Académique Documents

Professionnel Documents

Culture Documents

Hot Work Permitting

Transféré par

sandipsarma0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues23 pagesHot work permit

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentHot work permit

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues23 pagesHot Work Permitting

Transféré par

sandipsarmaHot work permit

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 23

1

NATIONAL PARK SERVICE

Hot Work

Permit Process

Structural Fire Program

2

Hot Work Permits

Why do we need hot work permits?

Every year fires occur that could have

been prevented had employees used appropriate

fire prevention measures.

The National Park Service requires the use of the

Hot Work Permit Process as the primary means of

preventing fires due to non-routine open flame and

high temperature processes. (NFPA standard 51B)

3

Hot Work Permits

Goals and Objectives:

At the end of this session you will able to:

- Recognize work that requires the use of

Hot Work permits.

- Be familiar with the Hot Work Permit System.

4

Hot Work Permits

Hot Work is any work using open

flames or sources of heat that could

ignite materials in the work area.

5

Hot Work Permits

Examples of hot work are:

welding

burning

brazing

propane soldering

oxyacetylene cutting

grinding ferrous metals

6

Responsible Person:

A person in the park or

work unit with the

proper training will be

designated as the person

responsible for issuing

the Hot Work permits,

at most sites this is the

person designated as the

Park Structural Fire

Coordinator (PSFC)

Hot Work Permits

7

Hot Work Permits

Procedures:

Before beginning any

hot work project, contact the

Park Structural Fire

Coordinator (PSFC)

to have a Hot Work site inspected

and a permit issued.

8

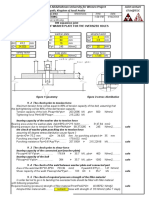

Hot Work Permits

Cutting / Welding

Permit

Location: Job No.

Date: Job No.

Location & Building: Floor

Nature of Job:

Welders Name:

The above location has been examined. The

precautions checked

on the reverse of this card have been taken to prevent

fire.

Permission is granted for this work.

Permit Date: Time:

Expires AM

PM

Permits are issued for the

specific job being done, and

for a specific time period.

The time period is usually

for the working shift, but

should never exceed 24

hours.

9

Hot Work Permits

Required checks:

Sprinklers are in service.

Cutting and welding equipment in good repair.

Precautions within 35 ft. (10 m.) of work.

Floors swept clean of combustibles.

Combustible floors wet down, covered with damp sand or

fire-resistive sheets.

Flammable liquids removed; other combustibles, if not

removed protected with fire-resistive tarpaulins or metal shields.

Explosive atmosphere in area eliminated.

All wall and floor openings covered.

Fire-resistive tarpaulins suspended beneath work.

Work on Walls or Ceilings

Construction is noncombustible and without combustible

covering or isolation.

Combustibles moved away from other side of wall.

Work on Enclosed Equipment

Enclosed equipment cleaned of all combustibles.

Containers purged of flammable liquids.

Fire Watch

Fire watch will be provided during and for at least 30 minutes

after work, and during any coffee or lunch breaks.

Fire watch is supplied with suitable extinguishers, or charged

small hose.

Fire watch is trained in use of this equipment and in

sounding alarm.

The PSFC has the

responsibility of

verifying that all

necessary

precautions have

been taken at the

worksite.

10

Hot Work Permits

Required Precautions:

Sprinklers are in service if

they are in the structure.

Welding and other Hot Work have been found to be high

ranking causes of fires. Sprinkler systems must

remain in service in the hot work area, unless specifically

approved by the PSFC.

11

Hot Work Permits

Required Precautions:

Cutting and welding equipment

in good repair.

Gas hoses, backflow preventers, fire resistive tarpaulins

and curtains are on site, the appropriate size and type of

portable fire extinguisher are available and other cutting

and welding equipment must be in good repair before the

permit is issued.

12

Hot Work Permits

Required Precautions:

Precautions within 35 ft. (10 m.) of work.

Floors swept clean of combustibles.

Combustible floors wet down, covered with damp sand or

fire-resistive sheets.

Flammable liquids removed; other combustibles, if not

removed protected with fire-resistive tarpaulins or metal

shields.

Explosive atmosphere in area eliminated.

All wall and floor openings covered.

Fire-resistive tarpaulins suspended beneath work.

Work on Walls or Ceilings

Construction is noncombustible and without combustible

covering or isolation.

Combustibles moved away from other side of wall.

Work on Enclosed Equipment

Enclosed equipment cleaned of all combustibles.

Containers purged of flammable liquids.

Anything that can burn must be removed from the

immediate work area.

13

Hot Work Permits

Required Precautions:

Fire Watch

Fire watch will be provided during and for at least 30

minutes

after work, and during any coffee or lunch breaks.

Fire watch is supplied with suitable extinguishers, or

charged

small hose.

Fire watch is trained in use of this equipment and in

sounding alarm.

Should other precautions fail, trained personnel

will be needed with fire fighting equipment to

extinguish any fires which start. Personnel and

equipment must be readily available before the permit

is issued.

14

Hot Work Permits

Required Precautions:

Fire Watch

Fire watch will be provided during and for at least 30 minutes

after work, and during any coffee or lunch breaks.

Fire watch is supplied with suitable extinguishers, or charged

small hose.

Fire watch is trained in use of this equipment and in

sounding alarm.

Fire Watch personnel may

not do other jobs which

detract from their primary

responsibility.

Fire Watch personnel must be trained to use fire extinguishment

media provided.

Fire Watch personnel must be aware of how to report emergencies,

and in emergency evacuation procedures.

Fire Watch personnel must be identified and their qualifications verified,

before permits are issued.

15

Hot Work Permits

Required Precautions:

CAN THE JOB BE AVOIDED?

IS THERE A SAFER WAY?

Before beginning any hot work, ask yourself if the work can be

done a safer way. Hot work is very hazardous and should be

avoided if not absolutely necessary.

16

Hot Work Permits

Final Checkup By Welder

Work area and all adjacent areas to which sparks and heat might have

spread (such as floors above and below and on opposite side of walls)

were inspected after the work was completed and were found fire safe.

Before leaving the area for the day, at least 60 minutes

after the last hot work has been completed, verify that no

smoldering fires have developed within walls, cracks in floors,

or in ceiling areas where you have been working.

17

Hot Work Permits - Summary

Jobs like electric arc welding, brazing, gas soldering, and

oxygen-acetylene cutting and welding should have hot

work permits issued by the Park Structural Fire Coordinator (PSFC)

before work begins.

Permits are issued for a specific job, for a

specific time frame, to a specific person.

All necessary equipment must be on site and in

good working order before work begins.

A fire watch must be present for the duration of hot work

and for at least 60 minutes after work is done.

A fire inspection must be conducted by the person doing the hot work

before leaving the job site.

Permits are to be returned to the person who issued them.

18

NFPA 909

Standard for the Protection of Cultural Resources

Including Museums, Libraries, Places of Worship, and

Historic Properties

3-6 Hot Work.

Hot work shall not be permitted unless there is no other viable alternative.

3-6.1 Hot Work Permit.

A hot work permit shall be issued by the PSFC to authorize work with

any open flame devices used in soldering, brazing, cutting, and welding.

19

NFPA 909

Standard for the Protection of Cultural Resources

Including Museums, Libraries, Places of Worship, and

Historic Properties

3-6.2 Permit Requirements.

The hot work permit shall prescribe measures to protect the collections and ensure

life safety, and shall include the following requirements as a minimum:

(a) A person trained in the use of fire extinguishers shall be stationed in the

vicinity of the hot work operation for the duration of the work and for 60 minutes

thereafter with frequent monitoring during the following 3 hours

(b) All combustibles within 35 ft (11 m) of the work site shall be relocated or

be covered with noncombustible or fire-retardant coated tarpaulins or otherwise

shielded with metal or noncombustible guards or curtains.

20

Where to get questions

answered?

Your supervisor is responsible for all necessary equipment

and for contacting the person in your park or work unit that

can provide additional assistance, such as the PSFC.

The PSFC will issue all permits and answer any specific

questions about fire protection systems, fire prevention

measures and precautions.

National Structure Fire Program Office, NIFC, Boise Idaho

208-387-5209 or 208-387-5245.

21

Another historic structure

damaged

3/18/02, 11:53 pm

212 firefighters, 33 engines, 19 trucks, 8

medical/rescue and 18 overhead responded

to a report of flames showing.

Renovation/adaptive reuse of a 196,000sf.,

4 story NPS owned historic cannery

building

Cause Accidental (welding operation)

22

Historic NPS structure damaged

from lack of enforced

Hotwork Permitting

Estimated property value = $10,000,000.00

Estimated contents value = $10,000,000.00

Estimated property damage = $6,000,000.00

Estimated content damaged =$5,000,000.00

23

These losses could have been easily prevented

had a hot work permitting process been in

place and enforced!

Dont let this happen to you!

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Tagalog English Construction TermsDocument3 pagesTagalog English Construction TermscyrawrPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Washer PlateDocument2 pagesWasher PlateНемања Караклајић100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Residential Building Design Using Excel Program - FinalDocument28 pagesResidential Building Design Using Excel Program - FinalGeneva Latorre92% (12)

- Loads On Structures (Case of Two-Way Slabs) : Preliminary DesignDocument5 pagesLoads On Structures (Case of Two-Way Slabs) : Preliminary DesignMrAlittle Finger100% (1)

- Chemical Resistance GuideDocument32 pagesChemical Resistance GuidevsvineeshPas encore d'évaluation

- Thesis-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry InfillDocument81 pagesThesis-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry Infillnirez14Pas encore d'évaluation

- 14 Heating Effect of Electric CurrentDocument8 pages14 Heating Effect of Electric CurrentCarmella Mae Quidilig100% (1)

- Pressure Rating PDFDocument4 pagesPressure Rating PDFMohamed AdelPas encore d'évaluation

- Augustin - A Contribution To The Design of Ribbed PlatesDocument10 pagesAugustin - A Contribution To The Design of Ribbed Platesm2auPas encore d'évaluation

- Lighting Design For Green and Adouless Public ToiletsDocument8 pagesLighting Design For Green and Adouless Public ToiletsSankaranarayanan ChandresekarPas encore d'évaluation

- Coating PrcessDocument21 pagesCoating PrcessJatin GadhokPas encore d'évaluation

- Construction Methods and Project Management: Group 1 - CE51FA2Document62 pagesConstruction Methods and Project Management: Group 1 - CE51FA2MhariecriszReazoPas encore d'évaluation

- ACSRDocument8 pagesACSRRajesh VauPas encore d'évaluation

- 3 - Current Electricity - Theory & Solved Exam Module-4Document40 pages3 - Current Electricity - Theory & Solved Exam Module-4Raju SinghPas encore d'évaluation

- QTSS - Sec 4 Exp MYE - Physics AnsDocument4 pagesQTSS - Sec 4 Exp MYE - Physics AnsHui XiuPas encore d'évaluation

- Katalog TEKIRO ToolsDocument131 pagesKatalog TEKIRO ToolslukasPas encore d'évaluation

- JCZ Marine Axial Fan: Safety - High Quality - Professional - Fast Delivery - Reliable PartnerDocument9 pagesJCZ Marine Axial Fan: Safety - High Quality - Professional - Fast Delivery - Reliable PartnerSea Man MktPas encore d'évaluation

- Structural Steel Design 1 Mini ProjectDocument24 pagesStructural Steel Design 1 Mini ProjectMohd SaufiPas encore d'évaluation

- Overview of EN and ISO Window Thermal Performance Standards: Calculation Methods Measurement MethodsDocument1 pageOverview of EN and ISO Window Thermal Performance Standards: Calculation Methods Measurement MethodsBojan BjelajacPas encore d'évaluation

- Willoughby Product CatalogDocument480 pagesWilloughby Product CatalogIsabel CarolinaPas encore d'évaluation

- IS 456 2000 Plain Reinf Concrete PDFDocument107 pagesIS 456 2000 Plain Reinf Concrete PDFHafizullah AminPas encore d'évaluation

- Partial Replacement of Cement With GGBS in ConcreteDocument10 pagesPartial Replacement of Cement With GGBS in ConcreteE Hammam El MissiryPas encore d'évaluation

- C Flex Ultra FLS 5096BDocument2 pagesC Flex Ultra FLS 5096BthynameisraymondPas encore d'évaluation

- Comprehensive Group Pile Settlement Formula Based On 3D Finite Element AnalysesDocument15 pagesComprehensive Group Pile Settlement Formula Based On 3D Finite Element AnalysesPhetole Pat RaseteloPas encore d'évaluation

- CIB9192 - Carbonation Testing of Hardened Concrete and The Effect of Cement TypeDocument10 pagesCIB9192 - Carbonation Testing of Hardened Concrete and The Effect of Cement TypePriscilla CordeiroPas encore d'évaluation

- Planum ENDocument20 pagesPlanum ENAmihay HararyPas encore d'évaluation

- FS OneDocument1 pageFS OneDario SantosPas encore d'évaluation

- Design and Fabrication of A Cavitation Demonstrating ApparatusDocument15 pagesDesign and Fabrication of A Cavitation Demonstrating ApparatusInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Table Of: (Click Item To View)Document29 pagesTable Of: (Click Item To View)Mohamed AboelazmPas encore d'évaluation

- Commercial - Building - Electrical - Design (Inc)Document17 pagesCommercial - Building - Electrical - Design (Inc)Stephany PolinarPas encore d'évaluation