Académique Documents

Professionnel Documents

Culture Documents

Chapter 12: Learning Objectives: - You Should Be Able To

Transféré par

DATitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 12: Learning Objectives: - You Should Be Able To

Transféré par

DADroits d'auteur :

Formats disponibles

Chapter 12: Learning Objectives

Instructor Slides

You should be able to:

1. Describe the conditions under which MRP is most appropriate

2. Describe the inputs, outputs, and nature of MRP processing

3. Explain how requirements in a MPS are translated into material requirements

for lower-level items

4. Discuss the benefits and requirements of MRP

5. Explain how an MRP system is useful in capacity requirements planning

6. Outline the potential benefits and some of the difficulties users have

encountered with MRP

7. Describe MRPII and its benefits

8. Describe ERP, what it provides, and its hidden costs

12-1

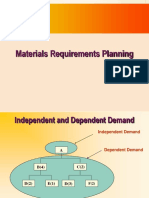

Independent and Dependent Demand

Independent Demand

A

B(4) C(2)

D(2) E(1) D(3)

F(2)

Dependent Demand

Independent demand is uncertain.

Dependent demand is certain.

Dependent Demand

Instructor Slides

Dependent demand

Demand for items that are subassemblies or

component parts to be used in the production of

finished goods.

Once the independent demand is known, the

dependent demand can be determined.

Dependent demand tends to be sporadic or

lumpy

Large quantities are used at specific points in

time with little or no usage at other times

12-3

Dependent vs Independent Demand

Instructor Slides

12-4

MRP

Material requirements planning (MRP):

A computer-based information system that

translates master schedule requirements for end

items into time-phased requirements for

subassemblies, components, and raw materials.

The MRP is designed to answer three questions:

1. What is needed? Type

2. How much is needed? quantity

3. When is it needed? time

Instructor Slides 12-5

Overview of MRP

Instructor Slides

12-6

MRP

MRP begins with a schedule for finished

goods that is converted into a schedule

of requirements for the subassemblies,

component parts, and raw materials

needed to produce the finished items in

the specified time frame.

MRP Inputs: Master Schedule

Instructor Slides

Master schedule:

One of three primary inputs in MRP; states which end items are to be

produced, when these are needed, and in what quantities.

Managers like to plan far enough into the future so they have

reasonable estimates of upcoming demands

The master schedule should cover a period that is at least equivalent

to the cumulative lead time

Cumulative lead time

The sum of the lead times that sequential phases of a process

require, from ordering of parts or raw materials to completion

of final assembly.

12-8

Cumulative Lead Time

Instructor Slides 12-9

MRP Inputs: Bill of Materials

Bill of Materials (BOM)

A listing of all of the assemblies, subassemblies,

parts, and raw materials needed to produce one

unit of a product

Product structure tree

A visual depiction of the requirements in a bill of

materials, where all components are listed by levels

Instructor Slides 12-10

Low-Level Coding

Instructor Slides

Low-level coding

Restructuring the bill of material so that multiple

occurrences of a component all coincide with the

lowest level at which the component occurs

Level 3

Level 2

Level 1

Level 0 X

B(2)

D(3)

E(4)

E

C

E(2)

F(2)

12-11

Example: product structure tree

diagram

An end item X is composed of two Bs and one C. moreover,

each B requires three Ds and one E, and each D requires four

Es. Similarly, each C is made up of two Es and two Fs. The

items at each level are components of the next level up and,

as in a family tree, are parents of their respective

components. The available inventory on hand of each items

B, C, D, and E are 4, 10, 8, and 60 respectively. Note that the

quantities of each item in the product structure tree refer only

to the amounts needed to complete the assembly at the next

higher level. Use this information to do the following:

a. Draw the product tree diagram

b. Determine the quantities of B, C, D, E, and F needed to

assemble one unit of X

c. Determine the quantities of these components that will

required to assemble 10 Xs, taking into account the quantities

on hand of various components

Solution: tree diagram

X

B(2)

C

D(3)

E

E(4)

E(2) F(2)

B: 2

C: 1

D: 2 3 = 6

E: 4 3 2 + 1 2 +2 1 = 28

F: 2

Solution: tree diagram

X

B(2)

C

D(3)

E

E(4)

E(2) F(2)

B: 2 10=20 - 4=16

C: 1 10 =10 -10 = 0

E: 1 16 = 16

D: 3 16 = 48 - 8 = 40

E: 4 40 = 160 60 = 100

B: 16

C: 0

D: 40

E: 116

F: 0

MRP Inputs: Inventory Records

Instructor Slides

Inventory records

Includes information on the status of each item by time period, called

time buckets

Information about

Gross requirements

Scheduled receipts

Expected amount on hand

Other details for each item such as

Supplier

Lead time

Lot size policy

Changes due to stock receipts and withdrawals

Canceled orders and similar events

12-15

Assembly Time Chart

Instructor Slides

12-16

MRP Processing

MRP processing takes the end item requirements

specified by the master schedule and explodes them into

time-phased requirements for assemblies, parts and raw

materials using the bill of materials offset by lead times.

The quantities that are generated by exploding the bill of

materials are gross requirements; they dont take into

consideration any inventory that is currently on hand or

due to be received.

The materials that a firm must actually acquire to meet

the demand generated by the master schedule are the

net material requirements which is calculated as the

gross requirements minus the projected inventory plus a

safety stock.

MRP Record

Instructor Slides

Gross requirements

Total expected demand

Scheduled receipts

Open orders scheduled to arrive

Projected on hand inventory

Expected inventory on hand at the beginning of each time

period

Week Number 1 2 3 4 5 6

Gross Requirements

Scheduled Receipts

Projected on hand

Net requirements

Planned-order-receipt

Planned-order release

12-18

MRP Record

Instructor Slides

Week Number 1 2 3 4 5 6

Gross Requirements

Scheduled Receipts

Projected on hand

Net requirements

Planned-order-receipt

Planned-order release

Net requirements

Actual amount needed in each time period

Planned-order receipts

Quantity expected to be received at the beginning of the

period offset by lead time

Planned-order releases

Planned amount to order in each time period

12-19

MRP: Development

The MRP is based on the product structure tree diagram

Requirements are determined level by level, beginning with

the end item and working down the tree

The timing and quantity of each parent becomes the basis for

determining the timing and quantity of the children items directly

below it.

The children items then become the parent items for the next

level, and so on

Instructor Slides 12-20

Example: MRP Processing

A firm that produces wood shutters and bookcases has

received two orders for shutters: one for 100 shutters and one

for 150 shutters. The 100-unit order is due for delivery at the

start of week 4 of the current schedule, and the 150-unit order

is due for delivery at the start of week 8. each shutter consists

of two frames and four slatted wood sections. The wood

sections are made by the firm, and fabrication takes one week.

The frames are ordered, and lead time is two weeks. Assembly

of the shutters requires one week. There is a scheduled receipt

of 70 wood sections in (i.e., at the beginning of) week1.

determine the size and timing of planned-order releases

necessary to meet delivery requirements under each of these

conditions:

1. lot-for-lot ordering (i.e., order size equal to net requirements)

2. Lot-size ordering with a lot size of 320 units for frames and 70

units for wood sections.

Example MRP

Shutter

Frames (2)

Wood

sections (4)

Instructor Slides 12-22

Solution: MRP Processing

a. Develop a master schedule:

Week number 1 2 3 4 5 6 7 8

Quantity 100

150

b. Develop a product structure tree

Shutter

Frames (2) Wood sections (4)

c. Using the master schedule, determine gross

requirements for shutters. Next compute net

requirements

Example MRP

Instructor Slides

12-24

Example MRP

Instructor Slides

12-25

Using the MRP

Instructor Slides

Pegging

The process of identifying the parent items that

have generated a given set of material

requirements for an item

12-26

Updating the System

Instructor Slides

An MRP is not a static document

As time passes

Some orders get completed

Other orders are nearing completion

New orders will have been entered

Existing orders will have been altered

Quantity changes

Delays

Missed deliveries

12-27

MRP Outputs: Primary

Instructor Slides

Primary Outputs

Planned orders

A schedule indicating the amount and timing of future

orders

Order releases

Authorizing the execution of planned orders

Changes

Revisions of the dates or quantities, or the cancellation of

orders

12-28

MRP Outputs: Secondary

Instructor Slides

Secondary Outputs

Performance-control reports

Evaluation of system operation, including deviations from plans and

cost information

e.g., missed deliveries and stockouts

Planning reports

Data useful for assessing future material requirements

e.g., purchase commitments

Exception reports

Data on any major discrepancies encountered

E.g., late and overdue orders, excessive scrap rates, requirements for

nonexistent parts

12-29

Other MRP Considerations:

Lot Sizing Rules

Lot-for-Lot (L4L) ordering

The order or run size is set equal to the demand for that period

Minimizes investment in inventory

It results in variable order quantities

A new setup is required for each run

Economic Order Quantity (EOQ)

Can lead to minimum costs if usage of item is fairly uniform

This may be the case for some lower-level items that are common to different

parents

Less appropriate for lumpy demand items because inventory remnants often

result

Fixed Period Ordering

Provides coverage for some predetermined number of periods

Instructor Slides 12-30

Other MRP Considerations:

Safety Stock

Safety Stock

Theoretically, MRP systems should not require safety stock

Variability may necessitate the strategic use of safety stock

A bottleneck process or one with varying scrap rates may cause

shortages in downstream operations

Shortages may occur if orders are late or fabrication or assembly

times are longer than expected

When lead times are variable, the concept of safety time is often

used

Safety time

Scheduling orders for arrival or completions sufficiently ahead

of their need that the probability of shortage is eliminated or

significantly reduced

Instructor Slides 12-31

MRP in Services

Food catering service

End item catered food

Dependent demand ingredients for each

recipe, i.e., bill of materials

Hotel renovation

Activities and materials exploded into

component parts for cost estimation and

scheduling

Instructor Slides 12-32

MRP Benefits

Instructor Slides

Enables managers to easily

determine the quantities of each component for a given order size

To know when to release orders for each component

To be alerted when items need attention

Additional benefits

Low levels of in-process inventories

The ability to track material requirements

The ability to evaluate capacity requirements

A means of allocating production time

The ability to easily determine inventory usage via backflushing

Exploding an end items BOM to determine the quantities of the

components that were used to make the item

12-33

MRP Requirements

Instructor Slides

To implement an effective MRP system requires:

A computer and the necessary software to handle computations and

maintain records

Accurate and up-to-date

Master schedules

Bills of materials

Inventory records

Integrity of data files

12-34

Vous aimerez peut-être aussi

- Chapter 12: Learning Objectives: - You Should Be Able ToDocument34 pagesChapter 12: Learning Objectives: - You Should Be Able Tochiji chzzzmeowPas encore d'évaluation

- MRPDocument34 pagesMRPPrashant KalaskarPas encore d'évaluation

- MRP and Erp: Planeacion de Requerimientos de Materiales Y Planeacion de Recursos de La EmpresaDocument46 pagesMRP and Erp: Planeacion de Requerimientos de Materiales Y Planeacion de Recursos de La Empresaagustin6551Pas encore d'évaluation

- Clase MRP 2Document45 pagesClase MRP 2Raed DallaliPas encore d'évaluation

- MRP & Erp: Prof. Eloida C. DagumboyDocument22 pagesMRP & Erp: Prof. Eloida C. DagumboyRowena MalinaoPas encore d'évaluation

- OM Chapter 3Document28 pagesOM Chapter 3Tuấn TrườngPas encore d'évaluation

- Material Requirement PlanningDocument41 pagesMaterial Requirement Planningmaxz123Pas encore d'évaluation

- MRP ExercisesDocument19 pagesMRP ExercisesCesar Corzo DiazPas encore d'évaluation

- Material Requirements PlanningDocument38 pagesMaterial Requirements PlanningTanimPas encore d'évaluation

- MRP and ErpDocument25 pagesMRP and ErpTaranjeetPas encore d'évaluation

- Chapter 14 - : Planning (MRP and ERP)Document31 pagesChapter 14 - : Planning (MRP and ERP)Arnab GhoshPas encore d'évaluation

- Operations Management: Dr. HasanuzzamanDocument37 pagesOperations Management: Dr. HasanuzzamanNandini KumarPas encore d'évaluation

- HK222. CH - 04 - Material Requirement PlanningDocument35 pagesHK222. CH - 04 - Material Requirement PlanningHOÀNG PHẠM HUYPas encore d'évaluation

- MRP CjaDocument26 pagesMRP CjaRendy FranataPas encore d'évaluation

- MRPDocument31 pagesMRPRajyalakshmiPas encore d'évaluation

- MRP Part IDocument48 pagesMRP Part IDanielle David AbandoPas encore d'évaluation

- Material Requirement PlanningDocument32 pagesMaterial Requirement PlanningNaima RashidPas encore d'évaluation

- Material Requirements Planning & ERP PPT at BEC DOMSDocument44 pagesMaterial Requirements Planning & ERP PPT at BEC DOMSBabasab Patil (Karrisatte)Pas encore d'évaluation

- School of EngineeringDocument11 pagesSchool of EngineeringJoyce ChoyPas encore d'évaluation

- Chapter Four: Material Requirement PlanningDocument34 pagesChapter Four: Material Requirement PlanningEthiopian Ayele SeyfePas encore d'évaluation

- Rama MRPDocument79 pagesRama MRPSanchit MishraPas encore d'évaluation

- Inventory Control in PPCDocument33 pagesInventory Control in PPCGaurav Gangwar SuryaPas encore d'évaluation

- MRP Overview ScribdDocument50 pagesMRP Overview Scribdh_kobi76100% (1)

- Chapter 14 MRPDocument8 pagesChapter 14 MRPeiaPas encore d'évaluation

- CH 18 MRPDocument37 pagesCH 18 MRPEric F. IrawanPas encore d'évaluation

- Chapter14 MRPDocument8 pagesChapter14 MRPKim WooPas encore d'évaluation

- PP Training Presentation M&MDocument49 pagesPP Training Presentation M&MNikhil WaniPas encore d'évaluation

- Material Requirements Planning (MRP) (CHAPTER 12)Document53 pagesMaterial Requirements Planning (MRP) (CHAPTER 12)Sahil ChaudharyPas encore d'évaluation

- Lect 3Document38 pagesLect 3shashikantppediaPas encore d'évaluation

- Material Requirements PlanningDocument40 pagesMaterial Requirements Planningazharama0% (1)

- Material Requirements PlanningDocument36 pagesMaterial Requirements PlanningKave MathiPas encore d'évaluation

- Material Requirement Planning (MRP)Document21 pagesMaterial Requirement Planning (MRP)Ramesh GarikapatiPas encore d'évaluation

- MRP Lot For LotDocument43 pagesMRP Lot For LotAmin ShafanezhadPas encore d'évaluation

- MRPDocument43 pagesMRPsandeepPas encore d'évaluation

- 06 PPCDocument75 pages06 PPCizharkhan12345Pas encore d'évaluation

- Material Requirements Planning: Dr. Everette S. Gardner, JRDocument28 pagesMaterial Requirements Planning: Dr. Everette S. Gardner, JRSunil MalikPas encore d'évaluation

- Material Requirements Planning (MRP)Document34 pagesMaterial Requirements Planning (MRP)soorajPas encore d'évaluation

- Material Requirements Planning: by Amrendra KumarDocument21 pagesMaterial Requirements Planning: by Amrendra KumarrejingeoPas encore d'évaluation

- Materaials Requirement Planning (MRP) : Venkateswara Rao .KorasigaDocument43 pagesMateraials Requirement Planning (MRP) : Venkateswara Rao .KorasigaERRAMESH1989Pas encore d'évaluation

- Material Requirement Planning PresentationDocument32 pagesMaterial Requirement Planning PresentationAmol BhongadePas encore d'évaluation

- Master Production ScheduleDocument9 pagesMaster Production ScheduleglamboyzPas encore d'évaluation

- MRPDocument32 pagesMRPvictorPas encore d'évaluation

- Manufacturing Resources PlanningDocument5 pagesManufacturing Resources PlanningSachin SalvanikarPas encore d'évaluation

- Material Requirements Planning (MRP)Document14 pagesMaterial Requirements Planning (MRP)jauhari4Pas encore d'évaluation

- Sap PP Production Planning MRP OverviewDocument36 pagesSap PP Production Planning MRP OverviewsameePas encore d'évaluation

- Production Planning: Devaki NadkarniDocument29 pagesProduction Planning: Devaki Nadkarnidsathiya100% (1)

- Material Requirements PlanningDocument151 pagesMaterial Requirements PlanningVinod Kumar PatelPas encore d'évaluation

- Ln08 MRP and ErpDocument16 pagesLn08 MRP and ErpTioPas encore d'évaluation

- Chapter 4 - Controlling Material Flow FULLDocument50 pagesChapter 4 - Controlling Material Flow FULLmaingcduPas encore d'évaluation

- Ob 12Document15 pagesOb 12cool908Pas encore d'évaluation

- Material Requirement Planning PresentationDocument30 pagesMaterial Requirement Planning PresentationAnchal AgarwalPas encore d'évaluation

- Student Slides Chapter 14Document15 pagesStudent Slides Chapter 14Anthony RoyupaPas encore d'évaluation

- Supply Chain Management Ch.15 Summary: When To Use MRPDocument3 pagesSupply Chain Management Ch.15 Summary: When To Use MRPYousef ShroufPas encore d'évaluation

- ME 4050 Lecture 11 MRP1-2 and ERPDocument24 pagesME 4050 Lecture 11 MRP1-2 and ERPK ROHITH SINGH me12b031Pas encore d'évaluation

- Material Requirements PlanningDocument15 pagesMaterial Requirements PlanningRayeed AliPas encore d'évaluation

- Perencanaan Dan Pengendalian Produksi: Master Production SchedulingDocument13 pagesPerencanaan Dan Pengendalian Produksi: Master Production SchedulinguddindjmPas encore d'évaluation

- Erp & MRPDocument44 pagesErp & MRPsobithkcPas encore d'évaluation

- APICS Dictionary App, "Material Requirements Planning," Accessed 14 September 2020Document9 pagesAPICS Dictionary App, "Material Requirements Planning," Accessed 14 September 2020Vanessa MeloPas encore d'évaluation

- Integrated Cost and Schedule Control in Project ManagementD'EverandIntegrated Cost and Schedule Control in Project ManagementÉvaluation : 2 sur 5 étoiles2/5 (1)

- BCSNotts&Derby October 2005Document37 pagesBCSNotts&Derby October 2005DAPas encore d'évaluation

- Attitude and Job SatisfactionDocument12 pagesAttitude and Job SatisfactionDAPas encore d'évaluation

- Assertive BehaviourDocument22 pagesAssertive BehaviourDAPas encore d'évaluation

- Britannia IndustriesDocument26 pagesBritannia IndustriesDAPas encore d'évaluation

- Soft Skills Conf Assertive Intro 2011, PPTDocument35 pagesSoft Skills Conf Assertive Intro 2011, PPTDAPas encore d'évaluation

- Barometric and Dominant Price LeadershipDocument14 pagesBarometric and Dominant Price LeadershipDA50% (4)

- Water Treatment PDFDocument87 pagesWater Treatment PDFJubin KumarPas encore d'évaluation

- Bekele (2005) Urbanization and Urban SprawlDocument65 pagesBekele (2005) Urbanization and Urban Sprawlentbeard77100% (3)

- BSBINews 78Document96 pagesBSBINews 78Anonymous dEztzVuePas encore d'évaluation

- Happy Learn Haskell Tutorial Vol 1Document243 pagesHappy Learn Haskell Tutorial Vol 1joorcePas encore d'évaluation

- Linda Raschke's 50 Time-Tested Trading RulesDocument4 pagesLinda Raschke's 50 Time-Tested Trading RulesISB3 333100% (1)

- Modeling of Deepwater-Type Rectangular Tuned Liquid Damper With Submerged NetsDocument10 pagesModeling of Deepwater-Type Rectangular Tuned Liquid Damper With Submerged NetsDhirendra Kumar PandeyPas encore d'évaluation

- Command ReferenceDocument368 pagesCommand Referenceom007Pas encore d'évaluation

- EstratehiyaDocument2 pagesEstratehiyaMikaella AlvarezaPas encore d'évaluation

- Public Relations vs. Propaganda: Alexandru BASTIANDocument6 pagesPublic Relations vs. Propaganda: Alexandru BASTIANFatima AshrafPas encore d'évaluation

- AucomDocument10 pagesAucomAlberto Suazo BasaezPas encore d'évaluation

- 2 Sim Hydraulics ReferenceDocument430 pages2 Sim Hydraulics ReferenceEnrico GambiniPas encore d'évaluation

- Blake and MuttonDocument4 pagesBlake and Muttonmohitegaurv870% (1)

- WebSphere Application Server AMI Cheatsheet For DemoDocument2 pagesWebSphere Application Server AMI Cheatsheet For DemoYakura CoffeePas encore d'évaluation

- Bonus, Alexander Evan - The Metronomic Performance Practice - A History of Rhythm, Metronomes, and The Mechanization of MusicalityDocument597 pagesBonus, Alexander Evan - The Metronomic Performance Practice - A History of Rhythm, Metronomes, and The Mechanization of MusicalityNoMoPoMo576100% (2)

- Ventures Priamry Heritage-Social StudiesDocument128 pagesVentures Priamry Heritage-Social StudiesWryter Business100% (2)

- Establishment of A Design Methodology For High-Performance Circuits Based On Automatic Optimization MethodsDocument2 pagesEstablishment of A Design Methodology For High-Performance Circuits Based On Automatic Optimization Methodscatalin85Pas encore d'évaluation

- Kritika Pandey (Kaushambi)Document15 pagesKritika Pandey (Kaushambi)nishink9Pas encore d'évaluation

- Chapter 3 - Basic Statistical ConceptsDocument16 pagesChapter 3 - Basic Statistical ConceptsChristian Alfred VillenaPas encore d'évaluation

- Virtual Earth SurveyDocument11 pagesVirtual Earth SurveyWenkatWenkatPas encore d'évaluation

- MARVEL 6000 Series High Power Fiber Laser Cutting Machine - Laser Cutting Farley Laserlab, CNC Laser Cutting Machine, Plasma Cutting Machine, Fiber Laser Cutting Machine, Cutting Machine PriceDocument1 pageMARVEL 6000 Series High Power Fiber Laser Cutting Machine - Laser Cutting Farley Laserlab, CNC Laser Cutting Machine, Plasma Cutting Machine, Fiber Laser Cutting Machine, Cutting Machine PriceTradiyo ForexPas encore d'évaluation

- CSSMasterclassBook PDFDocument168 pagesCSSMasterclassBook PDFyankeePas encore d'évaluation

- Correspondence Option: Society of Cosmetic Chemists South Africa Tel:011 792-4531 Email:bridget@coschem - Co.zaDocument1 pageCorrespondence Option: Society of Cosmetic Chemists South Africa Tel:011 792-4531 Email:bridget@coschem - Co.zanblaksPas encore d'évaluation

- Online Web Chat Application DocumentDocument8 pagesOnline Web Chat Application DocumentENGINEER HEREPas encore d'évaluation

- TPS - Quick AssessmentDocument2 pagesTPS - Quick AssessmentcssIllinois100% (1)

- Ps1 GeneralDocument2 pagesPs1 Generalkulin123456Pas encore d'évaluation

- ELECTROSTATICSDocument21 pagesELECTROSTATICSHemanthPas encore d'évaluation

- Difficult Doctrine of The Love of GodDocument93 pagesDifficult Doctrine of The Love of GodRocio Pireyek100% (8)

- The Role of Lay People in The Production and Dissemination of Scientific KnowledgeDocument15 pagesThe Role of Lay People in The Production and Dissemination of Scientific KnowledgeanferrufoPas encore d'évaluation

- 21 Clever Ways To Make Him Chase YouDocument1 page21 Clever Ways To Make Him Chase YouMagdalena SekulovaPas encore d'évaluation

- MD Nastran R3 - Explicit Nonlinear SOL 700 User's Guide PDFDocument602 pagesMD Nastran R3 - Explicit Nonlinear SOL 700 User's Guide PDFpezz07Pas encore d'évaluation