Académique Documents

Professionnel Documents

Culture Documents

Design of CC Pavement - VRVRLatest

Transféré par

Lori WallaceDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of CC Pavement - VRVRLatest

Transféré par

Lori WallaceDroits d'auteur :

Formats disponibles

Prof.

VR VINAYAKA RAO

DESIGN OF RIGID

HIGHWAY PAVEMENTS

5/10/2014 6:59 AM BITS Pilani

CONCRETE PAVEMENT OPTIONS

Jointed Plain Concrete Pavements

Continuously Reinforced Concrete

Pavements

Pre-stressed Concrete Pavement

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING PAVEMENT DAMAGE

Vehicle

Pavement

Environment

Speed

GVW

Pavement type, thickness, roughness

Axle forces

Axle and tyre properties

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING RIGID

PAVEMENT DESIGN

Axle/Wheel Loads

Single Axle 10.2t, Tandem 19t & Tridem Axle 24t

Load Repetitions

Tire Pressure (0.7 to 1 Mpa) 0.8 Mpa

Thickness > 20Cm Tire Pressure need not

be considered

Lateral Placement of the Axles

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING RIGID

PAVEMENT DESIGN (Contd..)

Unpredicted Heavy Truck Movements

Load Safety Factor (1.2, 1.1 & 1.0 for three

hierarchies of roads)

Design Axle Load 98

th

Percentile

Design Period (15 to 30 Years)

Design Traffic: IRC 9 Traffic Census

Tire Tangential to Longitudinal Edge - Critical

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING RIGID PAVEMENT

DESIGN (Contd..)

Fatigue 25% of Two-Lane Two-Way Commercial

Vehicles (Design Traffic)

Four or Multi Lane Highways 25% of

Commercial Vehicles in the Predominant

Direction

CSA = [365 * A * {(1+r)

n

1}] / r

Temperature Differential = f(Solar Radiation received,

Thermal Diffusibility

of CC, Losses Due to Wind

Velocity etc.)

Table 1 - IRC 58 2002 (Six Different Regions in India)

5/10/2014 6:59 AM BITS Pilani

CHARACTERISTICS OF SUB-GRADE & SUB-BASE

Modulus of Sub-grade Reaction (K) Pressure

per Unit Deflection of Foundation @ Limiting

Deflection

Limiting Deflection 1.25mm

Plate Diameter 75cm

K

75

= 0.5 x K

30

CBR K Correlations (Tables 2, 3 & 4)

125 Micron thick Polythene Layer between CC

and DLC Layers to Reduce Interlayer Friction

Drainage Layer above Sub-grade

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING RIGID PAVEMENT DESIGN

(Contd..)

Characteristics of Concrete

Design Strength

S = Target Ave. Flexural Strength @ 28 days

= S

+

Z

a

S

= Characteristic Flexural Strength @ 28 Days

Z

a

= Tolerance Factor for Desired Confidence

Limits (Table 5 IRC 58)

= Expected Standard Deviation of Field

Samples (IS 456 2000)

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING RIGID PAVEMENT DESIGN

(Contd..)

Flexural StrengthMR Test3

rd

Point LoadingIS 516

Aggregate Size > 19mm - 15x15x70 Cm

Aggregate Size < 19mm - 10x10x50 Cm

Flexural Strength 4.5 Mpa

E = 3 x 10

5

Kg/Cm

2

Poissons Ratio = = 0.15

Coefficient of Thermal Expansion

= 10 x 10

6

/

o

C

5/10/2014 6:59 AM BITS Pilani

FACTORS AFFECTING RIGID PAVEMENT DESIGN

(Contd..)

Fatigue Behavior of CC (Minors Hypothesis)

Stress Ratio (SR) = Flexural Stress / Flexural Strength

N = Unlimited for SR < 0.45

N = [4.2577 / (SR - .4325)]

3.268

for 0.45<SR<0.55

Log

10

N = (0.9718 SR) / 0.0828

for SR>0.55

Table No: 6 Allowable Repetitions

5/10/2014 6:59 AM BITS Pilani

JOINTED PLAIN CEMENT

CONCRETE PAVEMENT

Most Popular Rigid pavement Option

Maintenance Costs increases with the

increase in the joint spacing

Maximum joint spacing should be 12.2m

5/10/2014 6:59 AM BITS Pilani

CONTINUOUSLY REINFORCED

CEMENT CONCRETE PAVEMENT

Elimination of Joints Reduced

thickness

Thickness of CRCP Will Workout to be 70-

80% of the conventional pavement.

Cracks are held tightly by the reinforcement

Punch-outs are the major type of distress

Design equations for JRCP can be used for

CRCP

5/10/2014 6:59 AM BITS Pilani

PRESTRESSED CONCRETE PAVEMENT

Concrete is weak in Tension, strong in

compression

Thickness is governed by modulus of rupture

which varies with the tensile strength of

concrete

Pre-application of compressive stress

reduces the tensile stresses caused by traffic

loads, decreases the thickness

Less probability of cracking and fewer

transverse joints, less maintenance and

longer life

5/10/2014 6:59 AM BITS Pilani

PRESTRESSED CONCRETE PAVEMENT

Slab Length Varies from 90 to 232m

Slab Thickness 152mm (Maximum)

Post tension method is Frequently Adopted

More Frequently used for Airport Pavements,

Saving in Thickness

Thickness of Pre-stressed Highway Pavement

will be Sufficient Enough to Provide Cover for

the Pre-stressing Steel

Still in the Experimental Stage

5/10/2014 6:59 AM BITS Pilani

RIGID HIGHWAY PAVEMENT DESIGN

Guidelines for the Design of Plain Jointed

Rigid Pavements for Highways IRC: 58 2002,

2011

AASHTO Method, 1993

PCA Method

ACI Method

5/10/2014 6:59 AM BITS Pilani

IRC: 58 2002 METHOD OF

RIGID PAVEMENT DESIGN

Guidelines cover the design of Plain

Jointed cement concrete pavements with

or without dowels

Applicable to roads having a daily

commercial traffic (vehicles with laden

weight exceeding 3T) of over 150

5/10/2014 6:59 AM BITS Pilani

NEW FEATURES OF IRC: 58 - 2002

Computation of Flexural stress due to

placement of single and tandem axle

loads along the edge

Introduction of the cumulative fatigue

damage approach in the design

Revision of criteria for design of dowel

bars

5/10/2014 6:59 AM BITS Pilani

CRITICAL STRESS CONDITION

Additive Flexural Stresses due to Load and

Temperature Differentials Critical

Tandem Axle Causes 20% lesser load than single

axles Super Position of Negative Bending

Moment due to one dual wheel over the other

Average Spacing of Tandem Axles 1.31m

Curling - Top Convex during Day and Top

Concave during the Night

Corner Discontinuous in 2 Direction More

Critical

Corner Temp. Stress is Negligible

5/10/2014 6:59 AM BITS Pilani

CRITICAL STRESS CONDITION

Temp Stresses will be Maximum during the day

when there is maximum temp. differential at

Edge and Interior Regions

Night Critical for Corner Region Corners

tending to warp up

Corner Critical No Dowel Bars are Provided

Corner Critical Aggregate Interlock is Absent

5/10/2014 6:59 AM BITS Pilani

CALCULATION OF STRESSES

EDGE STRESSES

Due to Load: Westergaards and Pickett & Rays

Chart Techniques IITRIGID.EXE

Appendix 1 for Different Single and Tandem

Axle Loads (Stresses have been Given)

Westergaards Equation Modified by Teller and

Sutherland are not Applicable for Different Wheel

Configurations and hence not Useful

5/10/2014 6:59 AM BITS Pilani

EDGE STRESS

Due to Temperature: Westergaards

Equation using Bradburys Equation

S

te

= E t C / 2.0

Figure 2 for Bradburys Coefficient as well

as Stress Values

CALCULATION OF STRESSES

5/10/2014 6:59 AM BITS Pilani

CALCULATION OF STRESSES

CORNER STRESS

Westergaard's Equation (Modified by Kelly)

S

cl

= (3P/h

2

) * { 1 (a 2/l)

1.2

} (kg/Cm

2

)

a = Radius of Equivalent Circular Contact

Area (Cm)

l = Radius of Relative Stiffness (Cm)

= [(Eh

3

)/{12(1-

2

)K}]

0.25

5/10/2014 6:59 AM BITS Pilani

STRESS RATIO AND FATIGUE ANALYSIS

Cumulative Fatigue Damage for

Different Axle Loads shall be Less than

1.0

Procedure for Cumulative Fatigue

Damage is Given in Appendix 2 of

IRC 58 - 2002

5/10/2014 6:59 AM BITS Pilani

EROSION CONSIDERATION

& HARD SHOULDERS

Multi Axle Vehicles Usually Cause Erosion at the

Bottom of the Pavement

To Prevent, Paved Shoulder Shall be Extended by

1.5m beyond the Pavement

DLC Shall be Extended by 40 to 50 Cm towards the

Shoulder

In addition, Full Depth Bituminous Shoulder or tied

CC Shoulder Shall be Constructed to Protect

Pavement Edge

Anchor Beam and Terminal Slab

5/10/2014 6:59 AM BITS Pilani

IRC: 58 2002 DESIGN PROCEDURE

Stipulate design values for the various

parameters

Decide types and spacing between joints

Select a trial design thickness of

pavement slab

Compute the repetitions of axle loads of

different magnitudes during the design

period

5/10/2014 6:59 AM BITS Pilani

IRC: 58 2002 DESIGN PROCEDURE

Calculate the stresses due to single and

tandem axle loads and determine the

cumulative fatigue damage (CFD)

If the CFD is more than 1.0, select a higher

thickness and repeat the above steps

Compute the temperature stress at the

edge and if the sum of the temperature

stress and the flexural stress due to the

highest wheel load is greater than the

modulus of rupture, select higher

thickness and redesign

5/10/2014 6:59 AM BITS Pilani

IRC: 58 2002 DESIGN PROCEDURE

Design the thickness on the basis of

corner stress if no dowel is provided

and there is no load transfer due to lack

of aggregate interlocking

Design Dowel and Tie Bars if necessary

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

EXAMPLE

Two Lane Two Way Highway

Location: Karnataka State

Total Two Way Traffic = 3000 CVPD

Flexural Strength of Concrete = 45 Kg/Cm

2

Effective K with DLC = 8 Kg / Cm

2

E of Concrete = 3 x 10

5

Kg / Cm

2

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Poissons Ratio of Concrete = 0.15

Coefficient of Thermal Expansion of

Concrete = 10x10

-6

/

0

c

Tire Pressure = 8 Kg/Cm

2

Rate of Traffic Growth = 0.075

Spacing of Contraction Joints = 4.5m

Width of the Slab = 3.5m

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Single Axle Loads Tandem Axle Loads

Axle Load

Class (t)

% of Axle

Loads

Axle Load

Class (t)

% of Axle

Loads

19-21 0.6 34-38 0.3

17-19 1.5 30-34 0.3

15-17 4.8 26-30 0.6

13-15 10.8 22-26 1.8

11-13 22.0 18-22 1.5

9-11 23.3 14-18 0.5

<9 30.0 <14 2.0

Total 93.0 Total 7.0

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Present Traffic = 3000 CVD

Design Life = 20 Years

r = 0.075

Cumulative Repetitions

= 3000*365*[{(1.075)

20

1}/0.075]

= 47,418,626 CV

Design Traffic = 0.25 * 47,418,626

= 11,854,657 CV

5/10/2014 6:59 AM BITS Pilani

Single Axle Loads Tandem Axle Loads

Load in

Tonnes

Expected

Repetitions

Load in

Tonnes

Expected

Repetitions

20 71127 36 35564

18 177820 32 35564

16 569023 28 71128

14 1280303 24 213384

12 2608024 20 177820

10 2762135 16 59273

<10 3556397 <16 237093

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Trial Thickness = 32 Cm

Sub-grade Modulus = 8 Kg/Cm

3

Design Period = 20 Years

Modulus of Rupture = 45 Kg/Cm

2

Safety Factor = 1.2

5/10/2014 6:59 AM BITS Pilani

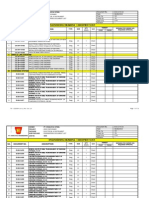

Axle Load

(t)

AL * 1.2 Stress

(Kg/Cm

2

)

Stress

Ratio

Expected

Repetitions

(n)

Fatigue

Life N

Fatigue Life

Consumed

1 2 3 4 5 6 Ratio (5/6)

Single Axle

20 24.0 25.19 0.56 71127 94100 0.76

18 21.6 22.98 0.51 177820 485000 0.37

16 19.2 20.73 0.46 569023 14330000 0.04

14 16.8 18.45 0.41 128030 Infinite 0.00

Tandem Axle

36 43.2 20.07 0.45 35560 62800000 0.0006

32 38.4 18.40 0.40 35560 Infinite

0

Cumulative Fatigue Life Consumed

1.1706

5/10/2014 6:59 AM BITS Pilani

Axle

Load (t)

AL *

1.2

Stress

(Kg/Cm

2

)

Stress

Ratio

Expected

Repetitions(n)

Fatigue Life

(N)

Fatigue Life

Consumed

1 2 3 4 5 6 Ratio (5/6)

Single Axle

20 24.0 24.10 0.53 71127 216000 0.33

18 21.6 21.98 0.49 177820 1290000 0.14

16 19.2 19.98 0.44 569023 Infinity 0.00

14 16.8 17.64 0.39 128030 Infinity 0.00

Tandem Axle

36 43.2 19.38 0.43 35560 Infinity 0.00

Cumulative Fatigue Life Consumed 0.47

Trial Thickness = 33 Cm

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Check for Temperature Stress

Edge Warping Stress (S

te

) = E t C / 2.0

= 17.3 Kg/Cm

2

( For L = 450Cm, B = 350 Cm, l = 103.5, L/l = 4.4 & C = 0.55

from Fig. 2 & Temp. Diff. = 21

o

C )

Total of Load (Highest) and Warping Stress = 24.10 + 17.3

= 41.4 Kg/Cm

2

< 45 Kg/Cm

2

Hence Safe

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Check for Corner Stress due to Load

S

cl

= (3P/h

2

) * { 1 (a 2/l)

1.2

}

98 Percentile Axle Load is 16 Tonnes

The Wheel Load = 8 Tonnes

Radius of Relative Stiffness( l ) = 103.5 Cm

5/10/2014 6:59 AM BITS Pilani

Radius of Contact of Wheel (a)

(Single Axle Dual Wheel)

a = [0.8521 * (P)/(q*)* (S/ )*{(P) / 0.5227*q}

0.5

]

0.5

P = Load

S = C/c Distance between Two Tires

q = Tire Pressure

a = 26.51 Cm

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

5/10/2014 6:59 AM BITS Pilani

ILLUSTRATION OF IRC 58-2002

DESIGN OF RIGID PAVEMENT

Corner Stress due to Load = 15.52 Kg/Cm

2

Flex. Strength of Concrete = 45 Kg/Cm

2

Hence the Proposed thickness of 33 Cm is safe

since Corner Stress Due to Load is Less than

the Flexural strength of Concrete

5/10/2014 6:59 AM BITS Pilani

AASHTO DESIGN PROCEDURE

Design of Slab Thickness

Estimate future Traffic

Reliability ( R )

Overall Standard Deviation (S

o

)

Design Serviceability Loss

Concrete Elastic Modulus (E

c

)

Concrete Modulus of Rupture (S

c

)

Load Transfer Coefficient (J)

Drainage Coefficient ( C

d

)

5/10/2014 6:59 AM BITS Pilani

AASHTO DESIGN PROCEDURE

Reliability

Accounts for the changes in variation in both traffic

prediction and performance prediction

50 - 80 50 80 Local

75 - 95 80 95 Collectors

75 - 95 80 99 Principal Arterials

80 99.9 85 - 99.9 Interstate and other

Freeways

Rural Urban

Recommended Levels of Reliability Functional

Classification

5/10/2014 6:59 AM BITS Pilani

AASHTO DESIGN PROCEDURE

Overall Standard Deviation ( So)

Rigid Pavement 0.35

Design Serviceability Loss

PSI Ranges from 5 (Perfect road) to 0

(Impossible Road)

Index of 2.5 for Design of Major Roads and 2.0

for Less Important Roads

Initial Serviceability for Rigid Pavements 4.5

5/10/2014 6:59 AM BITS Pilani

AASHTO DESIGN PROCEDURE

Concrete Elastic Modulus

Concrete Modulus of Rupture

S

c

= S

c

+ Z (SD

s

)

Where S

c

= Estimated mean value for PCC

modulus of rupture (psi)

S

c

= Construction specification on concrete

modulus of rupture

SD

s

= Estimated standard deviation of concrete

modulus of rupture

5/10/2014 6:59 AM BITS Pilani

AASHTO DESIGN PROCEDURE

Z = Standard normal variate

0.841 for PS = 20%

1.037 for PS = 15%

1.282 for PS = 10%

1.645 for PS = 5%

2.327 for PS = 1%

5/10/2014 6:59 AM BITS Pilani

AASHTO DESIGN PROCEDURE

Load Transfer coefficient (J)

Factor accounts for the ability of the

concrete pavement to transfer load

across joints

J = 3.2 for JCP and JRCP, with some

type of load transfer device

J = 3.8 to 4.4 when there is no load

transfer device

5/10/2014 6:59 AM BITS Pilani

PCA DESIGN OF RIGID PAVEMENTS

Flexural strength of Concrete (Modulus of

Rupture M

R

)

Strength of the subgrade or subgrade and

subbase combination (K)

The weights, frequencies and types of truck axles

loads that the pavement will carry

Design period, which in this and other pavement

design procedures is usually taken at 20 years,

but may be more or less

5/10/2014 6:59 AM BITS Pilani

PCA DESIGN PROCEDURE

Type of Joint and Shoulder

Concrete Flexural strength (M

R

) at 28 days

K value of the subgrade or subgrade and

subbase combination

Load safety factor (LSF)

Axle load distribution

Expected number of repetitions

5/10/2014 6:59 AM BITS Pilani

PCA DESIGN PROCEDURE

Fatigue analysis to control fatigue cracking

and erosion analysis to control foundation

and shoulder erosion, pumping, and faulting

Fatigue analysis will usually control the

design of light traffic pavements and

medium traffic pavements with doweled

joints

Erosion analysis will usually control the

design of medium and heavy traffic

pavements with undoweled joints and heavy

traffic with doweled joints

5/10/2014 6:59 AM BITS Pilani

PCA DESIGN PROCEDURE

For pavements carrying normal mix of truck

types, single-axle loads are usually more severe

in the fatigue analysis, and tandem axle loads are

more severe in the erosion analysis

Fatigue Analysis

Assume Trial Thickness and Equivalent Stress

Factor depending on the Trial Thickness and K

Value

Estimate the Expected and Allowable

Repetitions

The Ratio of Expected to Allowed Should Not

be More than 100%

5/10/2014 6:59 AM BITS Pilani

PCA DESIGN PROCEDURE

Erosion Analysis

Assume trial thickness and the equivalent

stress factor depending on the trial

thickness and k value

Estimate the expected and allowable

repetitions

The ratio of expected to allowed should not

be more than 100%

Vous aimerez peut-être aussi

- Design of Rigid Highway PavementsDocument52 pagesDesign of Rigid Highway PavementsVinayaka RamPas encore d'évaluation

- Half Day CC Roads Construction 9th March 2023 and Joints and ExmplesDocument123 pagesHalf Day CC Roads Construction 9th March 2023 and Joints and ExmplesrajibchattarajPas encore d'évaluation

- Design of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilDocument5 pagesDesign of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilsathishPas encore d'évaluation

- Advances in Rigid Pavement DesignDocument108 pagesAdvances in Rigid Pavement Designdhanush gtPas encore d'évaluation

- 1017 - 19.08m 9.4.14Document90 pages1017 - 19.08m 9.4.14ravi4paperPas encore d'évaluation

- Me8593 Design of Machine Elements: M.A.M. College of Engineering and TechnologyDocument66 pagesMe8593 Design of Machine Elements: M.A.M. College of Engineering and TechnologymanikandanPas encore d'évaluation

- PQC Design Tunnel PTLGDocument31 pagesPQC Design Tunnel PTLGrao shoaibPas encore d'évaluation

- Pavement DesignDocument104 pagesPavement DesignPankaj YadavPas encore d'évaluation

- chp0620 92923 A11yDocument36 pageschp0620 92923 A11yعبدالمعز المليانPas encore d'évaluation

- Maitree-00-UZA-ED-421603C002PEM-2 DESIGN OF ROADSDocument7 pagesMaitree-00-UZA-ED-421603C002PEM-2 DESIGN OF ROADSTAMIL SELVIPas encore d'évaluation

- IRC-58-2015-for Pakhdeva Kokha MargDocument9 pagesIRC-58-2015-for Pakhdeva Kokha MargRam Samujh SharmaPas encore d'évaluation

- Pavement Design Method NewDocument61 pagesPavement Design Method NewPrakash BhandariPas encore d'évaluation

- Rigid Pavement Construction As Per IRC SP 62 2004Document113 pagesRigid Pavement Construction As Per IRC SP 62 2004Vizag Roads98% (54)

- Pile Cap DesignDocument95 pagesPile Cap Designpravin100% (1)

- Design of Rigid Pavement for Minbuu-Ann-Sittway RoadDocument26 pagesDesign of Rigid Pavement for Minbuu-Ann-Sittway RoadMin Htet AungPas encore d'évaluation

- Tower Crane Foundation DesignDocument25 pagesTower Crane Foundation Designyousuf79Pas encore d'évaluation

- S04 - Basic Parameters and Design of Cast in Situ Box GirderDocument71 pagesS04 - Basic Parameters and Design of Cast in Situ Box GirderSMR STPPas encore d'évaluation

- Mechanistic Pavement Design Using IRC & AI MethodsDocument39 pagesMechanistic Pavement Design Using IRC & AI MethodsAmit Ruchi Yadav100% (1)

- IRC 58-2011 (Guidelines For The Design of Plain Jointed Rigid Pavements For Highways)Document8 pagesIRC 58-2011 (Guidelines For The Design of Plain Jointed Rigid Pavements For Highways)rekha kn0% (1)

- 060417163938preview - CP 65-1-1999+err1Document9 pages060417163938preview - CP 65-1-1999+err1Raabbit VithyeaPas encore d'évaluation

- Equivalent Axle LoadsDocument6 pagesEquivalent Axle LoadsKRISHNA YELDIPas encore d'évaluation

- IIT Kharagpur Concrete Pavement Design IRC MethodDocument49 pagesIIT Kharagpur Concrete Pavement Design IRC MethodAravind KumarPas encore d'évaluation

- Micropiles Design FundamentalsDocument38 pagesMicropiles Design FundamentalsHRCPas encore d'évaluation

- Rigid Pavement Design1Document21 pagesRigid Pavement Design1s100% (1)

- 242 246ncice 108Document6 pages242 246ncice 108masih ansariPas encore d'évaluation

- Final PPT On Life Cycle Cost AnalysisDocument33 pagesFinal PPT On Life Cycle Cost AnalysisBharath Kumar M100% (1)

- AASHTO 1993 Concrete Pavement Design with WinPASDocument9 pagesAASHTO 1993 Concrete Pavement Design with WinPASFabricio OrtegaPas encore d'évaluation

- Optimization of Rigid PavementDocument8 pagesOptimization of Rigid PavementIJRASETPublicationsPas encore d'évaluation

- Pavement Design ReportDocument11 pagesPavement Design ReportIrfanPas encore d'évaluation

- Concrete0709 PDFDocument144 pagesConcrete0709 PDFlu190765Pas encore d'évaluation

- Salient Changes in IRC 37 2012 and BitumDocument10 pagesSalient Changes in IRC 37 2012 and Bitumsuman subediPas encore d'évaluation

- Salient Changes in IRC 37 2012 and BitumDocument10 pagesSalient Changes in IRC 37 2012 and BitumNatarajan SaravananPas encore d'évaluation

- Concrete Bridge Design ProjectDocument23 pagesConcrete Bridge Design Projectpetersun825100% (2)

- 1 Ir STR Ra Inception Report Structures - DadriDocument46 pages1 Ir STR Ra Inception Report Structures - DadriNilay MohgaonkarPas encore d'évaluation

- BOX CULVERT LSM 1 X 5 X 3 PDFDocument67 pagesBOX CULVERT LSM 1 X 5 X 3 PDFamitkukna100% (2)

- Rigid Pavement DesignDocument2 pagesRigid Pavement DesignGautam DuttaPas encore d'évaluation

- 3 Revised Chapter 4 Pavement Design - RigidDocument38 pages3 Revised Chapter 4 Pavement Design - RigidUjjval SolankiPas encore d'évaluation

- Final Bridge Design Report (Berhampur AniDocument98 pagesFinal Bridge Design Report (Berhampur AniYogesh Indolia100% (6)

- STRUCTURAL Design CriteriaDocument11 pagesSTRUCTURAL Design Criteriamdkml2Pas encore d'évaluation

- Unit 2.1Document40 pagesUnit 2.1naren0143Pas encore d'évaluation

- Pavement DesignDocument12 pagesPavement Designmohsen.911.mkPas encore d'évaluation

- Design of 10m Portal Bridge at KM 258+500Document43 pagesDesign of 10m Portal Bridge at KM 258+500RAJENDRA PRASADPas encore d'évaluation

- IRC Guidelines for Design of Plain Jointed Rigid PavementsDocument3 pagesIRC Guidelines for Design of Plain Jointed Rigid PavementsBilal Ahmed Barbhuiya72% (18)

- Practical Training Presentation on Box Culvert ConstructionDocument30 pagesPractical Training Presentation on Box Culvert ConstructionVineet SinghPas encore d'évaluation

- BEAM-37 M Ow 12.5 - 0 Deg - FDocument120 pagesBEAM-37 M Ow 12.5 - 0 Deg - FSreedhar BhuduruPas encore d'évaluation

- PCCP Design PDFDocument61 pagesPCCP Design PDFKeeperPas encore d'évaluation

- Burj Vista F1 12 Panel Design Rev0 22feb16Document71 pagesBurj Vista F1 12 Panel Design Rev0 22feb16Kilaru HareeshPas encore d'évaluation

- INTERVIEWDocument5 pagesINTERVIEWMRITYUNJAY PANDEYPas encore d'évaluation

- Ssc-Je Ssc-Je Ssc-Je: Civil Engineering Civil Engineering Civil EngineeringDocument11 pagesSsc-Je Ssc-Je Ssc-Je: Civil Engineering Civil Engineering Civil EngineeringaditiPas encore d'évaluation

- Is 807 Design and Testing of Cranes and HoistsDocument76 pagesIs 807 Design and Testing of Cranes and HoistsKarthick VenkateshPas encore d'évaluation

- C 7 - Two Way SlabsDocument26 pagesC 7 - Two Way SlabsRekanPas encore d'évaluation

- 09 - VV - Pavement Design IRC37-2018 - 29jan2020 - Admin KHRI PDFDocument24 pages09 - VV - Pavement Design IRC37-2018 - 29jan2020 - Admin KHRI PDFAmit Rajendra Phadatare100% (1)

- 1 Construction and QC in Rigid Pavements As Per MORD SpecificationsDocument128 pages1 Construction and QC in Rigid Pavements As Per MORD SpecificationsCHETTIKULAM NATHAM projectPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Longwall Mining at Shallow Depth of Cover in IndiaD'EverandLongwall Mining at Shallow Depth of Cover in IndiaPas encore d'évaluation

- Rational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialD'EverandRational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialPas encore d'évaluation

- Machine Design Elements and AssembliesD'EverandMachine Design Elements and AssembliesÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsD'EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsPas encore d'évaluation

- CMU Electrical Engineering Course Syllabus for Calculus 2Document7 pagesCMU Electrical Engineering Course Syllabus for Calculus 2Alquien Engaling CapuyanPas encore d'évaluation

- Referensi Code & StandardDocument1 pageReferensi Code & StandardReza Harendra PutraPas encore d'évaluation

- PSOC Lession PlanDocument7 pagesPSOC Lession PlanskdwarakanathPas encore d'évaluation

- ENGG1100 PBL1-Week 1 - 2024Document31 pagesENGG1100 PBL1-Week 1 - 2024L JacksonPas encore d'évaluation

- M.Tech-Construction Engineering & ManagementDocument76 pagesM.Tech-Construction Engineering & ManagementAmudhan V100% (1)

- Result GEC SreekrishnapuramDocument7 pagesResult GEC SreekrishnapuramAnonymous DbmKEDxPas encore d'évaluation

- Ieee Power Transmission and Distribution Standards Collection: Vuspec™Document3 pagesIeee Power Transmission and Distribution Standards Collection: Vuspec™Falcon EgyPas encore d'évaluation

- Safety - System ESD PSDDocument9 pagesSafety - System ESD PSDMakiber100% (1)

- 04 - Ignition Timing - InspectionDocument1 page04 - Ignition Timing - InspectionjordantPas encore d'évaluation

- 60 Toughest PuzzlesDocument33 pages60 Toughest Puzzlessagnik67% (3)

- Mil STD 1629a Notice 1Document11 pagesMil STD 1629a Notice 1Владимир МалићPas encore d'évaluation

- Verilog AMS TutorialDocument29 pagesVerilog AMS TutorialSiva KrishnaPas encore d'évaluation

- Overview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplDocument6 pagesOverview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplSami SyedPas encore d'évaluation

- Bridge EngineerDocument171 pagesBridge EngineerChu Do HuuPas encore d'évaluation

- How to Design Septic Tanks and Calculate VolumesDocument21 pagesHow to Design Septic Tanks and Calculate VolumeseteurePas encore d'évaluation

- Ce6012 - QB 3 - BY Civildatas - Blogspot.inDocument5 pagesCe6012 - QB 3 - BY Civildatas - Blogspot.invivek murthyPas encore d'évaluation

- Neil CVDocument2 pagesNeil CVHOSAM HUSSEINPas encore d'évaluation

- Core Skills Geotechnical Professionals Should MasterDocument6 pagesCore Skills Geotechnical Professionals Should MasternearmonkeyPas encore d'évaluation

- Weekly QA/QC ReportDocument4 pagesWeekly QA/QC ReportJoel AlcantaraPas encore d'évaluation

- The Waterfall ModelDocument1 pageThe Waterfall Modelajitkumarsahu4288Pas encore d'évaluation

- ISO Optical StandardsDocument16 pagesISO Optical Standardsflord21Pas encore d'évaluation

- Iso 14102 98Document10 pagesIso 14102 98최재호Pas encore d'évaluation

- Performance Evaluation of Flexible Pavement On National Highway-18 Kurnool District of Andhra PradeshDocument3 pagesPerformance Evaluation of Flexible Pavement On National Highway-18 Kurnool District of Andhra PradeshVenkataHussainReddyPas encore d'évaluation

- STRATEGIC COMMUNICATION AND UNMANNED SYSTEMS SBU JOBSDocument8 pagesSTRATEGIC COMMUNICATION AND UNMANNED SYSTEMS SBU JOBSKamalKaurPas encore d'évaluation

- Star Delta DiagramDocument2 pagesStar Delta Diagramgarv84090% (10)

- Document List DrawingDocument13 pagesDocument List Drawingzat572000Pas encore d'évaluation

- Contemporary Issues and The Impact of Technology On Management Accounting (Topic 1: Part 2)Document18 pagesContemporary Issues and The Impact of Technology On Management Accounting (Topic 1: Part 2)LHPas encore d'évaluation

- Course Coverage ReportDocument5 pagesCourse Coverage ReportAnnie Isabella100% (1)

- IIM Shillong PGP 2021-23 Admission Process - 281020Document8 pagesIIM Shillong PGP 2021-23 Admission Process - 281020Kumar PranayPas encore d'évaluation

- Comprehensive Finite Element Program for Geotechnical AnalysisDocument1 pageComprehensive Finite Element Program for Geotechnical AnalysisEka SupriantoPas encore d'évaluation