Académique Documents

Professionnel Documents

Culture Documents

Rajasthan Transformer 1

Transféré par

Bijay KumarDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rajasthan Transformer 1

Transféré par

Bijay KumarDroits d'auteur :

Formats disponibles

A PRESENTATION ON PRACTICAL

TRAINING AT

RAJASTHAN TRANSFORMERS AND

SWITCHGEARS

PRESENTED BY

GAURAV JAIN

http://powerpointpresentationon.blogspot.com

INTRODUCTION OF COMPANY

1.HISTORY

1.COMPANY

PROFILE

1.PRODUCT

OF RTS

2.PRODUCTION

RANGE

3.CUSTOMERS

VARIOUS DEPARTMENT IN

RTS

Pressed steel Radiator (PSR) department

Wire drawn department

Paper Covering department

Core cutting department

Winding department

Transformer connection department

Assembly department

Tanking department

Tank fabrication department

Testing department

Transmission and conducted wire department

INTRODUCTION OF TRANSFORMER

1.DEFINATION

2.GENERAL

PRINCIPLE

3.DIFFERENT

TYPES

CLASSIFICATION OF TRANSFORMER

Number Of Phases

Measuring purpose

(INSTRUMENT TRANSFORMER)

Relative position of winding &

magnetic ckt

(ON THE BASIS OF

CONSTRUCTION)

Rating/service in field of power

system

(ON THE BASIS OF SERVICE

CONDITION)

PRESSED STEEL RADIATOR (PSR)

DEPARTMENT(MECHANICAL DEPARTMENT)

(A). Required for cooling

In RTS-

1.Pressed steel radiator

2.Elliptical tube radiator

(B).FOR PSR-

Use cold rolled sheet of

thickness 1.18mm to1.25

mm

WIRE DRAWN DEPARTMENT-I

(L.V.)

For L.V. winding,

first of all, thick

(Cu\Al) wires of

12 mm diameter

are converted

into thin round

wire and then

into flat

(rectangular)

wires through

different dies

available. After

this, required

strip is annealed

for removing

hardness.

WIRE DRAWN DEPARTMENT-II

(H.V.)

For H.V.

winding, the

thick (Cu\Al)

wires of 12

mm or 9.5 mm

diameter are

converted into

thin round

wires (3mm

diameter)

through 11 die

machine and

then into

round wires of

1.22 mm

diameter

through 7 die

machine.

Specification for windings

For 25 kva (cu wound) HV LV

Conductor size (bare) .60 mm 4.10 mm

Conductor size (with Insulation) .68 mm .40 mm

Turns per coils 2772 126

No. of layers 23 3

Turns per layer 120/121 42

Inner diameter 147mm 98mm

Outside diameter 183mm 125mm

Axial length 87mm 194mm

PAPER COVERING DEPARTMENT

1.Paper for

insulation

purpose

2.Covering

3.Double

insulation

4.Insulation

paper-Electrical

grade craft

paper

CORE CUTTING DEPARTMENT

1.MANUFACTURING

2. METAL USED

3.MECHANICAL DESIGN

4.TYPES

CORE PLATES & CONSTRUCTION

WINDING DEPARTMENT

A. Conductor utilized-

Al or Cu

B.There are four various

types of windings-

1. Disc Type

2. Helical Type

3. Crossover Type

4. Spiral Type

ASSEMBLY DEPARTMENT

Coil Assembly

1.Spacers

2. Oil Ducts

3.Winding

Connection

Transformer connection

department

1

.

1.Types of connection

2. Process of Connection

In transformer

TANKING DEPARTMENT

complete job is dried in a

thermostatically controlled

oven at 105 C.

the megger insulation test

and the turn ratio tests

Lugs fitting and job fitting

inside the tank

gas kit and bushings are

fitted

insulating transformer oil is

filled in the tank

TRANSFORMER OIL & COOLING

SYSTEM

MAIN FUNCTION

ADVANTAGE

PROPERTIES OF TRANSFORMER OIL

CHEMICAL TESTING OFTRANSFORMER

OIL

TYPES OF COOLING ARRANGEMENTS

IMPORTANT STANDARD FITTING &TANK

FABRICATION DEPARTMENT

1.Conservator

2.Breather

3.Explosion vent

4.Buchholz relay

5.Bushing

6.Tapping and tap changing

switch

7.Oil temperature indicator

8.Thermometer pocket

TESTING DEPARTMENT

TYPE TEST

ROUTINE TEST

(A)PARAMETRIC TEST

(B) Di Electric Test

SPECIAL TEST

conducted wire manufacturing

department (L.V.)

1.Principle

2.working

conducted wire manufacturing

department (H.V.)

Transmission wire manufacturing

department

THANK YOU

QUERIES!

Vous aimerez peut-être aussi

- Dry Type VoltampDocument18 pagesDry Type VoltampjaikolangaraparambilPas encore d'évaluation

- 2020.8.5 Manual Book For Auto Steel Cage Welding Machine Operation ManualDocument21 pages2020.8.5 Manual Book For Auto Steel Cage Welding Machine Operation Manualarifhannasy3100% (1)

- 10mm Square Water-Proof (Snap-In Type)Document5 pages10mm Square Water-Proof (Snap-In Type)shyhuPas encore d'évaluation

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuPas encore d'évaluation

- Transformer PDFDocument35 pagesTransformer PDFjiguparmar1516100% (2)

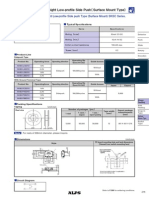

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuPas encore d'évaluation

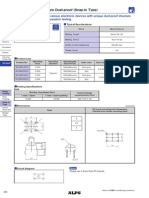

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocument4 pages12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuPas encore d'évaluation

- DM WaterDocument61 pagesDM WaterAmitraja DasPas encore d'évaluation

- Tall Height (4.3mm and 5.0mm) and Surface Mount TypeDocument3 pagesTall Height (4.3mm and 5.0mm) and Surface Mount TypeshyhuPas encore d'évaluation

- JJ22543-K3 Mast User ManualDocument23 pagesJJ22543-K3 Mast User ManualJohn SimancaPas encore d'évaluation

- 6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)Document3 pages6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)shyhuPas encore d'évaluation

- SKEGDocument4 pagesSKEGshyhuPas encore d'évaluation

- 6mm Square Dust-Proof (Snap-In Type)Document3 pages6mm Square Dust-Proof (Snap-In Type)shyhuPas encore d'évaluation

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDocument4 pages6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuPas encore d'évaluation

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuPas encore d'évaluation

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuPas encore d'évaluation

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuPas encore d'évaluation

- 6mm Square (Snap-In Type)Document6 pages6mm Square (Snap-In Type)shyhuPas encore d'évaluation

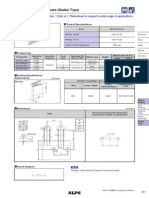

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuPas encore d'évaluation

- MAgnetrol 75 Seires LEvelDocument8 pagesMAgnetrol 75 Seires LEvelmarcoo8Pas encore d'évaluation

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuPas encore d'évaluation

- Quiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelDocument3 pagesQuiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelshyhuPas encore d'évaluation

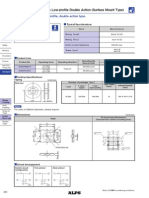

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuPas encore d'évaluation

- Industrial VisitDocument20 pagesIndustrial VisitKanchan kumarPas encore d'évaluation

- 350a Ac DC Tig Welding MachineDocument5 pages350a Ac DC Tig Welding MachinemahaveenPas encore d'évaluation

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuPas encore d'évaluation

- TCDPDocument88 pagesTCDPPrakash KumarPas encore d'évaluation

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuPas encore d'évaluation

- 18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueDocument4 pages18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueshyhuPas encore d'évaluation

- S753 E-32 6e2838105 TransformerDocument27 pagesS753 E-32 6e2838105 TransformerJosip ZohilPas encore d'évaluation

- KT NTPC Power TransformersDocument63 pagesKT NTPC Power TransformersKaran Tripathi100% (1)

- Oil Free Bushings - Technical InformationDocument1 pageOil Free Bushings - Technical InformationStedzavayPas encore d'évaluation

- Transformer Manual: Instructions ForDocument56 pagesTransformer Manual: Instructions Fordeepak2628100% (7)

- Andeli Mig-270tplDocument27 pagesAndeli Mig-270tpltao jogPas encore d'évaluation

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuPas encore d'évaluation

- CatalogueDocument2 pagesCatalogueebersworld_2011Pas encore d'évaluation

- Specification For Power Transformer:::: Document No. Description Item/Tag Imo NumberDocument30 pagesSpecification For Power Transformer:::: Document No. Description Item/Tag Imo NumberFILIN VLADIMIRPas encore d'évaluation

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umPas encore d'évaluation

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuPas encore d'évaluation

- ACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350Document48 pagesACTAIR - NG240 To NG700 DYNACTAIR - NG120 To NG350tommyPas encore d'évaluation

- SF6 GCB 24 - 36 KVDocument4 pagesSF6 GCB 24 - 36 KVMichael Parohinog GregasPas encore d'évaluation

- Group 11Document31 pagesGroup 11Mytheesh WaranPas encore d'évaluation

- 72.5-420kV Current TransformerDocument4 pages72.5-420kV Current TransformerPaulo CardosoPas encore d'évaluation

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuPas encore d'évaluation

- 4.5mm Square Compact (Snap-In Type)Document3 pages4.5mm Square Compact (Snap-In Type)shyhuPas encore d'évaluation

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuPas encore d'évaluation

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- Pressure Vessel Code Asme Section IxDocument132 pagesPressure Vessel Code Asme Section IxImane KhammouriPas encore d'évaluation

- Press Shop: Operations PerformedDocument15 pagesPress Shop: Operations PerformedRohit KumarPas encore d'évaluation

- Good BeadDocument21 pagesGood BeadFasil ParuvanathPas encore d'évaluation

- Weld RepireDocument91 pagesWeld RepireKapil ManloiPas encore d'évaluation

- Owner'S Manual: The Igbt Series of Mig/MagDocument27 pagesOwner'S Manual: The Igbt Series of Mig/MagTadas PPas encore d'évaluation

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuPas encore d'évaluation

- Technical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsDocument25 pagesTechnical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsK Vijay Bhaskar ReddyPas encore d'évaluation

- Die Casting DieDocument156 pagesDie Casting DieHeetPas encore d'évaluation

- Hot-Rolled Coils For The Manufacture of Large-Diameter PipesDocument2 pagesHot-Rolled Coils For The Manufacture of Large-Diameter PipesismailinesPas encore d'évaluation

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Acsaccacp 601 Ac DrivesDocument86 pagesAcsaccacp 601 Ac Driveshanner90Pas encore d'évaluation

- Cable Connectors To RMUDocument10 pagesCable Connectors To RMUSaqib RasoolPas encore d'évaluation

- Silflex Ewkf/ Ewkf +C: Heavy Duty, Tear Resistant, High Temperature Silicone Control CableDocument2 pagesSilflex Ewkf/ Ewkf +C: Heavy Duty, Tear Resistant, High Temperature Silicone Control CableM J VoraPas encore d'évaluation

- BushingDocument25 pagesBushingbpd21Pas encore d'évaluation

- Vi Physics WorksheetDocument4 pagesVi Physics WorksheetpodhigaifarmPas encore d'évaluation

- SRD T73 PDFDocument2 pagesSRD T73 PDFImo RobagPas encore d'évaluation

- TRF OilDocument47 pagesTRF Oilಶ್ರೀಕಾಂತ್ ತಿಪ್ಪೇರುದ್ರಪ್ಪPas encore d'évaluation

- Astor Accreditation Certificate 2022 (Id 1361648)Document6 pagesAstor Accreditation Certificate 2022 (Id 1361648)Dalibor84Pas encore d'évaluation

- BS en 50123-3Document26 pagesBS en 50123-3rohita kumar dahPas encore d'évaluation

- TES-P-119.06 R0 - Surge ProtectionDocument15 pagesTES-P-119.06 R0 - Surge ProtectionMohamed Eldin100% (2)

- GEI-M 1025 Vertical Motors - 0Document21 pagesGEI-M 1025 Vertical Motors - 0Eric AndrésPas encore d'évaluation

- A70-FAQ From Transformer Users - Part 1 - LinkedInDocument10 pagesA70-FAQ From Transformer Users - Part 1 - LinkedInanuragpugaliaPas encore d'évaluation

- Installation and Safety Instruction For Gas ValveDocument4 pagesInstallation and Safety Instruction For Gas Valvespscribd1Pas encore d'évaluation

- Catalogue of EHV CablesDocument27 pagesCatalogue of EHV Cablessreenivasreddi_bPas encore d'évaluation

- Insulation - Test (UENR1283-06)Document3 pagesInsulation - Test (UENR1283-06)ale gamingPas encore d'évaluation

- Crimp Tool For King InstallsDocument6 pagesCrimp Tool For King InstallssafariPas encore d'évaluation

- Fundamentals of Power System PDocument301 pagesFundamentals of Power System PDebanjan Dey100% (3)

- N2XSRYDocument1 pageN2XSRYYulian Dea ZollaPas encore d'évaluation

- Habilis Review Center 5Document8 pagesHabilis Review Center 5Al-nashreen AbdurahimPas encore d'évaluation

- 66 KV Single Core XLPE Power Cable PDFDocument11 pages66 KV Single Core XLPE Power Cable PDFRani VjPas encore d'évaluation

- Metrel Mi 2077Document40 pagesMetrel Mi 2077keyboard2515100% (3)

- Erico E1290b-UsenDocument24 pagesErico E1290b-UsenSỹ TháiPas encore d'évaluation

- Protective Relay Coordination PDFDocument78 pagesProtective Relay Coordination PDFXabi AlonsoPas encore d'évaluation

- Friction Tapes: Standard Test Methods ForDocument6 pagesFriction Tapes: Standard Test Methods ForMaxPas encore d'évaluation

- JAROL Assumes The Promotion of Energy-Saving Technology As Its Own Task! 1. PREFACE NOTICEDocument182 pagesJAROL Assumes The Promotion of Energy-Saving Technology As Its Own Task! 1. PREFACE NOTICEtrash49450% (2)

- All MCQ HVDC PDFDocument158 pagesAll MCQ HVDC PDFshaikh wajed khalil43% (7)

- Noisefilter eDocument46 pagesNoisefilter eLam quocPas encore d'évaluation

- EPRI AC Transmission Line Reference Book-200 KV and Above, Third Edition GlossaryDocument24 pagesEPRI AC Transmission Line Reference Book-200 KV and Above, Third Edition GlossaryALEX MECIAS YANCHAPAXI LLOCANAPas encore d'évaluation

- 7 Electric Fields in Material SpaceDocument19 pages7 Electric Fields in Material SpaceMarc RiveraPas encore d'évaluation

- Tele Pneumatic Gen CatDocument88 pagesTele Pneumatic Gen CatAliArababadiPas encore d'évaluation