Académique Documents

Professionnel Documents

Culture Documents

Fuel System

Transféré par

Balkishan DyavanapellyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fuel System

Transféré par

Balkishan DyavanapellyDroits d'auteur :

Formats disponibles

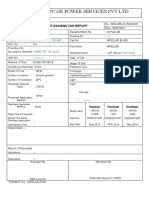

9 June 2014 PMI Revision 00 1

Fuel System

9 June 2014 PMI Revision 00 2

Presentation Plan

Fuel oil System

Oil burners

Coal mills and feeder

Types of feeders

Classification of Mills

Features of different Mills

Burner arrangement

9 June 2014 PMI Revision 00 3

Fuel oil System

Purpose: (a) to establish initial boiler light up. (b) to

support the furnace flame during low load

operation.

Fuel oil system Consists of

Fuel oil Pumps

Oil heaters

Filters

Steam tracing lines

Objective is to get filtered oil at correct pressure and

temperature

9 June 2014 PMI Revision 00 4

Atomization

Atomization breaks the fuel into fine particles that

readily mixes with the air for combustion. Oil should be

divided up into small particles for effective atomization.

The advantages of atomization are:

a) Atomizing burners can be used with heavier grades of

oil.

b) Can be adopted to large applications because of large

capacity range.

c) Complete combustion is assured by the ability of the

small particles to penetrate turbulent combustion.

9 June 2014 PMI Revision 00 5

Classification: Oil burners

Oil burners are classified according to the method

used for atomization, as follows:

a) Air-atomized burners

b) Steam-atomized burners

c) Mechanically atomized burners

Air atomizing system are not recommended for heavy

oil system as they tend to chill the oil and decrease

atomization quality

9 June 2014 PMI Revision 00 6

Steam Atomization

This System uses auxiliary steam to assist in the atomization of the

oil. The steam used in this method should be slightly superheated

and free cf moisture. As in the air atomizing system, the steam used

for atomizing as well as heating the fuel as it pass through the tip

and into the furnace. The main advantages of steam atomizing

burners over other are:

a) Simplicity of its design

b) Initial cost of installation is low

c) low pumping pressure

d) low preheating temperature.

Disadvantage is steam used in atomizing process

9 June 2014 PMI Revision 00 7

Oil Burners

The types of oil used in the oil burners are:

a) Light Diesel Oil

b) Heavyfuel oil

c) Low sulpher heavy stock (LSHS).

Heavy oil guns are used for stabilizing flame at low

load carrying. Warm up oil guns are used for cold

boiler warm up during cold start up and ignitor are

used for start up and oil flame stabilizing.

9 June 2014 PMI Revision 00 8

Oil Guns

The guns used in this

system have two main

components for

atomization. They are:

a) Mixing plate

b) Spray Plate.

9 June 2014 PMI Revision 00 9

Oil Gun Compartment

9 June 2014 10

9 June 2014 PMI Revision 00 11

Components

The Major components are :

Coal Preparation Equipments

Feeders

Mills

Coal Firing Equipments

Burners

9 June 2014 PMI Revision 00 12

Feeders

Volumetric Type feeder

Chain Feeder

Belt Feeder

Table type belt Feeder

Gravimetric Feeder

Chain

Feeder

9 June 2014 PMI Revision 00 13

Gravimetric Feeder

9 June 2014 PMI Revision 00 14

XRP

(BHEL)

E MILLS

(BABCOCK)

MPS

BOWL/

BALL & RACE

VERTICAL SPINDLE

PRESSURIZED

TUBE

CLASSIFICATION OF MILLS

9 June 2014 PMI Revision 00 15

Classification-As per Speed

Types of Mills

Medium Speed High Speed Low Speed

17 to 20 Rev/min 30 to 100 Rev/min 500 to 1000 Rev/min

Tube and ball mill

Bowl Mill, Ball and

Race mill

Beater Mill, Impact

Mill

9 June 2014 PMI Revision 00 16

BOWL MILL

Model no. Base

capacity(T/Hr)

623XRP 18.4

703XRP 26.4

763XRP 33.8

803XRP 36.5

883XRP 51.1

903XRP 54.1

1003XRP 68.1

1043XRP 72.0

BASE CAPACITY(T/HR)

AT

HGI -55

Total Moisture-10%

Fineness-70% THRU 200

MESH

9 June 2014 PMI Revision 00 17

Features of Bowl Mills

Grinding chamber

Classifier mounted above it

Pulverization takes place in rotating bowl

Rolls rotating free on journal do the crushing

Heavy springs provide the pressure between the coal and

the rolls

Rolls do not touch the grinding rings

Tramp iron and foreign material discharged.

9 June 2014 PMI Revision 00 18

Rollers

Coal Entry

Hot Air

Flow from

PA Fan

Classifiers

To burners

Pictures of Bowl Mill

9 June 2014 PMI Revision 00 19

Typical Mill (Pulveriser)

9 June 2014 PMI Revision 00 20

Internal

Details of a

Mill

9 June 2014 PMI Revision 00 21

BALL& RACE MILL(E MILL)

Model no. Base

capacity(T/Hr)

7E9 25

8.5E10 35

8.5E9 40

10E10 55

10.9E11 61

10.9E10 70

10.9E8 80

9 June 2014 PMI Revision 00 22

TUBE MILL

Model no. Base

capacity(T/Hr)

BBD4760 83

BBD4772 90

9 June 2014 PMI Revision 00 23

Tube Mill Internals

9 June 2014 PMI Revision 00 24

Feature of Tube Mill

Operate at 17 to 20 Rpm

Coal Feed from both end of the Tube

Small Ball of 30,40, 50 mm Sizes are used

Hot air blown to move coal to classifiers at two elevations

in boiler furnace

No Maintenance for long periods

Better availability so no spare mill required

Always a reserve of coal so there is no spark produced

between Steel balls

Consumption of power is more

High Foundation and Initial cost of Equipment

9 June 2014 PMI Revision 00 25

Ball and Tube Mill

RC Feeder

Drum Feeder

Coal entry to Drum

Classifiers Distributors

2 No.

Classifiers 4 No.

Hot Air

Entry

9 June 2014 PMI Revision 00 26

Pictures of Tube Mill

Steel Balls

9 June 2014 PMI Revision 00 27

Role of Mills

Produces Pulverized coal 80% of which passes through

200 mesh

Air mixed with Pulverized coal (PF) is carried to the coal

nozzle in the wind box assembly.

PF from coal nozzle is directed towards the centre of

boiler burning zone

Pre-heated secondary air enters boiler and surrounds the

PF and help in combustion

9 June 2014 PMI Revision 00 28

Why Pulverized Fuel?

The economic motives for the introduction and

development of pulverized fuel firing are:

i) Efficient utilization of cheaper low grade coals.

ii) Flexibility in firing with ability to meet fluctuating loads.

iii) Elimination of breaking losses.

iv) Better response to automatic control.

v) Ability to use high combustion air temperature;

increasing the overall efficiency of boiler.

vi) High availability.

9 June 2014 PMI Revision 00 29

Mill Dampers and

air system

PF temperature to be maintained 90

0

C

All Shut off valves are required to be kept

wide open during operation

Mill bearing is to be kept clean and no

dust should enter

Low Primary air flow will cause unstable

flame and high flow result in high mill

reject

9 June 2014 30

9 June 2014 PMI Revision 00 31

Firing System

Direct Firing System: Coal is fed to the mill at

controlled quantity. Hot air (temperature controlled) is

permitted to flow through the mill. The air dries the coal and

picks up the milled product and flows through the classifier

rejecting higher size particle. The fine coal is carried

through the coal burner to the combustion chamber.

Indirect Firing System: Mills are operated independent

of boiler loading and pulverised coal is stored in the

intermediate bunker. From the bunker it is taken to

combustion chamber with the help of primary air fan. Boiler

loading is controlled by the amount of pulverised fuel fed to

boiler.

9 June 2014 PMI Revision 00 32

Direct Firing

9 June 2014 PMI Revision 00 33

Indirect Firing

9 June 2014 PMI Revision 00 34

Coal Burners

Coal burners comprise of coal nozzle, steel tip, seal plate and

tilting link mechanism.

Housed in coal compartment in all four corners of the furnace

and connected with coal pipes.

One end (outlet) is rectangular and another end is cylindrical.

The burner can be tilted on a pivot pin

. The nozzle tip has separate coal and air passages.

Coal and air passages is divided into sevaral parts

9 June 2014 PMI Revision 00 35

Methods of Fuel Firing

Vertical Firing : A number of rectangular fan shaped nozzles are set

across the width of the furnace in an arch. Pulverised fuel mixture ignites

under the arch and is directed vertically downwards to the bottom of the

furnace where the gases are made to turn upwards to pass through the

combustion chamber this gives a long path to the flame and is

particularly suitable for coals of low volatile content.

Horizontal Firing: Horizontal firing with the turbulent type of burner are

set up usually in the front (front wall fired) or rear walls of the furnace.

Burner consists of an inner cone for primary air and fuel which is given a

rotary motion as it passes through the burner.

Impact Firing : This is the arrangement with the type of burner used

with slag tap furnaces where the ash is kept in a molten state on the

furnace floor and tapped off as and when necessary.

Corner or tangential Firing: Burners are set at each corner of

the furnace and are directed to strike the outside of an

imaginary circle in the centre of the furnace.

9 June 2014 PMI Revision 00 36

Tangential Firing System

9 June 2014 PMI Revision 00 37

Arrangement

9 June 2014 PMI Revision 00 38

Typical Flame

9 June 2014 PMI Revision 00 39

9 June 2014 PMI Revision 00 40

Various Losses in A Boiler

Heat loss from furnace surface.

Unburned carbon losses.

Incomplete combustion losses.

Loss due to hot ash.

Loss due to moisture in air.

Loss due to moisture in fuel.

Loss due to combustion generated moisture.

Dry Exhaust Gas Losses.

9 June 2014 PMI Revision 00 41

Vous aimerez peut-être aussi

- Best Practices in O&M of Thermal Power Stations: Tutorial Course OnDocument4 pagesBest Practices in O&M of Thermal Power Stations: Tutorial Course OnGaurav Singh0% (2)

- 2 - Boiler HydrotestDocument22 pages2 - Boiler HydrotestMY NAME IS NEERAJ..:):)Pas encore d'évaluation

- Index B31Document2 pagesIndex B31Balkishan DyavanapellyPas encore d'évaluation

- RT Flash CardsDocument13 pagesRT Flash CardsBalkishan DyavanapellyPas encore d'évaluation

- GHG Manual Thermal Power Plant PDFDocument45 pagesGHG Manual Thermal Power Plant PDFhonchoabhiPas encore d'évaluation

- Iiw India Individual Membership Application Form Apr 2020Document3 pagesIiw India Individual Membership Application Form Apr 2020Balkishan DyavanapellyPas encore d'évaluation

- OPGC O & M WorksDocument233 pagesOPGC O & M WorksBalkishan DyavanapellyPas encore d'évaluation

- Id Fan Technical SpecDocument8 pagesId Fan Technical SpecBalkishan DyavanapellyPas encore d'évaluation

- STG GuidelinesDocument31 pagesSTG GuidelinesJoseph2309100% (2)

- Asme B31e-2008Document34 pagesAsme B31e-2008Balkishan DyavanapellyPas encore d'évaluation

- Asnt Standard - Cp189 - 2020Document4 pagesAsnt Standard - Cp189 - 2020Balkishan DyavanapellyPas encore d'évaluation

- Asme B31e-2008Document34 pagesAsme B31e-2008Balkishan DyavanapellyPas encore d'évaluation

- Specification For Bare Electrodes and Rods For Surfacing: AWS A5.21:2001 An American National StandardDocument7 pagesSpecification For Bare Electrodes and Rods For Surfacing: AWS A5.21:2001 An American National StandardBalkishan DyavanapellyPas encore d'évaluation

- Based Hardfacing Alloys: Cobalt & NickelDocument20 pagesBased Hardfacing Alloys: Cobalt & NickelsabrunoPas encore d'évaluation

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyPas encore d'évaluation

- BQCP - 23 - Valves (Gate, Globe) Overhauling ProcedureDocument2 pagesBQCP - 23 - Valves (Gate, Globe) Overhauling ProcedureBalkishan DyavanapellyPas encore d'évaluation

- Radiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRDocument2 pagesRadiography Test Acceptance Criteria: Type of Defects Asme Sec - Ix ASME B31.1 Asme Sec - I Asme Sec Viii Div-1 IBRBalkishan DyavanapellyPas encore d'évaluation

- BQCP - 24 - Insitu Repair Procedure For Primary Reheater Stub WeldsDocument2 pagesBQCP - 24 - Insitu Repair Procedure For Primary Reheater Stub WeldsBalkishan DyavanapellyPas encore d'évaluation

- Support Structure ProtocolDocument11 pagesSupport Structure ProtocolBalkishan DyavanapellyPas encore d'évaluation

- RT Acceptance Criteria 10062019Document1 pageRT Acceptance Criteria 10062019Balkishan Dyavanapelly100% (2)

- Daily - Field Inspection Sheet (Date:-Xx - Xx.2018)Document7 pagesDaily - Field Inspection Sheet (Date:-Xx - Xx.2018)Balkishan DyavanapellyPas encore d'évaluation

- Record of Welder or Welding Operator Qualification TestsDocument1 pageRecord of Welder or Welding Operator Qualification TestsBalkishan DyavanapellyPas encore d'évaluation

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyPas encore d'évaluation

- System Punch List: CategoryDocument4 pagesSystem Punch List: CategoryBalkishan DyavanapellyPas encore d'évaluation

- Welding Report FormattedDocument1 pageWelding Report FormattedBalkishan DyavanapellyPas encore d'évaluation

- Consumable Receipt Report: Received Goods From:-C.R.R.No: - Delivery Challan No: - Delivery DateDocument1 pageConsumable Receipt Report: Received Goods From:-C.R.R.No: - Delivery Challan No: - Delivery DateBalkishan DyavanapellyPas encore d'évaluation

- Consumable Receipt ReportDocument1 pageConsumable Receipt ReportBalkishan DyavanapellyPas encore d'évaluation

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyPas encore d'évaluation

- Welding Report FormattedDocument1 pageWelding Report FormattedBalkishan DyavanapellyPas encore d'évaluation

- Daily - Field Inspection Sheet (Date:-Xx - Xx.2018)Document7 pagesDaily - Field Inspection Sheet (Date:-Xx - Xx.2018)Balkishan DyavanapellyPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Campus Waste Lab Proposal To Substitute Single-Use Plastic With Paper Products and Plastic Utensils For BambooDocument14 pagesCampus Waste Lab Proposal To Substitute Single-Use Plastic With Paper Products and Plastic Utensils For Bambooapi-529878933Pas encore d'évaluation

- c19 Standard Operating ProceduresDocument36 pagesc19 Standard Operating ProceduresahsPas encore d'évaluation

- The 24-Inch Gauge and The Common Gavel - An Entered Apprentice Mason's Perspective On The Medical ProfessionDocument4 pagesThe 24-Inch Gauge and The Common Gavel - An Entered Apprentice Mason's Perspective On The Medical ProfessionMarcelo Carlos RibeiroPas encore d'évaluation

- Chemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsDocument5 pagesChemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsShalini KumariPas encore d'évaluation

- Atlas Tool Specs SummaryDocument3 pagesAtlas Tool Specs SummaryWaleed Barakat MariaPas encore d'évaluation

- Everything You Need to Know About VodkaDocument4 pagesEverything You Need to Know About Vodkaudbhav786Pas encore d'évaluation

- Rexnord Thomas Flexible Disc Couplings - Series 71 - 8Document2 pagesRexnord Thomas Flexible Disc Couplings - Series 71 - 8Orlando ReisPas encore d'évaluation

- Binac Ao STR EET: Vicinity Map & Street View, Source Google MapsDocument17 pagesBinac Ao STR EET: Vicinity Map & Street View, Source Google MapsBee AnquilianoPas encore d'évaluation

- The Refugees - NotesDocument1 pageThe Refugees - NotesNothing Means to mePas encore d'évaluation

- Employment Law Lubs 3915Document4 pagesEmployment Law Lubs 3915ogunsatoPas encore d'évaluation

- Effects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersDocument45 pagesEffects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersJoseph Xyrel Malacad100% (1)

- Flexo Uv Ink TroubleshootingDocument22 pagesFlexo Uv Ink TroubleshootingHiba Naser100% (1)

- 4front Projects: BbbeeDocument12 pages4front Projects: BbbeeBrand Media OfficePas encore d'évaluation

- Science 6-Q1-M6Document14 pagesScience 6-Q1-M6John Philip LegaspiPas encore d'évaluation

- Personal and Group Trainer Juan Carlos GonzalezDocument2 pagesPersonal and Group Trainer Juan Carlos GonzalezDidier G PeñuelaPas encore d'évaluation

- Objectives and Aspects of School Health ServicesDocument4 pagesObjectives and Aspects of School Health ServicesRaed AlhnaityPas encore d'évaluation

- Being ProfessionalDocument3 pagesBeing ProfessionalPutra SyahrezaPas encore d'évaluation

- Persuasive Speech On Behalf of Inspector GooleDocument4 pagesPersuasive Speech On Behalf of Inspector GooleSahanaPas encore d'évaluation

- 6th Class EM All LessonsDocument33 pages6th Class EM All LessonsSathish PurushothamPas encore d'évaluation

- Neet Structural Organisation in Animals Important QuestionsDocument18 pagesNeet Structural Organisation in Animals Important QuestionsARKA NEET BIOLOGYPas encore d'évaluation

- 4a. PAE Ch-4a. Project-AnalysisDocument15 pages4a. PAE Ch-4a. Project-AnalysisProf. Dr. Anbalagan ChinniahPas encore d'évaluation

- Colours of the RainbowDocument16 pagesColours of the RainbowMd A RAZZAKPas encore d'évaluation

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezPas encore d'évaluation

- 2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryDocument5 pages2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryJulio Cesar Velasco CastroPas encore d'évaluation

- MIDWIFE1115ra Tugue e PDFDocument9 pagesMIDWIFE1115ra Tugue e PDFPhilBoardResultsPas encore d'évaluation

- Fundamentals of Plant BreedingDocument190 pagesFundamentals of Plant BreedingDave SubiyantoPas encore d'évaluation

- Year 8 Drama ScriptDocument8 pagesYear 8 Drama ScriptTISMSecondaryPas encore d'évaluation

- JDP Rainbox Attenuation CratesDocument6 pagesJDP Rainbox Attenuation CratesBerat DalyabrakPas encore d'évaluation

- Design of Low Cost, Energy Efficient, IotDocument6 pagesDesign of Low Cost, Energy Efficient, IotRulemaker Studios OfficialPas encore d'évaluation

- Section III - Topic 3Document7 pagesSection III - Topic 3KARINE HOVSEPYANPas encore d'évaluation