encore d'évaluation

- Aluminum Forging Process and Operations GuideDocument3 pagesAluminum Forging Process and Operations Guidenadeem_mechPas encore d'évaluation

- Hot Dip GalvanizingDocument38 pagesHot Dip Galvanizingtmmsekar100% (1)

- Welding Metallurgy of Titanium AlloysDocument46 pagesWelding Metallurgy of Titanium AlloysBaraneedharanPas encore d'évaluation

- Austenitic stainless steels properties and welding guideDocument4 pagesAustenitic stainless steels properties and welding guideandy1036Pas encore d'évaluation

- Stainless Steel: Weldability and Joining of MaterialsDocument3 pagesStainless Steel: Weldability and Joining of MaterialsMehmet SoysalPas encore d'évaluation

- Annealing Stainless Steel 304-316Document4 pagesAnnealing Stainless Steel 304-316nepcom9541Pas encore d'évaluation

- Welding of Cast IronDocument35 pagesWelding of Cast IronincaurcoPas encore d'évaluation

- Thermal Spray Coatings of Zinc and Aluminum Zinc MetallizingDocument37 pagesThermal Spray Coatings of Zinc and Aluminum Zinc MetallizingromwamaPas encore d'évaluation

- CSWIP NotesDocument6 pagesCSWIP Notestulasirao.nammiPas encore d'évaluation

- Welding Cast Iron in HouseDocument5 pagesWelding Cast Iron in Housesharif1974Pas encore d'évaluation

- Tips For Successfully Welding Stainless Steel To Carbon SteelDocument5 pagesTips For Successfully Welding Stainless Steel To Carbon SteelAchu Balachandran100% (1)

- Steels: Material TypesDocument5 pagesSteels: Material Typesnike_y2k100% (1)

- AGA Aluminum Welding BrochureDocument16 pagesAGA Aluminum Welding Brochureaghosh704Pas encore d'évaluation

- Forge WeldingDocument2 pagesForge WeldingDamo Daran GPas encore d'évaluation

- Ajp Module-2Document22 pagesAjp Module-2Naveen S BasandiPas encore d'évaluation

- An Excellent Reference On Fastener DesignDocument32 pagesAn Excellent Reference On Fastener DesignSuthirak SumranPas encore d'évaluation

- Structural Steel Welds PDFDocument28 pagesStructural Steel Welds PDFshekhar2681Pas encore d'évaluation

- Ch-19 Gas Welding, Gas Cutting - Arc WeldingDocument85 pagesCh-19 Gas Welding, Gas Cutting - Arc WeldingdiptyaPas encore d'évaluation

- Soft and Hard Soldering +brazingDocument28 pagesSoft and Hard Soldering +brazingJoseph Magbanua Dato-on67% (3)

- Cold Cracks: Causes and Cures: Low Ductility of The Weld, Residual Stress and Diffusible Hydrogen in The WeldDocument4 pagesCold Cracks: Causes and Cures: Low Ductility of The Weld, Residual Stress and Diffusible Hydrogen in The WeldSharad ValviPas encore d'évaluation

- لحیم و اشکالات کستینگDocument43 pagesلحیم و اشکالات کستینگvatankhahpooyaPas encore d'évaluation

- Gas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Document8 pagesGas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Willy UioPas encore d'évaluation

- Titanium WeldingDocument6 pagesTitanium WeldingMichael ClaphamPas encore d'évaluation

- Thermal SprayDocument35 pagesThermal SprayLalu SuhaimiPas encore d'évaluation

- Aluminum WeldingDocument7 pagesAluminum Weldingarbor020% (1)

- 61 MC Elvain Cave Durand Bingham Fluids HR ValueDocument12 pages61 MC Elvain Cave Durand Bingham Fluids HR Valueharoub_nasPas encore d'évaluation

- Insulation and Construction Material Box ListDocument1 pageInsulation and Construction Material Box Listharoub_nasPas encore d'évaluation

- Engineering FundamentalsDocument40 pagesEngineering FundamentalsKenneth Vogt100% (1)

- Air Distribution System Design: Good Duct Design Increases EfficiencyDocument6 pagesAir Distribution System Design: Good Duct Design Increases Efficiencyharoub_nasPas encore d'évaluation

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasPas encore d'évaluation

- PIPE SUPPORTS 2012 EDITION GUIDEDocument174 pagesPIPE SUPPORTS 2012 EDITION GUIDEharoub_nasPas encore d'évaluation

- Step index multimode fiber specsDocument1 pageStep index multimode fiber specsharoub_nasPas encore d'évaluation

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasPas encore d'évaluation

- U Bolt Torque ChartDocument2 pagesU Bolt Torque Chartharoub_nasPas encore d'évaluation

- 1B 2 1 Types Fire PumpsDocument25 pages1B 2 1 Types Fire Pumpsharoub_nasPas encore d'évaluation

- Fire StopDocument49 pagesFire StopJavier OrnaPas encore d'évaluation

- Engineering Reference Tools ChartDocument4 pagesEngineering Reference Tools Chartharoub_nasPas encore d'évaluation

- U Bolt Torque ChartDocument2 pagesU Bolt Torque Chartharoub_nasPas encore d'évaluation

- Air Duct CalculatorDocument1 pageAir Duct CalculatorgutmontPas encore d'évaluation

- Bolt Torque ChartDocument1 pageBolt Torque Chartharoub_nasPas encore d'évaluation

- Duct Size by Dp100Document8 pagesDuct Size by Dp100haroub_nasPas encore d'évaluation

- Engine: Fastening of Engine To FrameDocument12 pagesEngine: Fastening of Engine To Frameharoub_nasPas encore d'évaluation

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasPas encore d'évaluation

- Ductulator May 2010Document8 pagesDuctulator May 2010haroub_nasPas encore d'évaluation

- Bolted Bracket DesignDocument2 pagesBolted Bracket Designharoub_nasPas encore d'évaluation

- SSS (Converted)Document3 pagesSSS (Converted)haroub_nasPas encore d'évaluation

- Bolted Joint CalculatorDocument12 pagesBolted Joint Calculatorharoub_nasPas encore d'évaluation

- ASTM Materials GuideDocument1 pageASTM Materials Guideharoub_nasPas encore d'évaluation

- Bolted Bracket DesignDocument2 pagesBolted Bracket Designharoub_nasPas encore d'évaluation

- Types of Welding Equipment ExplainedDocument6 pagesTypes of Welding Equipment Explainedharoub_nasPas encore d'évaluation

- Barometer CorrectionsDocument6 pagesBarometer Correctionsharoub_nasPas encore d'évaluation

- Engine: Fastening of Engine To FrameDocument12 pagesEngine: Fastening of Engine To Frameharoub_nasPas encore d'évaluation

- Cooling Water Pipe Material and DimensionsDocument1 pageCooling Water Pipe Material and Dimensionsharoub_nasPas encore d'évaluation

- ConsumablesDocument28 pagesConsumablesharoub_nas100% (1)

- Welding Fundamentals GuideDocument163 pagesWelding Fundamentals Guideharoub_nas100% (2)

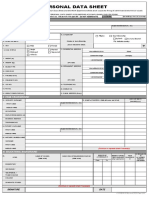

- PDS-1st PageDocument1 pagePDS-1st PageElmer LucreciaPas encore d'évaluation

- 2 - Nested IFDocument8 pages2 - Nested IFLoyd DefensorPas encore d'évaluation

- JIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test MethodsDocument43 pagesJIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test Methodsbignose93gmail.com0% (1)

- Coa - Ofx-8040a (H078K5G018)Document2 pagesCoa - Ofx-8040a (H078K5G018)Jaleel AhmedPas encore d'évaluation

- EE3331C Feedback Control Systems L1: Overview: Arthur TAYDocument28 pagesEE3331C Feedback Control Systems L1: Overview: Arthur TAYpremsanjith subramani0% (1)

- BILL OF SALE Pre ApproveDocument1 pageBILL OF SALE Pre ApprovedidinurieliaPas encore d'évaluation

- IT support tips for non-tech colleaguesDocument7 pagesIT support tips for non-tech colleaguesLeo KrekPas encore d'évaluation

- Market Participants in Securities MarketDocument11 pagesMarket Participants in Securities MarketSandra PhilipPas encore d'évaluation

- PHASE 2 - Chapter 6 Object ModellingDocument28 pagesPHASE 2 - Chapter 6 Object Modellingscm39Pas encore d'évaluation

- Scenemaster3 ManualDocument79 pagesScenemaster3 ManualSeba Gomez LPas encore d'évaluation

- Mechanical PropertiesDocument30 pagesMechanical PropertiesChristopher Traifalgar CainglesPas encore d'évaluation

- Shri Siddheshwar Co-Operative BankDocument11 pagesShri Siddheshwar Co-Operative BankPrabhu Mandewali50% (2)

- I-Parcel User GuideDocument57 pagesI-Parcel User GuideBrian GrayPas encore d'évaluation

- Sap Fi/Co: Transaction CodesDocument51 pagesSap Fi/Co: Transaction CodesReddaveni NagarajuPas encore d'évaluation

- Congress Policy Brief - CoCoLevyFundsDocument10 pagesCongress Policy Brief - CoCoLevyFundsKat DinglasanPas encore d'évaluation

- A CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHDocument9 pagesA CASE STUDY OF AU SMALL FINANCE BANK'S SHRIRAMPUR BRANCHprajakta shindePas encore d'évaluation

- Data SheetDocument14 pagesData SheetAnonymous R8ZXABkPas encore d'évaluation

- FilesDocument12 pagesFilesRajesh TuticorinPas encore d'évaluation

- Huawei 9000aDocument27 pagesHuawei 9000aAristideKonanPas encore d'évaluation

- Itec 3100 Student Response Lesson PlanDocument3 pagesItec 3100 Student Response Lesson Planapi-346174835Pas encore d'évaluation

- Triblender Wet Savoury F3218Document32 pagesTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- Verifyning GC MethodDocument3 pagesVerifyning GC MethodHristova HristovaPas encore d'évaluation

- Borneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Document6 pagesBorneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Cheng LeongPas encore d'évaluation

- Exam Venue For Monday Sep 25, 2023 - 12-00 To 01-00Document7 pagesExam Venue For Monday Sep 25, 2023 - 12-00 To 01-00naveed hassanPas encore d'évaluation

- Mint Delhi 13-12-2022Document18 pagesMint Delhi 13-12-2022Ayush sethPas encore d'évaluation

- Storage Reservior and Balancing ReservoirDocument19 pagesStorage Reservior and Balancing ReservoirNeel Kurrey0% (1)

- Personal InsuranceDocument11 pagesPersonal InsuranceSumit Kumar SharmaPas encore d'évaluation

- Final Biomechanics of Edentulous StateDocument114 pagesFinal Biomechanics of Edentulous StateSnigdha SahaPas encore d'évaluation

- 10 Consulting Frameworks To Learn For Case Interview - MConsultingPrepDocument25 pages10 Consulting Frameworks To Learn For Case Interview - MConsultingPrepTushar KumarPas encore d'évaluation

- SEEPZ Special Economic ZoneDocument2 pagesSEEPZ Special Economic ZonetarachandmaraPas encore d'évaluation