Académique Documents

Professionnel Documents

Culture Documents

Composite Insulator

Transféré par

Harsimran KaurCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Composite Insulator

Transféré par

Harsimran KaurDroits d'auteur :

Formats disponibles

The insulators or dielectric, is a material that resists

the flow of electric current. An insulating material has atoms with tightly bonded valence electron Material like glass, paper, Teflon are very good electric insulators.

A composite insulator in one made of at least two

insulating parts, namely a core and a housing equipped with metal fittings. Composite insulators, for example, can consist either of individual sheds mounted on the core, with or without an intermediate sheath, or alternatively, of a housing directly moulded or cast in one or several pieces on to the core. This kind of insulator can be used on transmission and distribution lines, and also the electric railways.

The first electrical systems to make use of insulators were telegraph lines;

direct attachment of wires to wooden poles was found to give very poor results, especially during damp weather. The first glass insulators used in large quantities had an unthreaded pinhole. These pieces of glass were positioned on a tapered wooden pin, vertically extending upwards from the pole's crossarm (commonly only two insulators to a pole and maybe one on top of the pole itself). Natural contraction and expansion of the wires tied to these "threadless insulators" resulted in insulators unseating from their pins, requiring manual reseating. Amongst the first to produce ceramic insulators were companies in the United Kingdom, with Stiff and Doulton using stoneware from the mid 1840s, Joseph Bourne (later renamed Denby) producing them from around 1860 and Bullers from 1868. Utility patent number 48,906 was granted to Louis A. Cauvet on July 25, 1865 for a process to produce insulators with a threaded pinhole. To this day, pin-type insulators still have threaded pinholes. The invention of suspension-type insulators made high-voltage power transmission possible. Pin-type insulators were unsatisfactory over about 60,000 volts. A large variety of telephone, telegraph and power insulators have been made.

Composite Suspension Long

Rod Insulators

Used on overhead suspension or tension

power transmission lines, and suitable for the middle and above contamination areas, particularly in the heavy contamination areas. There are several ways of connecting of fitting:ball & socket, clevis & tongue, Yclevis. Generally, the voltage level is from 10 KV to 1000KV. 15kv, 25kv, 35kv ANSI deadend insulator, 66KV, 110KV, 220KV, 400KV,500KV silicone rubber insulator and etc is normally used.

It is suitable for the rebuild

of city lines. The voltage levels typically from 6 to 36 KV. 11kv and 33kv pin composite insulators are normal types. Its top and bottom installed are the same as the corresponding size of porcelain insulator, so they can be interchangeable use.

The composite station post

insulators mainly apply to transformer substation and switches and other apparatus. The voltage can be upto 220KV and now most of the small apparatus has chosen polymer post insulator to instead of porcelain ones since they have more advantages.

It has an effective use of a

narrow corridor pressure transmission and applicable to rebuild of city power net. It can also reduce the tower height, saving manpower, material and financial resources. It has a superior performance than porcelain insulator.

Composite

insulator for railway traction lines is used in tunnels of electrified railway under severe conditions. They can effectively prevent pollution flashover outage and free from cleaning and maintenance work. It will hold on not only tension, but also bending. With a very small size, they can hardly be substituted by porcelain or glass insulators in case if small tunnel space

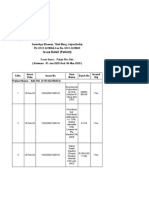

FACTORS Resistance to flashovers in Polluted atmosphere. Resistance to puncture Resistance to Cracking and Erosion in Polluted atmosphere Contamination & Pollution Low

CERAMIC High

COMPOSITE

Puncturable Low

Not puncturable High

Highly affected

Performance not affected

Hydrophobicity

Self cleaning property Maintenance

Non hydrophobic

Due to Glaze and inclination of sheds Needs maintenance like cleaning, washing, greasing More

Unique Hydrophobicity character.

Due to Hydrophobicity recovery characteristic. No maintenance is required

Weight

10% to 35% of Ceramic Insulator

Resistance to breakage and Vandalism

Breakable in Vandalism prone areas

Unbreakable

It is a new type to instead

of porcelain buy strain insulators and have better tensile strength, low weight and good looking, the normal type develop now is 97KN. Normally used in Africa. only the end fitting and fiber glass core and covered with something special to have better performance.

This type insulator is

suitable for outdoor used in AC switchgear and switch disconnectors with voltage up to 25 kV and 38.5KV. Main advatages are low weight, outstanding dielectric strength and extreme mechanical endurance

Light weight (25-30% less than ceramic insulator) Silicone rubber sheds provides perfect hydrophobic

performance, Good resistance to aging, tracking and erosion. Stable behavior at extreme climate conditions. Long term surface hydrophobicity. Suitability for polluted environment, salty atmospheres etc. Resistance to breakage and vandalism, Practically unbreakable. Superior anti-tracking properties. High mechnical strength. Ease of installation (easier handling with lighter equipment and labor at the job site) Resistance to Seismic Shock

The paper discusses selected advantages of composite

insulators and structures for lines with compact requirements. Beside the recognized properties of Silicone Rubber insulators in polluted areas, the mechanical performance offers with the safe failure mode a feature that improves the line reliability significantly and permits suitable arrangements for areas with limited right of ways. In respect to the principle performance, the shown examples for transmission level are applicable to distribution level as well. The substitution of steel as reinforcing material by carbon fibres is shown on the example of an 110kV pole for a line upgrade from 52 kV.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Microorganisms As Bio Indicators and BiosensorsDocument42 pagesMicroorganisms As Bio Indicators and BiosensorsJAFFER YOUSUF85% (13)

- DFCCILDocument6 pagesDFCCILHarsimran KaurPas encore d'évaluation

- Conventional Energy Source To Meet Power Demand of India in FutureDocument14 pagesConventional Energy Source To Meet Power Demand of India in FutureHarsimran KaurPas encore d'évaluation

- 15 Railways 19Document80 pages15 Railways 19Harsimran KaurPas encore d'évaluation

- SSC CGL Tier 1 Omr Answer SheetDocument2 pagesSSC CGL Tier 1 Omr Answer SheetHarsimran KaurPas encore d'évaluation

- Vigilance Manual2012Document236 pagesVigilance Manual2012Harsimran KaurPas encore d'évaluation

- Duplicate Bill: For Any Queries On This Bill Please Contact Sdo4405@ho - Mahadiscom.inDocument1 pageDuplicate Bill: For Any Queries On This Bill Please Contact Sdo4405@ho - Mahadiscom.inHarsimran KaurPas encore d'évaluation

- Recent Advances in Sensor Technology: Hans-Rolf Tränkler, Olfa KanounDocument8 pagesRecent Advances in Sensor Technology: Hans-Rolf Tränkler, Olfa KanounHarsimran KaurPas encore d'évaluation

- Determination of Available Transfer Capability (ATC) Considering Integral Square Generator Angle (ISGA)Document6 pagesDetermination of Available Transfer Capability (ATC) Considering Integral Square Generator Angle (ISGA)Harsimran KaurPas encore d'évaluation

- FINAL SeminarDocument28 pagesFINAL SeminarSree Poojitha ModupalliPas encore d'évaluation

- GtbitinfosysDocument3 pagesGtbitinfosysHarsimran KaurPas encore d'évaluation

- Facts About FACTSDocument31 pagesFacts About FACTSHarsimran KaurPas encore d'évaluation

- Determination of The Type of Fluid Flow Using Reynold's ApparatusDocument6 pagesDetermination of The Type of Fluid Flow Using Reynold's Apparatusleo besaPas encore d'évaluation

- Alkyd PrimerDocument1 pageAlkyd PrimerMihai AlexandruPas encore d'évaluation

- 21 Breuling Alfermann Reinhard 1985Document4 pages21 Breuling Alfermann Reinhard 1985nurul9535Pas encore d'évaluation

- Pompa WarmanDocument2 pagesPompa WarmanRahmad Saleh SiregarPas encore d'évaluation

- Module 4 Science 8Q3Document15 pagesModule 4 Science 8Q3Ratay EvelynPas encore d'évaluation

- F 2282 - 03 - RjiyodiDocument15 pagesF 2282 - 03 - RjiyodikrutikPas encore d'évaluation

- PChem Manual Ed 2023Document73 pagesPChem Manual Ed 2023rebecca niilonga fotolelaPas encore d'évaluation

- By Padiga Akhilesh Go6155 Vikas Reddy Marepally Go6148 Peketi Padmakanth Go6159Document35 pagesBy Padiga Akhilesh Go6155 Vikas Reddy Marepally Go6148 Peketi Padmakanth Go6159Wendel MeloPas encore d'évaluation

- Open Test Series - Paper-1 - (21-09-2021)Document31 pagesOpen Test Series - Paper-1 - (21-09-2021)Yogesh KhatriPas encore d'évaluation

- 01 Gaseous State#### PDFDocument49 pages01 Gaseous State#### PDFRohit JainPas encore d'évaluation

- Molecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineDocument7 pagesMolecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineThomas CharmPas encore d'évaluation

- GD-1884 Manual PDFDocument10 pagesGD-1884 Manual PDFAnonymous srwHCpAPas encore d'évaluation

- SD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)Document7 pagesSD - Cupric Tartrate TS, Alkaline (Fehling's Solution) (B) (USP204) (EU)atikah razakPas encore d'évaluation

- Mndy ParchiDocument858 pagesMndy ParchiPAN SERVICESPas encore d'évaluation

- Maintenance Solutions For Hvac Systems: Belzona Protective Coatings and Engineering CompositesDocument12 pagesMaintenance Solutions For Hvac Systems: Belzona Protective Coatings and Engineering CompositesSUHEL NEVREKARPas encore d'évaluation

- Post Activity PrelimDocument91 pagesPost Activity PrelimWYATT ASTERISCOPas encore d'évaluation

- Hydrodesulfurization Unit For Natural Gas Condensate: Simulation Based On Aspen Plus SoftwareDocument7 pagesHydrodesulfurization Unit For Natural Gas Condensate: Simulation Based On Aspen Plus SoftwareRuben MaciasPas encore d'évaluation

- Safety Data Sheet PropanDocument9 pagesSafety Data Sheet PropanFahri SofianPas encore d'évaluation

- Home Made Soap: Using Glitz Caustic SodaDocument1 pageHome Made Soap: Using Glitz Caustic Sodaabeiasa_biomedPas encore d'évaluation

- Carbon Fiber Reinforced CFRCDocument22 pagesCarbon Fiber Reinforced CFRCVince Carlo C GarciaPas encore d'évaluation

- Rioflex RapidDocument2 pagesRioflex RapidJaritza Tahiz Ramirez VallesPas encore d'évaluation

- A Look at Perfusion - The Upstream Continuous ProcessDocument2 pagesA Look at Perfusion - The Upstream Continuous ProcessFISHPas encore d'évaluation

- Final Key WednesdayDocument7 pagesFinal Key WednesdayThanh LêPas encore d'évaluation

- Inert Corrosion-Free Structural Repair and Protection SystemDocument16 pagesInert Corrosion-Free Structural Repair and Protection SystemLempira TorresPas encore d'évaluation

- List of HW RecyclersDocument11 pagesList of HW RecyclersUnitedWork ServicePas encore d'évaluation

- Effect of at Home Bleaching With Different Thickeners and Aging On Physical Properties of A NanocompositeDocument10 pagesEffect of at Home Bleaching With Different Thickeners and Aging On Physical Properties of A NanocompositeDelyana Fitria DewiPas encore d'évaluation

- Pre-Sanded Cemwash: PRE-SANDED CEMWASH Is An Economical Attractive Decorative Portland Cement-Based Paint Manufactured byDocument1 pagePre-Sanded Cemwash: PRE-SANDED CEMWASH Is An Economical Attractive Decorative Portland Cement-Based Paint Manufactured byTonderai RuserePas encore d'évaluation

- MRU Optima 7 BrochuresDocument3 pagesMRU Optima 7 BrochureshaizriPas encore d'évaluation

- MasoneilanDocument20 pagesMasoneilanJohn MarshalPas encore d'évaluation