Académique Documents

Professionnel Documents

Culture Documents

Case Study of Poly O Ring Failure

Transféré par

oasis420Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Case Study of Poly O Ring Failure

Transféré par

oasis420Droits d'auteur :

Formats disponibles

MUHAMMAD REHAN KHAN

CONTENTS

Background

PVC II Polymerizer

Man way specifications

Sequence of event

Analysis of failure

Probable causes

Conclusion

Recommendations

Cost Analysis

BACKGROUND

PVC II Polymerizer faces the VCM leakage most of the time when it get discharges

and taken on hold for next batch charging for more than 4 to 5 hours

NOTE: All the failures are of same nature and follows the same sequence, this was the

reason that led to the development of this Case Study and complete investigation.

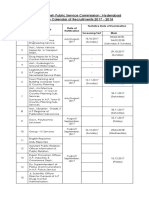

Date Event Observation Action Taken

23

rd

Nov 2010 VCM leakage detected from

the man way of PLY-1E

Polymerizer was on hold for batch charging Man way opened and the O-ring

was replaced

8

th

January 2011 VCM leakage detected from

the man way of PLY-1E

Polymerizer was on hold for batch charging Man way opened and the O-ring

was replaced

1

st

February 2011 VCM leakage detected from

the man way of PLY-1E

Polymerizer was on hold for batch charging Man way opened and the O-ring

was replaced

2

nd

April 2011

VCM leakage detected from

the man way of PLY-1E as

well as 2E

Both polymerizer were on waiting for batch

charging from 48 hrs and 24 hrs respectively

Man way opened and the O-ring

was replaced

2

nd

October 2011 Pressure test of all three

Polymerizers failed while

they were hold on for more

than 10 hours

All the Polymerizers were on hold due to the

power outage from GT B

Man way opened and the O-rings

were replaced

PVC II Polymerizer

Design Pressure & Temperature = 1.55MPa & 93

0

C

Operating Pressure & Temperature = 0.85MPa & 55

0

C

MOC: 16MnR (C-Mn-Si Steel) +304 (GB6654, A537M)

ID = 3810mm, H = 7068mm

Empty Weight = 44.7 M Tons

REACTION TEMPERATURES:

AFA Coating T = 85

0

C

Batch Charging T = 65

0

C

Reaction T = 59

0

C

Discharge T = 58

0

C

HP SEAL WATER CATALYST

DISPERSANT

SHORT STOP STEAM POLISHED WATER

VCM

FLUSH WATER MODIFIER

SHORT STOP

STEAM

COATING AGENT

INJECTION WATER

HP FLUSH WATER

ABOUT MANWAY

O-ring arrangement for man way

EPDM O-RING

SEQUENCE OF EVENTS

Polymerizer get discharge and hold on 4 to 5 hours for next batch charging

VCM leak from the man way which is detected by the VCM detectors and then soap test

Poly get depressurize completely (2.5 hours) and the o ring is replaced (1 hour)

V/A and Leak test done (5.5 hours)

Poly takes on service and found OK (Total outage 8-9 hours)

ANALYSIS OF FAILURE

CHEWED/ CHIPPED

APPEARANCE

PROBABLE CAUSES

1. Difference in thermal expansion of the mating surfaces i.e. man way and its

closure ring

2. Size of the O ring and its groove dimension

3. Softening of Elastomer due to incompatibility

4. Improper machining of O-ring gland i.e. Sharp edges (Not the case)

5. Elastomer too soft (Not the case)

Thermal expansion of mating surfaces

DATA:

Material = 0Cr18Ni9 (SS304)

Ambient Temp. = 30 C

Temp. Of Ring = 43 C

AFA Coating T = 85

0

C

Batch Charging T = 65

0

C

Reaction T = 59

0

C

Discharge T = 58

0

C

THERMAL EXPANSION

l = L * k * T (k = 17.2 X 10

-6

m/m-K)

l = 0.2mm

MANWAY

CLOSING RING

SIZE OF THE O-RING AND GROOVE DIMENSION

O-rings dimensions

O ring diameter = 7.5mm

OD = 633mm

Volume of the O-ring (2pi

2

Rr

2

) = 86,856 mm3

Grooves dimensions

Actual W = 6.5mm, H = 5.72mm

Volume of the Groove = 92,222mm3

Standard Groove Dimensions

As per AS568B for O ring diameter = 7.5mm,

W = 6.2mm, H = 6.2mm

Volume of the Std. Groove = 94,345 mm3

Which is greater than the total actual volume

O-ring groove is undersized

Softening of Elastomer due to incompatibility

EPDM IS NOT SUITABLE FOR VCM

OBSERVATIONS

SEQUENCE OF FAILURE

POLY GETS ON HOLD FOR MORE THAN 5 HOURS AND THE COOLING

OF MAN WAY LEFT THE SPACES IN THE O RING

SWELLING OF O-RING FURTHER CONTRIBUTES TO THE COMPRESSION

VCM STARTS PENETRATING AND CAUSES O-RING TO SWELL

THERMAL EXPANSION OF MAN WAY COMPRESSES IT MORE

WHICH CAUSES CRUSHING

O-RING INSTALLED (OVER COMPRESSED DUE TO UNDERSIZE GROOVE)

AFTER WHICH THE O RING DO NOT SEAL ANY MORE AND VCM LEAKAGE OSERVED

VCM

CONCLUSION

As per AS568B, the groove of the man-way O-ring is undersized which after

closing the man way, over compressed the O-ring and cause it to tear from the

edges

The different thermal expansions of man way and its ring causes the crushing

of the O-ring from its edges

EPDM is not suitable with the VCM service . During investigation PVC powder

found on the d/s of the O-ring which should not be a case in 100% sealed O-

ring. This EPDM O ring was suggested by the TCC vendor

RECOMMENDATIONS

Replaced the man way arrangement with a flanged arrangement like PVC I

polymerizer

Use Teflon or FFKM O-rings instead of EPDM

Machined the groove for increasing its volume to suit with our O-ring

dimensions

Use standard size of O-ring for this groove i.e.

ID = 633.48 +- 2.92, d = 6.99+-0.15 as per AS568B # 474

COST ANALYSIS

Total Outage time = 8-9 hours

Total loss of PVC / batch = 18 Tons

1 Tons = $1,070 (Reference: www.icis.com)

For one batch, we face the loss of 19,260$ (Rs 16,37,000)

FFKM O-ring cost = $ 3,000

REFERENCES

DISCHTOMATIC O-ring handbook

Parker O ring handbook

Standard (AS568), Metric O-Ring sizes

PVC II Process description by TCC

B-reports of O-ring failure

QUESTIONS

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Fittings: Fitting Buying GuideDocument2 pagesFittings: Fitting Buying GuideAaron FonsecaPas encore d'évaluation

- Studovaný Okruh: Physical Therapist Sample Test Questions (G5+)Document8 pagesStudovaný Okruh: Physical Therapist Sample Test Questions (G5+)AndreeaPas encore d'évaluation

- MSDS Lubriplate 105Document2 pagesMSDS Lubriplate 105mackyyo0% (1)

- Analyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioDocument12 pagesAnalyzing Activity and Injury: Lessons Learned From The Acute:Chronic Workload RatioLukas ArenasPas encore d'évaluation

- Monitoring AlkesDocument41 pagesMonitoring AlkesEndangMiryaningAstutiPas encore d'évaluation

- Global Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirDocument24 pagesGlobal Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirinderpreetPas encore d'évaluation

- Ineffective Breastfeeding - NCPDocument10 pagesIneffective Breastfeeding - NCPJullian PloyaPas encore d'évaluation

- Rar Vol11 Nro3Document21 pagesRar Vol11 Nro3Valentine WijayaPas encore d'évaluation

- ExamDocument10 pagesExamjohn ivan100% (1)

- Product Sheet - Parsys Cloud - Parsys TelemedicineDocument10 pagesProduct Sheet - Parsys Cloud - Parsys TelemedicineChristian Lezama Cuellar100% (1)

- Assignment 2: Loan Submission For Equipment FinanceDocument6 pagesAssignment 2: Loan Submission For Equipment FinanceIT'S SIMPLEPas encore d'évaluation

- APPSC Calender Year Final-2017Document3 pagesAPPSC Calender Year Final-2017Krishna MurthyPas encore d'évaluation

- Ifm Product Innovations PDFDocument109 pagesIfm Product Innovations PDFJC InquillayPas encore d'évaluation

- Biology 2 Chapter 4Document61 pagesBiology 2 Chapter 4Malas Nak TaipPas encore d'évaluation

- NCP On DiabetesDocument2 pagesNCP On DiabetesShumaila AlviPas encore d'évaluation

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 pagesAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutPas encore d'évaluation

- Group 7 Worksheet No. 1 2Document24 pagesGroup 7 Worksheet No. 1 2calliemozartPas encore d'évaluation

- Poisoned NeedleDocument147 pagesPoisoned NeedleMark Cooper100% (3)

- CH 13 RNA and Protein SynthesisDocument12 pagesCH 13 RNA and Protein SynthesisHannah50% (2)

- 348 - Ct-Tol Toluene TdsDocument1 page348 - Ct-Tol Toluene Tdsonejako12Pas encore d'évaluation

- Hasil Pemeriksaan Laboratorium: Laboratory Test ResultDocument1 pageHasil Pemeriksaan Laboratorium: Laboratory Test ResultsandraPas encore d'évaluation

- Api 579-2 - 4.4Document22 pagesApi 579-2 - 4.4Robiansah Tri AchbarPas encore d'évaluation

- EngineCleaningAndVolcanicAsh InternDocument69 pagesEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaPas encore d'évaluation

- Marine Advisory 03-22 LRITDocument2 pagesMarine Advisory 03-22 LRITNikos StratisPas encore d'évaluation

- #1 - The World'S Oldest First GraderDocument6 pages#1 - The World'S Oldest First GraderTran Van ThanhPas encore d'évaluation

- Narrative ReporDocument3 pagesNarrative ReporMARK LUKE ULITPas encore d'évaluation

- Updated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetDocument2 pagesUpdated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetRicardo HolleroPas encore d'évaluation

- AQ-101 Arc Flash ProtectionDocument4 pagesAQ-101 Arc Flash ProtectionYvesPas encore d'évaluation

- 1 BSC Iriigation Engineering 2018 19 Std1Document70 pages1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongPas encore d'évaluation

- Lesson 2 Basic Osah, General Provisions, Safety Rules..Document30 pagesLesson 2 Basic Osah, General Provisions, Safety Rules..GM VispoPas encore d'évaluation