Académique Documents

Professionnel Documents

Culture Documents

Airconditioningforlargemultistorybuildings 110522204801 Phpapp02

Transféré par

aravoof84Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Airconditioningforlargemultistorybuildings 110522204801 Phpapp02

Transféré par

aravoof84Droits d'auteur :

Formats disponibles

PREPARED BY NOOR AZILA BINTI JAMARI LECTURER CIVIL ENGINEERING DEPARTMENT

Most large multistory buildings use highly centralized air conditioning equipment. The roof and basement are the usual choice for these central station systems. The basement has the advantage of easy utility connections, noise isolation, not being valuable rental area and the fact that structural loads are not a problem.

The roof is the ideal location for fresh air intakes and heat rejection to the atmosphere. Cooling tower are noisy, produce very hot and humid exhaust air, so the best location for cooling rower is placed on the roof.

SECTION OF A TYPICAL MULTISTORY BUILDING WITH A ROOFTOP CENTRAL STATION MECHANICAL SYSTEM

In most buildings, the mechanical equipment is shown to be on the roof. This section shows an all-air system served by a single central air handling unit on the roof. To avoid the large vertical ducts, separate air handling units can be placed on each floor and only water circulates vertically. This saves much energy because moving air great distances requires much power.

MECHANICAL EQUIPMENT IS STILL ON THE ROOF, EACH FLOOR HAS A SEPARATE AHU

The advantage of all-air system is complete control over air quality is possible. The disadvantage is that all-air systems are very bulky and a significant part of the building volume must be devoted to them. There are 5 system in all-air system categories. i. Central Plants ii. Variable Air Volume (V.A.V) iii. Terminal Reheat System iv. Multizone System v. Double Duct System

The central air conditioning system has the limitation of the same air quality being delivered throughout the building. If the structure is zoned or divided and compartmented into several different functions such as offices, workshops, canteen. The temperature of each element can be controlled with zoned thermostats. The fan precedes the chiller and reheater coils and blow air through the air-handling unit. Several ducts radiate from the unit to designated zones within the building.

This is a single duct system that can easily have many zones. A variable air volume control box is located wherever a duct enters a separate zone. A thermostat in each zone controls the air flow by operating a damper in the V.A.V control box. More cooling is required, more cool air is allowed to enter the zone.

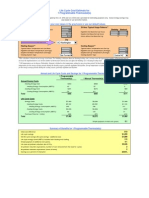

VAV system. Floor plan of a VAV system.

VAV control box.

At the first the terminal reheat system looks just like the V.A.V system but in fact it is very different. This system has terminal reheat boxes in which electric strip heaters or hot water coils reheat air previously cooled. All others zones will reheat the cold air to the desired temperature.

Terminal reheat system.

In this system, every zone receives air at the required temperature through a separate duct. These ducts are supplied by a special multizone air handling unit that custom mixes hot and cold air for each zone. This is accomplished by motorized dampers located in the air handling unit but controlled by thermostats in each zone. Depending on the temperature, the ratio of hot and cold air varies but the total amount of air is constant.

The multizone unit is supplied with hot water, chilled water and a small amount of fresh air. Each multizone unit can handle about 8 zones. Because moderate air temperatures are created by mixing hot and cold air, this system also wasteful of energy. Disadvantage this system are costs relatively high while the thermal control is relatively poor.

Like the multizone system, the double duct system mixes hot and cold air to achieve the required air temperature. Instead of mixing the air at a central air handling unit, mixing boxes are dispersed throughout the building. The double duct system creates a high level of thermal comfort and allows for great zoning flexibility, it is very expensive, requires much building space and its wasteful of energy.

Double duct system.

To reduce the size of the ducts, a highvelocity version of this system High-velocity air systems (6000 feet/minute) consume more fan power than normal velocity systems(2000 feet/minute). Because of these problem and because V.A.V system are a good alternative, dual duct systems are not used much anymore.

These system supply both airand water to each zone of a building. It greatly decreases the size of the equipment because of the immense heart-carrying capacity of water as opposed to air. Air is supplied mainly because of the need for ventilation. There are 2 system in air-water system categories. i. Induction System ii. Fan- coil with supplementary air But in this topic is cover induction system only

A small quantity of high-velocity air is supplied to each zone to supply the required fresh air and to induce room air to circulate. Most induction terminal units are found under windows where they can effectively neutralize the heat gain. As the high-velocity air shoots into the room it induces a large amount of room air to circulates. This combination of room air and fresh air, then passes over heating or cooling coils.

Local thermostats regulate the temperature by controlling the flow of either hot or cold water through the coils. It takes a lot of fan power to circulate air at high velocity throughout a building. Because of the high cost of energy and the expense of high-velocity ductwork, the use of induction systems is limited.

Induction system.

Induction system.

Induction unit with cooling or heating coils

These systems supply no air. There are 2 system in all-water system categories. i. Fan-coil System ii. Water Loop Heat Pump System But in this topic is cover Fan-coil system only.

The fan-coil unit basically consists of a fan and a coil within water circulates. The units are in the form of cabinets for placement under windows. The fan blows room air across coils containing either hot or cold water. Thermostatically controlled valves regulate the flow of water through the coils. A 4 pipe system, which is has 2 pipes for hot water supply and return and another 2 pipes for cold water supply and return.

Condensation on the cooling coils must be collected in a pan and drained away. When the fan-coil unit is on an outside wall, it is possible to have an outdoor air intake connected to the unit. A three-speed fan switch allows occupants of the zone to have some control over the temperature. Fan-coil units are most appropriate for air conditioning buildings with small zones (eg. Apartments, condominiums, motels, hotels, hospitals and schools). Fan coil units also located above windows, in small closets or in the dropped ceiling above a bathroom.

Fan Coil System.

Schematic diagram of an under window FCU ( 4 pipe system).

FCU placed in a small closet.

FCU placed above a dropped ceiling.

Vous aimerez peut-être aussi

- Hvacprogrammematerial 090703025103 Phpapp02Document95 pagesHvacprogrammematerial 090703025103 Phpapp02aravoof84Pas encore d'évaluation

- Air Duct CalculatorDocument1 pageAir Duct Calculatoraravoof84Pas encore d'évaluation

- Cooling Coil FormulasDocument2 pagesCooling Coil Formulasaravoof84Pas encore d'évaluation

- Calculator Programmable ThermostatDocument5 pagesCalculator Programmable Thermostataravoof84Pas encore d'évaluation

- Why Change The Chilled Water Temperature RangeDocument6 pagesWhy Change The Chilled Water Temperature RangeShabeer HamzaPas encore d'évaluation

- Induction unit system design manualDocument35 pagesInduction unit system design manualNahiyan AbdullahPas encore d'évaluation

- Do Building Energy Codes Go Far EnoughDocument28 pagesDo Building Energy Codes Go Far Enoughvarshneyrk@rediffmail.comPas encore d'évaluation

- Fire Apparatus Pump Theory 1Document25 pagesFire Apparatus Pump Theory 1aravoof84Pas encore d'évaluation

- Flow FansDocument35 pagesFlow Fansaries26march100% (2)

- Hvac Load CalculationsDocument68 pagesHvac Load CalculationsPrecisionetica100% (2)

- Mechanical FormulasDocument5 pagesMechanical FormulasSenthil KumarPas encore d'évaluation

- Sustainable HVACDocument28 pagesSustainable HVACaravoof84Pas encore d'évaluation

- Almost Everthing For MEPDocument55 pagesAlmost Everthing For MEPdkpushp100% (4)

- How To Determine The Sitting and Facing of A Home, Apartment or BuildingDocument8 pagesHow To Determine The Sitting and Facing of A Home, Apartment or Buildingaravoof84Pas encore d'évaluation

- How To Determine The Sitting and Facing of A Home, Apartment or BuildingDocument8 pagesHow To Determine The Sitting and Facing of A Home, Apartment or Buildingaravoof84Pas encore d'évaluation

- Pump Selection CriteriaDocument5 pagesPump Selection CriteriaAbbas RizviPas encore d'évaluation

- Mechanical FormulasDocument5 pagesMechanical FormulasSenthil KumarPas encore d'évaluation

- Valve & Type of ValesDocument82 pagesValve & Type of Valesvipinct83% (6)

- Hong Kong Stormwater Drainage Manual: Planning, Design and ManagementDocument108 pagesHong Kong Stormwater Drainage Manual: Planning, Design and ManagementFree Rain Garden Manuals0% (1)

- Air SeperatorDocument20 pagesAir Seperatoraravoof84Pas encore d'évaluation

- Workshop Exercise - Fans and BlowersDocument3 pagesWorkshop Exercise - Fans and BlowersShukla SuyashPas encore d'évaluation

- Tips For Filling Out The Performance Planning and Appraisal Form (PPAF)Document5 pagesTips For Filling Out The Performance Planning and Appraisal Form (PPAF)Sudhakar ChollangiPas encore d'évaluation

- Air Duct CalculatorDocument1 pageAir Duct Calculatoraravoof84Pas encore d'évaluation

- Calculation of Invert LevelsDocument8 pagesCalculation of Invert Levelsaravoof84100% (1)

- Module 123Document7 pagesModule 123aravoof84Pas encore d'évaluation

- Description & Design of Sprinkler SystemsDocument20 pagesDescription & Design of Sprinkler SystemsIrfanshah2013100% (4)

- Calculations/Design Procedures Basic Fire Protection Requirements For Hydrocarbon Hazards Offshore PlatformsDocument3 pagesCalculations/Design Procedures Basic Fire Protection Requirements For Hydrocarbon Hazards Offshore Platformsaravoof84Pas encore d'évaluation

- Air-Water Systems For Air Conditioning Design ManualDocument60 pagesAir-Water Systems For Air Conditioning Design ManualSchreiber_Dieses100% (1)

- WWDocument13 pagesWWonspsnonsPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CLASSIFICATION AND DESIGN OF PASSIVE HEATING TECHNIQUESDocument12 pagesCLASSIFICATION AND DESIGN OF PASSIVE HEATING TECHNIQUESzainab444Pas encore d'évaluation

- House Tender BoQDocument149 pagesHouse Tender BoQJhonny SarmentoPas encore d'évaluation

- Rainscreen WallDocument18 pagesRainscreen Wall20101495Pas encore d'évaluation

- Electrical ConduitDocument9 pagesElectrical ConduitAngling DharmaPas encore d'évaluation

- An Introduction To Modern ArchitectureDocument10 pagesAn Introduction To Modern ArchitecturePricilia N TamawiwyPas encore d'évaluation

- Structural Quantity Analysis of Tall BuildingsDocument8 pagesStructural Quantity Analysis of Tall BuildingsAnkushPas encore d'évaluation

- Dayworks Schedule of RatesDocument4 pagesDayworks Schedule of RatesRW Ponce BuildersPas encore d'évaluation

- Estimate of SlabDocument42 pagesEstimate of SlabNikhilPas encore d'évaluation

- National Building Code of India FFTGDocument31 pagesNational Building Code of India FFTGSrinivasan RanganathanPas encore d'évaluation

- The Great ExhibitionsDocument14 pagesThe Great ExhibitionsTaru MalhotraPas encore d'évaluation

- Assignment Constech - Sem 3Document30 pagesAssignment Constech - Sem 3Venessa WahPas encore d'évaluation

- Failed Wall MunyonyoDocument289 pagesFailed Wall MunyonyoSolomon BalemeziPas encore d'évaluation

- Project Mapping For Interior Design Related To CraftsDocument30 pagesProject Mapping For Interior Design Related To CraftsShruti KohliPas encore d'évaluation

- SUN 2399 VaughnB 139selkirk 08 March 2012 WebDocument2 pagesSUN 2399 VaughnB 139selkirk 08 March 2012 WebCarringtonPas encore d'évaluation

- Boq 01Document7 pagesBoq 01abobeedoPas encore d'évaluation

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Document10 pagesBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14jklo12Pas encore d'évaluation

- Learning Level-1,2: Use of MaterialsDocument34 pagesLearning Level-1,2: Use of MaterialsUmair AshrafPas encore d'évaluation

- Vernacular Terms in Philippine ConstructionDocument4 pagesVernacular Terms in Philippine Constructioncristian borjePas encore d'évaluation

- Steel + Wood StructuresDocument129 pagesSteel + Wood StructuresYigezu YehombaworkPas encore d'évaluation

- A Paper On Dhajji WallDocument12 pagesA Paper On Dhajji WallDanish Ansari100% (7)

- Assignment in FoundationDocument6 pagesAssignment in FoundationFrancis Prince ArtiagaPas encore d'évaluation

- Ram Structural ReportDocument67 pagesRam Structural ReportRam Reddy100% (1)

- Floor, wall and roof finishesDocument2 pagesFloor, wall and roof finishesAmal AmranPas encore d'évaluation

- Le Corbusier and Mies Van Der Rohe Before World War IIDocument196 pagesLe Corbusier and Mies Van Der Rohe Before World War IIjacqs2Pas encore d'évaluation

- RMAX Direct Fix EIFS Cladding Product Range Technical Data and Installation ManualDocument40 pagesRMAX Direct Fix EIFS Cladding Product Range Technical Data and Installation ManualAzahar Bin HashimPas encore d'évaluation

- Soal PAS Kelas 3 Semester 1Document3 pagesSoal PAS Kelas 3 Semester 1ramzulPas encore d'évaluation

- Steel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardDocument8 pagesSteel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardElumalai Srinivasan75% (8)

- Revit MEP PresentationDocument73 pagesRevit MEP PresentationShubham PuriPas encore d'évaluation

- Test 3C: Gothic CathedralsDocument846 pagesTest 3C: Gothic CathedralsPradyumna Somashekar Mysore83% (6)