Académique Documents

Professionnel Documents

Culture Documents

Valve Sizing Selection 1231875721684103 3

Transféré par

lutfi awnTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Valve Sizing Selection 1231875721684103 3

Transféré par

lutfi awnDroits d'auteur :

Formats disponibles

Valve Sizing & Selection

Ranjeet Kumar

M.Tech Chemical

08 Jan 09 Ranjeet Kr. 2

Steps in Sizing

Science with many rules of thumb

Define the System.

Maximum Pressure Drop for the Valve.

Calculate the valve Characteristics (C

v

).

Preliminary valve selection.

Check the C

v

and stroke percentage at minimum flow.

Check the gain across applicable flow rates.

08 Jan 09 Ranjeet Kr. 3

Define the System Key Variables

Total pressure drop,

Design flow,

Operating flow,

Minimum flow,

Pipe diameter,

Specific gravity

08 Jan 09 Ranjeet Kr. 4

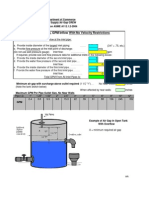

Maximum Allowable Pressure Drop

The usual rule of thumb is that a valve should be designed

to use 10-15% of the total pressure drop or 10 psi,

whichever is greater.

Investigate the Pump & its maximum available head.

MAPD = NPHSA NPSHR.

Trade off-

larger pressure drops increase the pumping cost (operating) &

smaller pressure drops increase the valve cost because a

larger valve is required (capital cost).

08 Jan 09 Ranjeet Kr. 5

Valve Characteristics C

v

Note Check thumb rules before referring valve chart or

characteristic curve.

08 Jan 09 Ranjeet Kr. 6

Preliminary Valve Selection

Thumb Rules

Never use a valve that is less than half the pipe size.

Avoid using the lower 10% and upper 20% of the valve stroke.

The valve is much easier to control in the 10-80% stroke

range.

Select the type of valve & use its corresponding valve

chart.

Valve chart is supplied by manufacturer.

Check C

v

for minimum flow with selected size of valve &

check for minimum flow should not fall below 10% of valve

stroke.

08 Jan 09 Ranjeet Kr. 7

Valve Chart / Characteristics Curve

Table 1 Chart for Equal Percentage Globe Valve

08 Jan 09 Ranjeet Kr. 8

Gain across applicable flow rates

Gain #1 = 85/38 = 2.2

Gain #2 = 40/12 = 3.3

Acceptance criteria :

Gain should never be less than 0.5.

Gain#2 Gain#1 < 50% of (max of Gain#1 or Gain#2)

Here 0.5 (3.3) = 1.65

and 3.3 - 2.2 = 1.10. Since 1.10 is less than 1.65 so it can be a

choice

Flow

(GPM)

Stroke

(%)

Change in

Flow(GPM)

Change in

stroke (%)

25 35 110 25

= 85

73 35 =

38

110 73

150 85 150-110

= 40

85 73 =

12

08 Jan 09 Ranjeet Kr. 9

Choke Flow F

L

At max restriction flow rate is max & pressure is

minimum.

Vapor bubbles flashes if liquid pressure falls below Vapor

Pressure of liquid.

Bubbles has (a) no effect on flow, (b) increases pressure

drop across valve, (c) cavitations

Decreased efficiency

Noise

Vibration

Material loss sand blasted surface

F

L

checking is recommended when difference in Max & Min

flow exceed 90% of Max flow.

08 Jan 09 Ranjeet Kr. 10

Basic Valve Types mechanical characteristics

Ball valves;

Diaphragm valves;

Gate valves;

Globe valves;

Butterfly valves;

Plug valves;

Check valve;

Safety/relief valve

08 Jan 09 Ranjeet Kr. 11

Basic Valve Types control / openness

Equal Percentage: equal increments of valve travel produce

an equal percentage in flow change.

Large changes in pressure drop are expected

Minimum pressure drop due to valve

In temperature & pressure control loop

Linear: valve travel is directly proportional to the valve stoke

In liquid level or flow loops

Pressure drop across valve is almost constant.

Quick opening: large increase in flow with a small change in

valve stroke

For frequent on-off services

Instantly large flow is needed.

08 Jan 09 Ranjeet Kr. 12

Gate Valve

Best Suited Control: Quick Opening

Recommended Uses:

Fully open/closed, non-throttling

Infrequent operation

Minimal fluid trapping in line

Advantages:

High capacity

Tight shut off, Low cost, Little resistance to flow

Disadvantages:

Poor control

Cavitate at low pressure drops

Cannot be used for throttling

Applications: Oil, Gas, Air, Slurries, Heavy liquids, Steam, Non-

condensing gases, and Corrosive liquids

08 Jan 09 Ranjeet Kr. 13

Globe valve

Best Suited Control: Linear and Equal percentage

Recommended use-

Throtteling services/flow regulation

Frequent operation

Advantages:

Efficient throttling

Accurate flow control valves

Available in multiple ports

Disadvantages:

High pressure drop

More expensive than other

Applications: Liquids, vapors, gases, corrosive substances,

slurries

08 Jan 09 Ranjeet Kr. 14

Ball valve

Best suited control Quick opening linear.

Recommended uses

Fully open/closed limited throttling

Higher temperature fluids

Advantages

Low cost

High capacity

Low leakage & maintenance

Tight sealing with low torque

Disadvantages

Poor throttling characteristics

Prone to cavitation

Applications Most Liquids, high temperatures, slurries

08 Jan 09 Ranjeet Kr. 15

Butterfly valve

Best Suited Control: Linear, Equal percentage

Recommended Uses:

Fully open/closed or throttling services

Frequent operation

Minimal fluid trapping in line

Advantages:

Low cost and maint.

High capacity

Good flow control

Low pressure drop

Disadvantages

High torque required to control

Prone to cavitation at lower flows

Applications: Liquids, gases, slurries, liquids with suspended

solids

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Air Compressor Curve ToolDocument14 pagesAir Compressor Curve Toollutfi awnPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDocument11 pagesHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Bitumen Upgrading Shell Canada LimitedDocument301 pagesBitumen Upgrading Shell Canada Limitedlutfi awnPas encore d'évaluation

- Liquid Pressure DropDocument8 pagesLiquid Pressure Droplutfi awnPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Document30 pagesLiquid and Gas Velocity Gas Compressibility and Renolds Number.lutfi awnPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- E10 Blending Study Final ReportDocument107 pagesE10 Blending Study Final Reportlutfi awnPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- 04 Jet Mixing Design ApplicationsDocument6 pages04 Jet Mixing Design Applicationslutfi awnPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Air Compressor Tools APODocument7 pagesAir Compressor Tools APOlutfi awnPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hydraulic Calculations MKIIDocument8 pagesHydraulic Calculations MKIIlutfi awnPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Lubricating Oils: Test Methods Test MethodsDocument32 pagesLubricating Oils: Test Methods Test MethodsCorina StanculescuPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Viscosity-Classifications Astm d2422Document8 pagesViscosity-Classifications Astm d2422Francisco TipanPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Plumbing H 2 Osu Pair Gap CalculatorDocument9 pagesPlumbing H 2 Osu Pair Gap Calculatorlutfi awnPas encore d'évaluation

- Astm D 86Document8 pagesAstm D 86lutfi awnPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Mixer Tank Jet Pumps Gea - tcm11 34889Document4 pagesMixer Tank Jet Pumps Gea - tcm11 34889Venodaren VelusamyPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Fonds Bombes - Surface MouilleeDocument3 pagesFonds Bombes - Surface MouilleesegunoyesPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Petroleum Average Conversion FactorsDocument2 pagesPetroleum Average Conversion Factorslutfi awnPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 2011 Chaudhuri U R Fundamentals of Petroleum and PetrochDocument33 pages2011 Chaudhuri U R Fundamentals of Petroleum and Petrochlutfi awnPas encore d'évaluation

- Water Demand Calculation 1Document2 pagesWater Demand Calculation 1lutfi awnPas encore d'évaluation

- Calculation ExampelDocument21 pagesCalculation Exampellutfi awnPas encore d'évaluation

- H2S RiskDocument6 pagesH2S Risklutfi awnPas encore d'évaluation

- Valve Sizing Worksheet InstructionsDocument11 pagesValve Sizing Worksheet Instructionslutfi awnPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- PumpDocument31 pagesPumpkajale_shrikant2325Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- PCVDocument2 pagesPCVlutfi awnPas encore d'évaluation

- Conversion of Milligrams Per Cubic Meter To PPMDocument2 pagesConversion of Milligrams Per Cubic Meter To PPMlutfi awnPas encore d'évaluation

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationlutfi awn100% (1)

- Gas TurbDocument10 pagesGas Turblutfi awnPas encore d'évaluation

- Gas ReservesDocument8 pagesGas Reserveslutfi awnPas encore d'évaluation

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- GOR Vs GVFDocument8 pagesGOR Vs GVFlutfi awnPas encore d'évaluation

- Centrifugalcompressorpower Si UnitsDocument4 pagesCentrifugalcompressorpower Si UnitsJoshi DhvanitPas encore d'évaluation

- Pump CurvesDocument8 pagesPump CurvesKrishna Chaitanya KalagaPas encore d'évaluation

- Lem Lel eDocument4 pagesLem Lel eHussenuPas encore d'évaluation

- What Is Cavitation in Hydraulic Pump & How To Prevent ItDocument2 pagesWhat Is Cavitation in Hydraulic Pump & How To Prevent ItbhushanPas encore d'évaluation

- Fisher® Easy-E® Control ValvesDocument12 pagesFisher® Easy-E® Control ValvesAhmed KhairyPas encore d'évaluation

- Centrifugal Pump Complete Lab ReportDocument23 pagesCentrifugal Pump Complete Lab Reportriz48577% (61)

- SI FM 2e SM Chap14Document78 pagesSI FM 2e SM Chap14ttaerack100% (1)

- 4 Forensic Engineering - Metallurgical Failure AnalysisDocument30 pages4 Forensic Engineering - Metallurgical Failure AnalysisJOSE ANTONIO FRAUSTO ESPARZAPas encore d'évaluation

- Installation, Operation and Maintenance Manual FOR De-Watering PumpDocument18 pagesInstallation, Operation and Maintenance Manual FOR De-Watering PumpsatfasPas encore d'évaluation

- Fiche Technique ClapetDocument5 pagesFiche Technique ClapetIheb HammiPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- TLV Powertrap GP5Document8 pagesTLV Powertrap GP5Artur MkrtchyanPas encore d'évaluation

- Squeeze Film BearingDocument6 pagesSqueeze Film Bearingsuresh krishnaPas encore d'évaluation

- Vane de Control Nivel Cu PlutitorDocument2 pagesVane de Control Nivel Cu Plutitorsergethomas2010Pas encore d'évaluation

- Advanced Experimental and Numerical Techniques For Cavitation-Erosion (Chahine 2014)Document407 pagesAdvanced Experimental and Numerical Techniques For Cavitation-Erosion (Chahine 2014)daviqperezPas encore d'évaluation

- Flow Meters PDFDocument2 pagesFlow Meters PDFLyndsey Baker100% (1)

- Reflex Pressure Vessels Design and CalculationDocument52 pagesReflex Pressure Vessels Design and CalculationcsharpplusPas encore d'évaluation

- Operation and Maintenance ManualDocument39 pagesOperation and Maintenance Manualhdf17Pas encore d'évaluation

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevPas encore d'évaluation

- IWAKI MX-250,505 ManualDocument44 pagesIWAKI MX-250,505 Manualtayakee_jernPas encore d'évaluation

- Pump - Suction Side System DesignDocument9 pagesPump - Suction Side System Designashumishra007100% (1)

- Data Sheet Caudalimetro CoriolisDocument198 pagesData Sheet Caudalimetro CoriolisMarco CetiPas encore d'évaluation

- Problem Solving - Positive Displacement PumpsDocument46 pagesProblem Solving - Positive Displacement PumpsMatthieu33% (3)

- Injection Brochure MC-BauchemieDocument28 pagesInjection Brochure MC-BauchemieAlinMariciucPas encore d'évaluation

- Centrifugal Pumps BasicsDocument23 pagesCentrifugal Pumps BasicsalibahcesarayPas encore d'évaluation

- 6 Boiler Feedwater PumpsDocument20 pages6 Boiler Feedwater PumpsCristhian Garcia VillarroelPas encore d'évaluation

- Liquid Ring Vacuum Pumps & Compressors - Tech Details - Sterling Fluid Systems GroupDocument71 pagesLiquid Ring Vacuum Pumps & Compressors - Tech Details - Sterling Fluid Systems Groupsl1828100% (1)

- Chapter-7 Turbine and Governing SpecificationsDocument24 pagesChapter-7 Turbine and Governing Specificationshangmann169Pas encore d'évaluation

- EngineerDocument11 pagesEngineerphaindikaPas encore d'évaluation

- Cat Piston Pump Service ManualDocument8 pagesCat Piston Pump Service ManualMiguel Angel Santos PintadoPas encore d'évaluation

- Pumps Fans BlowersDocument39 pagesPumps Fans BlowersAnant Joshi100% (2)

- Bill Hakim (Error at Biblio)Document20 pagesBill Hakim (Error at Biblio)Bill HakimPas encore d'évaluation