Académique Documents

Professionnel Documents

Culture Documents

Composites

Transféré par

singh011sandeepDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Composites

Transféré par

singh011sandeepDroits d'auteur :

Formats disponibles

Ken Youssefi Mechanical Engineering Dept.

1

Ken Youssefi Mechanical Engineering Dept.

2

What is a composite Material?

A broad definition of composite is: Two or more chemicall distinct

materials which when combined ha!e impro!ed properties o!er

the indi!idual materials. "omposites could be natural or snthetic.

#ood is a good e$ample of a natural composite% combination of cellulose fiber

and lignin. The cellulose fiber pro!ides strength and the lignin is the &glue& that

bonds and stabili'es the fiber.

The ancient Egptians manufactured composites( Adobe bric)s are a good

e$ample. The combination of mud and straw forms a composite that is

stronger than either the mud or the straw b itself.

*amboo is a !er efficient wood composite structure. The components

are cellulose and lignin% as in all other wood% howe!er bamboo is

hollow. This results in a !er light et stiff structure. "omposite fishing

poles and golf club shafts cop this natural design.

Ken Youssefi Mechanical Engineering Dept.

+

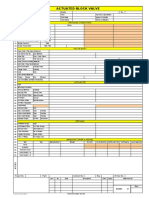

Composites

Composites are combinations of two materials in which one of the material is

called the reinforcing phase% is in the form of fibers% sheets% or particles% and

is embedded in the other material called the matrix phase.

Tpicall% reinforcing materials are strong with low densities while the

matri$ is usuall a ductile or tough material. ,f the composite is designed

and fabricated correctl% it combines the strength of the reinforcement with

the toughness of the matri$ to achie!e a combination of desirable

properties not a!ailable in an single con!entional material.

-einforcement: fibers

.lass

"arbon

/rganic

*oron

"eramic

Metallic

Matri$ materials

0olmers

Metals

"eramics

,nterface

*onding

surface

Components of composite materials

Ken Youssefi Mechanical Engineering Dept.

1

Composites

The essence of the concept of composites is that the load is applied

o!er a large surface area of the matri$. Matri$ then transfers the load

to the reinforcement% which being stiffer% increases the strength of the

composite. ,t is important to note that there are man matri$ materials

and e!en more fiber tpes% which can be combined in countless was

to produce 2ust the desired properties.

,n the 3nited 4tates% composites manufacturing is a 25 billion dollar

a ear industr. There are about 6777 composites related

manufacturing plants and materials distributors across the 3.4. The

industr emplos more than 2+5%777 people. An additional 257%777

people are emploed in businesses that support the composites

industr% including materials suppliers% e8uipment !endors% and other

support personnel.

About 97: of all composites produced are comprised of glass fiber and

either polester or !inlester resin. "omposites are broadl )nown as

reinforced plastics.

Ken Youssefi Mechanical Engineering Dept.

5

Composites

Fibers

Matrix materials

Ken Youssefi Mechanical Engineering Dept.

6

Composites Polymer Matrix

0olmer matri$ composites ;0M"< and fiber reinforced plastics ;=-0<

are referred to as Reinforced Plastics. "ommon fibers used are

glass ;.=-0<% graphite ;"=-0<% boron% and aramids ;Ke!lar<. These

fibers ha!e high specific strength ;strength>to>weight ratio< and specific

stiffness ;stiffness>to>weight ratio<

Matri$ materials are usuall thermoplastics or thermosets? polester%

epo$ ;@7: of reinforced plastics<% fluorocarbon% silicon% phenolic.

Ken Youssefi Mechanical Engineering Dept.

A

Composites Polymer Matrix

Reinforcing fibers

.lass B most common and the least e$pensi!e% high strength% low stiffness

and high densit. .=-0 consists +7>67: glass fibers b !olume.

B highest specific strength% toughest fiber% undergoes

plastic deformation before fracture% but absorbs moisture% and is e$pensi!e.

Aramids ;Ke!lar<

B boron fibers consist of boron deposited on tungsten fibers% high

strength and stiffness in tension and compression% resistance to high

temperature% but the are hea! and e$pensi!e.

*oron

B more e$pensi!e

than glass fibers% but lower densit and higher stiffness with high strength.

The composite is called carbon>fiber reinforced plastic ;"=-0<.

.raphite ;99: carbon< or "arbon ;@7>95: carbon<

The average diameter of fibers used is usually less than .0004 inch (.01 mm.

The tensile strength of a glass fiber could be as high as !"0 #si (bul# glass

$

u

% "&1"0 #si

Ken Youssefi Mechanical Engineering Dept.

@

Properties of Reinforced Plastics

The mechanical properties of reinforced plastics !ar with the )ind%

shape% relati!e !olume% and orientation of the reinforcing material% and

the length of the fibers.

Effect of tpe% length% : !olume% and orientation of fibers in a fiber

reinforced plastic ;nlon<

Ken Youssefi Mechanical Engineering Dept.

9

Applications of Reinforced Plastics

0henolic as a matri$ with asbestos fibers was the first reinforced plastic

de!eloped. ,t was used to build an acid>resistant tan). ,n 1927s it was

=ormica% commonl used as counter top.% in 1917s boats were made of

fiberglass. More ad!anced de!elopments started in 19A7s.

Tpicall% although not alwas% consumer composites in!ol!e products that

re8uire a cosmetic finish% such as boats% recreational !ehicles% bathwear%

and sporting goods. ,n man cases% the cosmetic finish is an in>mold

coating )nown as gel coat.

Consumer Composites

A wide !ariet of composites products are used in industrial applications% where

corrosion resistance and performance in ad!erse en!ironments is critical.

.enerall% premium resins such as isophthalic and !inl ester formulations are

re8uired to meet corrosion resistance specifications% and fiberglass is almost

alwas used as the reinforcing fiber. ,ndustrial composite products include

underground storage tan)s% scrubbers% piping% fume hoods% water treatment

components% pressure !essels% and a host of other products.

'ndustrial Composites

Ken Youssefi Mechanical Engineering Dept.

17

Applications of Reinforced Plastics

This sector of the composites industr is characteri'ed b the use of

e$pensi!e% high>performance resin sstems and high strength% high stiffness

fiber reinforcement. The aerospace industr% including militar and

commercial aircraft of all tpes% is the ma2or customer for ad!anced

composites.

These materials ha!e also been adopted for use in sporting goods% where

high>performance e8uipment such as golf clubs% tennis rac)ets% fishing poles%

and archer e8uipment% benefits from the light weight B high strength offered

b ad!anced materials. There are a number of e$otic resins and fibers used

in ad!anced composites% howe!er% epo$ resin and reinforcement fiber of

aramid% carbon% or graphite dominates this segment of the mar)et.

(dvanced Composites

Ken Youssefi Mechanical Engineering Dept.

11

Composites Metal Matrix

The metal matri$ composites offer higher modulus of elasticit%

ductilit% and resistance to ele!ated temperature than polmer matri$

composites. *ut% the are hea!ier and more difficult to process.

Ken Youssefi Mechanical Engineering Dept.

12

Composites Ceramic Matrix

"eramic matri$ composites ;"M"< are used in applications where

resistance to high temperature and corrosi!e en!ironment is desired.

"M"s are strong and stiff but the lac) toughness ;ductilit<

Matri$ materials are usuall silicon carbide% silicon nitride and aluminum

o$ide% and mullite ;compound of aluminum% silicon and o$gen<. The

retain their strength up to +777

o

=.

=iber materials used commonl are carbon and aluminum o$ide.

Applications are in 2et and automobile engines% deep>see mining%

cutting tools% dies and pressure !essels.

Ken Youssefi Mechanical Engineering Dept.

1+

Ken Youssefi Mechanical Engineering Dept.

11

Application of Composites

0edestrian bridge in

Denmar)% 1+7 feet long

;199A<

4wedish Ca!% 4tealth

;2775<

Dance ArmstrongEs 2>lb.

Tre) bi)e% 2771 Tour de

=rance

Ken Youssefi Mechanical Engineering Dept.

15

Advantages of Composites

"omposites ha!e a higher specific strength than man other materials. A

distinct ad!antage of composites o!er other materials is the abilit to use

man combinations of resins and reinforcements% and therefore custom

tailor the mechanical and phsical properties of a structure.

)igher $pecific $trength (strength&to&*eight ratio

The lowest properties for each material are associated with simple manufacturing

processes and material forms ;e.g. spra la>up glass fibre<% and the higher

properties are associated with higher technolog manufacture ;e.g. autocla!e

moulding of unidirectional glass fibre<% the aerospace industr.

Ken Youssefi Mechanical Engineering Dept.

16

Advantages of Composites

"omposites ha!e an ad!antage o!er other materials because the can be

molded into comple$ shapes at relati!el low cost. This gi!es designers the

freedom to create an shape or configuration. *oats are a good e$ample of

the success of composites.

+esign flexibility

"omposites products pro!ide long>term resistance to se!ere chemical and

temperature en!ironments. "omposites are the material of choice for

outdoor e$posure% chemical handling applications% and se!ere en!ironment

ser!ice.

Corrosion ,esistance

Ken Youssefi Mechanical Engineering Dept.

1A

Advantages of Composites

/ne reason the composites industr has been successful is because of

the low relati!e in!estment in setting>up a composites manufacturing

facilit. This has resulted in man creati!e and inno!ati!e companies in

the field.

-o* ,elative 'nvestment

"omposite products and structures ha!e an e$ceedingl long life span.

"oupled with low maintenance re8uirements% the longe!it of composites is a

benefit in critical applications. ,n a half>centur of composites de!elopment%

well>designed composite structures ha!e et to wear out.

+urability

,n 191A the 3.4. "oast .uard built a series of fort>foot patrol boats%

using polester resin and glass fiber. These boats were used until the

earl 19A7s when the were ta)en out of ser!ice because the design was

outdated. E$tensi!e testing was done on the laminates after

decommissioning% and it was found that onl 2>+: of the original strength

was lost after twent>fi!e ears of hard ser!ice.

Ken Youssefi Mechanical Engineering Dept.

1@

Application of Composites in

Aircraft Industry

27: more fuel efficienc

and +5%777 lbs. lighter

Ken Youssefi Mechanical Engineering Dept.

19

Disadvantages of Composites

The e$perience and intuition gained o!er the ears about the beha!ior of

metallic materials does not appl to composite materials.

properties in composites !ar from point to point in the material. Most

engineering structural materials are homogeneous.

Composites are heterogeneous

Composites are highly anisotropic

The strength in composites !ar as the direction along which we measure

changes ;most engineering structural materials are isotropic<. As a result%

all other properties such as% stiffness% thermal e$pansion% thermal and

electrical conducti!it and creep resistance are also anisotropic. The

relationship between stress and strain ;force and deformation< is much

more complicated than in isotropic materials.

Ken Youssefi Mechanical Engineering Dept.

27

Disadvantages of Composites

"omposites materials are difficult to inspect with con!entional ultrasonic%

edd current and !isual CD, methods such as radiograph.

American Airlines =light 5@A% bro)e apart o!er

Cew Yor) on Co!. 12% 2771 ;265 people died<.

Airbus A+77Es 2A>foot>high tail fin tore off.

Much of the tail fin% including the so>called

tongues that fit in groo!es on the fuselage and

connect the tail to the 2et% were made of a

graphite composite. The plane crashed

because of damage at the base of the tail that

had gone undetected despite routine

nondestructi!e testing and !isual inspections.

Ken Youssefi Mechanical Engineering Dept.

21

Disadvantages of Composites

,n Co!ember 1999% AmericaEs "up boat FYoung AmericaG bro)e in two due

to debonding faceHcore in the sandwich structure.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Earthing of High Voltage Electrical Apparatus For The Protection of PersonnelDocument56 pagesEarthing of High Voltage Electrical Apparatus For The Protection of PersonnelDavoPas encore d'évaluation

- Prepared For: Puan Khair Shakira Bustamam Prepared By: Anis Shahireen Effah Atiqah Fatinah Husna Nur FatinDocument9 pagesPrepared For: Puan Khair Shakira Bustamam Prepared By: Anis Shahireen Effah Atiqah Fatinah Husna Nur FatinFatinah Husna100% (2)

- 001 GetStarted EditorManual PDFDocument618 pages001 GetStarted EditorManual PDFLuka SPas encore d'évaluation

- Self PublishingDocument84 pagesSelf PublishingFrancesco CusumanoPas encore d'évaluation

- MCQs DOMDocument5 pagesMCQs DOMyuvraj PrajapatiPas encore d'évaluation

- Commander SK Size 2 To 6 Getting Started GuideDocument80 pagesCommander SK Size 2 To 6 Getting Started GuidesunhuynhPas encore d'évaluation

- Guidelines For Noise Labelling and Emission Limits of Outdoor Sources 2nd Edition 2007Document30 pagesGuidelines For Noise Labelling and Emission Limits of Outdoor Sources 2nd Edition 2007sl1828Pas encore d'évaluation

- Et 321 06-23-15Document2 pagesEt 321 06-23-15Shishan AhmadPas encore d'évaluation

- NI Tutorial 3921 enDocument5 pagesNI Tutorial 3921 encasa4presidentPas encore d'évaluation

- 0111 Tension Load Cell Datasheet enDocument2 pages0111 Tension Load Cell Datasheet enJosipaPas encore d'évaluation

- Devops Training in Bangalore - Devops Training in Bangalore MarathahalliDocument8 pagesDevops Training in Bangalore - Devops Training in Bangalore MarathahalliitrainPas encore d'évaluation

- Manual en Español Kip 3000Document2 pagesManual en Español Kip 3000Ja De OstiaPas encore d'évaluation

- DSS2060D Actuated Block Valve DatasheetDocument1 pageDSS2060D Actuated Block Valve Datasheetkrishna kumarPas encore d'évaluation

- Export Ssrs Report To PDF LandscapeDocument2 pagesExport Ssrs Report To PDF LandscapeVictoriaPas encore d'évaluation

- Slack Byte and Structure Padding in StructuresDocument3 pagesSlack Byte and Structure Padding in StructureskrishnanandPas encore d'évaluation

- Air Intake AccessoriesDocument42 pagesAir Intake AccessoriesMark CarterPas encore d'évaluation

- Importance of Writing Thesis Skills in EnglishDocument3 pagesImportance of Writing Thesis Skills in Englishdanial 96Pas encore d'évaluation

- Proposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsDocument11 pagesProposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsShipra MishraPas encore d'évaluation

- ASHIDA Product CatalogueDocument4 pagesASHIDA Product Cataloguerahulyadav2121545Pas encore d'évaluation

- Intelligent Network: © Bharat Sanchar Nigam LimitedDocument50 pagesIntelligent Network: © Bharat Sanchar Nigam LimitedshridonPas encore d'évaluation

- Wireless Sensor Network Using Zigbee: Nidhi Patel, Hiren Kathiriya, Arjav BavarvaDocument5 pagesWireless Sensor Network Using Zigbee: Nidhi Patel, Hiren Kathiriya, Arjav BavarvaDavidleonardo GalindoPas encore d'évaluation

- Wind Load On Cable TraysDocument10 pagesWind Load On Cable TraysAaron EasleyPas encore d'évaluation

- Legendary Units 1.1Document5 pagesLegendary Units 1.1Alejandro Sanchez GarciaPas encore d'évaluation

- A Comparative Study Between Multinational and Private IT Industries To Understand The Effect of Talent Management and Managerial Competencies On Employee Engagement Seema PanickerDocument369 pagesA Comparative Study Between Multinational and Private IT Industries To Understand The Effect of Talent Management and Managerial Competencies On Employee Engagement Seema PanickerMd Delowar Hossain MithuPas encore d'évaluation

- Chapter 3Document12 pagesChapter 3Adet the moralistaemPas encore d'évaluation

- D 2320 - 98 R03 RdizmjaDocument3 pagesD 2320 - 98 R03 RdizmjaEliKax!Pas encore d'évaluation

- EHP 200A 11-10-NardaDocument7 pagesEHP 200A 11-10-NardaDrughinsPas encore d'évaluation

- Architectural Design of Bangalore Exhibition CentreDocument24 pagesArchitectural Design of Bangalore Exhibition CentreVeereshPas encore d'évaluation

- Dyeing Process Guide: Types, Machines & OptimizationDocument3 pagesDyeing Process Guide: Types, Machines & OptimizationVipin Singh KandholPas encore d'évaluation

- Vs 235 Ag E: Api STD 602 Trim MaterialsDocument1 pageVs 235 Ag E: Api STD 602 Trim Materialskais rguiguiPas encore d'évaluation