Académique Documents

Professionnel Documents

Culture Documents

Biological Treatment I - Trickling Filter

Transféré par

nitin_verma30Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Biological Treatment I - Trickling Filter

Transféré par

nitin_verma30Droits d'auteur :

Formats disponibles

AIR

Sprinkler

FEED PIPE

TRICKLING FILTER

0.9-

3.5m

Diameter : 30 to 60 m

0.1-0.2

mm

Organic present in wastewater is

degraded by a population of microbes

attached to the filter media.

1. Organics will be adsorbed onto the

biological slimy layer (0.1-0.2 mm

thick)

2. the organics gets degraded by

aerobic microorganism s.

3. Thickness of slime layer increases

as the organisms grow in number

4. Oxygen will be consumed before it

can penetrate full depth,

anaerobic situation will grow, and

anaerobes grow.

5. Further growth of slimy layer shall limit the penetration of food. Food will get

exhausted before it can go to the anaerobes

6. Anaerobes then die and no longer can cling to the media surface. The whole

slimy layer breaks out and comes out with the treated wastewater. This is

called Sloughing. Sloughing is a function of organic and hydraulic loading of

the filter

ATTACHED GROWTH PROCESS

Wastewater trickles through a bed of

highly permeable porous media of plastic

or rock containing microbes and treated

water gets collected at the bottom. It

resembles like a filter bed but

operationally it is much different.

Recirculation of wastewater is not for

the same reason as Activated sludge

process. It does not help to increase the

efficiency of the system.

Recirculation is done only to ensure a low-

strength influent and constant hydraulic

loading rate to maintain a thin layer of

biofilm on the media and avoiding the

periodic sloughing of the microbes.

Recirculation helps to maintain a minimum

wetting ratio so that they do not run dry at

certain points inside the filter at any

particular point of time.

Types of Systems

Partial

BOD

removal

Intermediate- and High-Rate Filters

Recirculation of the filter effluent or final effluent permits higher

organic loadings, provides higher dosing rates on the filter to

improve the liquid distribution and better control of the slime layer

thickness, provides more oxygen in the influent wastewater flow,

and returns viable organisms. Recirculation also helps to prevent

ponding in the filter and to reduce the nuisance from odors and flies.

Low-Rate Filters

Dosing tanks are small, usually with only a 2-min detention time

based on twice the average design flow, so that intermittent dosing is

minimized. Even so, at small plants, low night-time flows may result in

intermittent dosing and recirculation may be necessary to keep the

packing moist. If the interval between dosing is longer than 1 or 2 h,

the efficiency of the process deteriorates because the character of the

biological slime is altered by a lack of moisture.

Distribution Systems

Clearance of 150 to 225 mm should be allowed between the bottom of

the distributor arm and the top of the bed. The clearance permits the

wastewater streams from the nozzles to spread out and cover the bed

uniformly. The maximum diameter is 60 m. Hence the designer should

consider this fact while fixing the size of the trickling filter units.

Nozzles are spaced unevenly so that greater flow per unit of length is

achieved near the periphery of the filter than at the center. Headloss

through the distributor is in the range of 0.6 to 1.5 m.

The underdrain system for a rock filter usually has

precast blocks of vitrified clay or fiberglass grating

laid on a reinforced-concrete subfloor

Underdrains

The floor and underdrains

must have sufficient strength

to support the packing, slime

growth, and the wastewater

and should slope to a central

or peripheral drainage

channel at a 1 to 5 percent

grade. The effluent channels

are sized to produce a

minimum velocity of 0.6 m/s

at the average daily flowrate.

Underdrains may be open at both ends, so that they may be inspected easily

and flushed out if they become plugged

Airflow

Natural ventilation has historically been

the primary means of providing airflow,

but it is not always adequate and forced

ventilation using low-pressure fans

provides more reliable and controlled

airflow.

In the case of natural ventilation, the

driving force for airflow is the

temperature difference between the

ambient air and the air inside the pores..

upward flow means the air enters from the bottom ventilation port and flow

upwards. As it flows upwards, the DO shall get consumed and when it reaches at the

top it will be much depleted. This situation is undesirable because the wastewater at

the top has the highest oxygen demand and there the concentration of oxygen shall

be the least.

If the wastewater is colder than the ambient air, the pore air will be cold and the

direction of flow will be downward. If the ambient air is colder than the

wastewater, the flow will be upward.

FILTER

Primary Clarifier

Secondary Clarifier

ONE-STAGE WITH RECIRCULATION

FILTER

STAGE 1

Primary

Clarifier

Secondary

Clarifier

Secondary

Clarifier

TWO-STAGE WITH RECIRCULATION

FILTER

STAGE 2

Q

r

Q, S

i

Q, S

Process Design For Trickling Filter

For Trickling Filters with Rock Media: (NRC Equation): Single Stage

VF

W

E

44 . 0 1

100

+

=

E= efficiency of BOD removal in the filter

W= BOD loading to the Filter, kg/day

V= volume of the filter media, m

3

F= Recirculation Factor

R= Recirculation ratio

2

) 10 / 1 (

1

R

R

F

+

+

=

Q

Q

r

=

For Trickling Filters with Rock Media: (NRC Equation): Two Stage

21 21

21

21

44 . 0 1

100

F V

W

E

+

=

E

21

= efficiency of BOD removal in the first

filter of two stage process

W

21

= BOD loading to the Filter1 of 2 stage

process, kg/day

V

21

= volume of the filter media, m

3

F= Recirculation Factor

R

21

= Recirculation ratio in filter 1 of 2 stage

filtration

22 22

22

21

22

1

44 . 0

1

100

F V

W

E

E

+

=

For Trickling Filter Made of Plastic Media

Eckenfelders Equation

] ) ( exp[

n

v

m

a

i

Q D KS

S

S

=

Germains Equation

] ) ( exp[

, 20

n

v D

i

Q D k

S

S

=

S= BOD

5

of the settled effluent, mg/L

S

0

= Total BOD5 of wastewater influent to

the filter, mg/L

D = Depth of the filter. M

Q

v

= Q/A

A= surface area of the filter

S

a

= Specific surface area of the filter,

= surface area/ volume.

K= observed reaction rate constant, m/d

k

20,D

= treatability constant for a filter with a

specific depth D

n= experimental constant, usually 0.5

x= 0.5 for vertical and rock media filters

=0.3 for cross-flow plastic media filters

Temperature correction for k is same as

that of BOD, but = 1.035 (not 1.047)

x

D D

D

D

k k

|

|

.

|

\

|

=

2

1

1 , 20 2 , 20

Design a trickling filter using rock media to treat wastewater with flowrate 4.5

million liters per day. BOD of the raw sewage 250 mg/L. BOD removed in the

primary clarifier is 25%. The treated wastewater needs to discharged to a surface

water body where the regulatory limit for BOD5 is 30 mg/L. The fluctuation in the

wastewater flowrate can be controlled by keeping a recirculation ratio of 1.4.

Influent BOD5 = 75% of 250 mg/L =187.5 mg/L

Effluent BOD5= 30 mg/L

Efficiency, E =

% 84 100 *

5 . 187

30 5 . 187

=

VF

W

E

44 . 0 1

100

+

=

2

) 10 / 4 . 1 1 (

4 . 1 1

+

+

= F

846 . 1 =

W= BOD loading to the Filter, kg/day

=4.5*10

6

*187.5/10

6

=843.75 kg/day

846 . 1 *

75 . 843

44 . 0 1

100

84

V

+

=

3

m 96 . 2438 = V

Assume a depth of 1.5 m

m 5 . 45

5 . 1

96 . 2438 4 4

= = =

t t H

V

Dia

It is proposed to use a two stage plant instead of the single stage plant in the

previous example. The total volume of filter media remains the same and gets

equally divided, (i.e each filter is to contain half of the filter media as earlier). Use

the same recirculation ratio. Find out the effluent BOD

5

.

3 3

22 21

m 5 . 1219 2 / m 96 . 2438 = = =V V

2

22 21

) 10 / 4 . 1 1 (

4 . 1 1

+

+

= = F F

846 . 1 =

21 21

21

21

44 . 0 1

100

F V

W

E

+

=

W

21

= BOD

5

loading to the first Filter, kg/day

=4.5*10

6

*187.5/10

6

=843.75 kg/day

% 77 . 78

846 . 1 * 5 . 1219

75 . 843

44 . 0 1

100

21

=

+

= E

W

22

=BOD loading of the 2

nd

filter =BOD of wastewater in the effluent of first stage

% 11 . 63

846 . 1 * 5 . 1219

05 . 179

1

44 . 0

1

100

21

22

=

+

=

E

E

Effluent BOD

5

= (1-0.631)*39.80

= 14.68 mg/L

Effluent BOD

5

after 1

st

stage

= (1-0.7877)*187.5

= 39.80 mg/L

=(1-0.7877)*843.75= 179.05 kg/day

Design a two stage trickling filter process for wastewater with influent BOD

5

=250

mg/L. The treated effluent should have a BOD

5

of 30 mg/L. For both the filters

use same depth of 2 m and recirculation ratio 2. The quantity of wastewater is

8000 cum/day. Assume that efficiencies of the two filters are the same.

Overall efficiency = E =

% 88 100 *

250

30 250

=

2 1

E E =

FILTER

STAGE 1

FILTER

STAGE 2

S

i

E

1

S

e1

S

e

E

2

Overall efficiency =E

i

e i

S

S S

E

=

i e

S E S ) 1 ( =

i e

S E S ) 1 (

1 1 ,

=

i e e

S E E S E S ) 1 )( 1 ( ) 1 (

1 2 1 , 2

= =

i i

S E E S E ) 1 )( 1 ( ) 1 (

1 2

=

65 . 0

2 1

= = E E

Overall Efficiency

After First Stage,

After second Stage,

Equating S

e

from above

Stage 1

2

22 21

) 10 / 2 1 (

2 1

+

+

= = F F

083 . 2 =

W

21

= BOD

5

loading to the first Filter, kg/day

=8000*10

3

*250/10

6

=2000 kg/day

21 21

21

21

44 . 0 1

100

F V

W

E

+

=

083 . 2 *

2000

44 . 0 1

100

65

21

V

+

=

3

21

m 02 . 641 = V

m 2 . 20

2

02 . 641 4 4

21

21

= = =

t t H

V

D

Stage 2

W

22

= BOD

5

loading to the second Filter, kg/day

=8000*10

3

*250(1-0.65)/10

6

=700 kg/day

22 22

22

21

22

1

44 . 0

1

100

F V

W

E

E

+

=

083 . 2 *

700

65 . 0 1

44 . 0

1

100

65

22

V

+

=

3

22

m 76 . 1831 = V

H

21

= 2 m

m 14 . 34

2

76 . 1831 4 4

22

22

22

= = =

t t H

V

D

H

22

= 2 m

1. Compute BOD

5

loading to each of the filters

2. Compute hydraulic loading onto each of the filters

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

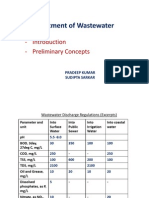

- Treatment of Wastewater IntroductionDocument14 pagesTreatment of Wastewater Introductionnitin_verma30Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Determination of Caffeine in Tea SamplesDocument5 pagesDetermination of Caffeine in Tea Samplesnitin_verma30100% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- NarayanaDocument1 pageNarayananitin_verma30Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Calendar For Examinations - 2010Document9 pagesCalendar For Examinations - 2010nitin_verma30Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Principles of Gas Chromatography 2Document12 pagesPrinciples of Gas Chromatography 2Enanahmed EnanPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Winter Intership SyllabusDocument14 pagesWinter Intership SyllabusAjayPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Flume User GuideDocument48 pagesFlume User GuideRajulPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- RXM XXX ES Data GuideDocument11 pagesRXM XXX ES Data GuideAstrid PorticaPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Integrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsDocument17 pagesIntegrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsBodieTechPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Seam Strength of Corrugated Plate With High Strength SteelDocument15 pagesSeam Strength of Corrugated Plate With High Strength SteelMariano SalcedoPas encore d'évaluation

- MDM Heiana Nadia Hamzah: Prepared byDocument50 pagesMDM Heiana Nadia Hamzah: Prepared bySyarfa FurzannePas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Google F1 DatabaseDocument12 pagesGoogle F1 DatabasenullonePas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- GGDocument8 pagesGGGaurav SharmaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 001-MBA-SPSS Applications - 10-06-2023Document74 pages001-MBA-SPSS Applications - 10-06-2023seyon sithamparanathanPas encore d'évaluation

- Soil Mechanics PowerpointDocument239 pagesSoil Mechanics PowerpointEdcel Angelo TomasPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- QuesTeksFerriumC61C64andC6 PDFDocument23 pagesQuesTeksFerriumC61C64andC6 PDFEmily MillerPas encore d'évaluation

- Experiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormDocument29 pagesExperiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormModi rutvikPas encore d'évaluation

- Grade9 Physics PDFDocument2 pagesGrade9 Physics PDFRajPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- CATL 37V 50ah Lithium Ternary Battery Cell - LiFePO4 BatteryDocument4 pagesCATL 37V 50ah Lithium Ternary Battery Cell - LiFePO4 BatterymlutfimaPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- ME361 - Manufacturing Science Technology: Measurements and MetrologyDocument20 pagesME361 - Manufacturing Science Technology: Measurements and MetrologyKartikeyaPas encore d'évaluation

- S32K14X RM Rev 4Document1 929 pagesS32K14X RM Rev 4Nguyễn Duy HùngPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Chapter 1 AssignmentDocument4 pagesChapter 1 Assignmenthamster808100% (3)

- Bipolar Junction Transistor ModelsDocument21 pagesBipolar Junction Transistor ModelsecedepttPas encore d'évaluation

- Webinar HPLC PT GeneCraft LabsDocument44 pagesWebinar HPLC PT GeneCraft LabsBayu Indra Permana100% (1)

- Field Guide To Visual and Ophthalmic Optics PDFDocument120 pagesField Guide To Visual and Ophthalmic Optics PDFRani AprianiPas encore d'évaluation

- The Equation of The Straight Line: y MX CDocument6 pagesThe Equation of The Straight Line: y MX CMarc SugruePas encore d'évaluation

- Harnack and Mean Value Inequalities On Graphs: 1 Introduction and Main ResultsDocument8 pagesHarnack and Mean Value Inequalities On Graphs: 1 Introduction and Main ResultsNo FacePas encore d'évaluation

- Contoh SRSDocument46 pagesContoh SRSFatur RachmanPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Preserving and Randomizing Data Responses in Web Application Using Differential PrivacyDocument9 pagesPreserving and Randomizing Data Responses in Web Application Using Differential PrivacyInternational Journal of Innovative Science and Research Technology100% (1)

- STR ReportDocument30 pagesSTR ReportrahulPas encore d'évaluation

- Civil Engineering - Development Length Calculation As Per Indian CodeDocument2 pagesCivil Engineering - Development Length Calculation As Per Indian CodeOsthePrakashPas encore d'évaluation

- Tutorial 1 PDFDocument2 pagesTutorial 1 PDFSYAFIQAH ISMAIL100% (1)

- Chapter 9 and 10Document18 pagesChapter 9 and 10billPas encore d'évaluation

- Medium Voltage Swgr9Document3 pagesMedium Voltage Swgr9kjfensPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)