Académique Documents

Professionnel Documents

Culture Documents

IC Engines - Abstracted

Transféré par

Hareesh R IyerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IC Engines - Abstracted

Transféré par

Hareesh R IyerDroits d'auteur :

Formats disponibles

IC ENGINES

1. Basics

2. Classification

3. Terminology

4. Components

Basics Combustion Engines

Chemical energy in fuel converted to thermal energy by

combustion or oidation

!eat engine converts chemical energy into mechanical energy

Thermal energy raises temperature and pressure of gases "ithin

engine# and gas epands against mechanical mechanisms of

engine

Combustion

$nternal% fuel is burned "ithin the engine properly &including e.g.

roc'et engines# (et engines)

Eternal% combustion is eternal to the engine &e.g. steam# *tirling

engine)

Jet

engine

Stirling

engine

Steam

engine

Gas

Turbine

1. Basics

2. Classification

3. Terminology

4. Components

Classification of $C engines

$gnition

+umber of stro'es

,alve location

-esign

.osition and number of cylinders

/ir inta'e

0uel input method

0uel used

Cooling

/pplication

$gnition

Spark ignition &*$)% high1voltage electrical discharge bet"een t"o

electrodes ignites air1fuel miture in combustion chamber

surrounding spar' plug# .etrol Engine

Compression ignition &C$)% air1fuel miture self1ignites due to high

temperature in combustion chamber caused by high compression#

-iesel engine

+o. of stro'es

0our1stro'e% four piston movements over t"o

engine revolutions for each engine cycle

T"o1stro'e% t"o piston movements over one

revolution for each engine cycle

,alve location

,alves in head

,alves in bloc'

2ne valve in head and one in bloc' &less common)

-esign

3eciprocating

o

Engine has one or more cylinders in "hich pistons

reciprocate bac' 4 forth

o

Combustion chamber in closed end of the cylinder

o

.o"er delivered to rotating output cran'shaft by mechanical

lin'age "ith pistons

3otary

o

Engine made of bloc' built around large non1

concentric rotor 4 cran'shaft

o

Combustion chambers are built into the non1rotating

bloc'

Reciprocating engine

Rotary

engine

.osition 4 +o. of Cylinders

*ingle cylinder &e.g. la"nmo"ers)

$n1line or straight% cylinders in straight line# one behind the other

in length of cran'shaft

,% t"o ban's of cylinders at an angle "ith each other along a

single cran'shaft# angle typically 561768

0lat or opposed cylinder &, "ith 1968)% t"o ban's of cylinders

opposite each other on a single cran'shaft &small aircrafts)

:% three ban's of cylinders on same cran'shaft ¬ common)

2pposed piston engine% t"o pistons in each cylinder# combustion

chamber bet"een pistons

3adial engine% cylinders positioned radially around cran'shaft

Inline engine

V engine

Flat/opposed cylinder

engine

W engine

pposed piston engine

Radial engine

/ir inta'e

+aturally aspirated% no air pressure boost

*upercharged% air pressure increased "ith

compressor driven by cran'shaft

Turbocharged% air pressure increased by

turbine1compressor driven by ehaust gases

Cran'case compressed% t"o1stro'e engine "ith

cran'case as inta'e air compressor

Superc!arge

d

Turboc!arge

d

0uel input method

Carburated% air1fuel mied at throat

Fuel injection

;ultipoint .ort 0uel $n(ection% one or more in(ectors at

each cylinder inta'e

Throttle Body 0uel $n(ection% in(ectors upstream of

inta'e manifold

Cooling

/ir cooled

<i=uid cooled

0uel used

>asoline

-iesel or fuel oil

>as &natural gas or methane)

<i=uefied petroleum gas &<.>)% mainly propane#

propylene# butane and butylene

/lcohol ðyl# methyl)

-ual fuel &e.g. methane?diesel)

>asohol &e.g. 76@ gasoline# 16@ alcohol)

Biodiesel% cleaner1burning diesel fuel made from

natural# rene"able sources such as vegetable

oils

1. Basics

2. Classification

3. Terminology

4. Components

Terminology

TDC% top dead center# piston position farthest from

cran'shaft

BDC% bottom dead center# piston position nearest to

cran'shaft

Direct fuel injection% into main combustion chamber

Indirect fuel injection% into a secondary chamber

Bore% diameter of cylinder or piston face

Stroke% distance that piston moves

Clearance volume% volume in combustion chamber at T-C

Displacement volume% volume displaced by piston

Ignition delay% Time bet"een start of ignition and start of

combustion

Terminology &Contd.)

Air-fuel ratio% 3atio of mass flo" rate of air to

that of fuel

Specific fuel consumption% fuel used per unit

po"er

missions% +2# C2# !C# solids

1. Basics

2. Classification

3. Terminology

4. Components

Components of an engine

Components

Block% body of engine containing cylinders

Bearing% main bearing for cran'shaft

Cams!aft% rotating shaft used to push open valves at the

proper time in engine cycle

Carburetor% ,enturi flo" device to dra" fuel and mi "ith

air

Catalytic converter% reduces emissions by chemical

reaction

Combustion c!amber% volume bet"een cylinder head

and piston face

Connecting rod% connects piston "ith cran'shaft

Crankcase% part of engine bloc' surrounding cran'shaft

Cranks!aft% rotating shaft through "hich engine "or'

output is supplied to eternal systems# rotated by

reciprocating pistons through connecting rods

Components &Contd.)

"!aust manifold% piping "hich carries ehaust gases

a"ay from engine cylinders

Fan% to increase air flo" through radiator

Fly#!eel% to smoothen engine rotation

Fuel injector% pressuriAed noAAle to in(ect fuel into air or

cylinder

Fuel pump% to move fuel from tan' to engine

$lo# plug% electrical resistance inside combustion

chamber to help cold start

%ead% piece "hich closes end of cylinders

%ead gasket% sealant bet"een engine bloc' and head

Intake manifold% piping "hich delivers incoming air to

cylinders

&il pan% oil reservoir on bottom of engine bloc'# part of

the cran'case

Components &Contd.)

2il pump% to distribute oil from sump

2il sump% reservoir for the oil system of the engine

.iston rings% metal rings around piston to seal gap

bet"een piston and cylinder

.ush rods% lin'age bet"een camshaft and valves on

2!, engines

3adiator% li=uid to air heat echanger to cool engine

3od bearing% rod connecting the piston "ith the rotating

cran'shaft

*par' plug% creates high1voltage discharge across an

electrode gap

*peed control1cruise control% control system

*tarter% hand starter# electric motor# or small $C engines

for large $C engines

Components &Contd.)

Superc!arger% compressor po"ered from cran'shaft to

compress incoming air

T!rottle% butterfly valve at upstream end of inta'e

manifold to control air flo" rate into *$ engine

Turboc!arger% turbine1compressor po"ered by ehaust

flo" to compress incoming air

'alves% controls flo" of air in and out of the cylinders

(ater jacket% li=uid flo" passages around cylinder for

cooling

(ater pump% to circulate coolant

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 2nd Page of Reports - DumberDocument1 page2nd Page of Reports - DumberHareesh R IyerPas encore d'évaluation

- Transformer Method StatementDocument13 pagesTransformer Method StatementHareesh R IyerPas encore d'évaluation

- 3nd Page of Reports - DumbestDocument2 pages3nd Page of Reports - DumbestHareesh R IyerPas encore d'évaluation

- SCADA Overall DiagramDocument1 pageSCADA Overall DiagramHareesh R IyerPas encore d'évaluation

- 1nd Page of Reports - DumbDocument1 page1nd Page of Reports - DumbHareesh R IyerPas encore d'évaluation

- ERT & SRT Technology R0Document4 pagesERT & SRT Technology R0Hareesh R IyerPas encore d'évaluation

- Analytic & Synthetic SurfacesDocument12 pagesAnalytic & Synthetic SurfacesHareesh R Iyer0% (1)

- 2nd Page of Reports - DumberDocument1 page2nd Page of Reports - DumberHareesh R IyerPas encore d'évaluation

- 2nd Page of Reports - DumberDocument1 page2nd Page of Reports - DumberHareesh R IyerPas encore d'évaluation

- Aluminium Alloy (LM6) Graphite Parameter Value Units Parameter Value UnitsDocument2 pagesAluminium Alloy (LM6) Graphite Parameter Value Units Parameter Value UnitsHareesh R IyerPas encore d'évaluation

- LM6 + 5% Graphite - Tension 3DDocument4 pagesLM6 + 5% Graphite - Tension 3DHareesh R IyerPas encore d'évaluation

- FEA in Heat TransferDocument1 pageFEA in Heat TransferHareesh R IyerPas encore d'évaluation

- 2nd Page of Reports - DumberDocument1 page2nd Page of Reports - DumberHareesh R IyerPas encore d'évaluation

- Numerical Analysis of Road Tunnel VentilationDocument1 pageNumerical Analysis of Road Tunnel VentilationHareesh R IyerPas encore d'évaluation

- Preprocessing: Defining The ProblemDocument4 pagesPreprocessing: Defining The ProblemHareesh R IyerPas encore d'évaluation

- Simple Dam Break Analysis FLUENT SettingsDocument7 pagesSimple Dam Break Analysis FLUENT SettingsHareesh R IyerPas encore d'évaluation

- Seminar Contents & Other ListsDocument5 pagesSeminar Contents & Other ListsHareesh R IyerPas encore d'évaluation

- Technology Tools To Enhance Learning in EngineeringDocument3 pagesTechnology Tools To Enhance Learning in EngineeringHareesh R IyerPas encore d'évaluation

- Computer Aided Design & AnalysisDocument7 pagesComputer Aided Design & AnalysisHareesh R IyerPas encore d'évaluation

- Curve GenerationDocument5 pagesCurve GenerationHareesh R IyerPas encore d'évaluation

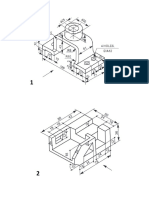

- 3D Models For CAD PracticeDocument1 page3D Models For CAD PracticeHareesh R IyerPas encore d'évaluation

- 3D Cad Models For PracticeDocument1 page3D Cad Models For PracticeHareesh R IyerPas encore d'évaluation

- Lesson Plan: No. Modu Le Description Hours Reqd. & Expected Time of DeliveryDocument1 pageLesson Plan: No. Modu Le Description Hours Reqd. & Expected Time of DeliveryHareesh R IyerPas encore d'évaluation

- AMoS EquationsDocument1 pageAMoS EquationsHareesh R IyerPas encore d'évaluation

- Mechanics of Materials Sample Question PaperDocument4 pagesMechanics of Materials Sample Question PaperHareesh R IyerPas encore d'évaluation

- Mon NM (3M1) Tue EGA (1R1) NM (3M2) Wed FEA (TS2) NM (3M2) Thu Thesis NM (3M1) Fri Fea (Ts2) / Thesis Thesis EGA (1E)Document3 pagesMon NM (3M1) Tue EGA (1R1) NM (3M2) Wed FEA (TS2) NM (3M2) Thu Thesis NM (3M1) Fri Fea (Ts2) / Thesis Thesis EGA (1E)Hareesh R IyerPas encore d'évaluation

- Mechanics of Materials Sample Test QuestionsDocument1 pageMechanics of Materials Sample Test QuestionsHareesh R IyerPas encore d'évaluation

- 3D MODEL - 1 Shaft SupportDocument1 page3D MODEL - 1 Shaft SupportHareesh R IyerPas encore d'évaluation

- Dom 6M2 Cad Lab 6M2 Cad 6M1 Dom 6M2 Lab 6M1 Cad 6M2 Cad 6M1 Cad 6M2 Cad Lab 6M2 Proj M8 Dom 6M2Document2 pagesDom 6M2 Cad Lab 6M2 Cad 6M1 Dom 6M2 Lab 6M1 Cad 6M2 Cad 6M1 Cad 6M2 Cad Lab 6M2 Proj M8 Dom 6M2Hareesh R IyerPas encore d'évaluation

- MOM HandoutDocument7 pagesMOM HandoutHareesh R IyerPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CostingDocument5 pagesCosting83pankajPas encore d'évaluation

- The Principles of Pulp Washing - PdfaDocument9 pagesThe Principles of Pulp Washing - Pdfashabi049Pas encore d'évaluation

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocument23 pagesInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamPas encore d'évaluation

- App Dev Guide 1062Document770 pagesApp Dev Guide 1062khiladi2100% (3)

- WP - High Efficiency Axial Flux Machines - Whitepaper v1.5Document21 pagesWP - High Efficiency Axial Flux Machines - Whitepaper v1.5unknown234uPas encore d'évaluation

- A Primer On Spray Drying Chemical Engineering Nov09Document7 pagesA Primer On Spray Drying Chemical Engineering Nov09Hikmah Triana HadiPas encore d'évaluation

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesPas encore d'évaluation

- Acoustics in Religious BuildingsDocument31 pagesAcoustics in Religious Buildingsrusydi.dpikPas encore d'évaluation

- C Ds Unit - II NotesDocument50 pagesC Ds Unit - II NotesAshish ThirunagariPas encore d'évaluation

- Specification For Construction of Concrete ReservoirsDocument18 pagesSpecification For Construction of Concrete ReservoirsKeysha ApriliaPas encore d'évaluation

- AFTES Geological Tunnel RisksDocument46 pagesAFTES Geological Tunnel RisksmerinofalPas encore d'évaluation

- Company Names and Number UAEDocument35 pagesCompany Names and Number UAESoju Suresh100% (1)

- KP Sharma Estimate PDFDocument3 pagesKP Sharma Estimate PDFSudip GhimirePas encore d'évaluation

- Annex 1 - Air Dryer Duct DRG List - 140717Document1 pageAnnex 1 - Air Dryer Duct DRG List - 140717vemanreddy29Pas encore d'évaluation

- LogisticsDocument72 pagesLogisticsqzm74lPas encore d'évaluation

- Hoshin Policy Deployment TemplatesDocument8 pagesHoshin Policy Deployment Templatesjcruz909Pas encore d'évaluation

- Ammendement No.1 - List of Approved VendorsDocument3 pagesAmmendement No.1 - List of Approved VendorsLakhwant Singh KhalsaPas encore d'évaluation

- Rail Mechanical PropertiesDocument46 pagesRail Mechanical PropertiesAGnes Stephani MunthePas encore d'évaluation

- Vray Material Settings: COMP 423: Cadd For ArchitectureDocument18 pagesVray Material Settings: COMP 423: Cadd For ArchitectureMarvin GonzalesPas encore d'évaluation

- Flapper Diverter Valve BrochureDocument4 pagesFlapper Diverter Valve BrochureRicardo Ramírez ZapataPas encore d'évaluation

- Structural MembersDocument37 pagesStructural Membersmario gadianoPas encore d'évaluation

- Ipromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Document5 pagesIpromsa Ltda: FILE: EMAG240-IBMPEDM-0001-Rev.1Cristobal Leal ArandaPas encore d'évaluation

- Fastner and Tooling Components. Fertrading Group Venezuela.Document4 pagesFastner and Tooling Components. Fertrading Group Venezuela.Renso PiovesanPas encore d'évaluation

- Cored Wires - ESAB - OK TubrodDocument87 pagesCored Wires - ESAB - OK TubrodElias KapaPas encore d'évaluation

- Dielectric HeatingDocument2 pagesDielectric HeatingPallavi JainPas encore d'évaluation

- Cooling Tower Fan#1 Breakdown/Maintenance Report: Site Name: Tata Metaliks Ltd. (1 X 10 MW CPP)Document4 pagesCooling Tower Fan#1 Breakdown/Maintenance Report: Site Name: Tata Metaliks Ltd. (1 X 10 MW CPP)amresh kumar tiwariPas encore d'évaluation

- Huawei Sun2000-60ktl-Hv-d1-001 Datasheet Draft A en - (20170217)Document2 pagesHuawei Sun2000-60ktl-Hv-d1-001 Datasheet Draft A en - (20170217)Jose VicentePas encore d'évaluation

- DASApplicationForm PDFDocument3 pagesDASApplicationForm PDFEngr.Hamid Ismail CheemaPas encore d'évaluation

- 10 Famous Shipping Canals of The WorldDocument7 pages10 Famous Shipping Canals of The Worldparth_upadhyay_1Pas encore d'évaluation

- Rashid Ch10 ImagesDocument47 pagesRashid Ch10 ImagesAtiq Ur RehmanPas encore d'évaluation