Académique Documents

Professionnel Documents

Culture Documents

Ceramics 130430211844 Phpapp02

Transféré par

Omar Abd ElsalamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ceramics 130430211844 Phpapp02

Transféré par

Omar Abd ElsalamDroits d'auteur :

Formats disponibles

CERAMICS

BY GROUP 2

CERAMICS

From Greek word Keramos (clay)

Compounds of metallic and non-metallic

elements

Most frequently oxides, nitrides, carbides

and silicates

2 Classes of Ceramics

TRADITIONAL CERAMICS

Ceramic materials that are derived from common,

naturally occurring raw materials such as clay

minerals and quartz sand.

A type of ceramic used in traditional applications

such as construction, earthenware, and glassware.

ADVANCED CERAMICS

A type of ceramic exhibiting a high degree of

industrial efficiency.

A type of ceramic used in specialized, recently

developed applications.

Advanced ceramics are ideally suited for industrial

applications that provide a physical interface

between different components due to their ability to

withstand high temperatures, vibration and

mechanical shock.

4 CLASSIFICATION OF

CERAMICS

AMORPHOUS CERAMICS

Lacking a definite repeating form, shape or

structure

Glasses

CRYSTALLINE CERAMICS

- atoms (or ions) are arranged in a regularly repeating pattern in three

dimensions (i.e., they have long-range order)

- Crystalline ceramics are the Engineering ceramics

High melting points

Strong

Hard

Brittle

Good corrosion resistance

EXAMPLE OF CRYSTAL

STRUCTURE

Rock salt structure(AX)(NaCl ) Spinel structure(AB2X4)(MgAl2O4)

BONDED CERAMICS

Individual crystals are bonded together by a glassy

matrix, as with most clay - derived products

CEMENTS

some are crystalline, while others contain both

crystalline and amorphous phases

STRUCTURES OF CERAMICS

SIMPLE CRYSTAL STRUCTURES

Containing ionic or covalent bonds, or a mixture of

two.

COMPLEX SILICATE STRUCTURES

The majority of ceramic materials, in particular

those derived from clay, sand, or cement, contain

the element silicon in the from of silicates.

CLAY

Al

2

Si

2

O

5

(OH)

4

.

TRICALCIUM SILICATE

Ca

3

SiO

5

ALUMINA

Al

2

O

3

TYPES OF CERAMIC PRODUCTS

STRUCTURAL

A common traditional ceramic used in the

construction industry. Structural ceramics include

brick, clay pipes, and concrete.

REFRACTORIES

A type of ceramic that can withstand extremely

high temperatures. Refractories are used in

industrial furnaces.

WHITEWARES

A traditional ceramic used to make pottery and

porcelain. Whiteware ceramics often have a glassy

structure.

GLASSES

A type of ceramic material characterized by its

noncrystalline structure. Glasses do not solidify at

a specific temperature. Instead, they gradually

solidify as the temperature decreases.

ABRASIVES

type of ceramic material that is very hard and wear

resistant. Abrasives also refer to tools used to

wear away and remove material.

SYNTHETIC

Type of ceramic material that is made from

chemicals or artificial substances rather than from

natural ones.

CEMENT

Bind other materials together. Used for roads, bridges,

buildings, dams, etc.

ADVANCED CERAMICS

Advanced or Technical Ceramics are parts made from oxide

ceramics, non-oxide ceramics, or composites; each providing

unique material properties of the finished piece. The majority

of these products are manufactured with high density and low

porosity and are used in high performance applications.

APPLICATION OF ADVANCED

CERAMICS

STRUCTURAL

ELECTRICAL

COATINGS

CHEMICAL AND ENVIRONMENTAL

3 CLASSIFICATION OF

TECHNICAL CERAMICS

OXIDES

Oxidation resistant

chemically inert

electrically insulating

generally low thermal conductivity

slightly complex manufacturing

low cost for alumina

more complex manufacturing

higher cost for zirconia.

NON-OXIDES

Low oxidation resistance

extreme hardness

chemically inert

high thermal conductivity

electrically conducting

difficult energy dependent manufacturing and high cost.

CERAMIC BASED COMPOSITE

Toughness

low and high oxidation resistance (type related)

variable thermal and electrical conductivity

complex manufacturing processes

high cost.

PROPERTIES OF CERAMICS

MECHANICAL

Mechanical properties are important in structural

and building materials as well as textile fabrics.

They include the many properties used to

describe the strength of materials such as:

elasticity / plasticity, tensile strength,

compressive strength, shear strength, fracture

toughness & ductility (low in brittle materials),

and indentation hardness.

ELECTRICAL

Insulating properties

In contrast to Metals Ceramics have very low electrical

conductivity due to Ionic-Covalent Bonding which does

not form free electrons.

Electrical conductivity

Electrical conductivity is ability of material to conduct

electric current.

Most of ceramic materials are dielectric (materials,

having very low electric conductivity, but supporting

electrostatic field).

Dielectric Strength

ability of a material to prevent electron

conductivity at high voltage. Dielectric strength is

determined as value of electric field strength

(expressed in v/m) at which electron conductivity

breakdown occurs.

Dielectric Constant

relative (to vacuum) ability of a material to carry

alternating current (dielectric constant of vacuum

equals to 1).

Semi-conducting properties

used for manufacturing varistors (resistors

with non-linear current-voltage

characteristic, which are used for over-

voltage protection) and Positive

Temperature Coefficient (PTC) Resistors.

Superconducting properties

near-to-zero electric resistivity

THERMAL

Thermal Conductivity ()

amount of heat passing in unit time

through unit surface in a direction normal

to this surface when this transfer is driven

by unite temperature gradient under

steady state conditions.

Thermal Expansion (Coefficient

of Thermal Expansion)

is relative increase in length per unite

temperature rise

Heat Capacity is amount of heat required to

raise material temperature by one unit.

Specific Heat Capacity is amount of heat

required to raise temperature of unit mass of

material by one unit

Thermal Shock Resistance

ability of material to withstand sharp

changes in temperature.

Maximum Service Temperature

Ceramic materials retain

their properties at elevated temperatures

due to the strong ionic-covalent bonding.

MAGNETIC

Isotropic ceramic magnet - equal

magnetic properties in all directions

Anisotropic ceramic magnets -

magnetic properties in the direction of

pressing.

OPTICAL

REFRACTION

+ Light that is transmitted from one medium into another,

undergoes refraction.

+ Refractive index, (n) of a material is the ratio of the speed of light

in a vacuum (c = 3 x 108 m/s) to the speed of light in that

material.

+ n = c/v

CHEMICAL

Ceramics usually have a combination of

stronger bonds called ionic (occurs between a

metal and nonmetal and involves the

attraction of opposite charges when electrons

are transferred from the metal to the

nonmetal); and covalent (occurs between two

nonmetals and involves sharing of atoms).

GENERAL COMPARISON OF

MATERIALS

Property Ceramic Metal Polymer

Hardness Very High Low Very Low

Elastic modulus Very High High Low

Thermal expansion High Low Very Low

Wear resistance High Low Low

Corrosion resistance High Low Low

GENERAL COMPARISON OF

MATERIALS

Property Ceramic Metal Polymer

Ductility Low High High

Density Low High Very Low

Electrical conductivity Depends High Low

on material

Thermal conductivity Depends High Low

on material

Magnetic Depends High Very Low

on material

CERAMIC PROCESSING STEPS

O MILLING - Milling is the process by which materials

are reduced from a large size to a smaller size.

It involves the ff:

breaking up cemented material

pulverization

attrition

compression

impact

Crushing & Grinding (to get

ready ceramic powder for

shaping)

Ball Milling

OBATCHING The process of weighing oxides

according to recipes, and preparing them for mixing and

drying.

OMIXING - occurs after batching and is performed with

various machines, such as dry mixing ribbon mixers.

OFORMING - making the mixed material into shapes

FORMING involves the ff:

EXTRUSION - a process used to create objects of a

fixed cross-sectional profile

Pressing to make shaped parts

Slip casting

ODRYING is removing the water or binder from

the formed material.

O FIRING is where the dried parts pass through

a controlled heating process, and the oxides

are chemically changed to cause sintering

and bonding.

RIBBON MIXERS

SLIP CASTING

DRYING PROCESS

APPLICATIONS OF CERAMICS

Aerospace: space shuttle tiles, thermal

barriers, high temperature glass

windows, fuel cells

Consumer Uses: glassware, windows,

pottery, Corning ware, magnets,

dinnerware, ceramic tiles, lenses, home

electronics, microwave transducers

Automotive: catalytic converters, ceramic filters,

airbag sensors, ceramic rotors, valves, spark

plugs, pressure sensors, thermistors, vibration

sensors, oxygen sensors, safety glass

windshields, piston rings

Medical (Bioceramics): orthopedic joint

replacement, prosthesis, dental restoration,

bone implants

Military: structural components for ground, air

and naval vehicles, missiles, sensors

Computers: insulators, resistors,

superconductors, capacitors, ferroelectric

components, microelectronic packaging

Other Industries: bricks, cement,

membranes and filters, lab equipment

Communications: fiber optic/laser

communications, TV and radio

components, microphones

EXAMPLES OF CERAMICS

Barium titanate widely used in

electromechanical transducers, ceramic

capacitors, and data storage elements.

Bismuth strontium calcium copper oxide a high-

temperature superconductor

Boron nitride a graphite-like one used as a

lubricant, and a diamond-like one used as an

abrasive.

Ferrite is used in the magnetic cores of electrical

transformers and magnetic core memory.

Lead zirconate titanate (PZT) PZT is used as an

ultrasonic transducer, as its piezoelectric properties

greatly exceed those of Rochelle salt.

Magnesium diboride (MgB2) is an unconventional

superconductor.

Porcelain is used for a wide range of household and

industrial products.

Sialon (Silicon Aluminium Oxynitride) has high strength;

high thermal, shock, chemical and wear resistance, and

low density. These ceramics are used in non-ferrous

molten metal handling, weld pins and the chemical

industry.

Silicon carbide (SiC) is used as a susceptor in

microwave furnaces, a commonly used abrasive, and as

a refractory material.

Silicon nitride (Si3N4) is used as an abrasive powder.

Steatite (magnesium silicates) is used as an electrical insulator.

Titanium carbide Used in space shuttle re-entry shields and

scratchproof watches.

Uranium oxide (UO2), used as fuel in nuclear reactors.

Yttrium barium copper oxide (YBa2Cu3O7-x), another high

temperature superconductor.

Zinc oxide (ZnO), which is a semiconductor, and used in the

construction of varistors.

Zirconium dioxide (zirconia), Its high oxygen ion conductivity

recommends it for use in fuel cells and automotive oxygen sensors.

Most ceramic knife blades are made of this material.

Partially stabilised zirconia (PSZ) is much less brittle than other

ceramics and is used for metal forming tools, valves and liners,

abrasive slurries, kitchen knives and bearings subject to severe

abrasion.

END

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Synthetic Fibres & PlasticsDocument17 pagesSynthetic Fibres & PlasticsOmar Abd ElsalamPas encore d'évaluation

- NBSS Final PresentationDocument15 pagesNBSS Final PresentationOmar Abd ElsalamPas encore d'évaluation

- 978 3 659 36178 4 - Coverpreview 2Document1 page978 3 659 36178 4 - Coverpreview 2Omar Abd ElsalamPas encore d'évaluation

- Fortna SyllabusDocument10 pagesFortna SyllabusOmar Abd ElsalamPas encore d'évaluation

- Graphene Materials 2Document2 pagesGraphene Materials 2Omar Abd ElsalamPas encore d'évaluation

- Ceramics 120325085721 Phpapp02Document13 pagesCeramics 120325085721 Phpapp02Omar Abd ElsalamPas encore d'évaluation

- Particle Processing Research: Terry A. Ring Chemical Engineering University of UtahDocument58 pagesParticle Processing Research: Terry A. Ring Chemical Engineering University of UtahOmar Abd ElsalamPas encore d'évaluation

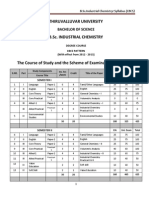

- B.sc. Industrial ChemistryDocument79 pagesB.sc. Industrial ChemistryOmar Abd Elsalam0% (1)

- Electron Withdrawing and Electron Donating GroupsDocument2 pagesElectron Withdrawing and Electron Donating GroupsOmar Abd ElsalamPas encore d'évaluation

- Syllabus For Ceramics and Ceramics and Ceramic Sculpture: Hans CoperDocument9 pagesSyllabus For Ceramics and Ceramics and Ceramic Sculpture: Hans CoperOmar Abd ElsalamPas encore d'évaluation

- AnticorrosionDocument128 pagesAnticorrosionOmar Abd ElsalamPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ecosys Fs-C8520Mfp Ecosys Fs-C8525Mfp: Parts ListDocument45 pagesEcosys Fs-C8520Mfp Ecosys Fs-C8525Mfp: Parts ListPavel0% (1)

- CUAS Infographic FINAL 012519 PrintDocument1 pageCUAS Infographic FINAL 012519 PrintTsymetric GreyPas encore d'évaluation

- Melles Griot - Diode Laser Optics - Broadband Hybrid Dielectric Cube BeamsplittersDocument2 pagesMelles Griot - Diode Laser Optics - Broadband Hybrid Dielectric Cube BeamsplittersnorbertscribdPas encore d'évaluation

- Test4-Reading Passage 3Document2 pagesTest4-Reading Passage 3vanpham248Pas encore d'évaluation

- 2004 Corolla Electrical Diagram - Glossary of Terms and SymbolsDocument2 pages2004 Corolla Electrical Diagram - Glossary of Terms and SymbolsNick BaptistePas encore d'évaluation

- Lexmark 4505 E230 E232 E234 E23x E33x Service ManualDocument160 pagesLexmark 4505 E230 E232 E234 E23x E33x Service ManualmariofoPas encore d'évaluation

- ImageCLASS MF3010 - Canon India - PersonalDocument2 pagesImageCLASS MF3010 - Canon India - Personaldmurali73Pas encore d'évaluation

- B.E R2016-Curriculum and SyllabusDocument149 pagesB.E R2016-Curriculum and SyllabusAjay Krishna R VPas encore d'évaluation

- Incandescent LampDocument3 pagesIncandescent LampPramod TiwariPas encore d'évaluation

- Noise: Optical Communication Lecture NotesDocument20 pagesNoise: Optical Communication Lecture NotesrazifhamzahPas encore d'évaluation

- Ir5075 Series SMDocument646 pagesIr5075 Series SMGabriel VoicuPas encore d'évaluation

- Step by Step CT ScanDocument210 pagesStep by Step CT ScanMohsin Shehzad Waxir68% (22)

- Glass PresentationDocument26 pagesGlass PresentationTariq AhmedPas encore d'évaluation

- SemiconductorsDocument12 pagesSemiconductorsNiraj MishraPas encore d'évaluation

- KoneDocument2 pagesKoneImran OdePas encore d'évaluation

- Ti30 User Manual ENGDocument104 pagesTi30 User Manual ENGvineet181183vPas encore d'évaluation

- Understanding The Principles of InstrumentationDocument11 pagesUnderstanding The Principles of InstrumentationJubile Kairos MagnoPas encore d'évaluation

- Parts Catalog B039/B040/B043: Ricoh Group CompaniesDocument112 pagesParts Catalog B039/B040/B043: Ricoh Group CompaniesfefotroncitoPas encore d'évaluation

- 9006 CT 0201Document44 pages9006 CT 0201wilfredoPas encore d'évaluation

- FLiR E50Document8 pagesFLiR E50edcooPas encore d'évaluation

- Wave Guide DispersionDocument3 pagesWave Guide DispersionSriraj ChinnaPas encore d'évaluation

- Safetyware Catalogs 2012Document163 pagesSafetyware Catalogs 2012thongtn2007100% (1)

- Solar NanoantennaDocument38 pagesSolar Nanoantennaanu balakrishnanPas encore d'évaluation

- Multipath FadingDocument18 pagesMultipath FadingJulia JosephPas encore d'évaluation

- Protocol Labels India P LTDDocument2 pagesProtocol Labels India P LTDMuthukumar ArumugamPas encore d'évaluation

- LD208 SLAMTEC Rplidar Datasheet A2M8 v1.0 enDocument19 pagesLD208 SLAMTEC Rplidar Datasheet A2M8 v1.0 enPetra SSTPas encore d'évaluation

- Atlas Users1Document1 691 pagesAtlas Users1Tanu chaudharyPas encore d'évaluation

- PHD Thesis LaserDocument4 pagesPHD Thesis LaserAmber Ford100% (2)

- ISO 21501-4 Perspectiva MetrológicaDocument8 pagesISO 21501-4 Perspectiva MetrológicaNicolas VargasPas encore d'évaluation

- Extended Depth of Focus Iols The Next Chapter in Refractive TechnologyDocument4 pagesExtended Depth of Focus Iols The Next Chapter in Refractive TechnologyCDloperPas encore d'évaluation