Académique Documents

Professionnel Documents

Culture Documents

Durazone 37 A Non-Migratory Antiozonant

Transféré par

tomcroftTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Durazone 37 A Non-Migratory Antiozonant

Transféré par

tomcroftDroits d'auteur :

Formats disponibles

2013 Addivant

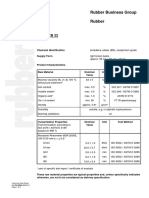

DURAZONE 37

A NON-MIGRATORY, HIGH PERFORMANCE

ANTIOZONANT DESIGNED TO MAINTAIN ORIGINAL

RUBBER PRODUCT APPEARANCE

TOM CROFT

TECHNICAL SERVICE MANAGER FOR TIRE AND RUBBER

APPLICATIONS

1

2013 Addivant

DURAZONE 37

2

CAS Number: 121246-28-4

Molecular Weight: 694

Melting Point : 70 74C (158 165F)

Physical Form: Purple flake

Specific Gravity: 1.05

Solubility: Insoluble in water, Soluble in hexane,

benzene, xylene. Slightly soluble in acetone and MEK

2,4,6-Tris-(N-1,4-dimethylpentyl-p-phenylenediamino)-1,3,5-triazine

2013 Addivant

BENEFITS OF DURAZONE

IN RUBBER COMPOUNDING

Can be used in colored compounds where

discoloration is a problem

Low softening point makes DURAZONE 37

usable in single pass mixing operations

No harmful effects on shelf life of mixed

compound

For Non-

tire

producers:

Protects the original appearance of tires from

unwanted changes due to surface bloom in

sidewall and other visible components

Can be combined with Naugard Q for synergistic

impact on resistance to oxidation and ozonation

Equal or improved ozone resistance when

compared to 6PPD

Can be used in sidewall compounds in contact

with white labeling or striping with no

problematic staining

For Tire

producers:

3

2013 Addivant

High Molecular Weight: Will be stable in the rubber matrix. Volatilization is not

a problem in most rubber compounds.

Non-Discoloring : Can be used in light colored compounds without the

problems associated with staining or discoloring of traditional antiozonants.

Can be Combined with Other Antidegradants: Can be combined with other

antidegradants that offer other unique properties such as NAUGARD Q or

OCTAMINE to give a protection package to resist oxidation and ozone attack.

These synergistic blends are often very cost effective means to protect a rubber

compound.

No Impact on Rubber Compound Physical Properties: Has been used with a

variety of elastomer types (NR, SBR, NBR, CR, BR, etc) with minimal or no

negative effect on physical properties such as hardness, tensile and elongation.

IMPORTANT FEATURES OF DURAZONE 37

4

2013 Addivant

Tire Sidewalls

Hose Cover

Windshield Wiper

Automotive Trim

Tire Tread

APPLICATIONS FOR DURAZONE 37

5

Athletic Footwear

Architectural Seals

Sponge Compounds

Playground Equipment

2013 Addivant

DURAZONE 37 HAS LITTLE TO NO

IMPACT ON CURE RATE

6

Polychloroprene GW 100 100 100

Mg Oxide 4 4 4

Polyethylene wax 3 3 3

N990 50 50 50

Clay 50 50 50

ZnO 5 5 5

TBTD 1.5 1.5 1.5

DOTG 0.5 0.5 0.5

OCTAMINE 0 2 0

DURAZONE 37 0 0 2

Rheometer, @ 160

0

C

ts1,min 1.2 1.1 1.2

tc90, min 7.91 7.72 7.87

DURAZONE 37 Impact on Cure Rate

2013 Addivant

DURAZONE 37 PERFORMANCE

7

0

200

400

600

800

1000

1200

Control Octamine 2 phr Durazone 37 2 phr

Hrs to

Cracking

Polychloroprene Compound, ASTM D1149, Ozone

Exposure, 50 pphm, Hours to Cracking

2013 Addivant

DURAZONE 37

SHOWS LITTLE TO NO SURFACE BLOOM

8

SMR 5CV 60 60

EPDM 70 70

N660 45 45

ZnO 3 3

Stearic Acid 1 1

TBBS 0.9 0.9

Sulfur 1.5 1.5

6PPD 2.4 0

Durazone 37 0 2.4

Extension Cycling Fatigue Test

ASTM D4482

Aged 70 hrs @100C,

KC to failure 368 378

Appearance Change in Sidewall Compound

2013 Addivant

DURAZONE

37

THE NON-MIGRATORY ANTIOZONANT

9

9

Ozone Aging, NR / EPDM Sidewall Compound,

Run 72 hrs Continuously, 50 pphm @ 40C

Left 6PPD (2.4 phr) and Right DURAZONE37 (2.4 phr)

2013 Addivant

NON-STAINING PERFORMANCE OF

DURAZONE 37

10

SMR-5CV 100 100

N-326 50 50

ZnO 3 3

Stearic Acid 1 1

Naphthenic Oil 15 15

TBBS 0.7 0.7

Sulfur 2.2 2.2

DURAZONE 37 4 0

6PPD 0 4

Aged 2 weeks, 70

0

C

ASTM D573

% Retention

Tensile Strength 121 118

Elongation 81 83

300% Modulus 220 208

NR Sidewall Compound for Non-staining Comparison

2013 Addivant

NON-STAINING PERFORMANCE OF

DURAZONE 37

11

(l) 4.0 PHR 6PPD (r) 4.0 PHR DURAZONE 37

Ageing Period 30 Days at Room Temperature

2013 Addivant

IMPROVING DYNAMIC PROPERTIES WITH

DURAZONE 37

12

SBR 1502 50 50

SBR 1778 70 70

N234 55 55

ZnO 3 3

Stearic Acid 1 1

DURAZONE 37 1 0

6PPD 0 1

TBS 0.5 0.5

MBS 0.5 0.5

Sulfur 1.8 1.8

DURAZONE 37 versus 6PPD in Dynamic Flexing Testing

2013 Addivant

DYNAMIC PROPERTIES PERFORMANCE

WITH DURAZONE 37

13

Relationship of tan delta to temperature change

equal for DURAZONE 37 and 6PPD.

Tan delta is an indicator for rolling resistance properties in tire tread

compounds. Lower tan delta would indicate improved rolling

resistance.

6PPD

Durazone 37

Antiozonant, phr 1.0 1.0

Dynamic Properties, Cured 10 min. at 177C (350F)

Extension Cycling Fatigue Test - ASTM D4482

Aged 70 hrs at 100C (212F), kc 82.8 107.4

Dynamic Properties

Tangent Delta at 4C (39F) 0.184 0.179

Tangent Delta at 28C (82F) 0.166 0.155

Tangent Delta at 53C (127F) 0.143 0.131

Tangent Delta at 77C (171F) 0.133 0.121

Tangent Delta at 102C (216F) 0.120 0.120

Dynamic Modulus (G*) at 4C (39F), MPa 8.53 7.75

Dynamic Modulus (G*) at 28C (82F), MPa 6.16 5.53

Dynamic Modulus (G*) at 53C (127F), MPa 4.62 4.34

Dynamic Modulus (G*) at 77C (171F), MPa 4.00 3.73

Dynamic Modulus (G*) at 102C (216F), MPa 3.58 3.39

2013 Addivant

WORKER SAFETY CONCERNS

In addition to the low migration tendencies

of DURAZONE 37 when fully

incorporated into a rubber compound,

DURAZONE 37 is quite low for volatility

in normal rubber processing conditions.

In normal mixing, milling, extrusion,

molding and calendaring operations, there

should be minimal to no worker exposure

to vaporized DURAZONE 37.

14

2013 Addivant

Weight loss is less than 0.15% from 100 150

o

C

THERMAL STABILITY OF

DURAZONE 37 IN PROCESSING

2013 Addivant

No significant Weight Loss for DURAZONE 37 Until Well Past Processing

Temperatures

THERMAL STABILITY OF

DURAZONE 37 IN PROCESSING

2013 Addivant

DURAZONE 37 is capable of providing excellent protection

from ozone degradation for many different elastomers

DURAZONE 37 does not significanatly impact the cure rate

DURAZONE 37 does not discolor or stain in rubber compounds

DURAZONE 37 does not present a threat to worker safety due

to off gassing during processing

Dynamic properties of compounds with DURAZONE 37 equal

or slightly improved to those using 6PPD

CONCLUSIONS

17

2013 Addivant

Vous aimerez peut-être aussi

- Santoflex (TM) 77PD: Safety Data SheetDocument13 pagesSantoflex (TM) 77PD: Safety Data SheetMarcos ROSSI100% (1)

- Vulkazon® AFS/LG - 0020eDocument2 pagesVulkazon® AFS/LG - 0020eTmacPas encore d'évaluation

- Exxonmobil New Exxpro 3563 Specialty Elastomer With Superior Impermeability For TiresDocument20 pagesExxonmobil New Exxpro 3563 Specialty Elastomer With Superior Impermeability For TiresAmir Hossein ShahdadiPas encore d'évaluation

- Vamac Formulating and Compounding OverviewDocument6 pagesVamac Formulating and Compounding Overviewchethugowda7Pas encore d'évaluation

- SX105 Data SheetDocument1 pageSX105 Data SheetArturo BLANCAS MARTINEZPas encore d'évaluation

- Teflon Ptfe Disp 30 Product InfoDocument2 pagesTeflon Ptfe Disp 30 Product InfoThusith WijayawardenaPas encore d'évaluation

- Isopar Series Isoparaffinic Hydrocarbons BrenntagDocument1 pageIsopar Series Isoparaffinic Hydrocarbons BrenntagAlexis TorreelePas encore d'évaluation

- Pinhas TDS Lushan AR493Document2 pagesPinhas TDS Lushan AR493Zirve PolimerPas encore d'évaluation

- Mowilith DM 2641: Division TLP - Polymer DispersionsDocument2 pagesMowilith DM 2641: Division TLP - Polymer DispersionsoxyeePas encore d'évaluation

- Cardolite Ultra LITE 2009: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite Ultra LITE 2009: Epoxy Curing Agent Technical Datasheettrường phạmPas encore d'évaluation

- Bruggolite FF6 MDocument13 pagesBruggolite FF6 Michsan hakimPas encore d'évaluation

- Silane-Terminated Polyurethanes (STPS) For Sealants & AdhesivesDocument2 pagesSilane-Terminated Polyurethanes (STPS) For Sealants & Adhesivessriatul2006Pas encore d'évaluation

- Lubrizol 2063: Product DescriptionDocument2 pagesLubrizol 2063: Product DescriptionMOHAMED GamalPas encore d'évaluation

- B62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDocument15 pagesB62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDiego CamargoPas encore d'évaluation

- Nuplex Resins Katalog enDocument9 pagesNuplex Resins Katalog enmaged_abdnaghoPas encore d'évaluation

- Priolube 3970Document2 pagesPriolube 3970Agenk VambudyPas encore d'évaluation

- 09-40-002 LP Printing Inks - 4S GB - FinDocument4 pages09-40-002 LP Printing Inks - 4S GB - FinFiras_karboujPas encore d'évaluation

- Pvi PDFDocument3 pagesPvi PDFBharat ChatrathPas encore d'évaluation

- Roskydal-K-36 en A4 PDFDocument2 pagesRoskydal-K-36 en A4 PDFmariem rahmouniPas encore d'évaluation

- Ethoxylated Nonylphenol - ChemistryDocument15 pagesEthoxylated Nonylphenol - Chemistrysimbua720% (1)

- SurfaceDocument26 pagesSurfacejmet2008Pas encore d'évaluation

- Engage Product ChartDocument7 pagesEngage Product Chartmusmanghani70scribdPas encore d'évaluation

- Evonik Additives For PU Shoe SoleDocument12 pagesEvonik Additives For PU Shoe SoleSigneyWangPas encore d'évaluation

- Buna CB 22Document2 pagesBuna CB 22Tmac100% (1)

- Potential of A Production DI Two-Stroke Engine Adapted For Range Extender and Motorcycle ApplicationsDocument24 pagesPotential of A Production DI Two-Stroke Engine Adapted For Range Extender and Motorcycle ApplicationsManuelLentiPas encore d'évaluation

- Gal StaffDocument27 pagesGal StaffLuiz Henrique Arnaud Camargo100% (1)

- Nox-Rust 311 HMDocument1 pageNox-Rust 311 HMNavin JoshiPas encore d'évaluation

- Kraton PolymerDocument24 pagesKraton PolymerSCion Shyuan Hong100% (2)

- Desmopan BayerDocument22 pagesDesmopan BayerGabriel SalomonPas encore d'évaluation

- TDS Irganox B 215Document2 pagesTDS Irganox B 215Jorge David Rojas CardenasPas encore d'évaluation

- Encor367 - en o Ucar 367 ArkemaDocument2 pagesEncor367 - en o Ucar 367 ArkemaAlvaro Hernandez VidalPas encore d'évaluation

- Fact Sheet Starting Formulations For Kraton DDocument11 pagesFact Sheet Starting Formulations For Kraton DCarlPas encore d'évaluation

- Chemlok 205 - 220 영문Document5 pagesChemlok 205 - 220 영문Ardiansyah Andry100% (1)

- Arlanxeo NBR Product PortofolioDocument8 pagesArlanxeo NBR Product PortofolioErwin ErwinPas encore d'évaluation

- NeoCryl A-1049 PdsDocument1 pageNeoCryl A-1049 PdsLeandro EsvizaPas encore d'évaluation

- Einar 303 Product ProfileDocument4 pagesEinar 303 Product ProfileThanh Linh NguyenPas encore d'évaluation

- Conductive Bladders Brochure RhenoshapeDocument16 pagesConductive Bladders Brochure RhenoshapeAldiPas encore d'évaluation

- RAK3284Document10 pagesRAK3284vilas123456Pas encore d'évaluation

- SC2043Document3 pagesSC2043A MahmoodPas encore d'évaluation

- HoltacDocument8 pagesHoltacdargil66Pas encore d'évaluation

- SP84 (D332) PDFDocument3 pagesSP84 (D332) PDFNurul Zakiah Zamri TanPas encore d'évaluation

- D 3194 - 17Document3 pagesD 3194 - 17Salma Farooq100% (1)

- Inakyd 3623-X-70Document2 pagesInakyd 3623-X-70roybombomPas encore d'évaluation

- K08798 Wood Plastic Fusabond Brochure 0408Document4 pagesK08798 Wood Plastic Fusabond Brochure 0408anon_850523309Pas encore d'évaluation

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire IndustriesDocument5 pagesA Review On Rubber Compound Mixing in Banbury Mixer at Tire IndustriesPrashantha NandavarPas encore d'évaluation

- Elastollan Sup ® Sup +-+Thermoplastic+Polyurethane+Elastomers+ (TPU) +-+Product+RangeDocument40 pagesElastollan Sup ® Sup +-+Thermoplastic+Polyurethane+Elastomers+ (TPU) +-+Product+RangeCeasar CapunoPas encore d'évaluation

- Selection of Test Methods For Ethylene Propylene Diene Terpolymer (EPDM) GeomembranesDocument3 pagesSelection of Test Methods For Ethylene Propylene Diene Terpolymer (EPDM) Geomembranesmohamed abd eldayemPas encore d'évaluation

- TDS KH-8011S en 21Document2 pagesTDS KH-8011S en 21Carlos Lizarraga FloresPas encore d'évaluation

- 029 Butyl Rubber CompoundsDocument6 pages029 Butyl Rubber Compoundsrossifam777Pas encore d'évaluation

- Evonik-Ancamine K54 EUDocument2 pagesEvonik-Ancamine K54 EUOswaldo Manuel Ramirez MarinPas encore d'évaluation

- Furadur Cement (Steuler Tis 322)Document2 pagesFuradur Cement (Steuler Tis 322)SHAIK ASIMUDDINPas encore d'évaluation

- Final1 Additive StandardsDocument16 pagesFinal1 Additive StandardsmohammedPas encore d'évaluation

- Harwick AcceleratorsDocument5 pagesHarwick AcceleratorsAkash KumarPas encore d'évaluation

- CAS Nos. & Chemical Structures For Epotec Range: Epoxy Resins Based On Bisphenol - ADocument4 pagesCAS Nos. & Chemical Structures For Epotec Range: Epoxy Resins Based On Bisphenol - AAditya ShrivastavaPas encore d'évaluation

- Effect of Waterborne Polyurethane CoatingDocument11 pagesEffect of Waterborne Polyurethane CoatingDionne Antoine BacudPas encore d'évaluation

- Akfix Eng Technical Catalog 2022 Rev16Document211 pagesAkfix Eng Technical Catalog 2022 Rev16ahmed.serefPas encore d'évaluation

- Influence of Isomer Composition and Functionality of The Final Properties of Aromatic Polyurea Spray Coatings PDFDocument10 pagesInfluence of Isomer Composition and Functionality of The Final Properties of Aromatic Polyurea Spray Coatings PDFA Mahmood100% (1)

- Dupont Packaging & Industrial PolymersDocument3 pagesDupont Packaging & Industrial PolymersAlan FerreiraPas encore d'évaluation

- Gazguard 026: Units Typical Value Initial PropertyDocument2 pagesGazguard 026: Units Typical Value Initial PropertyTeguh SetionoPas encore d'évaluation

- Santoflex 6PPDDocument2 pagesSantoflex 6PPDAdriana Soto ArzolayPas encore d'évaluation

- FVMQDocument115 pagesFVMQNguyên NguyễnPas encore d'évaluation

- Compressor Oil Safety Data Sheet: General Air Products Part Number: APC01QDocument5 pagesCompressor Oil Safety Data Sheet: General Air Products Part Number: APC01QvankarpPas encore d'évaluation

- HACCP Analysis Self 123Document76 pagesHACCP Analysis Self 123Sana KhaliqPas encore d'évaluation

- Synthetic Opioids-2020Document2 pagesSynthetic Opioids-2020H Yudi IriantoPas encore d'évaluation

- International Standard: ISO 105-E01Document10 pagesInternational Standard: ISO 105-E01Tahir NizamPas encore d'évaluation

- Engineering Materials and MetallurgyDocument14 pagesEngineering Materials and Metallurgyashok pradhanPas encore d'évaluation

- Medicines List DeveloperDocument115 pagesMedicines List DeveloperAsim Shahzad MasihPas encore d'évaluation

- TXD 1 Physical Methods of Test ScopeDocument84 pagesTXD 1 Physical Methods of Test ScopeMoshiur RahmanPas encore d'évaluation

- GPC Application Notebook - 2Document58 pagesGPC Application Notebook - 2Юрій ЖуравінськийPas encore d'évaluation

- Exercise AnswerDocument3 pagesExercise AnswerMaridjan WiwahaPas encore d'évaluation

- MetrohmDocument29 pagesMetrohmBasPas encore d'évaluation

- Tie Rod Tieback SystemsDocument12 pagesTie Rod Tieback SystemsHarmandeep BhattiPas encore d'évaluation

- Photostabilization of Poly (Vinyl Chloride) - Still On The RunDocument28 pagesPhotostabilization of Poly (Vinyl Chloride) - Still On The RunAnonymous avGU1iPas encore d'évaluation

- Moisture Regain and Moisture ContentDocument14 pagesMoisture Regain and Moisture ContentRatul HasanPas encore d'évaluation

- Industrial Hemp Fibers An OverviewDocument16 pagesIndustrial Hemp Fibers An OverviewHua Hidari YangPas encore d'évaluation

- Fluorescent DyeDocument12 pagesFluorescent DyeFathi MustafaPas encore d'évaluation

- TSR 20 e SMR GPDocument31 pagesTSR 20 e SMR GPGabrielly LaylaPas encore d'évaluation

- RRL 4Document17 pagesRRL 4Carlben Jan RadaPas encore d'évaluation

- Con Chem ReviewerDocument5 pagesCon Chem ReviewerJed Riel BalatanPas encore d'évaluation

- Thermal Stability, Swelling Behaviour and Dielectric Proper-Ties of Nbr/Pvc-Pvac BlendsDocument8 pagesThermal Stability, Swelling Behaviour and Dielectric Proper-Ties of Nbr/Pvc-Pvac BlendssdfsdfssdfsdPas encore d'évaluation

- HN Lab - 1 2 Types of ReactionsDocument3 pagesHN Lab - 1 2 Types of Reactionskyle_tosh3382Pas encore d'évaluation

- Glossary of Energy and Financial TermsDocument2 pagesGlossary of Energy and Financial TermsJoseAndresCarreñoPas encore d'évaluation

- Castrol Alphasyn EP 220Document2 pagesCastrol Alphasyn EP 220Vusal HasanovPas encore d'évaluation

- Aromatic CompoundsDocument5 pagesAromatic CompoundsShuchi HossainPas encore d'évaluation

- ASTM Volume 08.02, June 2018: Plastics (II) : D3222-D5083Document9 pagesASTM Volume 08.02, June 2018: Plastics (II) : D3222-D5083s0n1907Pas encore d'évaluation

- 10C Polymer ProcessingDocument18 pages10C Polymer ProcessingAhmed AliPas encore d'évaluation

- (VC60) Natural Derived Fullerene CatalogDocument4 pages(VC60) Natural Derived Fullerene CatalogcantuscantusPas encore d'évaluation

- BICON Prysmian BX1 225 Electrical Joint CompoundDocument1 pageBICON Prysmian BX1 225 Electrical Joint CompoundkarimiPas encore d'évaluation

- Types of DeformationDocument2 pagesTypes of DeformationAPas encore d'évaluation

- DIAGRAMS ARE GUIDELINES ONLY: Parts Indicated May Not Be Included With Your PoleDocument1 pageDIAGRAMS ARE GUIDELINES ONLY: Parts Indicated May Not Be Included With Your PoleSamuel MoraPas encore d'évaluation