Académique Documents

Professionnel Documents

Culture Documents

Cellular Light Weight Concrete Presentation

Transféré par

Prince KumarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cellular Light Weight Concrete Presentation

Transféré par

Prince KumarDroits d'auteur :

Formats disponibles

PRESENTED BY S.BHARATHI P.K.S.

NANDHINI

Lightweight concrete can be prepared either by injecting air in its composition or can be achieved by omitting the finer sizes of the aggregate or even replacing them by a hollow, cellular or porous aggregate.

i ) No-fines concrete

ii) Lightweight aggregate concrete iii) Aerated/Foamed concrete

NO FINES CONCRETE

Cellular Lightweight Concrete (CLC) is produced by the mixing of sand, fly-ash cement foam and water in requisite proportion in ready mix plant or ordinary concrete mixer. It is very light colour. The quality of CLC production can be controlled accurately at the project site, just like concrete.

Produced with the help of a Foam Generator by using a foaming agent. It contains isolated air bubbles, which creates million of unconnected tiny voids or cells in the mix. Wide range of controlled densities from 400 kg/m3 to 1,800 kg/m3. The density recommended is 1kg/m3 for blocks and 1.2 kg/ m3 for prefab elements and walls cast in-situ.

Increasing its strength and mechanical properties. CLC is an excellent and competitive material for low -rise, load-bearing construction and outside walls as well as partitioning work in multi storage block Curing takes place within the same period as conventional concrete.

Thermal properties Sound insulation Fire and vermin resistance Durability and moisture resistance Toxicity and Breath-ability Sustainability Build ability, availability and cost

1. One mould one block

2. Cutting by wire

3. Cutting by saw blade

Heavy concrete tiles

Leyco tiles

It is being used long time ago as a conventional, simple and economical solution for buildings roofing. The practical experience shows a number of disadvantages related to using the conventional Concrete tiles for roofing.

It is one of the newly produced materials used instead of the Concrete tiles. The most ideal solution for roofing in Iraq and the Middle East where temperature varies extremely.

The area to which high performance cellular concrete can be applied in the development of light weight binary density insulating control panel system Product consideration of future generation in new building

Optimum thermal insulation Substantial weight reduction Highly increased fire rating Maximum sound absorption Fast progress in construction Saving in raw material Savings in steel reinforcement in high rise Savings in transportation Savings in craning

Very sensitive with water content in the mixtures Difficult to place and finish because of the porosity and angularity of the aggregate.

In some mixes the cement mortar may separate the aggregate and float towards the surface

Mixing time is longer than conventional concrete to assure proper mixing

As reinforced load-bearing in-situ walls and roofs in Low Rise Buildings. Even block-work can also be used for load-bearing low rise constructions. Non load-bearing internal or external walls in High Rise Buildings. Thermal Insulation of building roofs and walls & roofs of cold storage.

The lightweight concrete has a desirable strength to be an alternative construction material for the industrialized building system. Nevertheless the compressive strength is accepted to be produced as non-load bearing structure.

Vous aimerez peut-être aussi

- Foamed ConcreteDocument23 pagesFoamed ConcretebhanukerniPas encore d'évaluation

- Interiors / Art / Architecture / Travel / Style: Asia Edition / Issue 30Document20 pagesInteriors / Art / Architecture / Travel / Style: Asia Edition / Issue 30POPLY ARPas encore d'évaluation

- Project Report On Cellular Light Weight ConcreteDocument21 pagesProject Report On Cellular Light Weight ConcreteVishal Kumar100% (1)

- Rain Screen Detailing Article, by Gary Katz and Bill RobinsonDocument6 pagesRain Screen Detailing Article, by Gary Katz and Bill RobinsonDesignerLibrary100% (1)

- Architectural Period Styles TimelineDocument88 pagesArchitectural Period Styles TimelineErick Anopol Del MontePas encore d'évaluation

- Lightweight ConcreteDocument44 pagesLightweight ConcretePraveen Jain100% (2)

- DSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)Document2 pagesDSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)vijayakapoorPas encore d'évaluation

- Report On AAC BlocksDocument8 pagesReport On AAC Blocksroan sthaPas encore d'évaluation

- Glass Fiber Reinforced ConcreteDocument15 pagesGlass Fiber Reinforced ConcretevamshiPas encore d'évaluation

- "Precast Concrete Construction" (A Case Study)Document25 pages"Precast Concrete Construction" (A Case Study)honin alshaeerPas encore d'évaluation

- Green Concrete: BY Amal JamalDocument16 pagesGreen Concrete: BY Amal JamalAMAL JAMAL BITPas encore d'évaluation

- Foamed ConcreteDocument2 pagesFoamed ConcreteErwinpro ErwinPas encore d'évaluation

- Purvi Enterprises: Detailed Project ReportDocument19 pagesPurvi Enterprises: Detailed Project Report8897477809Pas encore d'évaluation

- Sika Concrete Hand BookDocument151 pagesSika Concrete Hand BookIwan TirtaPas encore d'évaluation

- Building Structural SystemsDocument13 pagesBuilding Structural SystemsAbdurahman SuleymanPas encore d'évaluation

- NSCP 2010 v1 Chapter 6 - Wood - Final DraftDocument77 pagesNSCP 2010 v1 Chapter 6 - Wood - Final DraftArnel Novales Aspe100% (14)

- Aac BlocksDocument14 pagesAac Blocksanurag singhPas encore d'évaluation

- 3-Admixtures For ConcreteDocument35 pages3-Admixtures For ConcreteMa ThiPas encore d'évaluation

- TOS 1 Unit 3 Transfer of LoadDocument13 pagesTOS 1 Unit 3 Transfer of Loadflower lily100% (1)

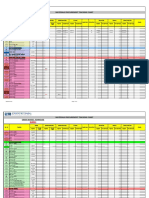

- Procurement Tracking ChartDocument5 pagesProcurement Tracking ChartjayPas encore d'évaluation

- Aac Blocks PPT 1Document13 pagesAac Blocks PPT 1Bhagyashree VenturesPas encore d'évaluation

- Light Weight ConcreteDocument27 pagesLight Weight ConcreteShashi KumarPas encore d'évaluation

- Bendable ConcreteDocument18 pagesBendable ConcreteScarlordPas encore d'évaluation

- Design of Pre Engineered Steel Building For Aircraft Hangar Using Staad Pro V8iDocument2 pagesDesign of Pre Engineered Steel Building For Aircraft Hangar Using Staad Pro V8iDharma banothuPas encore d'évaluation

- Precast Hollowcore BrochureDocument10 pagesPrecast Hollowcore BrochurecblerPas encore d'évaluation

- Investment Guidelines For CLC BlockDocument38 pagesInvestment Guidelines For CLC BlockSibiyarasu Rock Rider100% (2)

- MINI PROJECT REPORT. (Original)Document19 pagesMINI PROJECT REPORT. (Original)Yashaswi M Gowda100% (1)

- Present & Future of Lightweight ConcreteDocument7 pagesPresent & Future of Lightweight ConcreteGlobal_FriendshipPas encore d'évaluation

- Low Cost TechniquesDocument24 pagesLow Cost TechniquesAkanksha Rajput100% (1)

- Contemporary Building Material-Unit - 2Document120 pagesContemporary Building Material-Unit - 2architect sowmyaaPas encore d'évaluation

- Rapid WallsDocument13 pagesRapid WallsGeetha_shnPas encore d'évaluation

- BOQ For Aluminium PartitionDocument13 pagesBOQ For Aluminium PartitionSasanka Sekhar50% (2)

- Precast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringDocument12 pagesPrecast Cement Concrete Block Construction - Seminar Report, PPT, PDF For Civil EngineeringSoc Rua NguyenPas encore d'évaluation

- 2 Precast and Ferro CementDocument10 pages2 Precast and Ferro CementAnchal SharmaPas encore d'évaluation

- CLC Plant DetailDocument17 pagesCLC Plant DetailSibiyarasu Rock RiderPas encore d'évaluation

- Scope For Future Shear WallDocument2 pagesScope For Future Shear WallermadankrPas encore d'évaluation

- Seminar Reactive Powder ConcreteDocument16 pagesSeminar Reactive Powder ConcreteBharath MuraliPas encore d'évaluation

- Transparent Concrete SeminarDocument17 pagesTransparent Concrete Seminarimul100% (2)

- Dissertation On Earthquake Resistant DesignDocument22 pagesDissertation On Earthquake Resistant DesignVijay Kumaran100% (2)

- Requirements of Good ConcreteDocument2 pagesRequirements of Good ConcreteMuniswamaiah MohanPas encore d'évaluation

- Stabilized Mud Block - Seminar Report, PPT, PDF For Civil EngineeringDocument21 pagesStabilized Mud Block - Seminar Report, PPT, PDF For Civil EngineeringSoc Rua Nguyen100% (1)

- Composite MasonryDocument1 pageComposite MasonrySushant WaghmarePas encore d'évaluation

- Light Weight ConcreteDocument23 pagesLight Weight ConcretePavan EkbotePas encore d'évaluation

- 15 Precast Construction PDFDocument6 pages15 Precast Construction PDFJignesh PingulPas encore d'évaluation

- Air Cleaning BricksDocument4 pagesAir Cleaning BricksRaval ShivamPas encore d'évaluation

- GUNITINGDocument11 pagesGUNITINGPavithravasu100% (1)

- Internship ReportDocument107 pagesInternship Reportprem rajan100% (1)

- 10 - Multi Storey BuildingDocument33 pages10 - Multi Storey Buildinghari1008108100% (1)

- Autoclaved Aerated Concrete BlockDocument53 pagesAutoclaved Aerated Concrete BlocksharanyaPas encore d'évaluation

- Construction BlocksDocument50 pagesConstruction BlocksDivisha Jindal50% (2)

- GFRG PanelsDocument13 pagesGFRG PanelsAjay PGI/15/CV/006Pas encore d'évaluation

- Internship SeminarDocument28 pagesInternship Seminarkavya kruthiPas encore d'évaluation

- Speedy ConsDocument11 pagesSpeedy ConsRemya R. Kumar100% (1)

- U Boot TechnologyDocument8 pagesU Boot TechnologyTalmeez KundgolPas encore d'évaluation

- Research MethodologyDocument10 pagesResearch MethodologyAhmad Nasri Abdul Rahim100% (1)

- The Methods of Using Low Cost HousingDocument20 pagesThe Methods of Using Low Cost HousingAamna FatimaPas encore d'évaluation

- An Intro To Tensile Structures PDFDocument20 pagesAn Intro To Tensile Structures PDFSuraj De SilvaPas encore d'évaluation

- Reactive Powder ConcreteDocument25 pagesReactive Powder ConcreteAbhiram Ravipati100% (1)

- ElectiveDocument12 pagesElectiveayoushika abrolPas encore d'évaluation

- 14 Alternative TechnologiesDocument6 pages14 Alternative Technologiesshudhai jobePas encore d'évaluation

- Seminar Presentation On BitumenDocument18 pagesSeminar Presentation On BitumenRohit SinghPas encore d'évaluation

- BUBBLE DECK SLAB FinalDocument25 pagesBUBBLE DECK SLAB FinalAkhila Das67% (3)

- Cellular Light Weight Concrete PresentationDocument20 pagesCellular Light Weight Concrete PresentationAlokPas encore d'évaluation

- CLC Project Report.Document6 pagesCLC Project Report.polakisagar100% (1)

- CL CDocument4 pagesCL CSagar MandaleekaPas encore d'évaluation

- Module 6 - High Performance Concretes PDFDocument32 pagesModule 6 - High Performance Concretes PDFabinash choudharyPas encore d'évaluation

- CBM Unit1 Part1Document26 pagesCBM Unit1 Part1RajeshPas encore d'évaluation

- Warehouse 370 221217111832 136Document23 pagesWarehouse 370 221217111832 136nunikPas encore d'évaluation

- P2 - Basilica of Sant'andrea - MantuaDocument4 pagesP2 - Basilica of Sant'andrea - MantuaDevyani RamamoorthyPas encore d'évaluation

- Builders Guide ProductivityDocument86 pagesBuilders Guide ProductivitySSYPas encore d'évaluation

- Notes On Prestressed ConcreteDocument42 pagesNotes On Prestressed ConcreteSushant DahalPas encore d'évaluation

- Sverre Fehn Biography Pritzker 1997Document5 pagesSverre Fehn Biography Pritzker 1997Adriana HaiașPas encore d'évaluation

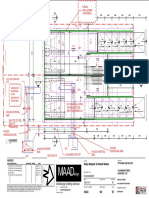

- Submission: Block B5 - Typical Storey Framing Plan Smiliar: Block B6 (Handed) (3Rd To 5Th Storey)Document1 pageSubmission: Block B5 - Typical Storey Framing Plan Smiliar: Block B6 (Handed) (3Rd To 5Th Storey)fade2black11Pas encore d'évaluation

- Rockshield External Wall Insulation System: Système D'Isolation Pour Murs Extérieurs Wärmedämmung Für AußenwandDocument23 pagesRockshield External Wall Insulation System: Système D'Isolation Pour Murs Extérieurs Wärmedämmung Für AußenwandManasviPas encore d'évaluation

- QC02001 BRC DRW SDW STR 06 Fe1 80204Document1 pageQC02001 BRC DRW SDW STR 06 Fe1 80204hbfbfkbfPas encore d'évaluation

- Interim Payment For Concrete WorksDocument52 pagesInterim Payment For Concrete Worksarchie_728Pas encore d'évaluation

- Mark Up Basement and Footing ConcordDocument2 pagesMark Up Basement and Footing ConcordSaiful IslamPas encore d'évaluation

- Jose Maria ZaragozaDocument18 pagesJose Maria ZaragozaChin Tuason71% (7)

- Daily Concrete LogDocument28 pagesDaily Concrete Logbkrishna.g1896Pas encore d'évaluation

- Student Response To Dormitory Buildings PDFDocument14 pagesStudent Response To Dormitory Buildings PDFmthgroupPas encore d'évaluation

- Viila Terrace - Priced BOQDocument2 pagesViila Terrace - Priced BOQBano SaudPas encore d'évaluation

- Boq Room 1 PDFDocument1 pageBoq Room 1 PDFAdithya PratamaPas encore d'évaluation

- Museum Romeins Halder - RESET ARCHITECTURE - ArchDailyDocument11 pagesMuseum Romeins Halder - RESET ARCHITECTURE - ArchDailyDaiana MaciulschiPas encore d'évaluation

- Some Aspects of Indo-Islamic Architecture 2Document26 pagesSome Aspects of Indo-Islamic Architecture 2Akash SharmaPas encore d'évaluation

- RIBA MARCH 2022 CompressedDocument43 pagesRIBA MARCH 2022 Compressedmayank badiwalPas encore d'évaluation

- Arches and LintlesDocument48 pagesArches and LintlesamrithakhubaPas encore d'évaluation

- Housing R&B SOR 21-22Document31 pagesHousing R&B SOR 21-22vikramjeet singhPas encore d'évaluation

- Flame SpreadDocument4 pagesFlame Spreadjack peterson milePas encore d'évaluation

- Brick Masonry Work: Masonry Work For FT Masonry Work For MeterDocument5 pagesBrick Masonry Work: Masonry Work For FT Masonry Work For MeterRauf BeşerPas encore d'évaluation

- Grade Beam Design CalculationDocument3 pagesGrade Beam Design CalculationArnold VercelesPas encore d'évaluation