Académique Documents

Professionnel Documents

Culture Documents

BioGas Production

Transféré par

Moaz Abbas100%(1)100% ont trouvé ce document utile (1 vote)

263 vues28 pagesThis presentations gives a brief overview about Bio Gas as a source of energy and its potential.

Copyright

© © All Rights Reserved

Formats disponibles

PPT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis presentations gives a brief overview about Bio Gas as a source of energy and its potential.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

263 vues28 pagesBioGas Production

Transféré par

Moaz AbbasThis presentations gives a brief overview about Bio Gas as a source of energy and its potential.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 28

Project BIOGAS

Sub group members

M. Abdullah

Aemun Khalid

Arhum Hassan

Moaz Abbas

Contents of Presentation

Motivation for the project

Introduction

Properties of Biogas and Its potential

Benefits of Biogas technology

Selection of best production process

Factors affecting efficiency

Objective and work plan

Experiments, proposals and their potential benefits

Business opportunities

Further optimization through integration

Motivation for Biogas Project

Public health Hazards

Typhoid, Malaria, Cholera

Breeding of flies, mosquitos, rats and other disease

bearing insects

Deforestation for Wood-fuel which leads to soil

erosion

Introduction

This project is to convert harmful waste

materials into useful energy source to get

multiple benefits.

Business opportunity

Social Service

To Play a constructive role

in Energy crises

Properties of Biogas and Its Potential

1 kg Biogas = 5.2(approx) kWh of energy

Properties of Biogas and Its Potential

Composition depends upon feed material

20% lighter than air

Ignition temperature range=650-750

o

C

Burns with blue flame similar to LPG

Calorific value= 20 MJ/m

3

Burns with 60% efficiency on a conventional

stove

Benefits of Biogas Technology

Cost effective and eco-friendly

Slurry (the best alternative of chemical

fertilizers)

No geographical limitations

No sophisticated technology required

Selection of Best Production Method

We discarded some alternative processes due to

following reasons:

Economics of Scale

Requirement of sophisticated technology

Lesser efficiency

The Process of our choice is

Wet Anaerobic Digestion

Why Anaerobic Digestion

High yield

Easier to homogenize the waste in wet

condition to obtain a consistent yield

More methane yield and nitrogen rich

compost (slurry).

Factors Affecting Efficiency

Feedstock characteristics

Design of reactor

Operation conditions (36 degree optimum)

Moisture content

Volatile solids

Particle size

Biodegradability

Objective and Work Plan

Objective of this project is to explore the

factors through which efficiency can be

enhanced, to carry out feasibility study and to

discover business opportunities related to this

project

Work Plan

To check the workability of Biogas plant on

smaller scale

To carry out experiments to verify the effect of

different constraints

To optimize the process

To use Economics of scale to design the smallest

possible commercial plant that is profitable

To explore the growth potential in this business

Experiment 1

We took a polymer semi-transparent white bottle

Attached inlet pipe for waste

Outlet pipe for Gas output

Painted it black so that light passage becomes as

low as possible

Filled with feedstock (water + cow dung)

Waiting for fermentation and detectable gas

output

Pictures of Experiment 1

Problems Faced

The process is extremely slow

The time projected for complete fermentation

is almost 5 weeks

The same assembly has already been used in

some rural areas and not appreciated due to

inefficiency, high initial cost and limitations

Possible Reasons and Solutions proposed

The feedstock we used (cow dung) has very

low calorific values

We can achieve better results if light blockage

was better

pH decreases during the process due to

volatile fatty acids

Solutions

Use of feedstock with starchy or sugary

content. This includes kitchen waste, rotten

fruits, green leaves and other wastes

containing fats and lipids.

painting green color instead of black.

The pH can be controlled by using alkaline

additives. (NaOH)

Potential benefits of purposed changings

faster generation of methanogens bacteria.

Same amount of gas is produced by 95%

lesser amount of waste.

The fermentation reaction completes in 24-30

hours that would have taken 5 weeks in case

of cow dung

These factors increase the efficiency up to

roughly 800%.

Potential benefits of purposed changings

Size reduction

Due to smaller size and nature of waste input,

the urban areas where availability of cow

dung and space is an issue can also take

benefit of this technology

Business Opportunities

What business is all about?

We are here to serve people, to provide them

solutions, and to gain trust. Money is just a

by-product

But we can create a win-win situation. Where

people get the solution and we get the by-

product. How will we do it? The answer is in

upcoming slides

Problem Analysis

Loop holes leading to business opportunities.

Energy crises and gas/electricity load shedding

People need a solution, a way out, a shortcut,

an escape from this problem.

How Can We Help

Independent Power Producing

Company (IPP)

Operational Steps

Biogas Production

(gas condensation and purification)

Bio-methane production

(can be injected into gas grid or fed to

vehicles)

Electricity and heat generation by CHP

Vous aimerez peut-être aussi

- Science Act Practice Test 67cDocument12 pagesScience Act Practice Test 67capi-232033431100% (1)

- Gold Extraction and Recovery ProcessesDocument20 pagesGold Extraction and Recovery ProcessesNataniel LinaresPas encore d'évaluation

- 5 Steps Homemade BiogasDocument5 pages5 Steps Homemade BiogasJan Aguilar EstefaniPas encore d'évaluation

- CRD - c124 CRD-C124-73 Method of Test For Specific Heat of Aggregates, Concrete, and Other Materials (Method of Mixtures)Document3 pagesCRD - c124 CRD-C124-73 Method of Test For Specific Heat of Aggregates, Concrete, and Other Materials (Method of Mixtures)azharbPas encore d'évaluation

- Thesis Biogas Production Using Anaerobic Bio Dig Ester From CADocument55 pagesThesis Biogas Production Using Anaerobic Bio Dig Ester From CAApocolyse100% (2)

- Anaerobic Digester DesignDocument85 pagesAnaerobic Digester Designprannoy100% (1)

- Pipe Hanger CatalogDocument228 pagesPipe Hanger CatalogIldefonso FloresPas encore d'évaluation

- To Heat Treatment of Welded Structures and Technical Data: CooperheatDocument11 pagesTo Heat Treatment of Welded Structures and Technical Data: Cooperheatsnipertomb100% (9)

- CMT Lesson 2Document14 pagesCMT Lesson 2Pam SyPas encore d'évaluation

- Biogas NotesDocument28 pagesBiogas NotesPaul HarrisPas encore d'évaluation

- Handbook On Biogas UtilizationDocument148 pagesHandbook On Biogas UtilizationRusty MacCharles100% (3)

- DIY Methane GeneratorDocument5 pagesDIY Methane GeneratorGermanHundPas encore d'évaluation

- Biogas DigesterDocument35 pagesBiogas DigesterXylester Kenn FabrePas encore d'évaluation

- Introduction To Solar Thermal SystemsDocument100 pagesIntroduction To Solar Thermal SystemsFazil Hassan100% (2)

- Home Biogas System (Philippine BioDigesters) - Appropedia - The Sustainability Wiki PDFDocument9 pagesHome Biogas System (Philippine BioDigesters) - Appropedia - The Sustainability Wiki PDFel jeoPas encore d'évaluation

- ICED OJK Overview of Biogas Power 160926 BK FinDocument57 pagesICED OJK Overview of Biogas Power 160926 BK FinDigdo Setyaji100% (1)

- ANSI C80.1 - Electrical Rigid Steel Conduit (ERSC) PDFDocument21 pagesANSI C80.1 - Electrical Rigid Steel Conduit (ERSC) PDFHarry RamirezPas encore d'évaluation

- Biogas Plant - Food WastesDocument33 pagesBiogas Plant - Food Wastesayman1111167% (3)

- Biogas TechDocument40 pagesBiogas TechAko Si JhadongPas encore d'évaluation

- Bio GasDocument37 pagesBio GasSam PradhanPas encore d'évaluation

- Simulations and Modeling of Biomass Gasification Processes - MITDocument173 pagesSimulations and Modeling of Biomass Gasification Processes - MITGXGGXG100% (1)

- Biogas Calculation Guide v3.0 - )Document98 pagesBiogas Calculation Guide v3.0 - )swordprakashPas encore d'évaluation

- Biogas 101 CIAPR Rev 1.1Document72 pagesBiogas 101 CIAPR Rev 1.1Tony PowerPas encore d'évaluation

- Sector Handbook BiogasDocument39 pagesSector Handbook BiogasMann HumanPas encore d'évaluation

- Biogas Technology: Construction, Utilization and Operation ManualDocument52 pagesBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoPas encore d'évaluation

- ANAEROBIC DIGESTION, GASIFICATION AND PYROLYSIS FOR MUNICIPAL SOLID WASTEDocument22 pagesANAEROBIC DIGESTION, GASIFICATION AND PYROLYSIS FOR MUNICIPAL SOLID WASTEJoao Minho100% (1)

- A Project Report On BiogasDocument13 pagesA Project Report On BiogasNarendra Pandit79% (24)

- Report-Biogas and Syngas UpgradingDocument97 pagesReport-Biogas and Syngas UpgradingKhong Yu NengPas encore d'évaluation

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationD'EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationPas encore d'évaluation

- Biogas Power PlantDocument130 pagesBiogas Power PlantRahul Tomar100% (3)

- Business Plan BiodieselDocument8 pagesBusiness Plan BiodieselManas KelaskarPas encore d'évaluation

- Biogas NotesDocument35 pagesBiogas NotesNupur BhadraPas encore d'évaluation

- Design, Construction and Maintenance of A Biogas GeneratorDocument23 pagesDesign, Construction and Maintenance of A Biogas GeneratorOxfam100% (4)

- Fuel Source For A Renewable Future: BiogasDocument27 pagesFuel Source For A Renewable Future: BiogasAbdul LathifPas encore d'évaluation

- Design of Biogas DigestersDocument22 pagesDesign of Biogas DigestersSharath Chandra100% (5)

- A Presentation ON Biogas Power Plant: Submitted By: Gaurangi Saxena 1212240091Document30 pagesA Presentation ON Biogas Power Plant: Submitted By: Gaurangi Saxena 1212240091ratgauriPas encore d'évaluation

- Calculations Biogas ProductionDocument4 pagesCalculations Biogas ProductionTony Deligiorgis100% (5)

- BIOGASDocument61 pagesBIOGASlivre i natural67% (3)

- Detailed Project Report For Biogas Power PlantDocument132 pagesDetailed Project Report For Biogas Power PlantShubham Jain100% (2)

- BiogasDocument420 pagesBiogasNagireddy Venkat Suresh100% (1)

- Chapter 1 To 4Document121 pagesChapter 1 To 4Haiqal Aziz100% (1)

- Biogas Revolution Secrets Biogas PlansDocument16 pagesBiogas Revolution Secrets Biogas PlanslimlerianPas encore d'évaluation

- Biogas Plant Designs and Engery CalculationsDocument22 pagesBiogas Plant Designs and Engery CalculationsHussein El Zikry88% (17)

- Design and Theory of a Basic Anaerobic DigesterDocument7 pagesDesign and Theory of a Basic Anaerobic DigesterOpen Knowledge and Education Book ProgramsPas encore d'évaluation

- Biogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Document17 pagesBiogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Madhav Mohan100% (1)

- GTZ - Biogas Plants - 1993Document24 pagesGTZ - Biogas Plants - 1993Kroya HunPas encore d'évaluation

- Anaerobic Digestion Mass BallanceDocument100 pagesAnaerobic Digestion Mass Ballancetaufany99Pas encore d'évaluation

- Biogas HandbookDocument124 pagesBiogas HandbookDaniel Gonzalo Herrera Peña100% (6)

- BiogasDocument46 pagesBiogasSiddharth KrishnaPas encore d'évaluation

- Biogas Power PlantDocument7 pagesBiogas Power PlantShailesh Sankdasariya100% (1)

- BIOGAS PresentationDocument33 pagesBIOGAS PresentationAndreas Abraham91% (11)

- Plug Flow Biogas Plant Model Generates Gas from BiomassDocument5 pagesPlug Flow Biogas Plant Model Generates Gas from Biomassanil_johny_1Pas encore d'évaluation

- Biogas Presentation PDFDocument44 pagesBiogas Presentation PDFAli Aamir100% (1)

- Biogas TechnologyDocument101 pagesBiogas TechnologyRanjan Mano100% (1)

- Types of Biogas PlantDocument73 pagesTypes of Biogas PlantSethumadhavan Padmanabhan67% (3)

- Bio Gas Plant - Details 2013Document23 pagesBio Gas Plant - Details 2013lram70Pas encore d'évaluation

- Biogas PlantDocument42 pagesBiogas PlantPradeepLokhande100% (1)

- Anaerobic Digesters: Frequently Asked Questions: What Is The Anaerobic Digestion Process?Document4 pagesAnaerobic Digesters: Frequently Asked Questions: What Is The Anaerobic Digestion Process?Kate MayerPas encore d'évaluation

- Biogas ScrubberDocument4 pagesBiogas ScrubberKaivalya SavePas encore d'évaluation

- What is biogas? Explained in 40 charactersDocument72 pagesWhat is biogas? Explained in 40 charactersParth PatelPas encore d'évaluation

- Biomass EnergyDocument1 pageBiomass EnergyrapPas encore d'évaluation

- Minorprojectfinal 2Document12 pagesMinorprojectfinal 2Anshu SinghPas encore d'évaluation

- The Nature of Chemical Process Design and IntegrationDocument27 pagesThe Nature of Chemical Process Design and IntegrationKS Andy MukilPas encore d'évaluation

- Key Initiatives in Sustainable Development: DR M G Palekar Atul LTDDocument22 pagesKey Initiatives in Sustainable Development: DR M G Palekar Atul LTDIndustrial Green Chemistry WorldPas encore d'évaluation

- 3 A Green ChemistryDocument26 pages3 A Green Chemistrystudy fullPas encore d'évaluation

- Methanol Recovery SystemDocument17 pagesMethanol Recovery SystemJoao JesusPas encore d'évaluation

- DR Reddy's Laboratories, CTO 2, HyderabadDocument15 pagesDR Reddy's Laboratories, CTO 2, HyderabadjaydeepsinhPas encore d'évaluation

- Alcor Atf Super - enDocument2 pagesAlcor Atf Super - enronaldPas encore d'évaluation

- Organic Chemistry: Alkanes and AlkenesDocument73 pagesOrganic Chemistry: Alkanes and AlkenesRosemaryTanPas encore d'évaluation

- Econo SprayDocument1 pageEcono SprayEliasPas encore d'évaluation

- MSDS Anios ZemDocument9 pagesMSDS Anios ZemRumah Sakit Bhakti Asih BrebesPas encore d'évaluation

- Hematology Services GuideDocument34 pagesHematology Services GuideLorelie CarlosPas encore d'évaluation

- MAGNESIUM QC AND CONVERSIONDocument5 pagesMAGNESIUM QC AND CONVERSIONDinesh SreedharanPas encore d'évaluation

- Intellipak Manual ProgrammingDocument157 pagesIntellipak Manual ProgrammingArt kPas encore d'évaluation

- Catalog - Performa 2011 (En)Document94 pagesCatalog - Performa 2011 (En)Anonymous FTBYfqkPas encore d'évaluation

- Chapter 16Document55 pagesChapter 16Khalil AlluhaybiPas encore d'évaluation

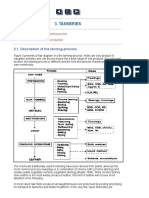

- TANNERIESDocument7 pagesTANNERIESzalabiPas encore d'évaluation

- Aerodynamics - IIDocument10 pagesAerodynamics - IIVejay RamPas encore d'évaluation

- Spot Welding BasicDocument6 pagesSpot Welding BasicPaulPas encore d'évaluation

- Supreme Motor Oil MSDSDocument7 pagesSupreme Motor Oil MSDSsofelsbabaPas encore d'évaluation

- Mandals - Superman HVTDocument1 pageMandals - Superman HVTDavid ChoquenairaPas encore d'évaluation

- Magnesium Chloride PowderDocument2 pagesMagnesium Chloride PowderNatalia NeliPas encore d'évaluation

- Halogenoalkanes Alcohols and Modern Analytical TechniquesDocument17 pagesHalogenoalkanes Alcohols and Modern Analytical TechniquesDaniel KirovPas encore d'évaluation

- D19 2 en Fuel SpecificationDocument35 pagesD19 2 en Fuel SpecificationPaulo GodinhoPas encore d'évaluation

- Functions Of: Split Spoon Sampler, Shelby Tube, Hydraulic Piston SamplerDocument6 pagesFunctions Of: Split Spoon Sampler, Shelby Tube, Hydraulic Piston SamplerMuhammad Arslan100% (1)

- GE - 200802 - Technical Specs Jenbacher Type 6 PDFDocument2 pagesGE - 200802 - Technical Specs Jenbacher Type 6 PDFsakthivelPas encore d'évaluation

- Brass Is An Alloy of Copper and ZincDocument9 pagesBrass Is An Alloy of Copper and ZincKunj ShahPas encore d'évaluation

- OBATDocument10 pagesOBATDeiLa SariPas encore d'évaluation

- Additive Puts New Life in Lead AcidDocument6 pagesAdditive Puts New Life in Lead AcidincimPas encore d'évaluation