Académique Documents

Professionnel Documents

Culture Documents

Chapter 4

Transféré par

lockas222Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 4

Transféré par

lockas222Droits d'auteur :

Formats disponibles

Chapter 4 :

Flow Through pipes and

Immersed Bodies

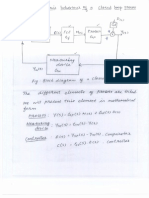

Pipe System

A pipe system include the pipes themselves

(perhaps of more than one diameter), the various

fittings, the flowrate control devices valves) , and

the pumps or turbines.

Pipe Flow vs. Open Channel Flow

Pipe flow: Flows completely filling the pipe. (a)

The pressure gradient along the pipe is main driving force.

Open channel flow: Flows without completely filling the

pipe. (b)

The gravity alone is the driving force.

Indication of

Laminar or Turbulent Flow

The term flowrate should be replaced by Reynolds

number, ,where V is the average velocity in

the pipe.

It is not only the fluid velocity that determines the

character of the flow its density, viscosity, and the pipe

size are of equal importance.

For general engineering purpose, the flow in a round pipe

Laminar

Transitional

Turbulent

= / VD R

e

2100 R

e

<

4000 R

e

Entrance Region and

Fully Developed Flow

1/2

Any fluid flowing in a pipe had to enter the pipe at some

location.

The region of flow near where the fluid enters the pipe is

termed the entrance region.

Entrance Region and

Fully Developed Flow

2/2

The shape of the velocity profile in the pipe depends on

whether the flow is laminar or turbulent, as does the length

of the entrance region,

e

.

e

e

R 06 . 0

D

=

6 / 1

e

e

R 4 . 4

D

=

For laminar flow For turbulent flow

Dimensionless entrance length

Pressure Distribution along Pipe

In the entrance region of a pipe, the fluid

accelerates or decelerates as it flows. There is

a balance between pressure, viscous, and

inertia (acceleration) force.

The magnitude of the

pressure gradient is

constant.

The magnitude of the

pressure gradient is larger

than that in the fully

developed region.

0

p

x

p

<

A

=

c

c

Fully Developed Laminar Flow

1/3

The shear stress distribution

Volume flowrate

A t

=

t

= = t = =

} }

128

p D

Q

2

V R

..... rdr 2 ) r ( u A d u Q

4

C

4

R

0

A

Poiseuilles Law

Valid for Laminar flow only

D

4

p

w

t

= A

Fully Developed Laminar Flow

2/3

Average velocity

Point of maximum velocity

A

=

t

= =

32

pD

R

Q

A

Q

V

2

2

average

0

dr

du

=

at r =0

average

2

max

V 2

4

p R

U u u =

A

= = =

Fully Developed Laminar Flow

3/3

Making adjustment to account for nonhorizontal pipes

u A A sin p p u>0 if the flow is uphill

u<0 if the flow is downhill

r

2 sin p t

=

u A

( )

u A

=

32

D sin p

V

2

average

( )

u A t

=

128

D sin p

Q

4

Example 4.1 Laminar Pipe Flow

An oil with a viscosity of = 0.40 N s/m

2

and density = 900 kg/m

3

flows in a pipe of diameter D= 0.20m . (a) What pressure drop, p

1

-p

2

,

is needed to produce a flowrate of Q=2.010

-5

m

3

/s if the pipe is

horizontal with x

1

=0 and x

2

=10 m? (b) How steep a hill, ,must the

pipe be on if the oil is to flow through the pipe at the same rate as in

part (a), but with p

1

=p

2

? (c) For the conditions of part (b), if p

1

=200

kPa, what is the pressure at section, x

3

=5 m, where x is measured

along the pipe?

Example 4.1 Solution

1/2

2100 87 . 2 / VD R

e

< = =

s / m 0637 . 0

A

Q

V = =

The flow is laminar flow

kPa 4 . 20 ...

D

Q 128

p p p

4

2 1

= =

t

= = A

= u =

t

= u 34 . 13 ...

gD

Q 128

sin

4

If the pipe is on the hill of angle with p=0

( )

u A t

=

128

D sin p

Q

4

Example 4.1 Solution

2/2

With p

1

=p

2

the length of the pipe, , does not appear in the flowrate

equation

kPa 200 p p p

3 2 1

= = =

p=0 for all

Fully Developed Turbulent Flow

Turbulent pipe flow is actually more likely to occur than

laminar flow in practical situations.

Turbulent flow is a very complex process.

Numerous persons have devoted considerable effort in an

attempting to understand the variety of baffling aspects of

turbulence. Although a considerable amount if knowledge

about the topics has been developed, the field of turbulent

flow still remains the least understood area of fluid

mechanics.

Much remains to be learned about the nature of turbulent flow.

Transition from Laminar to Turbulent

Flow in a Pipe

1/2

For any flow geometry, there is one (or more)

dimensionless parameters such as with this parameter

value below a particular value the flow is laminar, whereas

with the parameter value larger than a certain value the

flow is turbulent.

The important parameters involved and their critical

values depend on the specific flow situation involved.

Consider a long section of pipe that is

initially filled with a fluid at rest.

For flow in pipe : 2100<Re..Re>4000

For flow along a plate Re

x

~5000

Transition from Laminar to Turbulent

Flow in a Pipe

2/2

As the valve is opened to start the flow, the flow velocity and, hence,

the Reynolds number increase from zero (no flow) to their

maximum steady flow values.

For the initial time period the Reynolds number is small enough for

laminar flow to occur.

At some time the Reynolds

number reaches 2100, and the

flow begins its transition to

turbulent conditions.

Intermittent spots or burst

appear..

Energy Considerations

1/4

For steady, incompressible, frictional flow

0 q u u

in net in out

>

loss gz

2

V p

gz

2

V p

in

2

in in

out

2

out out

+ +

= + +

Defining useful or available energy

gz

2

V p

2

+ +

Defining loss of useful or available energy

Frictional flow

Energy Considerations

2/4

( )

in net shaft in net in out

2

in

2

out in out

in out

W Q z z g

2

V V p p

u u m

+ =

(

+

|

|

.

|

\

|

|

|

.

|

\

|

+

m

) q u u ( w gz

2

V p

gz

2

V p

in net in out in net shaft in

2

in in

out

2

out out

+ + +

= + +

For steady, incompressible flow with friction and shaft work

loss w gz

2

V p

gz

2

V p

in net shaft in

2

in in

out

2

out out

+ + +

= + +

g

L s in

2

in in

out

2

out out

h h z

g 2

V p

z

g 2

V p

+ + +

= + +

Q

W

g m

W

g

w

h

in net shaft in net shaft in net shaft

S

= =

g

loss

h

L

= Head loss Shaft head

Energy Considerations

4/4

Total head loss , h

L

, is regarded as the sum of major losses,

h

L major

, due to frictional effects in fully developed flow

in constant area tubes, and minor losses, h

L minor

, resulting

from entrance, fitting, area changes, and so on.

or min major

L L L

h h h + =

Major Losses: Friction Factor

The energy equation for steady and incompressible flow

with zero shaft work

L 2

2

2 2 2

1

2

1 1 1

h gz

2

V p

gz

2

V p

=

|

|

.

|

\

|

+

o

+

|

|

.

|

\

|

+

o

+

L 1 2

2 1

h ) z z ( g

p p

+ =

>>>

For fully developed flow through a constant area pipe ,

o

1

= o

2

=1 , V

1

= V

2

(o : Kinetic energy coefficient)

For horizontal pipe, z

2

=z

1

L

2 1

h

p p p

=

A

=

>>>

Major Losses: Laminar Flow

In fully developed laminar flow in a horizontal pipe, the

pressure drop

( )

2

V

D R

64

VD

64

2

V

D D

V

D

32 h

2

V

D

f p

D Re

64

D VD

64

V

2

1

p

D

V

D

32

D

4 / D V 128

D

Q 128

p

2

e

2

L

2

2

4

2

4

|

|

.

|

\

|

=

|

|

.

|

\

|

= >>

= A

=

=

t

t

=

t

= A

Re

64

f

ar min la

=

Friction Factor ( ) ( ) 2 / V / / D p f

2

A =

Major Losses: Turbulent Flow

1/3

In turbulent flow we cannot evaluate the pressure drop analytically;

we must resort to experimental results and use dimensional analysis

to correlate the experimental data.

( ) c = A , , , , D , V F p

In fully developed turbulent flow the

pressure drop, p , caused by friction

in a horizontal constant-area pipe is

known to depend on pipe diameter,D,

pipe length, , pipe roughness,e,

average flow velocity, V, fluid density,

and fluid viscosity,.

Major Losses: Turbulent Flow

2/3

Applying dimensional analysis, the result were a correlation of the

form

Experiments show that the nondimensional head loss is directly

proportional to /D. Hence we can write

|

.

|

\

|

c

| =

A

D

Re,

D V

p

2

2

1

|

.

|

\

|

c

|

D

Re, f

g 2

V

D

f h

2

L

major

2

V

D

f p

2

= A

Darcy-Weisbach equation

|

|

.

|

\

| c

| =

A

D

,

D

,

VD

V

p

2

2

1

Roughness for Pipes

Friction Factor by L. F. Moody

Depending on the specific

circumstances involved.

About Moody Chart

For laminar flow, f=64/Re, which is independent of the

relative roughness.

For very large Reynolds numbers, f=(/D), which is

independent of the Reynolds numbers.

For flows with very large value of Re, commonly termed

completely turbulent flow (or wholly turbulent flow), the

laminar sublayer is so thin (its thickness decrease with

increasing Re) that the surface roughness completely

dominates the character of the flow near the wall.

For flows with moderate value of Re, the friction factor

f=(Re,/D).

Major Losses: Turbulent Flow

3/3

Colebrook To avoid having to use a graphical method for

obtaining f for turbulent flows.

Miler suggests that a single iteration will produce a result within

1 percent if the initial estimate is calculated from

(

+

c

=

f Re

51 . 2

7 . 3

D /

log 0 . 2

f

1

2

9 . 0

0

Re

74 . 5

7 . 3

D /

log 25 . 0 f

(

+

c

=

Valid for the entire nonlaminar

range of the Moody chart.

Colebrook formula

Example 4.2 Comparison of Laminar or

Turbulent pressure Drop

Air under standard conditions flows through a 4.0-mm-diameter

drawn tubing with an average velocity of V = 50 m/s. For such

conditions the flow would normally be turbulent. However, if

precautions are taken to eliminate disturbances to the flow (the

entrance to the tube is very smooth, the air is dust free, the tube does

not vibrate, etc.), it may be possible to maintain laminar flow. (a)

Determine the pressure drop in a 0.1-m section of the tube if the

flow is laminar. (b) Repeat the calculations if the flow is turbulent.

Example 4.2 Solution

1/2

flow Turbulent 700 , 13 ... / VD R

e

= = =

Under standard temperature and pressure conditions

V=1.23kg/m

3

, =1.7910

-5

Ns/m

The Reynolds number

kPa 179 . 0 ... V

2

1

D

f p

2

= = = A

If the flow were laminar

f=64/Re=`=0.0467

Example 4.2 Solution

2/2

kPa 076 . 1 ... V

2

1

D

f p

2

= = = A

If the flow were turbulent

From Moody chart f=(Re,/D) =0.028

Minor Losses

1/5

Most pipe systems consist of

considerably more than straight

pipes. These additional

components (valves, bends, tees,

and the like) add to the overall

head loss of the system.

Such losses are termed MINOR

LOSS.

The flow pattern through a valve

Minor Losses

2/5

The theoretical analysis to predict the details of flow

pattern (through these additional components) is not, as

yet, possible.

The head loss information for essentially all components is

given in dimensionless form and based on experimental

data. The most common method used to determine these

head losses or pressure drops is to specify the loss

coefficient, K

L

Minor Losses

3/5

2

L

2

2

L

L

V

2

1

K p

V

2

1

p

g 2 / V

h

K

or min

= A

A

= =

Re) , geometry ( K

L

| =

f

D

K

g 2

V

D

f

g 2

V

K h

L eq

2

eq

2

L L

or min

=

= =

Minor losses are sometimes

given in terms of an equivalent

length

eq

The actual value of K

L

is strongly dependent on the geometry of

the component considered. It may also dependent on the fluid

properties. That is

Minor Losses

4/5

For many practical applications the Reynolds number is

large enough so that the flow through the component is

dominated by inertial effects, with viscous effects being of

secondary importance.

In a flow that is dominated by inertia effects rather than

viscous effects, it is usually found that pressure drops and

head losses correlate directly with the dynamic pressure.

This is the reason why the friction factor for very large

Reynolds number, fully developed pipe flow is

independent of the Reynolds number.

Minor Losses

5/5

This is true for flow through pipe components.

Thus, in most cases of practical interest the loss

coefficients for components are a function of geometry

only,

) geometry ( K

L

| =

Minor Losses Coefficient

Entrance flow 1/3

Entrance flow condition

and loss coefficient

(a) Reentrant, K

L

= 0.8

(b) sharp-edged, K

L

= 0.5

(c) slightly rounded, K

L

= 0.2

(d) well-rounded, K

L

= 0.04

K

L

= function of rounding of

the inlet edge.

Minor Losses Coefficient

Entrance flow 2/3

A vena contracta region may result because the fluid

cannot turn a sharp right-angle corner. The flow is said to

separate from the sharp corner.

The maximum velocity velocity at section (2) is greater

than that in the pipe section (3), and the pressure there is

lower.

If this high speed fluid could slow down efficiently, the

kinetic energy could be converted into pressure.

Minor Losses Coefficient

Entrance flow 3/3

Such is not the case. Although

the fluid may be accelerated very

efficiently, it is very difficult to

slow down (decelerate) the fluid

efficiently.

(2)(3) The extra kinetic energy

of the fluid is partially lost

because of viscous dissipation,

so that the pressure does not

return to the ideal value.

Flow pattern and pressure distribution

for a sharp-edged entrance

Minor Losses Coefficient

Exit flow

Exit flow condition and

loss coefficient

(a) Reentrant, KL = 1.0

(b) sharp-edged, KL = 1.0

(c) slightly rounded, KL = 1.0

(d) well-rounded, KL = 1.0

Minor Losses Coefficient

varied diameter

Loss coefficient for sudden

contraction, expansion,typical

conical diffuser.

2

2

1

L

A

A

1 K

|

|

.

|

\

|

=

Minor Losses Coefficient

Bend

Carefully designed guide vanes

help direct the flow with less

unwanted swirl and disturbances.

Character of the flow in bend

and the associated loss

coefficient.

Internal Structure of Valves

(a) globe valve

(b) gate valve

(c) swing check valve

(d) stop check valve

Loss

Coefficients

for Pipe

Components

Example 4.3 Minor Loss

1/2

Air at standard conditions is to flow through the test section

[between sections (5) and (6)] of the closed-circuit wind tunnel

shown if Figure E8.6 with a velocity of 200 ft/s. The flow is driven

by a fan that essentially increase the static pressure by the amount

p

1

-p

9

that is needed to overcome the head losses experienced by the

fluid as it flows around the circuit. Estimate the value of p

1

-p

9

and

the horsepower supplied to the fluid by the fan.

Example 4.3 Minor Loss

2/2

Example 4.3 Solution

1/3

The maximum velocity within the wind tunnel occurs in the

test section (smallest area). Thus, the maximum Mach number

of the flow is Ma

5

=V

5

/c

5

9 1 L 9

2

9 9

1

2

1 1

h z

g 2

V p

z

g 2

V p

+ + +

= + +

s / ft 1117 ) KRT ( c s / ft 200 V

2 / 1

5 5 5

= = =

The energy equation between points (1) and (9)

9 1

9 1 L

p p

h

The total head loss from (1) to (9).

Example 4.3 Solution

2/3

The energy across the fan, from (9) to (1)

9 1 L 5 5 p 5 5 p a

h V A h V A Qh P

= = =

9 1 L

9 1

p

h

p p

h

=

=

1

2

1 1

p 9

2

9 9

z

g 2

V p

h z

g 2

V p

+ +

= + + +

H

p

is the actual head rise supplied

by the pump (fan) to the air.

The actual power supplied to the air

(horsepower, P

a

) is obtained from the

fan head by

Example 4.3 Solution

3/3

The total head loss

hp 3 . 62 s / lb ft 34300 ... P

psi 298 . 0 ... ) ft 560 )( ft / lb 765 . 0 ( h p p

a

2

9 1 L 9 1

= = =

= = = =

scr noz dif 3 corner 2 corner 8 corner 7 corner

L L L L L L L 9 1 L

h h h h h h h h + + + + + + =

0 . 4 K 2 . 0 K

g 2

V

6 . 0

g 2

V

K h

g 2

V

2 . 0

g 2

V

K h

scr noz

dif dif corner

L L

2 2

L L

2 2

L L

= =

= = = =

Noncircular Ducts

1/4

The empirical correlations for pipe flow may be used for

computations involving noncircular ducts, provided their

cross sections are not too exaggerated.

The correlation for turbulent pipe flow are extended for

use with noncircular geometries by introducing the

hydraulic diameter, defined as

P

A 4

D

h

Where A is cross-

sectional area, and P

is wetted perimeter.

Noncircular Ducts

2/4

For a circular duct

For a rectangular duct of width b and height h

The hydraulic diameter concept can be applied in the

approximate range <ar<4. So the correlations for pipe

flow give acceptably accurate results for rectangular ducts.

b h a

a

h

h b

bh

P

A

D

r

r

h

/

1

2

) ( 2

4 4

=

+

=

+

=

D

P

A 4

D

h

=

Noncircular Ducts

3/4

The friction factor can be written as f=C/Re

h

, where the

constant C depends on the particular shape of the duct, and

Re

h

is the Reynolds number based on the hydraulic

diameter.

The hydraulic diameter is also used in the definition of the

friction factor, , and the relative

roughness c/D

h

.

) g 2 / V )( D / ( f h

2

h L

=

Noncircular Ducts

4/4

For Laminar flow, the value of C=f Re

h

have been

obtained from theory and/or experiment for various shapes.

For turbulent flow in ducts of noncircular cross section,

calculations are carried out by using the Moody chart data

for round pipes with the diameter replaced by the hydraulic

diameter and the Reynolds number based on the hydraulic

diameter.

The Moody chart, developed for round pipes, can also

be used for noncircular ducts.

Friction Factor for Laminar Flow in

Noncircular Ducts

Example 4.4 Noncircular Duct

Air at temperature of 120F and standard pressure flows from a

furnace through an 8-in.-diameter pipe with an average velocity of

10ft/s. It then passes through a transition section and into a square

duct whose side is of length a. The pipe and duct surfaces are

smooth (=0). Determine the duct size, a, if the head loss per foot is

to be the same for the pipe and the duct.

Example 4.4 Solution

1/3

The head loss per foot for the pipe

2

s h

a

49 . 3

A

Q

V a

P

A 4

D = = = =

For given pressure and temperature =1.8910

-4

ft

2

/s

g 2

V

D

f h

2

L

=

35300

VD

Re =

v

=

0512 . 0

g 2

V

D

f h

2

s

h

L

= =

For the square duct

Example 4.4 Solution

2/3

Have three unknown (a,f, and Re

h

) and three equation

Eqs. 1, 2, and either in graphical form the Moody chart or

the Colebrook equation

The Reynolds number based on the hydraulic diameter

a

10 89 . 1

10 89 . 1

a ) a / 49 . 3 ( D V

Re

4

4

2

h s

h

=

v

=

5 / 1

2 2 2

s

h

L

f 30 . 1 a

) 2 . 32 ( 2

) a / 49 . 3 (

a

f

0512 . 0

g 2

V

D

f h

= = = =

(1)

(2)

Find a

Example 4.4 Solution

3/3

Use the Moody chart

Assume the friction factor for the duct is the same as for the pipe.

That is, assume f=0.022.

From Eq. 1 we obtain a=0.606 ft.

From Eq. 2 we have Re

h

=3.0510

4

From Moody chart we find f=0.023, which does not quite agree the

assumed value of f.

Try again, using the latest calculated value of f=0.023 as our guess.

The final result is f=0.023, Re

h

=3.0510

4

, and a=0.611ft.

Pipe Flow Examples

1/2

The energy equation, relating the conditions at any two

points 1 and 2 for a single-path pipe system

by judicious choice of points 1 and 2 we can analyze not

only the entire pipe system, but also just a certain section

of it that we may be interested in.

g 2

V

D

f h

2

L

major

+ = =

|

|

.

|

\

|

+

o

+

|

|

.

|

\

|

+

o

+

or min major L L L 2

2

2 2 2

1

2

1 1 1

h h h z

g 2

V

g

p

z

g 2

V

g

p

Major loss

Minor loss

g 2

V

K h

2

L L

or min

=

Pipe Flow Examples

2/2

Single pipe whose length may be interrupted by various

components.

Multiple pipes in different configuration

Parallel

Series

Network

Single-Path Systems

1/2

Pipe flow problems can be categorized by what parameters

are given and what is to be calculated.

Single-Path Systems

2/2

Given pipe (L and D), and flow rate, and Q, find pressure

drop p

Given p, D, and Q, find L.

Given p, L, and D, find Q.

Given p, L, and Q, find D.

Given L , D, and Q, find p

The energy equation

The flow rate leads to the Reynolds number and hence the

friction factor for the flow.

Tabulated data can be used for minor loss coefficients and

equivalent lengths.

The energy equation can then be used to directly to obtain

the pressure drop.

+ = =

|

|

.

|

\

|

+

o

+

|

|

.

|

\

|

+

o

+

or min major L L L 2

2

2 2 2

1

2

1 1 1

h h h z

g 2

V

g

p

z

g 2

V

g

p

Given p, D, and Q, find L

The energy equation

The flow rate leads to the Reynolds number and hence the

friction factor for the flow.

Tabulated data can be used for minor loss coefficients and

equivalent lengths.

The energy equation can then be rearranged and solved

directly for the pipe length.

+ = =

|

|

.

|

\

|

+

o

+

|

|

.

|

\

|

+

o

+

or min major L L L 2

2

2 2 2

1

2

1 1 1

h h h z

g 2

V

g

p

z

g 2

V

g

p

Given p, L, and D, find Q

1/2

These types of problems required either manual iteration

or use of a computer application.

The unknown flow rate or velocity is needed before the

Reynolds number and hence the friction factor can be

found.

Repeat the iteration process

f V Re f until convergence

Given p, L, and D, find Q

2/2

First, we make a guess for f and solve the energy equation

for V in terms of known quantities and the guessed

friction factor f.

Then we can compute a Reynolds number and hence

obtain a new value for f.

Repeat the iteration process

f V Re f until convergence

Given p, L, and Q, find D

1/2

These types of problems required either manual iteration

or use of a computer application.

The unknown diameter is needed before the Reynolds

number and relative roughness, and hence the friction

factor can be found.

Given p, L, and Q, find D

2/2

First, we make a guess for f and solve the energy equation

for D in terms of known quantities and the guessed

friction factor f.

Then we can compute a Reynolds number and hence

obtain a new value for f.

Repeat the iteration process

f D Re and /D f until convergence

Example 4.5 Type I Determine Pressure

Drop

Water at 60F flows from the basement to the second floor through the

0.75-in. (0.0625-fy)-diameter copper pipe (a drawn tubing) at a rate of

Q = 12.0 gal/min = 0.0267 ft

3

/s and exits through a faucet of diameter

0.50 in. as shown in Figure.

Determine the pressure at

point (1) if: (a) all losses

are neglected, (b) the only

losses included are major

losses, or (c) all losses are

included.

Example 4.5 Solution

1/4

The energy equation

45000 / VD Re ft / s lb 10 34 . 2

ft / slug 94 . 1 s / ft 70 . 8 ...

A

Q

V

2 5

3

1

1

= = =

= = = =

s / ft 6 . 19 ... A / Q V

) jet free ( 0 p , ft 20 z , 0 z

2 2

2 2 1

= = =

= = =

L 2

2

2 2 2

1

2

1 1 1

h z

g 2

V

g

p

z

g 2

V

g

p

+ +

o

+

= +

o

+

The flow is turbulent

L

2

1

2

2 2

1

2 1

h ) V V ( z p + + =

Head loss is different for

each of the three cases.

Example 4.5 Solution

2/4

(a) If all losses are neglected (h

L

=0)

45000 Re 10 8 D / 000005 . 0

5

= = c = c

psi 7 . 10 ft / lb 1547 ... ) V V ( z p

2

2

1

2

2 2

1

2 1

= = = + =

f = 0.0215

(b) If the only losses included are the major losses, the head loss is

g 2

V

D

f h

2

1

L

=

Moody chart

psi 3 . 21 ft / lb 3062 ...

2

V

D

) ft 60 (

f ) V V ( z p

2

2

1

2

1

2

2 2

1

2 1

= = =

=

+ + =

Example 4.5 Solution

3/4

(c) If major and minor losses are included

] 2 ) 5 . 1 ( 4 10 [

2

) s / ft 70 . 8 (

) ft / slugs 94 . 1 ( psi 3 . 21

2

V

K psi 3 . 21 p

2

V

K

g 2

V

D

f ) V V ( z p

2

3

2

L 1

2

L

2

1

2

1

2

2 2

1

2 1

+ + + =

+ =

+ + + =

psi 5 . 30 psi 17 . 9 psi 3 . 21 p

1

= + =

Example 4.5 Solution

4/4

Example 4.6 Type I, Determine Head Loss

Crude oil at 140F with =53.7 lb/ft

3

and = 810-5 lb s/ft

2

(about

four times the viscosity of water) is pumped across Alaska through

the Alaska pipeline, a 799-mile-along, 4-ft-diameter steel pipe, at a

maximum rate of Q = 2.4 million barrel/day = 117ft

3

/s, or

V=Q/A=9.31 ft/s. Determine the horsepower needed for the pumps

that drive this large system.

Example 4.6 Solution

1/2

The energy equation between points (1) and (2)

Assume that z

1

=z

2

, p

1

=p

2

=V

1

=V

2

=0 (large, open tank)

ft 17700 ...

g 2

V

D

f h h

2

P L

= = = =

L 2

2

2 2

P 1

2

1 1

h z

g 2

V p

h z

g 2

V p

+ + +

= + + +

h

P

is the head provided to the oil

by the pump.

Minor losses are negligible because of the large length-to-

diameter ratio of the relatively straight, uninterrupted pipe.

f=0.0124 from Moody chart /D=(0.00015ft)/(4ft), Re=..

Example 4.6 Solution

2/2

The actual power supplied to the fluid.

hp 202000

s / lb ft 550

hp 1

... Qh P

P a

=

|

.

|

\

|

= =

Example 4.7 Type II, Determine Flowrate

According to an appliance manufacturer, the 4-in-diameter

galvanized iron vent on a clothes dryer is not to contain more than

20 ft of pipe and four 90 elbows. Under these conditions determine

the air flowrate if the pressure within the dryer is 0.20 inches of

water. Assume a temperature of 100 and standard pressure.

Example 4.7 Solution

1/2

Application of the energy equation between the inside of the dryer,

point (1), and the exit of the vent pipe, point (2) gives

+ + + +

= + +

g 2

V

K

g 2

V

D

f z

g 2

V p

z

g 2

V p

2

L

2

2

2

2 2

1

2

1 1

Assume that z

1

=z

2

, p

2

=0, V

1

=0

2 3

1

O H

1

ft / lb 04 . 1 ) ft / lb 4 . 62 (

. in 12

ft 1

.) in 2 . 0 ( p in 2 . 0

p

2

=

|

.

|

\

|

= =

With =0.0709lb/ft

3

, V

2

=V, and =1.7910

-4

ft

2

/s.

2

V ) f 60 5 . 7 ( 945 + =

(1)

f is dependent on Re, which is dependent on V, and unknown.

Example 4.7 Solution

2/2

V 1860 ...

VD

Re = =

v

=

(2)

We have three relationships (Eq. 1, 2, and the /D=0.0015 curve of

the Moody chart) from which we can solve for the three unknowns f,

Re, and V.

This is done easily by iterative scheme as follows.

Assume f=0.022V=10.4ft/s (Eq. 1)Re=19,300 (Eq.2)f=0.029

Assume f=0.029 V10.1ft/sRe=18,800 f=0.029

/s 0.881ft ... AV Q

3

= = =

Example 4.8 Type II, Determine Flowrate

The turbine shown in Figure E8.11 extracts 50 hp from the water

flowing through it. The 1-ft-diameter, 300-ft-long pipe is assumed to

have a friction factor of 0.02. Minor losses are negligible. Determine

the flowrate through the pipe and turbine.

Example 4.8 Solution

1/2

The energy equation can be applied between the surface of the lake

and the outlet of the pipe as

T L 2

2

2 2

1

2

1 1

h h z

g 2

V p

z

g 2

V p

+ + + +

= + +

Where p

1

=V

1

= p

2

=z

2

=0, z

1

=90ft, and V

2

=V, the fluid velocity in

the pipe

0 561 V 90 V 107 . 0

3

= +

ft V 0932 . 0

g 2

V

D

f h

2

2

L

= =

ft

V

561

...

Q

P

h

a

T

= =

=

There are two real, positive roots: V=6.58 ft/s or V=24.9 ft/s. The third

root is negative (V=-31.4ft/s) and has no physical meaning for this flow.

Example 4.8 Solution

2/2

Two acceptable flowrates are

s / ft 6 . 19 ... V D

4

Q

s / ft 17 . 5 ... V D

4

Q

3 2

3 2

= =

t

=

= =

t

=

However, in either case the product of the turbine head times the

flowrate is the same

Example 4.9 Type III Without Minor

Losses, Determine Diameter

Air at standard temperature and pressure flows through a horizontal,

galvanized iron pipe (=0.0005 ft) at a rate of 2.0ft

3

/s. Determine the

minimum pipe diameter if the pressure drop is to be no more than

0.50 psi per 100 ft of pipe.

Example 4.9 Solution

1/2

Assume the flow to be incompressible with =0.00238 slugs/ft

3

and

=3.7410

-7

lbs/ft

2.

If the pipe were too long, the pressure drop from one end to the other,

p

1

-p

2

, would not be small relative to the pressure at the beginning, and

compressible flow considerations would be required.

With z

1

=z

2

, V

1

=V

2

, The energy equation becomes

g

V

D

f p p

2

2 1

+ =

2

D

55 . 2

A

Q

V = =

g 2

V

) ft / slugs 00238 . 0 (

D

) ft 100 (

f ft / lb ) 144 )( 5 . 0 ( p p

2

3 2

2 1

= =

1/5

0.404f D=

(1)

Example 4.9 Solution

2/2

D

10 62 . 1

...

VD

Re

4

= =

=

(2)

(3)

D

0005 . 0

D

=

c

We have four equations (Eq. 1, 2, 3, and either the Moody chart or

the Colebrook equation) and four unknowns (f, D, /D, and Re)

from which the solution can be obtained by trial-and-error methods.

Repeat the iteration process

f D Re and /D f until convergence

(1) (2)

(3)

Example 4.10 Type III With Minor Losses,

Determine Diameter

Water at 60F (=1.2110

-5

ft

2

/s) is to flow from reservoir A to

reservoir B through a pipe of length 1700 ft and roughness 0.0005 ft

at a rate of Q= 26 ft

3

/s as shown in Figure. The system contains a

sharp-edged entrance and four flanged 45 elbow. Determine the

pipe diameter needed.

Example 4.10 Solution

1/2

The energy equation can be applied between two points on the

surfaces of the reservoirs (p

1

=V

1

= p

2

=z

2

=V

2

=0)

|

.

|

\

|

+ =

+ + +

= + +

L

2

1

L 2

2

2 2

1

2

1 1

K

D

f

g 2

V

z

h z

g 2

V p

z

g 2

V p

2

D

1 . 33

A

Q

V = = K

Lent

=0.5, K

Lelbow

=0.2, and K

Lexit

=1

|

.

|

\

|

+ + + = ] 1 5 . 0 ) 2 . 0 ( 4 [

D

1700

f

) s / ft 2 . 32 ( 2

V

ft 44

2

2

(1)

D 00135 . 0 D 00152 . 0 f

5

=

Example 4.10 Solution

2/2

D

10 74 . 2

...

VD

Re

6

= =

v

= (2)

(3)

D

0005 . 0

D

=

c

We have four equations (Eq. 1, 2, 3, and either the Moody chart or

the Colebrook equation) and four unknowns (f, D, /D, and Re)

from which the solution can be obtained by trial-and-error methods.

Repeat the iteration process

D f Re and /D f until convergence

(1) (2)

(3)

Multiple-Path Systems

Series and Parallel Pipe System

3 2 1 L L L 3 2 1

h h h Q Q Q Q = = + + =

3 2 1 B A L L L L 3 2 1

h h h h Q Q Q + + = = =

Multiple-Path Systems

Multiple Pipe Loop System

( )

( )

3 L 2 L

3 L 1 L B

2

B B

A

2

A A

2 L 1 L B

2

B B

A

2

A A

3 2 1

h h

3 1 h h z

g 2

V p

z

g 2

V p

2 1 h h z

g 2

V p

z

g 2

V p

Q Q Q

=

+ + + +

= + +

+ + + +

= + +

+ =

Multiple-Path Systems

Three-Reservoir System

If valve (1) was closed, reservoir B reservoir C

If valve (2) was closed, reservoir A reservoir C

If valve (3) was closed, reservoir A reservoir B

With all valves open.

( )

( ) C B h h z

g 2

V p

z

g 2

V p

B A h h z

g 2

V p

z

g 2

V p

Q Q Q

3 L 2 L C

2

C C

B

2

B B

2 L 1 L B

2

B B

A

2

A A

3 2 1

+ + + +

= + +

+ + + +

= + +

+ =

Example 4.11 Three reservoir, Multiple

Pipe System

Three reservoirs are connected by three pipes as are shown in Figure

E8.14. For simplicity we assume that the diameter of each pipe is 1

ft, the frictional factor for each is 0.02, and because of the large

length-to-diameter ratio, minor losses are negligible. Determine the

flowrate into or out of each reservoir.

Example 4.11 Solution

1/4

The continuity equation requires that

By using the fact that p

A

=V

A

= p

C

=V

C

=z

C

=0

The diameters are the same for each pipe

3 2 1 3 2 1

V V V Q Q Q = + = +

g 2

V

D

f

g 2

V

D

f z

g 2

V p

z

g 2

V p

2

3

3

3

3

2

1

1

1

1 C

2

C C

A

2

A A

+ + + +

= + +

The energy equation for the fluid that flows from A to C in

pipes (1) and (3) can be written as

g 2

V

D

f

g 2

V

D

f z

2

3

3

3

3

2

1

1

1

1 A

+ =

2

2

2

1

V 4 . 0 V 322 + =

(2)

(1)

Flows out of

reservoir B

3

Example 4.11 Solution

2/4

Similarly the energy equation for fluid following from B to C

g 2

V

D

f

g 2

V

D

f z

g 2

V p

z

g 2

V p

2

3

3

3

3

2

2

2

2

2 C

2

C C

B

2

B B

+ + + +

= + +

g 2

V

D

f

g 2

V

D

f z

2

3

3

3

3

2

2

2

2

2 B

+ =

2

3

2

2

V 4 . 0 V 5 . 0 4 . 64 + =

(3)

No solution to Eqs. 1, 2, and 3 with real, positive values of V

1

, V

2

,

and V

3

. Thus, our original assumption of flow out of

reservoir B must be incorrect.

Example 4.11 Solution

3/4

The continuity equation requires that

3 2 1 3 2 1

V V V Q Q Q + = + =

g 2

V

D

f

g 2

V

D

f z z

g 2

V

D

f

g 2

V

D

f z z

2

3

3

3

3

2

1

1

1

1 C A

2

2

2

2

2

2

1

1

1

1 B A

+ + =

+ + =

The energy equation between points A and B and A and C

2

3

2

1

V 4 . 0 V 322 + =

(5)

(4)

Flows into

reservoir B

2

2

2

1

V 5 . 0 V 258 + =

(6)

Solve

s / ft 88 . 2 V s / ft 9 . 15 V

2 1

= =

Example 4.11 Solution

4/4

The corresponding flowates are

C o int s / ft 2 . 10 Q Q Q

B o int s / ft 26 . 2 V A Q

A from s / ft 5 . 12 V A Q

3

2 1 3

3

2 2 2

3

1 1 1

= =

= =

= =

Flow Through

Immersed

Bodies

Definition

When any body moves through a fluid, an interaction between the

body and the fluid occurs; this effect can be described in terms of

the forces at the fluidbody interface.

The resultant force in the direction of the upstream velocity is

termed the drag, and the resultant force normal to the upstream

velocity is termed the lift, as is indicated in Fig.

When the Reynolds number is high enough to induce turbulence, we

again see an entrance region followed by fully-developed flow.

However, the structure of the entrance region is somewhat more

complicated. There is a laminar boundary layer near the entrance,

which transitions to a turbulent boundary layer eventually.

Flow Past a Flat plate

Boundary layer: Region next to

an object where fluid has its

velocity changed due to shear

resistance of the boundary.

Velocity gradient exists between

free stream and object, thus

shear stress exists at surface

which retards the flow.

Boundary layer grows in

downstream direction, until the

onset of turbulence

Shear stress is high at leading

edge and decreases until

transition and then increases

again

000 , 500 Re Transition , Re Plates

000 , 2 Re Transition , Re Pipes

~ =

~ =

Vx

VD

Flow Past a Flat plate

( )

( )

( )

L

L o

F

L

o

x

o

U A

F

C

BL U F

U

Re

1520

Re * 06 . 0 ln

523 . 0

: t Coefficien

Re

072 . 0

5 . 0 : Resistance

Re

058 . 0

5 . 0 : Stress

region Turbulent

2 2

5 / 1

2

5 / 1

2

= =

=

=

t

L

o

s

F

L o

x

o

U BL

F

C

U B F

x

U

Re

33 . 1

2 /

: t Coefficien

Re 664 . 0 : Resistance

Re 332 . 0 : Stress

region Laminar

2

= =

=

=

t

Shear Stress Coefficients

Shear stress coefficient = ratio

of shear stress at wall to

dynamic pressure of free

stream

Total shearing force

2 /

2

0

o

f

U

c

t

=

2 /

2

2

2

0

o

s

f

A

f

o

A

s

U

F

C

dA c

U

dA F

t

=

}

=

}

=

Lift of an Airfoil

Forces acting on airfoil: Velocity

over the top of foil is greater

than free stream velocity,

pressure there is less than free-

stream. Similarly, the pressure

on the bottom of the foil is

greater than free-stream pressure.

This difference in pressure

contributes to the lift of the foil.

Shear stress along the foil acts to

drag on the foil.

Drag of a Thin Plate

For a plate parallel to the flow,

shear forces are the only ones

acting

For a plate normal to the flow,

shear and pressure forces act

For a more general object

2

2

2

o

f D

V

BL C F =

2

) 2 . 1 8 . 0 (

2

o

D

V

BL F + =

2

2

o

p D D

V

A C F =

Drag Coefficients

Coefficient of Drag

2

2

o

p

D

D

V

A

F

C

=

Example 4.12

Given: Pressure distribution is shown,

flow is left to right.

Find: Find C

D

Solution: C

D

is based on the projected area

of the block from the direction of flow.

Force on downstream face is:

The total force on each side face is:

The drag force on one face is:

The total drag force is:

Coefficient of Drag is: C

D

=1

( ) 2 / 5 . 0 2 /

2 2

V A V A C F

p p p

Drag

D

= =

2 / 5 . 0 2 /

2 2

V A V A C F

p p p S

= =

( ) 5 . 0 * 2 / 5 . 0 sin

2

V A F F

p S

Drag

S

o = =

2 / 2 / 5 . 0 ) 5 . 0 * 2 / 5 . 0 ( * 2

) ( ) ( 2

2 2 2

V A C V A V A

F F F

p D p p

Drag

D

Drag

S Drag

= + =

+ =

Example 4.13

Given: Flag pole, 35 m high, 10 cm diameter, in 25-m/s wind, P

atm

=

100 kPa, T=20

o

C

Find: Moment at bottom of flag pole

Solution:

3 2 5

/ 20 . 1 , / 10 51 . 1 m kg s m x = =

v

5

5

10 66 . 1

10 51 . 1

1 . 0 * 25

Re x

x

VD

= = =

v

5) 11 (figure 95 . 0 =

D

C

kN

H V

A C

H

F M

o

p D D

8 . 21

2

35

*

2

25

* 2 . 1 * 35 * 10 . 0 * 95 . 0

2 2 2

2

2

=

=

= =

Example 4.14

Given: Spherical balloon 2-m

diameter, filled with helium @std

conditions. Empty weight = 3 N.

Find: Velocity of ascent.

Solution:

W

B

W

He

F

B

F

D

D

D

p D

D

o

o

p D D

C

C

A C

F

V

V

A C F

739 . 0

225 . 1 * 2 * ) 4 / (

422 . 1 * 2 2

2

2

2

= = =

=

t

N

D F

D F D

W W F F F

air

He air D

He D air

He B D B y

422 . 1

2

6

)

077 , 2

287

1 ( 3

6

) ( 3

6

3

6

0

3

3

3 3

=

=

=

+ =

+ = =

t

t

t

Iteration: Guess C

D

=0.4

s m V

o

/ 36 . 1

4 . 0

739 . 0

= =

Check Re

5

5

10 86 . 1

10 46 . 1

2 * 36 . 1

Re x

x

VD

= = =

v

Iteration: C

D

=0.42

s m V

o

/ 33 . 1

42 . 0

739 . 0

= =

Vous aimerez peut-être aussi

- Fluid 08Document159 pagesFluid 08Marco MeraPas encore d'évaluation

- Viscous Flow in PipesDocument34 pagesViscous Flow in PipesShinee JayasilanPas encore d'évaluation

- Viscous FlowDocument31 pagesViscous FlowNavinan SubramaniamPas encore d'évaluation

- Flow in Circular Pipes: ObjectiveDocument25 pagesFlow in Circular Pipes: ObjectivePatrickAndradePas encore d'évaluation

- Viscous Flow in PipesDocument58 pagesViscous Flow in PipesTakeshi Tanohuye TanohuyePas encore d'évaluation

- FM Minor Losses 1Document14 pagesFM Minor Losses 1mahesh100% (1)

- Ch. 8 Viscous Flow in PipesDocument8 pagesCh. 8 Viscous Flow in PipesGopi NathPas encore d'évaluation

- Orifcie Sizing CalulationDocument25 pagesOrifcie Sizing CalulationmgkvprPas encore d'évaluation

- Transition To Turbulence: Kerosene/Water Manometer Dye Reservoir KDocument6 pagesTransition To Turbulence: Kerosene/Water Manometer Dye Reservoir Kdist2235Pas encore d'évaluation

- 42 Mach NumberDocument22 pages42 Mach Numberyared sitotawPas encore d'évaluation

- Gas Flow in PipelineDocument18 pagesGas Flow in Pipelineamaleena_muniraPas encore d'évaluation

- Lid Driven CavityDocument24 pagesLid Driven CavityShashank MishraPas encore d'évaluation

- Transport PhenomenaDocument7 pagesTransport PhenomenaC. MPas encore d'évaluation

- Coles-The Law of The Wake in The Turbulent Boundary LayerDocument36 pagesColes-The Law of The Wake in The Turbulent Boundary LayermohdrashdansaadPas encore d'évaluation

- 8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberDocument6 pages8.performance Evaluation of Centrifugal Type Boiler Feed Pump by Varying Blade NumberHazim HazimPas encore d'évaluation

- Ch4-Fluid PDFDocument37 pagesCh4-Fluid PDFShannon HayesPas encore d'évaluation

- Lecture 5 - Centrifugal PumpDocument104 pagesLecture 5 - Centrifugal Pumphasan bishPas encore d'évaluation

- Heat Trans Final ExamDocument1 pageHeat Trans Final ExamAaron GamezPas encore d'évaluation

- Chapter 8 - Part A - Fully Developed Laminar Flow PDFDocument12 pagesChapter 8 - Part A - Fully Developed Laminar Flow PDFShubham ChoudharyPas encore d'évaluation

- Enhancement Porformence of Heat Exchanger 2018-19Document44 pagesEnhancement Porformence of Heat Exchanger 2018-19Srinivasa bnPas encore d'évaluation

- Agitation and Mixing-H4 Class-TKMCEDocument111 pagesAgitation and Mixing-H4 Class-TKMCERaghulal SethumadhavanPas encore d'évaluation

- Experiment No.-1: With Continuous Supply of Fresh Gas and Removal of The Products of DiffusionDocument7 pagesExperiment No.-1: With Continuous Supply of Fresh Gas and Removal of The Products of DiffusionSiddharth MohapatraPas encore d'évaluation

- L27 - The Brayton CycleDocument12 pagesL27 - The Brayton CycleHaliunaa BatboldPas encore d'évaluation

- Problems-Convection 1Document2 pagesProblems-Convection 1Ira Octavia100% (1)

- Pitot Static TubeDocument2 pagesPitot Static TubeMelvin MagbanuaPas encore d'évaluation

- Heat TranferDocument17 pagesHeat TranferLuis González Cos Alcocer100% (1)

- AbsorptionDocument15 pagesAbsorptionbarkhaPas encore d'évaluation

- Governing Equations of FluidDocument31 pagesGoverning Equations of FluidhaftommmmPas encore d'évaluation

- Chapter - 2 - Introduction To ConductionDocument31 pagesChapter - 2 - Introduction To ConductionIrfan MaulanaPas encore d'évaluation

- Mass Transfer CoefficientDocument37 pagesMass Transfer CoefficientnivedhithaPas encore d'évaluation

- OrificeDocument10 pagesOrificeRicha GhoshPas encore d'évaluation

- Dissolution of Benzoic AcidDocument2 pagesDissolution of Benzoic AcidAngela Calatayud100% (1)

- Fluid MechanicsDocument25 pagesFluid MechanicsforzamaPas encore d'évaluation

- Lecture 2-3 - Introduction To Aerodynamics & FundamentalsDocument15 pagesLecture 2-3 - Introduction To Aerodynamics & FundamentalsAli RazaPas encore d'évaluation

- Two Phase FlowDocument3 pagesTwo Phase FlowNITESH SAHPas encore d'évaluation

- Transport Phenomena - Heat Conduction Through A Composite WallDocument11 pagesTransport Phenomena - Heat Conduction Through A Composite WallFarhan HazeeqPas encore d'évaluation

- Mechanics of Fluids: Introduction To Fluid MechanicsDocument46 pagesMechanics of Fluids: Introduction To Fluid Mechanicsearl pannilaPas encore d'évaluation

- Fluid Mechanics EquationsDocument8 pagesFluid Mechanics EquationsRaman ChawlaPas encore d'évaluation

- Assignment Thermal UiTMDocument29 pagesAssignment Thermal UiTMiwe1234Pas encore d'évaluation

- CFD Class M.techDocument52 pagesCFD Class M.techdankshavali shaikPas encore d'évaluation

- 3241 Lecture 8Document45 pages3241 Lecture 8Jamal AlshaweshPas encore d'évaluation

- Thermodynamics Workshop Problems Model Answers 2010-2011 1Document9 pagesThermodynamics Workshop Problems Model Answers 2010-2011 1djsmilie77Pas encore d'évaluation

- Venturi MeterDocument51 pagesVenturi MeterPriteshShahPas encore d'évaluation

- Rayleigh FlowDocument2 pagesRayleigh FlowpraveenrajjPas encore d'évaluation

- Chapter 4 Frictional Losses in Hydraulic PipelinesDocument56 pagesChapter 4 Frictional Losses in Hydraulic PipelinesTu Dang TrongPas encore d'évaluation

- Non Interacting SystemsDocument6 pagesNon Interacting SystemsGuruPrasadOtta100% (1)

- Liquid - Liquid Extraction in A Packed Bed: Experiment No: 2Document23 pagesLiquid - Liquid Extraction in A Packed Bed: Experiment No: 2Sameep JainPas encore d'évaluation

- Weighted Residual MethodsDocument17 pagesWeighted Residual MethodsYoosef NadireePas encore d'évaluation

- Suction Specific SpeedDocument6 pagesSuction Specific SpeedSeohyun PaikPas encore d'évaluation

- 29 Cavitation & FlashingDocument90 pages29 Cavitation & FlashingSureshbabu ThamburajPas encore d'évaluation

- Fanno FlowDocument30 pagesFanno FlowAitizaz KhanPas encore d'évaluation

- Agitation DevicesDocument5 pagesAgitation DevicesPassmore DubePas encore d'évaluation

- Camphor BallsDocument8 pagesCamphor BallsGurunath EpiliPas encore d'évaluation

- Energy Balances On A Nonreactive Systems: Chapter 8, FelderDocument76 pagesEnergy Balances On A Nonreactive Systems: Chapter 8, Feldermuhammad izzulPas encore d'évaluation

- Internal Forced ConvectionDocument18 pagesInternal Forced ConvectionMohd Jamal Mohd MoktarPas encore d'évaluation

- Pressure Drop in Pipes Group 28Document28 pagesPressure Drop in Pipes Group 28kefiloe LetsiePas encore d'évaluation

- Chapter 17 Solver Heat ConductionDocument47 pagesChapter 17 Solver Heat ConductionMiguel GomezPas encore d'évaluation

- Chapter - 1Document9 pagesChapter - 1Sahil PatilPas encore d'évaluation

- If t7 1 PPTX Agitacion y Mezcla PDFDocument43 pagesIf t7 1 PPTX Agitacion y Mezcla PDFHugo de la FuentePas encore d'évaluation

- Sistem Instalasi MekanikalDocument156 pagesSistem Instalasi MekanikalDharmestha DewantoroPas encore d'évaluation

- Supply Chain QuestionDocument22 pagesSupply Chain Questionlockas22280% (5)

- Germany Guideline SBDocument123 pagesGermany Guideline SBlockas222Pas encore d'évaluation

- Green Building RevolutionDocument229 pagesGreen Building Revolutionlockas222Pas encore d'évaluation

- Green Building Project Example: Located in Historic DowntownDocument30 pagesGreen Building Project Example: Located in Historic Downtownlockas222Pas encore d'évaluation

- PDC CH 10.3 (Problems)Document6 pagesPDC CH 10.3 (Problems)lockas222Pas encore d'évaluation

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesPas encore d'évaluation

- Ammonia Plant DesignDocument75 pagesAmmonia Plant Designlockas22288% (16)

- Lecture 5Document44 pagesLecture 5lockas222Pas encore d'évaluation

- Design of Acetone HYSYSDocument6 pagesDesign of Acetone HYSYSlockas222100% (1)

- Acetone BDocument9 pagesAcetone BIrdani IdrisPas encore d'évaluation

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesPas encore d'évaluation

- PDC Chapter 10.1Document16 pagesPDC Chapter 10.1lockas222Pas encore d'évaluation

- Start AgainDocument1 pageStart Againlockas222Pas encore d'évaluation

- Manufacturing Process FertilizerDocument14 pagesManufacturing Process FertilizermoentaseerPas encore d'évaluation

- Chapter 4 Shell and Tube Heat ExchangersDocument45 pagesChapter 4 Shell and Tube Heat Exchangerslockas222Pas encore d'évaluation

- Chapter 7Document28 pagesChapter 7lockas222Pas encore d'évaluation

- PCT100Document2 pagesPCT100lockas222Pas encore d'évaluation

- Tech - 16a2d0707412ca70pct 100 071Document2 pagesTech - 16a2d0707412ca70pct 100 071lockas222Pas encore d'évaluation

- Start AgainDocument1 pageStart Againlockas222Pas encore d'évaluation

- A Summary of Thermodynamic FundamentalsDocument11 pagesA Summary of Thermodynamic Fundamentalslockas222Pas encore d'évaluation

- Fluid Mechanics IntroductionDocument49 pagesFluid Mechanics IntroductionIastraPas encore d'évaluation

- Manufacturing Process FertilizerDocument14 pagesManufacturing Process FertilizermoentaseerPas encore d'évaluation

- BackgroundDocument9 pagesBackgroundlockas222Pas encore d'évaluation

- BackgroundDocument9 pagesBackgroundlockas222Pas encore d'évaluation

- Neraca Massa ATKDocument49 pagesNeraca Massa ATKMuhammad KholidinPas encore d'évaluation

- Material BalanceDocument42 pagesMaterial Balancealireza_e_20% (1)

- Neraca Massa ATKDocument49 pagesNeraca Massa ATKMuhammad KholidinPas encore d'évaluation

- 3.what Is Meant by Mach ReflectionDocument3 pages3.what Is Meant by Mach ReflectionBenny E J (RC2113002011006)Pas encore d'évaluation

- Assignment Fluid Mechanics 3rd WeekDocument2 pagesAssignment Fluid Mechanics 3rd Weekchristos032Pas encore d'évaluation

- 1 s2.0 S099775462200108X MainDocument11 pages1 s2.0 S099775462200108X MainMario Alberto Sanchez RosasPas encore d'évaluation

- AMC Escaid 110Document1 pageAMC Escaid 110Yudha Satria100% (1)

- Estatus Aprobación X Area (ACTUALIZADO) 28.12.2020Document248 pagesEstatus Aprobación X Area (ACTUALIZADO) 28.12.2020viviana vasquez garciaPas encore d'évaluation

- How To Size A Gas Control ValveDocument10 pagesHow To Size A Gas Control ValvejayakumarPas encore d'évaluation

- Head Loss Calculation PE PipeDocument4 pagesHead Loss Calculation PE Pipekip2008Pas encore d'évaluation

- Week 12 of Aqs110 Fluid Mechanics PDFDocument8 pagesWeek 12 of Aqs110 Fluid Mechanics PDFvigneshPas encore d'évaluation

- Problems Cap3Document5 pagesProblems Cap3Sharon Osorio Calderon0% (1)

- Momentum Transfer: Lecture 3: Equations of Change For Isothermal SystemsDocument31 pagesMomentum Transfer: Lecture 3: Equations of Change For Isothermal SystemsLisajanelollyPas encore d'évaluation

- Chen 801-T2Document27 pagesChen 801-T2hussainiPas encore d'évaluation

- ANSUL Between Flanged ProportionersDocument2 pagesANSUL Between Flanged ProportionersAngel Mendieta100% (1)

- University of TripoliDocument10 pagesUniversity of TripoliRahaf NasrPas encore d'évaluation

- Exp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctDocument7 pagesExp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctKawar Abid100% (1)

- Centrifugal Pump - Working Principle, Main PartsDocument13 pagesCentrifugal Pump - Working Principle, Main Partsrishabh tomarPas encore d'évaluation

- Stabilization of Curtain Coater at High Speeds DOEDocument109 pagesStabilization of Curtain Coater at High Speeds DOESivasankar Jeyabaskaran100% (1)

- Colloidal System: by Msc. Dua'A M. HadiDocument22 pagesColloidal System: by Msc. Dua'A M. HadiYahya Daham Zafeer SakhrPas encore d'évaluation

- Hydraulics Secttion4Document7 pagesHydraulics Secttion4Rezeile RoxasPas encore d'évaluation

- Surface ChemistryDocument1 pageSurface ChemistryNabinPas encore d'évaluation

- Training ReportDocument1 pageTraining ReportNova KurniawanPas encore d'évaluation

- FLUID-I-CH 1 Introduction Properties Tut 1Document4 pagesFLUID-I-CH 1 Introduction Properties Tut 1Naser KhalidPas encore d'évaluation

- Paper Poster No 1 - On Estimation of Water Cut Changes and PVT Calculation - Technip FMCDocument12 pagesPaper Poster No 1 - On Estimation of Water Cut Changes and PVT Calculation - Technip FMCابوالحروف العربي ابوالحروفPas encore d'évaluation

- Principles of Sedimentation-Discrete ParticlesDocument7 pagesPrinciples of Sedimentation-Discrete ParticlesAhmad SalihPas encore d'évaluation

- Vessel Data: 900@100oc 1.02@100ocDocument2 pagesVessel Data: 900@100oc 1.02@100ocDhvanit JoshiPas encore d'évaluation

- Evals Fluids Answersheet Nov2021Document10 pagesEvals Fluids Answersheet Nov2021Yedda M IlaganPas encore d'évaluation

- Surface Chemistry Colloidal SolutionsDocument7 pagesSurface Chemistry Colloidal Solutionsramr krishPas encore d'évaluation

- Tomato Paste HandlingDocument11 pagesTomato Paste HandlingRomanPas encore d'évaluation

- ALKYLATION LINE SCHEDULE - A545-142-02-LSC-001 - Rev-9Document68 pagesALKYLATION LINE SCHEDULE - A545-142-02-LSC-001 - Rev-9EILA545 QAQCPas encore d'évaluation

- Lubes Induction ProgramDocument26 pagesLubes Induction ProgramTanmoy SahaPas encore d'évaluation

- Hydro GraphDocument52 pagesHydro GraphSamer ElabdPas encore d'évaluation