Académique Documents

Professionnel Documents

Culture Documents

Session 8 ERP and BPM

Transféré par

Gregory Wilson0 évaluation0% ont trouvé ce document utile (0 vote)

33 vues41 pagesThis document discusses process management through ERP, RM, and SOA. It begins by explaining that while ERPs have configurable modules, they are functionally developed and a process-oriented implementation approach is required. Reference models (RMs) and service-oriented architectures (SOAs) allow for more flexible business processes and automation of best practices. The document then provides examples of key business processes in ERP like fulfillment, production, and procurement. It also discusses process reference models like SCOR that define supply chain processes and performance metrics. Finally, it introduces the American Productivity & Quality Center (APQC) as a non-profit organization that supports process improvement through best practice research.

Description originale:

ppt of session by ssbhardawaj

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document discusses process management through ERP, RM, and SOA. It begins by explaining that while ERPs have configurable modules, they are functionally developed and a process-oriented implementation approach is required. Reference models (RMs) and service-oriented architectures (SOAs) allow for more flexible business processes and automation of best practices. The document then provides examples of key business processes in ERP like fulfillment, production, and procurement. It also discusses process reference models like SCOR that define supply chain processes and performance metrics. Finally, it introduces the American Productivity & Quality Center (APQC) as a non-profit organization that supports process improvement through best practice research.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

33 vues41 pagesSession 8 ERP and BPM

Transféré par

Gregory WilsonThis document discusses process management through ERP, RM, and SOA. It begins by explaining that while ERPs have configurable modules, they are functionally developed and a process-oriented implementation approach is required. Reference models (RMs) and service-oriented architectures (SOAs) allow for more flexible business processes and automation of best practices. The document then provides examples of key business processes in ERP like fulfillment, production, and procurement. It also discusses process reference models like SCOR that define supply chain processes and performance metrics. Finally, it introduces the American Productivity & Quality Center (APQC) as a non-profit organization that supports process improvement through best practice research.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 41

Process Management through

ERP, RM, SOA

Sangeeta Shah Bharadwaj

Are ERPs Process Oriented or

functional?

A business process oriented implementation

approach is required for functionally

developed ERPs

ERPs have configurable modules

All modules necessary to support an entire

business process must be implemented

RMs vs ERP vs SOA

Best practice process definitions

Automation of best practices

Flexible business Processes

ERP Processes: Production Unit

A basic fulfillment Process

Production Process

Procurement Process

Sufficie

nt

Finishe

d

Goods?

Receive

Custom

er

Inquiry

Create

& Send

Quotati

on

Receive

Customer

Purchase

Order

Creat

e

Sales

Order

Prepare

Shipmen

t (Pick &

Pack)

Send

Shipme

nt

(Ship)

Create

& Send

Invoice

Recei

ve

Payme

nt

Go

Warehouse

Sales Accounting

No

A fulfillment Process

Request

Production

Authorize

Production

Sufficien

t Raw

Materials

?

G

o

Issue Raw

Material

Create

Produc

ts

Receive

Finished

Goods

Warehouse

Warehouse Warehouse Production Production

No

Production Process

Create

Requisition

Create &

Send

Purchase

Order

Receive

Shipment

Send

Payment

Receive

Invoice

Warehouse Purchasing Warehouse

Accounting

Continue

in Parallel

Procurement Process

Sufficie

nt

Finishe

d

Goods?

Receive

Custom

er

Inquiry

Create

& Send

Quotati

on

Receive

Customer

Purchase

Order

Creat

e

Sales

Order

Prepare

Shipmen

t (Pick &

Pack)

Send

Shipme

nt

(Ship)

Create

& Send

Invoice

Recei

ve

Payme

nt

Request

Producti

on

Go

Authorize

Production

Sufficient

Raw

Materials

?

Go

Issue

Raw

Mater

ial

Create

Products

Receive

Finished

Goods

STOP

STOP

Create

Requisition

Create &

Send

Purchase

Order

Receive

Shipment

Send

Payment

Receive

Invoice

Warehouse Purchasing Warehouse Accounting

Warehouse Warehouse Warehouse Production Production

Warehouse Sales Accounting

No

No

Procure Goods

Continue

in

Parallel

Procure Raw

Material

Integrated, end-to-end process

ERP : The traditional Path to process

Execution

What are good aspects?

Automation to execute a specific process

Best practices implementation

Pre defined business processes

What are the challenges with ERP

processes?

??

Difficult to change the processes

Customization is very costly

How do you incorporate changes?

Either not able to incorporate changes or

Integration of add on software through

predefined interfaces

Is this sufficient?

Yes for many scenarios

No if processes are critical to achieve competitive

advantage

SOA: New Flexibility in Process

Execution

Enable separation of business process design

and support through appropriate software

application/ component called services.

Enables execution of next practice business

process

SOA a perfect fit for achieving goals of Agility

and innovation.

Promotes reuse of services

SOA will be discussed in detail later

Other process best practices and

Implementation

Does any such practice/ standard exist?

Process definition delivered through standards

Reference Models

APSQ :American Productivity & Quality Center

Process Classification Framework

SM

Reference Models

A process reference model is a powerful

management tool

Process knowledge is formalized and structured

and is a step towards making it a product

a complex management process is captured in

standard process reference model form

It is then easy to measure, manage, and

controlled

It can also be tuned and re-tuned to achieve a

specific purpose or attain a competitive

advantage

How to obtain RMs?

Software Companies: SAP documented business

processes in the form of event driven process

chains

ERP companies are Key drivers in the development of

RM

Consulting companies also structure their

knowledge in the form of RM to increase their

own productivity

PMOLink sells RM as product, RM for Project

Management based on PMBOK

How to obtain RMs?

Industry organization also deliver knowledge

in the form of RM

Supply Chain Council offers Supply Chain

Operations Reference Model (SCOR)

Academic Organization also deliver RM

Scheers Y Model

Beckers Retail H

SCOR Example

SCOR is a business process reference model

that has all supply chain activities, from

suppliers supplier to customers customer

The structural framework of the SCOR

model

standard descriptions of the individual elements

that make up the supply chain processes,

standard definitions of key performance

measurements,

descriptions of best practices associated with

each of the process elements,

identification of software functionality (features)

that enables best practices

identification of information exchanged between

processes.

Supplier

Plan

Customer

Customers

Customer

Suppliers

Supplier

Make Deliver Source Make Deliver Make Source Deliver Source Deliver

Internal or External Internal or External

YOUR COMPANY

Source

Supply Chain Operations Reference Model

Plan Plan Plan Plan

Return

SCOR defines supply chain as the integrated processes of Plan, Source, Make,

Deliver and Return, spanning your suppliers supplier to your customers customer,

aligned with Operational Strategy, Material, Work & Information Flows.

The SCOR Framework

Supply Chain Reference Models (SCOR)

All customer interactions, from order entry

through paid invoice.

All product (physical goods, services, etc.)

transactions, including equipment, supplies,

spare parts, bulk product, software, etc.

All market interaction, from the understanding

of the aggregate demand to the fulfillment of

each order.

SCOR contains three levels of process detail.

The top level (process types) defines the scope

and content. It consists of the five top-level

processes:

Plan

Source

Make

Deliver

Return

The second level of SCOR, the configuration level

(process categories), contains more than 30

process categories

such as make to stock, make to order,

engineer to order, or production execution.

These process categories can be used to

configure a companys supply chain

Companies implement their operations strategy

through the configuration they choose for their

supply chain.

Plan

P1-Plan supply chain

P2-Plan Source

P3-Plan Make

P4-Plan Deliver

P5-Plan Return

Source

S1-Source stocked product

S2-Source make-to-order products

S3-Source Engineer-to-order products

Make

M1-Make-to-stock

M2-Make-to-order

M3-Engineer-to-order

Deliver

D1-Deliver-stocked product

D2-Deliver Make-to-order

D3-Deliver Engineer-to-order

Return

DR1-Deliver Return Defective product

DR2-DR MRO Product (maintenance repair

overall product)

DR3-DR Excess Product

SR1-Source Return Defective product

SR2-SR MRO Product

SR3-SR Excess Product

The third SCOR level, the process element level

(decomposed processes), is used to fine tune the

operations of a company. It consists of the

following:

Process element definitions

Process element information inputs and outputs

Process performance metrics

Best practices

System capabilities necessary to support best

practices

Systems/ tools to be used

S3 Source Engineer-to-Order

Schedule product

deliveries

Receive

product

Verify

product

Transfer

product

Authorize

support

payment

European

RM Supplier

Key Other

RM Supplier

S2

S1

M2

M1

D2

D1

S2

S1

M1 D1 S1 D1 S1

RM Suppliers

ALPHA

Alpha Regional

Warehouse

Customer

A SCOR thread diagram of a simple supply chain process

Performance

Attribute

Performance Attribute Definition Level 1 Metric

Supply Chain

Delivery

Reliability

The performance of the supply chain

in delivering: the correct product , to

the correct place, at the correct time,

in the correct condition and

packaging, in the correct quantity,

with the correct documentation, to

the correct customer.

Delivery Performance

Fill Rates

Perfect Order

Fulfillment

Supply Chain

Responsiveness

The velocity at which a supply chain

provides products to the customer.

Order Fulfillment Lead

Times

Supply Chain

Flexibility

The agility of a supply chain in

responding to marketplace changes

to gain or maintain competitive

advantage.

Supply Chain Response

Time

Production Flexibility

C

u

s

t

o

m

e

r

F

a

c

i

n

g

A

t

t

r

i

b

u

t

e

s

SCOR performance attributes and Level 1 metrics

Supply Chain

Costs

The costs associated with

operating the supply chain.

Cost of Goods Sold

Total Supply Chain

Management Costs

Value Added

Productivity

Warranty/ Returns

Processing Costs

Supply Chain

Asset

Management

Efficiency

The effectiveness of an

organization in managing assets

to support demand satisfaction.

This includes the management

of all assets: fixed and working

capital.

Cash-to-Cash Cycle Time

Inventory Days of Supply

Asset turns

I

n

t

e

r

n

a

l

F

a

c

i

n

g

A

t

t

r

i

b

u

t

e

s

SCOR performance attributes and Level 1

metrics

Companies implement their supply chain

solution on level 4 (or even more detailed

levels)

Level four, or the implementation level

(decomposed sub process), defines practices

to achieve competitive advantage and to

adapt to changing business conditions

This level is company specific and not in the

scope of SCOR

APSQ :American Productivity &

Quality Center

APQC : Who are they?

APQC is a member-based, non-profit organization

Founded in 1977

Started with donations from 100 corporations

Non-profit, tax-exempt 501(c)(3)

Serves more than 500 organizations around the

world

32-year reputation founded on integrity and the

support of rapid innovation through

Process improvement and

measurement

Best practice research and

implementation

Knowledge capture, transfer, and

reuse

Why do Organizations use APQCs

Process Classification Framework

define the processes that need to be improved,

benchmark internally and with other organizations,

organize improvement efforts,

align IT rollouts and updates for similar processes

across the organization,

discuss organizational performance using the same

terminology across business units and departments,

better understand how their business works, and

organize enterprise content and knowledge.

PROCESS CLASSIFICATION FRAMEWORK : 12

enterprise level categories

1. Develop Vision and Strategy

2. Design and Manage Products and Services

3. Market and Sell Products and Services

4. Deliver Products and Services

5. Manage Customer Service

6. Develop and Manage Human Capital

7. Manage Information Technology

8. Manage Financial Resources

9. Acquire, Construct, and Manage Property

10. Manage Environmental Health and Safety

11. Manage External Relationships

12. Manage Knowledge, Improvement, and Change

Understanding the Numbering

INTERPRETING THE PCF

Category: The highest level within the PCF is indicated by whole

numbers (e.g., 8.0 and 9.0)

Process Group: Items with one decimal numbering (e.g., 8.1

and 9.1)

are considered a process group.

Process: Items with two decimal numberings (e.g., 8.1.1 and

9.1.2)

are considered processes.

Activity: Items with three decimal numbering (e.g. 8.3.1.1 and

9.1.1.1)

are considered activities within a process

One Example

1.0 Develop Vision and Strategy (10002)

1.1 Define the business concept and long-term

vision (10014)

1.1.1 Assess the external environment (10017)

1.1.1.1 Analyze and evaluate competition (10021)

1.1.1.2 Identify economic trends (10022)

1.1.1.3 Identify political and regulatory issues (10023)

1.1.1.4 Assess new technology innovations (10024)

1.1.1.5 Analyze demographics (10025)

1.1.1.6 Identify social and cultural changes (10026)

1.1.1.7 Identify ecological concerns (10027)

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 10515-0413-4200 Operacion PDFDocument345 pages10515-0413-4200 Operacion PDFSaul Tula100% (4)

- DC Power Potential Applications.Document24 pagesDC Power Potential Applications.siva anandPas encore d'évaluation

- Case Solutions For Case Studies in Finance Managing For Corporate Value Creation 6th Edition by BrunerDocument12 pagesCase Solutions For Case Studies in Finance Managing For Corporate Value Creation 6th Edition by BrunerGregory Wilson50% (2)

- SAP Product CostingDocument2 pagesSAP Product CostingRona RussellPas encore d'évaluation

- Ottlite Executive Desk Lamp ManualDocument1 pageOttlite Executive Desk Lamp ManualVlad75% (4)

- Quality Part 1-Subcontractor Quality Management Requirements AIRTELDocument26 pagesQuality Part 1-Subcontractor Quality Management Requirements AIRTELAnonymous KKtWOIKMA6100% (1)

- ADAS Automotive EngineeringDocument15 pagesADAS Automotive EngineeringAman PatelPas encore d'évaluation

- 23 Things That They Don't Tell YouDocument8 pages23 Things That They Don't Tell YouGregory WilsonPas encore d'évaluation

- Group 3 Section B HRMDocument5 pagesGroup 3 Section B HRMGregory WilsonPas encore d'évaluation

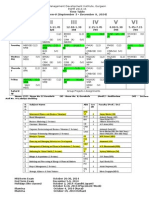

- Time Table For Term VDocument2 pagesTime Table For Term VGregory WilsonPas encore d'évaluation

- MonopolyDocument21 pagesMonopolyDhaval ShahPas encore d'évaluation

- Innovating For Shared ValueDocument16 pagesInnovating For Shared ValueGregory WilsonPas encore d'évaluation

- NikhilDocument2 pagesNikhilGregory WilsonPas encore d'évaluation

- Kelsey Manufacturing CompanyDocument7 pagesKelsey Manufacturing CompanyGregory WilsonPas encore d'évaluation

- CH 11Document51 pagesCH 11Gregory WilsonPas encore d'évaluation

- T4 PGPM 2013-15Document2 pagesT4 PGPM 2013-15Gregory WilsonPas encore d'évaluation

- Las Activities q2Document3 pagesLas Activities q2Anna Jane AdanPas encore d'évaluation

- Core Task 2 - Ayushi BoliaDocument3 pagesCore Task 2 - Ayushi BoliaAyushi BoliaPas encore d'évaluation

- LIENSON Company ProfileDocument8 pagesLIENSON Company ProfileShino Ping PoongPas encore d'évaluation

- Compiling A C Program - Behind The ScenesDocument2 pagesCompiling A C Program - Behind The ScenesKrishanu ModakPas encore d'évaluation

- GV75MG User Manual V1.01Document16 pagesGV75MG User Manual V1.01eduardoPas encore d'évaluation

- Sony Education Projectors 2019Document60 pagesSony Education Projectors 2019alanPas encore d'évaluation

- Cosco Fitness Catalogue 2020 - 17778246990Document144 pagesCosco Fitness Catalogue 2020 - 17778246990arpit99990Pas encore d'évaluation

- EIE412 - Lecture Modules & Contents (2021 - 22)Document18 pagesEIE412 - Lecture Modules & Contents (2021 - 22)sopuruPas encore d'évaluation

- Unit 2Document17 pagesUnit 2PRASATH RPas encore d'évaluation

- Memorandum Data PrintDocument51 pagesMemorandum Data PrintGabyyOstosPicon0% (1)

- LexionAir Flyer UKDocument2 pagesLexionAir Flyer UKficom123Pas encore d'évaluation

- Professional Radio: User GuideDocument30 pagesProfessional Radio: User GuideTraci MorganPas encore d'évaluation

- Panel Coker BP PDFDocument2 pagesPanel Coker BP PDFAlejandro José Poveda GuevaraPas encore d'évaluation

- TractorsDocument12 pagesTractorsBekalu DanielPas encore d'évaluation

- Planning Guide PMP450i CambiumDocument237 pagesPlanning Guide PMP450i CambiumPedro MarroquinPas encore d'évaluation

- DELTA IA-SI DIAView C EN 20190517 web-SCADADocument20 pagesDELTA IA-SI DIAView C EN 20190517 web-SCADAchandra mouliPas encore d'évaluation

- I'm About To Reduce My Cost For Launching ProductsDocument1 pageI'm About To Reduce My Cost For Launching ProductsJose Luis FloresPas encore d'évaluation

- SKMW30 & DKMW30: 30W 1"x1" Package DC-DC Regulated ConverterDocument5 pagesSKMW30 & DKMW30: 30W 1"x1" Package DC-DC Regulated ConverterEng SamPas encore d'évaluation

- Grades of Reinforcing SteelDocument15 pagesGrades of Reinforcing Steelshuckss taloPas encore d'évaluation

- 1298Document136 pages1298Iker BasqueAdventurePas encore d'évaluation

- EE610: CMOS Analog EE610: CMOS Analog Circuits: L3: MOS Models-3Document47 pagesEE610: CMOS Analog EE610: CMOS Analog Circuits: L3: MOS Models-3Epili Rajkiran SarabaPas encore d'évaluation

- SP - 15180 - 180605 TurbinaDocument457 pagesSP - 15180 - 180605 Turbinajavier rangelPas encore d'évaluation

- DORNA EPS-B1 Servo User Manual V1.11 OcrDocument191 pagesDORNA EPS-B1 Servo User Manual V1.11 Ocrnapo3tPas encore d'évaluation

- Rishabh ResumeDocument4 pagesRishabh ResumeRishabh BhatiaPas encore d'évaluation