Académique Documents

Professionnel Documents

Culture Documents

Design and Development Process

Transféré par

Arun AbDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design and Development Process

Transféré par

Arun AbDroits d'auteur :

Formats disponibles

DESIGN AND DEVELOPMENT

PROCESS

R&D department

LEEL Bhiwadi.

DESIGN PROCESS ?

Design process is a collection of

procedures and habits that help teams

design better products

The Process of Design

Designing is the process of making many

decisions that converts an abstract concept

into a hardware reality.

Concept Product

R&D DEPARTMENT

NPD ( new product development)

C&D ( continuous and derivatives)

ONGOING PROJECTS

NPD

DMRC HVAC 14 TR Unit

BMRC HVAC 14 TR Unit

RMVU Ventilation Unit

GETS CAB HVAC Unit

ICF Ventilation Unit

Hot case

C&D ( continuous and derivatives)

RMPU 407c

RMPU reverse cycle

LHB

GUIDING PRINCIPLES FOR NPD

PROCESS DESIGN

Develop a comprehensive process that caters to

various types of projects undertaken by Lloyd

Electrical and Engineering Limited.

Ensure that the process is easy to understand and

is user friendly

Define clear scope of the NPD process and clarify

project initiation point

Enable fact based and timely decision making at

appropriate levels (senior management, functional

heads, and project team) during project execution.

Define business and technical criteria for effective

decision making

Provide clarity on process deliverables, their

ownership, timing for completion, and related inputs.

Improve NPD quality by integrating design for

functional excellence (DFS, DFM,DFA) and design for

six sigma (DFMEA, PFMEA) concepts in the process

Enable cross-functional and concurrent execution of

projects.

Integrate Qualicon process and leverage the materials

wherever relevant

Lloyds 7-Step Design Process

1. Project definition (management/Engg.)

2. External Search (Research)

3. Internal Search (Brainstorming)

4. Evaluation and Selection (Engineering)

5. Detail Design (Engineering)

6. Prototyping (Testing)

7. Documentation (Engineering)

NPD Process gate structure for leel

( following IRIS standards)

Identification of

design inputs

Design activity

planning

Designing

Design review

and verification

Drawing release

and changes

Design Validation

Documentation

GATE 1

GATE 2

GATE 3

GATE 3

IDENTIFICATION OF DESIGN

INPUTS

Following design inputs are considered while

planning the design and development activities:-

Customers functional & performance requirements /

specifications and relevant standards

Information from previous similar designs.

Material selection charts.

Engineers Designs Hand books.

Technical Literature on similar products

Feed back from customer on product quality on

previously designed similar product.

Statutory & Regulatory requirements related to the

product.

DESIGN ACTIVITY PLANNING

Design activity planning involves identification

of design stages including review, verification ,

validation and responsibility & authority for

each design stage.

Project plan will be made

Target dates

Responsibilities

DESIGNING

Product Design and its modification is evolved by

qualified and experienced design engineers, using

Auto CAD / Design-PRO/Solid works software.

General arrangement drawing is prepared and positioning of

components and their matching is seen on 3-D scales with

the objective to visualize the fitment and placing of parts

Following analyses are applicable to ensure the design;-

Thermal analysis (CFD)

Structure analysis (FEA)

Airofoil analysis

Shock and vibration analysis

Component selection from rolling stock approved vendors

only.

DESIGN REVIEWS &

VERIFICATION

Design reviews are conducted at each stage of design by the

R & D engineer, to evaluate the ability of the results of design

and to identify any problem. Where ever appropriate,

representatives of Production Deptt., Marketing, Purchase &

Quality Assurance also attend design review meetings. Design

outputs are approved by Head Design / Design Engineer,

before these are released for procurement & production..

Internal brain storming sessions for design review.

Problem identification and their root cause analyses.

DESIGN RELEASE &

SUBSEQUENT CHANGES

Design Outputs, Related data, Material

specifications are frozen after Design Verification

and are released for procurement of materials and

implementation. Changes to technical data made

during design sequences & design reviews are

recorded in corresponding product file.

DESIGN VALIDATION

Design validation is done after commissioning of

the machine as per customers usage condition. Type

test for the designed parameters are conducted and

report is prepared which acts as Validation Record.

Validation design and performance target

achievement through proto build.

Factory tests

Field trials

Report preparation.

Customer approval

Work station release

DOCUMENTATION

After design validation and performance target

achievement through proto build these documents to

be prepared

Service manuals

Test reports

Installation drawings

Training presentation

Final BOM

LIST OF DELIVERABLES AS

PER IRIS STANDARD

GATE 1

GATE 2 FROM AJAY

GATE 3

GATE 4

Product Design Specifications

Customer Needs

Cooling capacity

Affordable as a birthday present

Fully assembled

Uses alternate power source for emergency

It is safe

Looks good

Heating capacity

Automatic controls

Last a long time

Product Design Specifications

Engineering Specs

Climbs at 1 ft/s or faster

Retail cost is to be less than $30

Uses 2 AA batteries (not included)

Has no removable small parts

Music loudness between 20-30 db

Luminosity is to be more than 5 W

Works for more than 3 hours on 2 AA

External Search

Level-I

Rope climbing toys / machines

Rope climbers (sports or circus)

Nature (spiders, bats, etc)

Level-II (Team uses friction wheels)

Hoists

Trolleys

Ski Lifts

Internal Search & Evaluation

Brainstorming

Generate many ideas

Evaluate against PDS

Select one to engineer

Lift and Drag Coefficients

(as effected by ground promimity)

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0 0.05 0.1 0.15

h/L

C

o

e

f

f

i

c

i

e

n

t

Drag Coefficient

Lift Coefficient

Detail Design (Engineering)

More Abstract

Engineering

Less Abstract

Design Process

Top-level problem definition is called PDS

(Product Design Specifications)

Problem definitions at lower levels derive

from PDS:

Sub-system design specifications.

Component design specifications.

Feature design specifications.

Product Development Process

Market Research

Product Design Specifications & QFD

Design Brief (Mission Statement)

Product Planning

Product Development Process

Concept Synthesis

PDS

Concept Evaluation

Candidate Design

Detail Design

Candidate Design

Release for Production

Prototyping

Detail Design

Parameter Design

Candidate Design

Release for Production

System-Level Design

Prototype Testing

Components

No Numbers

Numbers

Customers

People who are affected by the product

Team

Company

(Internal)

Globe

(External)

External Customers

EXTERNAL

End

Users

Maintenance

Society

Retailer

Buyers

Government

&

Standards

Internal Customers

Internal

Marketing

Legal

Manufacturing

&

Procurement

Management

Shipping

What Do They Want?

End Users

Performance & Functionality

Affordability

Ease of use including ergonomics

Reliability and Long life

Versatility

Safety

Low maintenance and easy assembly

Esthetics

External Customers

Buying managers

Low Cost/Performance

Safety

Ruggedness (abuse resistance)

Ergonomics

Long warrantees

Reliable with Low downtime

Low operating cost

External Customers

Retailers

Small and attractive packaging

Long shelf life

Low cost/performance and Exciting features

Maintenance

Ease of maintenance

External Customers

Government / Standards / Society

Conformance to laws and regulations

Promotion of public health and safety

Protection of environment

Solution to chronic problems in society

Traffic

Energy

Noise

Drugs, abuse and other crimes

Diversity / Social tolerance / Security

Internal Customers

Management

Make a big profit

On time delivery

Low failure risk

Documentation

Process: Conformance to company

product development process

Internal Customers

Marketing

Attractive features to target buyers

Low production cost

Esthetics

Attractive packaging

On time delivery

Long Warrantees

Internal Customers

Manufacturing

Manufacturability using standard

methods and schedules.

Conformance to company documentation

formats.

Use of products from preferred

vendors.

Internal Customers

Legal

No patent infringements

Safety

All required safety warnings and labels

Designed protection against reasonable

abuse

Codes and regulations

Internal Customers

Shipping and Packaging

Ease of user assembly

Small packaged size

Ability of locking or fixing sensitive

components

Resistance against damage due to

dropping, vibrations, moisture, heat, and

cold.

Performance cost Ease of use Reliability Safety

Users ***** ***** ***** ***** *****

Buyers **** ***** ** ***** *****

Retailers *** *** *** ** **

Govrnmnt ****

Mangmnt ** **** ** ** ***

Marketng **** ***** *** **** ***

Product Design

Specification

Elements of PDS

Performance (User)

Speed,

Capacity,

Power,

Accuracy,

etc.

Elements of PDS

Environment: (User)

Temperature range, humidity, dust and dirt,

etc.

Life in service: (User)

10 years, 5000 cycles, etc.

Maintenance: (User)

What is the market policy, what customers

accept

Target production cost: (User)

Cost of comparable products and company

policy.

Elements of PDS

Shipping:

Package sizes

Damage resistance

Elements of PDS

Quantity (Manufacturing)

Determined by market analysis.

Manufacturing facility (Manufacturing)

Is the design constrained by existing facility?

Are parts to be contracted and assembled in-

house?

Does the company policy dictate certain

facilities?

Element of PDS

Size and shape (Marketing)

Weight (Marketing)

What is the desired weight?

Should handles or lifting points be

provided?

Should it be modular for better

handling?

Aesthetics (Marketing,User)

Color, shape, form, texture, finish.

Market research.

Elements of PDS

Materials (Marketing, Codes, Regulations)

Left to designers unless company

guidelines or regulations restrict certain

materials (asbestos, lead).

Product life span (Marketing, Manufacturing)

Life of a product as a marketable entity.

Several months or several years?

Elements of PDS

Laws, Codes, and standards (Government)

Ergonomics (User)

Elements of PDS

Quality and reliability (Marketing)

Company policy regarding warranties

Competitors warranty policies

Testing (Marketing, QA)

What tests would be performed to verify

performance

Standard tests

Elements of PDS

Shelf life (storage) - Retail

Possibility of rust, decay, deterioration

Processes (company guidelines)

Use of certain standards (GD&T for

example)

Use of certain procedures

Time-scales (deadlines) - Management

Whole design project, milestones

Elements of PDS

Safety (User, Government, Legal)

What safety requirements are

mandated by government

Professional society's codes and

standards

Need for warning labels

Likely degrees of abuse or

misinterpretation of operating

procedures.

Elements of PDS

Company constraints (Management)

Compatibility with other products

Documentation (Management Legal)

A product design must include a full

formal documentation per company

guidelines.

Safety, Operation, and Service

documents.

Etc.

Elements of PDS

Legal (Lawyers)

What product liability law suits are

associated with similar products and

why.

Note the legal terms:

defect of specification

defect of design

defect of manufacture

Relevant patents

Element of PDS

Installation (Installers)

Many products must interface with

other products or be assembled with

other products.

Disposal (Society)

Should any parts by recyclable?

bio-degradable?

Wording of the PDS

Document

Format of most statements in PDS:

The device must ..

The device is to

The device is desired to .

Avoid mixing requirements.

One sentence per requirement.

Cast PDS statements in a positive

format

PDS is a Dynamic

Document

A design statement usually begins as

a vague statement

The device is to be easy to use

The device is to be safe

The device is to be inexpensive

The device is to be rugged and reliable

The device is to be portable

Wording of the PDS

Document

Example: ESCOs Pin Remover

The pin-remover is to be light.

The pin-remover must work in a wet,

cold, and dusty environment.

The Pin-remover must be safe

The Pin-remover must have a 3-year

warranty.

PDS Example

The PR is to be rugged.

must work with air pressure.

is be easy to use.

is to pass HTS tests.

is to last 5 years in normal usage.

is to be easy to carry.

PDS Example

is to sell for less than $150.

is to costless than $50 to make.

is to have low maintenance needs.

is to be difficult to use as a

hammer.

must not infringe on patented

devices.

Production volume is to be 300 per

year

PDS Example

is to be tested by June 2006.

is to be released by Sep. 2006.

is to be used with Dredge Point

models.

is to work faster than the hammer

Engineering

Specifications

What is

Fast, accurate, high-performing?

Light, Small, portable?

Easy to use?

Safe?

Stylish?

Engineering Specifications

Verifiable PDS statements

Developed for important PDS

statements

Have associated target

numbers (Yes/No OK)

Engineering Specifications

Tips

Set up metrics and targets

so the designer has

maximum options in

accomplishing the PDS

Engineering Specifications

Tips

PDS: The Dog Feeder must not tip

over when bumped or pushed by a dog.

Bad: The DF must weigh 50 lbs

Good: The dog feeder must

withstand 30 lbs applied to its

top from side

A Typical PDS Page

Requirement: PR is to be easy to

maintain

Primary customer: End users

Priority: High

Metrics and Targets

Daily maintenance: None

Weekly maintenance: < 10 minutes field

Yearly maintenance: < 1 hour Shop

Cost of weekly maintenance < 10c

Cost of yearly maintenance < $10

Customer

Needs

PDS

Statements

Engineering Requirements

Competition

I

M

P

O

R

T

A

N

C

E

Competition

Relation Between

Engineering and

Customer

Requirements

Target

Vous aimerez peut-être aussi

- FOD Prevention GuidelineDocument16 pagesFOD Prevention GuidelinejamilvoraPas encore d'évaluation

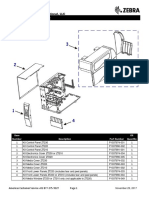

- ZT200 Series Parts Catalog: Outer Casing ComponentsDocument10 pagesZT200 Series Parts Catalog: Outer Casing ComponentsSharad KokatePas encore d'évaluation

- Product DesignDocument27 pagesProduct DesignrubensPas encore d'évaluation

- SDLC and Agile Methodologies Explained in Detail/TITLEDocument17 pagesSDLC and Agile Methodologies Explained in Detail/TITLEhiteshpuri206100% (1)

- The Design Process & The Role of CADDocument12 pagesThe Design Process & The Role of CADSyafiqah Shahuri100% (1)

- Design Process: Design Process Is A Collection of Procedures and Habits That Help Teams Design Better ProductsDocument51 pagesDesign Process: Design Process Is A Collection of Procedures and Habits That Help Teams Design Better ProductsNataraj Mohan100% (1)

- MECHANICAL ENGINEERING DESIGN 1Document28 pagesMECHANICAL ENGINEERING DESIGN 1Aloha NamiPas encore d'évaluation

- Manufacturing Systems: Concurrent EngineeringDocument42 pagesManufacturing Systems: Concurrent EngineeringrudipramanaPas encore d'évaluation

- Design for X Guidelines and Prototyping MethodsDocument48 pagesDesign for X Guidelines and Prototyping Methodsthamilarasu100% (1)

- VDA6.3 Procss QuestionaireDocument24 pagesVDA6.3 Procss Questionairedesurkarb100% (1)

- Strategic Analysis Of StarbucksDocument17 pagesStrategic Analysis Of StarbucksJasweetSinghPas encore d'évaluation

- Phases of Process DesignDocument18 pagesPhases of Process Designankur2061Pas encore d'évaluation

- Design Documentation for Biomedical DevicesDocument26 pagesDesign Documentation for Biomedical Devicesvignesh kumarPas encore d'évaluation

- Risk Assessment of Plastic Packaging Materials for Food SafetyDocument39 pagesRisk Assessment of Plastic Packaging Materials for Food SafetyHon Le VanPas encore d'évaluation

- Product DesignDocument43 pagesProduct DesignShivakami RajanPas encore d'évaluation

- Design For Assembly (Dfa) : Engr. Wan Sharuzi HJ Wan Harun Industrial Engineering, FKMDocument124 pagesDesign For Assembly (Dfa) : Engr. Wan Sharuzi HJ Wan Harun Industrial Engineering, FKMsharuzi67% (3)

- Topic 5 - Product and Process DesignDocument49 pagesTopic 5 - Product and Process DesignCPas encore d'évaluation

- Walmart Stores Discount Operations CaseDocument1 pageWalmart Stores Discount Operations CaseArun Ab100% (2)

- 1 Product Development ProcessDocument100 pages1 Product Development Processzaid zainol100% (1)

- Packaging Supplier QuestionnaireDocument5 pagesPackaging Supplier QuestionnaireRidho SaputraPas encore d'évaluation

- Sterile Medical Device Package DevelopmentDocument34 pagesSterile Medical Device Package DevelopmentSofiaProtopsalti100% (2)

- BUDGET OF WORK TLE 9 COOKERY EditedDocument10 pagesBUDGET OF WORK TLE 9 COOKERY EditedAlfred John Quiaoit Gatcho82% (11)

- Chapter 5 Operation Management (Design of Goods and Services)Document7 pagesChapter 5 Operation Management (Design of Goods and Services)syaarose75% (4)

- Module 3 TranscriptDocument17 pagesModule 3 TranscriptHakim AliPas encore d'évaluation

- UNit - III Product Design Tools-1Document74 pagesUNit - III Product Design Tools-1Sandeep ChandPas encore d'évaluation

- Design Process: Design Process Is A Collection of Procedures and Habits That Help Teams Design Better ProductsDocument51 pagesDesign Process: Design Process Is A Collection of Procedures and Habits That Help Teams Design Better ProductsSammyJayPas encore d'évaluation

- System Design Considerations, Process and Stages: Presented by Deepender SinghDocument13 pagesSystem Design Considerations, Process and Stages: Presented by Deepender SinghdeependersheoranPas encore d'évaluation

- Quality Function Deployment (QFD) Quality Function DeploymentDocument5 pagesQuality Function Deployment (QFD) Quality Function DeploymentApril Rose BaquerosPas encore d'évaluation

- Existing Processes and Business EnvironmentDocument52 pagesExisting Processes and Business EnvironmentjsaulPas encore d'évaluation

- Operation ManagementDocument11 pagesOperation ManagementrabiaumarPas encore d'évaluation

- Design of GoodsDocument99 pagesDesign of GoodsKrislyn Ann Austria AldePas encore d'évaluation

- Electronic System Design ProcessDocument23 pagesElectronic System Design ProcessThota DeepPas encore d'évaluation

- Unlicensed Epd IIDocument113 pagesUnlicensed Epd IIBony SunnyPas encore d'évaluation

- Embedded System Development Process GuideDocument14 pagesEmbedded System Development Process GuideAbhishek ShrimaliPas encore d'évaluation

- PRDCT and Srvce DesDocument40 pagesPRDCT and Srvce DesAli SyedPas encore d'évaluation

- Concurrent Engineering ENOPRLZ0352Document23 pagesConcurrent Engineering ENOPRLZ0352sekarPas encore d'évaluation

- Product and Process DesignDocument47 pagesProduct and Process DesignGhanashyam YadavPas encore d'évaluation

- Product and Process DesignDocument47 pagesProduct and Process DesignJai HindPas encore d'évaluation

- Lesson 5-Product (And Service) Design Reasons Design or Re-DesignDocument7 pagesLesson 5-Product (And Service) Design Reasons Design or Re-DesignWindPas encore d'évaluation

- Design of Goods and ServicesDocument31 pagesDesign of Goods and ServicesViennah Marie Manansala BustosPas encore d'évaluation

- Engineering Design ProcessDocument31 pagesEngineering Design Processstudio electPas encore d'évaluation

- PresentationDocument32 pagesPresentationSame SamPas encore d'évaluation

- PLM Chapter 4Document16 pagesPLM Chapter 4Orville Sutari0% (1)

- Introduction of Design of Machine ElementDocument52 pagesIntroduction of Design of Machine ElementNiraj AryanPas encore d'évaluation

- PLM Fundamentals: Market Research and Conceptual DesignDocument26 pagesPLM Fundamentals: Market Research and Conceptual DesignNinad PawarPas encore d'évaluation

- Unit - 1: Introduction To Product Life Cycle ManagementDocument26 pagesUnit - 1: Introduction To Product Life Cycle Managementmahammad kamaluddeenPas encore d'évaluation

- Design For XDocument48 pagesDesign For XDhonny BramantoPas encore d'évaluation

- Product DesignDocument25 pagesProduct Designayushichaudhary72Pas encore d'évaluation

- 3 - Product and Service DesignDocument38 pages3 - Product and Service DesignJulie Pearl GuarinPas encore d'évaluation

- 4a. PSD Process Systems Design Workshop 2013Document27 pages4a. PSD Process Systems Design Workshop 2013samerricPas encore d'évaluation

- Technology Management 3Document6 pagesTechnology Management 3Joju JohnyPas encore d'évaluation

- Chapter Three: Design of The Operation SystemDocument116 pagesChapter Three: Design of The Operation Systemyordanosezerihun07Pas encore d'évaluation

- 2 Development Processes and OrganizationsDocument32 pages2 Development Processes and OrganizationsNani NRajPas encore d'évaluation

- Product Development CycleDocument61 pagesProduct Development CycleISHANPas encore d'évaluation

- 2013 L1 - IntroductionDocument34 pages2013 L1 - IntroductionPantheia DadpouPas encore d'évaluation

- Concept of Engineering DesignDocument46 pagesConcept of Engineering DesignSapari VelPas encore d'évaluation

- Presentation OM Chap 05Document52 pagesPresentation OM Chap 05Muhammad Muzamil HussainPas encore d'évaluation

- Micross Technical PresentationDocument28 pagesMicross Technical PresentationRaja KalyanPas encore d'évaluation

- CapacityDocument91 pagesCapacitySaŃjia KhÁn SivÁnPas encore d'évaluation

- Object-Oriented and Classical Software Engineering: Stephen R. SchachDocument47 pagesObject-Oriented and Classical Software Engineering: Stephen R. Schachturkapo24Pas encore d'évaluation

- Design of Products and Services: Chapter ThreeDocument27 pagesDesign of Products and Services: Chapter Threeputri enfPas encore d'évaluation

- Apple MDE's provide end-to-end manufacturing solutionsDocument1 pageApple MDE's provide end-to-end manufacturing solutionsvarun kumarPas encore d'évaluation

- Product and Service DesignDocument40 pagesProduct and Service DesignSapari VelPas encore d'évaluation

- How To Develop A New Electronic Hardware Device Step by StepDocument21 pagesHow To Develop A New Electronic Hardware Device Step by StepjackPas encore d'évaluation

- Introduction to Software Engineering FundamentalsDocument19 pagesIntroduction to Software Engineering FundamentalsHerlan NurachmanPas encore d'évaluation

- Design Process & Role of CADDocument59 pagesDesign Process & Role of CADfaqhrulPas encore d'évaluation

- Concurrent EngineeringDocument42 pagesConcurrent EngineeringAnonymous p8bHAAxPas encore d'évaluation

- Draft Karnataka Renewable Energy Policy 2021-2026 unveiled for stakeholder consultationDocument42 pagesDraft Karnataka Renewable Energy Policy 2021-2026 unveiled for stakeholder consultationArun AbPas encore d'évaluation

- Aim PDFDocument8 pagesAim PDFArun AbPas encore d'évaluation

- IEEFA - JMK - Rooftop Solar Commercial and Industrial Market - August 2023Document36 pagesIEEFA - JMK - Rooftop Solar Commercial and Industrial Market - August 2023saikrishna bethaPas encore d'évaluation

- 2016DC Designing Battery Based SystemDocument81 pages2016DC Designing Battery Based SystemArun AbPas encore d'évaluation

- GLMADocument7 pagesGLMAArun AbPas encore d'évaluation

- FinalDocument60 pagesFinalArun AbPas encore d'évaluation

- Net-metering Regulations & Solar Policies Fact SheetDocument13 pagesNet-metering Regulations & Solar Policies Fact SheetArun AbPas encore d'évaluation

- Corporate Renewable PPAs in India See Slowdown in 2020 Despite Cost CompetitivenessDocument32 pagesCorporate Renewable PPAs in India See Slowdown in 2020 Despite Cost CompetitivenessArun AbPas encore d'évaluation

- Date of Hearing: 24.08.2020 Date of Interim Order: 24.08.2020Document2 pagesDate of Hearing: 24.08.2020 Date of Interim Order: 24.08.2020Arun AbPas encore d'évaluation

- Avantgarde Case StudyDocument7 pagesAvantgarde Case StudyUdhbhav AryanPas encore d'évaluation

- Delhi Electric Vehicles Policy 2020Document13 pagesDelhi Electric Vehicles Policy 2020Annish KumarPas encore d'évaluation

- 10 Project Proposal WritingDocument57 pages10 Project Proposal WritingArun AbPas encore d'évaluation

- Before The Haryana Electricity Regulatory Commission at Panchkula Case No. HERC/PRO-51 of 2019 Date of Hearing: 18.08.2020 Date of Order: 18.08.2020Document2 pagesBefore The Haryana Electricity Regulatory Commission at Panchkula Case No. HERC/PRO-51 of 2019 Date of Hearing: 18.08.2020 Date of Order: 18.08.2020Arun AbPas encore d'évaluation

- CEEW-CEF Market Handbook Q1 2020-21Document21 pagesCEEW-CEF Market Handbook Q1 2020-21Arun AbPas encore d'évaluation

- Case Study 02 - Water Supply ManagementDocument4 pagesCase Study 02 - Water Supply ManagementArun AbPas encore d'évaluation

- CaseStudy IIMRaipurDocument2 pagesCaseStudy IIMRaipurArun AbPas encore d'évaluation

- Money SupplyDocument6 pagesMoney SupplyArun AbPas encore d'évaluation

- Case Study 01 - Apple Value ChainDocument3 pagesCase Study 01 - Apple Value ChainArun AbPas encore d'évaluation

- Case ProposalDocument1 pageCase ProposalArun AbPas encore d'évaluation

- Case Proposal 1Document1 pageCase Proposal 1Arun AbPas encore d'évaluation

- China's Competitiveness Case Study LenovoDocument44 pagesChina's Competitiveness Case Study LenovomanchorusPas encore d'évaluation

- Assignment TDocument2 pagesAssignment TArun AbPas encore d'évaluation

- ScoresheetDocument4 pagesScoresheetArun AbPas encore d'évaluation

- Brand Image of Motorcycles of YamahaDocument81 pagesBrand Image of Motorcycles of YamahaJogi Yadav80% (10)

- Capacity CalculationDocument4 pagesCapacity CalculationArun AbPas encore d'évaluation

- Marketing Plan Template and GuideDocument37 pagesMarketing Plan Template and GuideFahad Islam PalashPas encore d'évaluation

- Approach:: Source: EXIM Bank ReportDocument1 pageApproach:: Source: EXIM Bank ReportArun AbPas encore d'évaluation

- New Microsoft PowerPoint PresentationDocument1 pageNew Microsoft PowerPoint PresentationArun AbPas encore d'évaluation

- Training Courses for National Team 2021-2022Document10 pagesTraining Courses for National Team 2021-2022Hà LinhhPas encore d'évaluation

- PackingDocument8 pagesPackingCẩm Tú Phan ThịPas encore d'évaluation

- Metals Metals Are The Most Versatile of All Forms of Packaging. They Offer The Combination of ExcellentDocument5 pagesMetals Metals Are The Most Versatile of All Forms of Packaging. They Offer The Combination of ExcellentDalde LiezelPas encore d'évaluation

- CHP 2 LogisticsDocument26 pagesCHP 2 Logistics有川静寂Pas encore d'évaluation

- QQ-W-461H Wire, Steel Carbon (Round, Bare and Coated)Document14 pagesQQ-W-461H Wire, Steel Carbon (Round, Bare and Coated)lizPas encore d'évaluation

- Steamer ManualDocument68 pagesSteamer ManualPaulius TranavičiusPas encore d'évaluation

- OPERATIONS MANAGEMENT OF Fatt Choi CoffeeDocument9 pagesOPERATIONS MANAGEMENT OF Fatt Choi CoffeejhhPas encore d'évaluation

- GFCO Certification Standard v.2020Document13 pagesGFCO Certification Standard v.2020DANIELA ALEXANDRA MAYHUA ESTEBANPas encore d'évaluation

- How Paper Tubes and Cores are ManufacturedDocument7 pagesHow Paper Tubes and Cores are ManufacturedAjaysinh JadejaPas encore d'évaluation

- Regulations For Reduced Oxygen Packaging at RetailDocument2 pagesRegulations For Reduced Oxygen Packaging at RetailrajaytPas encore d'évaluation

- Acticide DDQ 50 Rev2 - 14 03 2014 SVDocument2 pagesActicide DDQ 50 Rev2 - 14 03 2014 SVAkhtar aliPas encore d'évaluation

- Epicor Eclipse BR ENSDocument24 pagesEpicor Eclipse BR ENSerickmokPas encore d'évaluation

- SCG Chemicals ENG PDFDocument9 pagesSCG Chemicals ENG PDFSunday TesshaPas encore d'évaluation

- Supply Chain ST-WPS OfficeDocument8 pagesSupply Chain ST-WPS Officegirmsh96Pas encore d'évaluation

- Usda Commodity Requirements: Dnac6Document11 pagesUsda Commodity Requirements: Dnac6ViolintsarPas encore d'évaluation

- B 42 - 15aDocument7 pagesB 42 - 15aphaindikaPas encore d'évaluation

- Guidance for Drugs in Clinical TrialsDocument25 pagesGuidance for Drugs in Clinical TrialsEve TaypePas encore d'évaluation

- Horti - CBLM and Assessment ToolDocument29 pagesHorti - CBLM and Assessment ToolArnulfo VargasPas encore d'évaluation

- A World of Experience: Continuous Motion Built To LastDocument6 pagesA World of Experience: Continuous Motion Built To LastmallikharjunareddyPas encore d'évaluation

- Operation Manual: Pneumatic Ribbon CoderDocument6 pagesOperation Manual: Pneumatic Ribbon CoderLuis Enrique Barreto GarciaPas encore d'évaluation

- Chemco Plastic Industries Pvt LtdDocument6 pagesChemco Plastic Industries Pvt Ltdrohit kanojiaPas encore d'évaluation

- Food Safety & Quality Policy: 1.2 Change ManagementDocument4 pagesFood Safety & Quality Policy: 1.2 Change ManagementMarc Dennis Angelo UgoyPas encore d'évaluation

- Cemfil 62 - 3Document2 pagesCemfil 62 - 3Kesavan DhuraiPas encore d'évaluation