Académique Documents

Professionnel Documents

Culture Documents

Kick-Off Meeting BLD4 Vinaconex E&C Rev.3 (END)

Transféré par

RoseaAlexander100%(1)100% ont trouvé ce document utile (1 vote)

319 vues38 pagesKick-off meeting document

Copyright

© © All Rights Reserved

Formats disponibles

PPT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentKick-off meeting document

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

319 vues38 pagesKick-Off Meeting BLD4 Vinaconex E&C Rev.3 (END)

Transféré par

RoseaAlexanderKick-off meeting document

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 38

VINACONEX E&C

AGENDA FOR NSRP BLD4-ZONE 2

AUG 2014

VINACONEX E&C KICK OFF MEETING

AGENDA FOR NSRP BLD4-ZONE 2

1. INTRODUCTION ABOUT VINACONEX E&C

2. SITE LAYOUT & SITE ESTABLISHMENT

3. SITE ORGANIZATION CHART & SUBCONTRACTOR

LIST

4. HSE PLAN & PROCEDURE

5. QC PLAN & PROCEDURE

6. DETAIL SCHEDULE

TABLE OF CONTENTS

COMPANY ORGANIZATION CHART

FIELD OF OPERATION

EXPERIENCED PROJECTS:

THI VAI GRINDING TERMINAL

PHU MY ROLLING STEEL PLANT

DUNG QUAT REFINERY

NGHI SON CEMENT FACTORY

DAMEN SONG CAM SHIPYARD

1. INTRODUCTION ABOUT VINACONEX E&C

Building

Construction

Industrial

Construction

Infrastructure

Construction

Project

Management

Real estate

Development

VINACONEX E&C

FIELD OF OPERATION

VINACONEX E&C is a general construction company, offers a

broad range of professional services in project management

and engineering as follows:

VINACONEX E&C

COMPANY ORGANIZATION CHART

EXPERIENCED PROJECT

Client: Holcim Vietnam

Location: Vung Tau

province, Vietnam

Construction period:

From Jun 2003 to Aug 2004

THI VAI GRINDING TERMINAL

EXPERIENCED PROJECT

Client: Southern Steel

Corporation

Location: Vung Tau

province, Vietnam

Construction period:

from 10/2003 to 1/2009

PHU MY ROLLING STEEL PLANT

EXPERIENCED PROJECT

Client: PetroVietnam

Location: Dung Quat Economic Zone,

Quang Ngai province, Vietnam

Construction period:

From Mar 2006 to Feb 2009

DUNG QUAT REFINERY

EXPERIENCED PROJECT

Client: Nghi Son Cement Corporation

Location: Tinh Gia, Thanh Hoa

province, Vietnam

Construction period:

From 2007 to 2009

NGHI SON CEMENT PLANT EXPANSION PHASE II

EXPERIENCED PROJECT

Client: Damen Song Cam Shipyard

Co., Ltd.

Location: Thuy Nguyen , Hai Phong

province, Vietnam

Construction period:

From 3/2013 to 3/2014

DAMEN SONG CAM SHIPYARD PROJECT

SCOPE OF WORK

BUILDING LIST & DETAIL

2. SITE LAYOUT & SITE ESTABLISHMENT

TEMPORARY FACILITY AT SITE

TYPICAL TEMPORARY FACILITY AT SITE

TEMPORARY DRAINAGE SYSTEM

TEMPORARY WORKER CAMP & TRANSPORTATION

PLAN FOR CRITICAL WORKS

SCOPE OF WORKS

PACKAGE 5

Cast in place Conc: 6485 m

3

Form : 21904 m

2

Rebar : 660 ton

Excavation : 8000 m

3

Backfilling : 6725 m

3

Remove soil : 2163 m

3

AREA

SS-M01 : 525 m

2

ISB-11 : 353 m

2

SS-U04 : 551 m

2

ISB-12 : 506 m

2

SS-U01 : 910 m

2

SS-M02 : 1028 m

2

Utility operator shelter: 150 m

2

PACKAGE 4

PPU (U-061)

CDU (U-010, 011, 012)

KHDS (U-013)

Aromatics (U-

047, 048, 049)

1/11/2014

15/9/2014

15/9/2014

15/9/2014

Pile head

treatment

Finishing

works

Furniture

Steel

structure

Earth work

HVAC

Grounding

&

Lightning

Fire

fighting

work

Plumbing

work

Electrical

Reinforced

Concrete Sanitary

M&E

Construction

PACKAGE: BLD4

ZONE 2

ISB-07

SS-P05

SS-P04

ISB-03

SS-P01

AT Catalyst

house

Peroxide Storage building

Packing

Storage

ISB-01

Extrusion

Shelter

SS-P08

ISB-10

POS-1

TEMPORARY FACILITIES AT SITE

WORKSHOP

WORKSHOP

WORKSHOP

VINACONEX E&C

MAIN SITE OFFICE

WORKSHOP

MAIN SITE OFFICE

Location: E100

Area: 100m2

EQUIPMENTS MOBILIZATION

Excavator 0.7 -1.2 m3 : 4

Compactor : 6

Bar Cutting Machine : 8

Bar-bending Machine : 8

Welding machine : 12

High-pressure Pump : 8

AT Catalyst

house

Peroxide Storage building

Packing

Storage

SS-P08

ISB-07

SS-P01

ISB-01

SS-P05

SS-P04

ISB-03

Extrusion

Shelter

ISB-10

25/8/2014

25/8/2014

25/8/2014

1/10/2014

POS-1

TEMPORARY DRAINAGE SYSTEM

- For general layout, Vinaconex E&C shall set up temporary trench

(W=600mm, H=400mm) around building (clear space of minimum

3m on all sides of building border).

- All the temporary trench shall be connected to projects gutter

along temporary road.

- For each excavation, rainwater or underground water shall be

collected from catch basin and discharged to temporary trench

system.

- At least 2 high-pressure pumps for each location are always

available for pumping rainwater from excavation to temporary

gutter.

- All the temporary trenches are always maintained.

WORKER CAMP & TRANSPORTATION

NSRP LOCATION

WORKER CAMP

Area: 1100m

2

Distance: 2km

Capacity: 160 persons

Density: 4.5m

2

/worker

Address : Anh Phat Land

TYPICAL WORKER CAMP

WORKER CAMP SCHEDULE

(According to manpower mobilization plan)

Phase 1: Construction for 80 persons:

from 25/08/2014 to 10/10/2014

Phase 2: Construction for 80 persons:

from 15/12/2014 to 30/1/2015

PLAN FOR CRITICAL WORK

- VINACONEX E&C shall maximize the structure work schedule for having more

spare time to execute and test waterproofing work, finishing concrete surface...

- We may use concrete curing compound and admixture for shortening concrete

curing period and increasing ultimate concrete strength, so the next works

(removing formwork and supporting scaffolding) shall be start sooner.

- Construction procedure and testing shall be strictly comply with projects

requirement and Manufacturers standard.

STRUCTURE WORK

RAINY SEASON

- VINACONEX E&C shall set up temporary open gutter to catch rainwater from

construction site and discharge to project temporary gutter (beside project

temp. road).

- At least 2 high-pressure pumps for each location shall be standby for pumping

rainwater from excavation to temp. gutter.

- We may consider to work at night shift when the schedule is in critical status.

- In order to minimize the affection of monsoon climate, VINACONEX E&C shall

mobilize all the workforce for boosting up the schedule of outer work finish

before rainy season.

COMMUNICATION CHANNELS

SITE ORGANIZATION CHART

LIST OF SUBCONTRACTOR

3. SITE ORGANIZATION CHART & SUB-SUBCONTRACTOR LIST

SITE ORGANIZATION CHART

HSSE Manager QS Manager QA/QC Manager

HSSE Officer (05) QS Staff (03)

Construction

NGUYEN DUY QUANG

VU MINH DUC DANG HOANG HAI NGUYEN CONG HIEN

HOANG DUC TUNG

Manager

Administration M&E Manager

NGUYEN SY MINH

Site supervisor (04)

Surveyor (03)

Q.C staff (05)

Shop DWG/Cadman

(02)

HVAC Engineer (04) Admin/Accountant (01)

Driver (03)

- HSSE management

- Site regulation

- HSE training

- Contract control

- Procurment

- Claim and payment

- Quantity survey - JSA report

- Material submission

- Site control

- Construction method

- Construction schedule

- Site supervising

- Construction report

- Quality control

- Check material, product

- Site supervising

- M&E works

- HVAC works

- Fire fighting work

- Office administration

- Document control

- Personnel management

- Legal affair

- Temporary M&E works

SITE MANAGEMENT BOARD

- First aid

- Prepare Shop DWG

- Planning

VU BA DAT

LE NGOC TUNG

0904.255.540 - vuduc1980@gmail.com 0912.433.677 - dhhai@vinaconexec.com.vn 0985.111.083 - lengoctung83@yahoo.com 0984.839.030 - nchien@vinaconexec.com.vn 0904.546.407 - nsminh@vinaconexec.com.vn

0903.224.148 - hdtung@vinaconexec.com.vn

0912.789.788 - ndquang@vinaconexec.com.vn

0912.152.931 - vbdat@vinaconexec.com.vn

DANG HOANG HAI

0912.433.677 - dhhai@vinaconexec.com.vn

Document Controller (1)

-Average worker: 200

-1 HSSE staff: 50 workers

-1 site supervisor for each

workplace

(total: 4 sub-zones)

-1 Q.C staff for each

workplace

-1 Q.C staff for M&E work

* Note: Manager positions are fixed and available from the beginning of works.

Staff positions shall be mobilized according to the Schedule of works and schedule of manpower on site.

ORGANIZATION CHART

PROJECT: NSRP COMPLEX

PACKAGE: BLD4 - ZONE 2

COMMUNICATION CHANNELS

1. SITE MANAGER

Mr. Nguyen Duy Quang

Email: ndquang@vinaconexec.com.vn

Tel: (84) 0912.789.788

2. DEPUTY SITE MANAGER

Mr. Hoang Duc Tung

Email: hdtung@vinaconexec.com.vn

Tel: (84) 0903.224.148

3. CONSTRUCTION MANAGER

Mr. Le Ngoc Tung

Email: lengoctung83@yahoo.com

Tel: (84) 0985.111.083

4. Q.S MANAGER / DOC. CONTROLLER

Mr. Dang Hoang Hai

Email: dhhai@vinaconexec.com.vn

Tel: (84) 0912.433.677

5. Q.C MANAGER

Mr. Nguyen Cong Hien

Email: nchien@vinaconexec.com.vn

Tel: (84) 0984.839.030

6. HSE MANAGER

Mr. Vu Minh Duc

Email: vuduc1980@gmail.com

Tel: (84) 0904.255.540

7. M&E MANAGER

Mr. Nguyen Sy Minh

Email: nsminh@vinaconexec.com.vn

Tel: (84) 0904.546.407

PROJECT MANAGER

Mr. Vu Ba Dat

Email: vbdat@vinaconexec.com.vn

Tel: (84) 0912.152.931

LIST OF SUBCONTRACTOR

STT Subcontractor's name (estimated) Scope of work Remark

1

Vimeco M&T

Fabrication and erection of steel structure works Lilama 10

or to be submit later

2

Sakura Batching Plant

Supply ready mix concrete & concrete pump

CMC Batching Plant

Vimeco Batching Plant

or to be submit later

3

Sohaco Vietnam

Raised access floor, vinyl floor

Abtech

Anh Ngoc Thanh

or to be submit later

4

Da Phuc Mechanical ., jsc

Doors & window work

Galaxy Vietnam

Vina-sanwa Co., Ltd

or to be submit later

5

Dai Nghia .,jsc

Executing M&E work

DQA Engineering Co., Ltd.

KD Vietnam .,jsc

or to be submit later

HSSE CERTIFICATE

HSSE POLICY

HSSE DOCUMENT STATUS

4. HSSE PLAN & PROCEDURE

HSSE PLAN & PROCEDURE

VINACONEX E&C determines that HSE work is the top work

among all other operations, on site as well as in the office. HSE

is the foundation for a sustainable development.

We put it at most care to the health, safety and work

performance of workers.

VINACONEX E&C urge all its affiliates to conform this HSE

plan and support adequately for management mechanism to

execute this HSE policy.

VINACONEX E&C ensure that

the HSE standards are met

throughout the construction

process, based on the projects

standards and the Vietnamese

standards.

HSSE CERTIFICATE

Vinaconex E&C., JSC archives the capability to control the environmental

system and workspace safety according to ISO 14001:2004 and OHSAS

18001:2007

HSSE DOCUMENT STATUS

No Items Status Schedule of submission

1 HSSE Management Plan Ready 12/08/2014

2 Traffic Management Plan Preparing 20/08/2014

3 Waste Management Plan Ready 12/08/2014

4 Security Management plan Ready 12/08/2014

5 Accommodation Management Plan Preparing 25/08/2014

6 Emergency Response Plan Ready 12/08/2014

7 Method statement for night work Preparing 25/08/2014

8 Management plan for working at high level Preparing 25/08/2014

9 Incident Management Plan Preparing 25/08/2014

Q.C SITE ORGANIZATION

Q.C POLICY

Q.C CERTIFICATE

5. Q.C PLAN & PROCEDURE

MAIN MATERIAL SUPPLIER (REBAR, CONCRETE)

QUALITY CONTROL POLICY

VINACONEX E&C determines that product and services quality is

as our prestige, effectiveness as well as foundation for a

sustainable development.

Paid special attention to the human, VINACONEX E&C commits

for ongoing training programs for all employees, facilitating a

favorable conditions with advanced equipments for staffs to fully

develop their ability.

VINACONEX E&C commits to build, implement, maintain and

continuously improve the quality management system to ISO 9001

: 2008 and to generate the highest-quality services meeting the

customers expectations.

Q.C SITE ORGANIZATION CHART

HSSE Section

HSSE Officers

Technical Section

Site Engineers

QC Staff

Truong Khac Chien

Nguyen Xuan Tung

Ta Anh Vinh

Tran Xuan Kieu

Project Manager

VINACONEX E&C

QC Manager

Nguyen Cong Hien

Tel: 0984.839.030

Email:

nchien@vinaconexec.com.vn

QUALITY CONTROL PLAN

PQP (Project Quality Plan

ITP(Inspection & Test Plan)

Quality Audit Plan

Vinaconex E&C., JSC committes

to an effective and comprehensive

Quality management system

according to ISO 9001:2008

Q.C DOCUMENT STATUS

Nos Document Status

Schedule of

Submission

1 Project Quality Plan Ready 12/08/2014

2 Nonconformity Control procedure Preparing 20/08/2014

3 Quality audit plan Ready 12/08/2014

4 ITP for excavation and backfilling plan Ready 12/08/2014

5 ITP for concrete work Ready 12/08/2014

6 ITP for compaction trial and compaction plan Preparing 20/08/2014

7 ITP for Architecture finishing works Preparing 20/12/2014

8 Material handling procedure Preparing 25/08/2014

9

Inspection and Test Equipment/ Tool list with

Calibration Procedure

Preparing 22/08/2014

REBAR SUPPLIERS

NSRP LOCATION

KYOEI VIET NAM

SSE

STEEL SUPPLIER 1

Brand: Hoa Phat Steel

Factory: Hung Yen province

VIS, HOA PHAT

STEEL SUPPLIER 2

Brand: Vietnam Italy Steel (VIS)

Factory: Hung Yen province

STEEL SUPPLIER 3

Brand: SSE Steel

Factory: Hai Phong province

STEEL SUPPLIER 4

Brand: Kyoei Steel

Factory: Ninh Binh province

READY MIX CONCRETE SUPPLIERS

NSRP LOCATION

VIMECO BATCHING

PLANT

60 + 90m

3

/h

CMC BATCHING

PLANT

120 + 90m

3

/h

SAKURA BATCHING

PLANT

120 + 90m

3

/h

MANPOWER CHART

CONSTRUCTION SCHEDULE FOR BLD4S BUILDING

EQUIPMENT MOBILIZATION

6. DETAIL SCHEDULE

EQUIPMENT MOBILIZATION

CONSTRUCTION SCHEDULE FOR BLD4

PAGE

1/3

CONSTRUCTION SCHEDULE FOR BLD4

PAGE

2/3

CONSTRUCTION SCHEDULE FOR BLD4

PAGE

3/3

MANPOWER CHART

- Max labors: 310 persons at Mar. 2015

- Average accommodation: 200 persons.

100%

95%

40%

Vietnamese worker

Northern Vietnamese worker

Local worker (Tinh Gia, Thanh Hoa)

PORTION OF LABOR ORIGIN

15/09/2014 1/11/2015

Traditional Tet

Holiday of VN

(10days)

Peak point with 310

wokers

0

50

100

150

200

250

300

350

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

Tet Holiday of

VN (10days)

Peak point with

310 workers

Manpower

(Half month)

TYPE OF WORKER

MAX. of

Worker

Number

1 Sep

14 1 Oct 14 1 Nov 14 1 Dec 14 1 Jan 15 1 Feb 15 1 Mar 15 1 Apr 15 1 May 15 1 Jun 15 1 Jul 15

30 15 30 15 30 15 30 15 30 15 30 15 30 15 30 15 30 15 30 15 30

Excavation worker

15

15

-

20

-

5

5

5

- - - 5 - - - - - - - - -

Pile head treatment

worker

20

10

20

-

20

- -

5

10

5

- - 5 - - - - - - - - -

Rebar worker 77

-

25

70

70

77

46

28

38

37

37

- 16

36

36

32

32

- - - - -

Formworker (capenter) 148

-

38

116

116

148

95

61

50

14

14

- 4

17

17

8

8

8

- - - -

Concrete worker 47

-

15

29

43

47

34

22

12

24

24

- 14

24

24

24

20

20

- - - -

Masonry worker 43

-

- - - - -

3

27

43

27

- 14

8

3

- -

3

20

17

17

17

Plastering worker 34

-

- - - - - -

3

25

34

- 11

14

3

3

- - -

9

9

9

Painting worker 81

-

- - - - -

9

39

13

29

- 59

81

42

39

23

7

-

6

6

8

Door and window

worker

12

-

- - - - - - - - - - 12

2

4

4

2

- - -

3

-

Steel structure worker 41

-

- - - -

6

22

38

- 39

41

25

23

15

11

7

7

7

7

Ceiling worker 29

-

- - - - - - - - - - 29

8

9

4

- - - -

4

-

Tilling worker 9

-

- - - - -

5

8

- 3

9

9

3

- - -

3

3

-

Access floor worker 14

-

- - - - - - - -

4

- 2

11

14

5

- - - - - -

M&E worker 85

-

4

17

17

31

34

49

52

57

53

- 50

59

85

66

60

41

30

27

27

27

MANPOWER MOBILIZATION

EQUIPMENT MOBILIZATION

Type of Equipment Max

2014 2015

10 11 12 1 2 3 4 5 6 7 8 9 10

Excavator - 1 (m3) 2 1 2 - 1 - - - - - - - - -

Excavator - 0,5 (m3) 5 4 5 3 4 2 1 4 1 1 - - - -

Dump truck - 36 (m3) 17 17 13 3 8 3 - 3 - - - - - -

Bulldozer D5 1 - - - - - - 1 - 1 - - - -

Vibrator Compactor - 25 (ton) 1 - - - - - - 1 - - - - - -

Vibrator Compactor - 5 (ton) 1 - - - - - - 1 - - - - - -

Jumping compactor 20 - 5 20 9 - - 10 5 8 - - - -

Pile head cutting machine 9 9 9 4 3 3 3 3 - - - - - -

Rebar bending machine 5kW 10 4 8 10 8 6 4 4 4 4 - - - -

Rebar cutting machine 5kW 10 4 8 10 8 6 4 4 4 4 - - - -

Welding machine 23kW 20 8 16 20 16 12 8 8 8 8 - - - -

Concrete batching plant 90 (m3/h) 7 2 6 7 5 4 2 1 1 1 - - - -

Rod concrete compactor 22 6 14 18 22 22 20 16 16 16 - - - -

Mortar mixer machine 80L 6 - - - 4 6 6 4 2 - 2 - - -

Discharge water pump TSURUMI

(0,5-3m3/1min) 7 3 7 7 4 4 4 5 3 2 - - - -

Crane Kobelco 25 ton 4 - - - 4 3 1 2 1 1 - - - -

Boom truck crane 10 ton 3 - - - 3 2 - 1 1 1 - - - -

Boom lift 30m 3 - - - 3 2 - - 1 1 - - - -

Vous aimerez peut-être aussi

- A. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationDocument4 pagesA. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationSyed Munawar Ali100% (1)

- Mobilization Construction Equipment & ToolsDocument1 pageMobilization Construction Equipment & ToolsallPas encore d'évaluation

- Pqp-Part 2Document2 pagesPqp-Part 2jparsbPas encore d'évaluation

- Procurement Plan - Detailed PlanDocument22 pagesProcurement Plan - Detailed PlanHosam SiefPas encore d'évaluation

- Excavation, Earthwork and Filling Method Statement - Planning Engineer EstDocument7 pagesExcavation, Earthwork and Filling Method Statement - Planning Engineer EstLazar AndonovPas encore d'évaluation

- Site Organisation Chart: Plant OperatorsDocument1 pageSite Organisation Chart: Plant OperatorsPatrick SipatelaPas encore d'évaluation

- Job Procedure For Earthwork Excavation and BackfillingDocument6 pagesJob Procedure For Earthwork Excavation and BackfillingJitesh SahiPas encore d'évaluation

- Itp - Building WorksDocument15 pagesItp - Building WorksVasilica BArbarasaPas encore d'évaluation

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaePas encore d'évaluation

- Project Execution Plan (PEP) (v2)Document30 pagesProject Execution Plan (PEP) (v2)Gerry100% (1)

- Resume For The Post of Project, Planning EngineerDocument5 pagesResume For The Post of Project, Planning Engineerssbapi33% (3)

- Project Client Date: Consultant: Day: Contractor A. B. A.Sur A.LtDocument2 pagesProject Client Date: Consultant: Day: Contractor A. B. A.Sur A.LtMahibul HasanPas encore d'évaluation

- Contract Administration-Sbd - 3Document105 pagesContract Administration-Sbd - 3Rajaratnam Tharakan100% (1)

- Transmittal Form TNBDocument1 pageTransmittal Form TNBNik Mohd BazliPas encore d'évaluation

- Civil Works Technical SpecificationsDocument33 pagesCivil Works Technical SpecificationsAsim KhanPas encore d'évaluation

- Piping Insulation Project Planned Schedule-Rev2Document1 pagePiping Insulation Project Planned Schedule-Rev2Anene EmmanuelPas encore d'évaluation

- Method Statement Trial TrenchDocument6 pagesMethod Statement Trial TrenchSasi KumarPas encore d'évaluation

- Pqp-Part 3Document9 pagesPqp-Part 3jparsbPas encore d'évaluation

- Models From NCTC - Construction Execution PlanDocument40 pagesModels From NCTC - Construction Execution PlanSherif Mohsen100% (1)

- Quality InductionDocument15 pagesQuality InductionaleemmurtazaPas encore d'évaluation

- Procurement Plan: FOR Epc For Constructing Pipe Line and Power Line For Sangsam Oil DevelopmentDocument9 pagesProcurement Plan: FOR Epc For Constructing Pipe Line and Power Line For Sangsam Oil DevelopmentHaekal RamadhanPas encore d'évaluation

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsDocument7 pages84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoPas encore d'évaluation

- Dashboard C-1101 MR 2013 Fox HillsDocument10 pagesDashboard C-1101 MR 2013 Fox HillsrmdarisaPas encore d'évaluation

- Appendix 8 - Typical Project Execution PlanDocument19 pagesAppendix 8 - Typical Project Execution PlanJonald DagsaPas encore d'évaluation

- Itp Civil WorkDocument9 pagesItp Civil WorkChristian Albert Sinaga RumajarPas encore d'évaluation

- Tac Company Profile 2012Document33 pagesTac Company Profile 2012vista_serverPas encore d'évaluation

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocument34 pages5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Design Professional Monthly Progress Report: Project Square FootageDocument2 pagesDesign Professional Monthly Progress Report: Project Square FootageCUPas encore d'évaluation

- Weekly Progress Report 23-10 PDFDocument4 pagesWeekly Progress Report 23-10 PDFMohamed ArafaPas encore d'évaluation

- EXHIBIT I - Project Execution Plan FDocument56 pagesEXHIBIT I - Project Execution Plan FMohamed SarfanPas encore d'évaluation

- PEPDocument37 pagesPEPShane EngelPas encore d'évaluation

- Safe Work Method StatementDocument6 pagesSafe Work Method StatementStansilous Tatenda NyagomoPas encore d'évaluation

- Earthworks-Excavation: Owner: Client: Consultant: Main Contractor: Civil ContractorDocument1 pageEarthworks-Excavation: Owner: Client: Consultant: Main Contractor: Civil ContractorPrasanna KumarPas encore d'évaluation

- Typical Organization ChartDocument1 pageTypical Organization ChartJaved MiandadPas encore d'évaluation

- External QC Inspection Request-Report FormDocument1 pageExternal QC Inspection Request-Report FormEdison WalitPas encore d'évaluation

- MIR Log - CivilDocument13 pagesMIR Log - CivilAnonymous yniiLtiPas encore d'évaluation

- Forte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationDocument2 pagesForte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationfrancisbautistaPas encore d'évaluation

- 03 Monthly Progress Report May 2022 Rev 00Document38 pages03 Monthly Progress Report May 2022 Rev 00Raj KamatPas encore d'évaluation

- 6.290 Project Handover Plan TempateDocument6 pages6.290 Project Handover Plan Tempatetuanthanh16Pas encore d'évaluation

- Site Visit SampleDocument3 pagesSite Visit SampleJerick RosePas encore d'évaluation

- Cleaner Resume: Name: Felix Ugochukwu RolandDocument4 pagesCleaner Resume: Name: Felix Ugochukwu RolandMetchidji Armand FuenguePas encore d'évaluation

- QM 105 Construction Execution PlanDocument1 pageQM 105 Construction Execution PlanAlejandro PáramoPas encore d'évaluation

- Basics of Project Scheduling: Create A Schedule Using CPMDocument11 pagesBasics of Project Scheduling: Create A Schedule Using CPMWali RahmanPas encore d'évaluation

- Method Statement Excavation Civil WorksDocument9 pagesMethod Statement Excavation Civil WorksRanjith GabrielPas encore d'évaluation

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelPas encore d'évaluation

- Project Close Out Report Procedure Rev ADocument6 pagesProject Close Out Report Procedure Rev AMoe.100% (2)

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Document6 pagesCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekPas encore d'évaluation

- Pour CardDocument2 pagesPour Cardrana pratap Singh100% (1)

- Project Engineer - Job DescriptionDocument2 pagesProject Engineer - Job DescriptionJan Vincent A. LadresPas encore d'évaluation

- 2338 - Rev 0 - Binladin Group PDFDocument5 pages2338 - Rev 0 - Binladin Group PDFVishnuPas encore d'évaluation

- Two Weeks Look Ahead ScheduleDocument53 pagesTwo Weeks Look Ahead ScheduleMohamed Reda Hussein SengarPas encore d'évaluation

- Itp - EifsDocument22 pagesItp - Eifssathiyaprasath100% (1)

- Project Work General Mobilization Plan:: A. IntroductionDocument2 pagesProject Work General Mobilization Plan:: A. IntroductionArjun SatheesanPas encore d'évaluation

- Fuel Tank Lifting REV01Document7 pagesFuel Tank Lifting REV01armagan55Pas encore d'évaluation

- Muhammad Ayub Bin Khalid: Personal DataDocument5 pagesMuhammad Ayub Bin Khalid: Personal DataAnwarul Shafiq AwalludinPas encore d'évaluation

- Method Statement - Upvc Piping - Rev 01Document10 pagesMethod Statement - Upvc Piping - Rev 01Tamil Da RasckalzPas encore d'évaluation

- Ponnarasan Murugesan CVDocument4 pagesPonnarasan Murugesan CVKshama RaiPas encore d'évaluation

- Project Description: H.K.K & Salem Construction Sdn. Bhd. C2-1Document10 pagesProject Description: H.K.K & Salem Construction Sdn. Bhd. C2-1Friendly LondonPas encore d'évaluation

- Prefabrication of Tunnel Elements On The Oresund TunnelDocument14 pagesPrefabrication of Tunnel Elements On The Oresund Tunnelilyas16Pas encore d'évaluation

- 5688 QTTNNTXDocument12 pages5688 QTTNNTXRoseaAlexanderPas encore d'évaluation

- Resort Tay Ho TayDocument22 pagesResort Tay Ho TayRoseaAlexanderPas encore d'évaluation

- File in Company Profile SunspaceDocument54 pagesFile in Company Profile SunspaceRoseaAlexander100% (1)

- English For Contructors 1618Document120 pagesEnglish For Contructors 1618Cuong Nguyen Tien100% (1)

- BS 1139-1.2-1990 Metal Scaffolding. Tubes. Specification For Aluminium TubeDocument6 pagesBS 1139-1.2-1990 Metal Scaffolding. Tubes. Specification For Aluminium TubeRoseaAlexanderPas encore d'évaluation

- Bar Be Que Writeup ColourDocument2 pagesBar Be Que Writeup ColourRoseaAlexanderPas encore d'évaluation

- AP Euro Unit 2 Study GuideDocument11 pagesAP Euro Unit 2 Study GuideexmordisPas encore d'évaluation

- Look Back in Anger-FátimaPais2002Document4 pagesLook Back in Anger-FátimaPais2002Fátima PaisPas encore d'évaluation

- The Rook 2022Document40 pagesThe Rook 2022The RookPas encore d'évaluation

- Louisiana PurchaseDocument29 pagesLouisiana PurchaseMartin TisherPas encore d'évaluation

- DCR 11parts - HVRM35UDocument9 pagesDCR 11parts - HVRM35UWili Alexander Interiano GarciaPas encore d'évaluation

- ASA and ASEAN, 1961-1967 Southeast Asian RegionalismDocument13 pagesASA and ASEAN, 1961-1967 Southeast Asian RegionalismlolitaesquePas encore d'évaluation

- Annotated Bib 5 13Document45 pagesAnnotated Bib 5 13api-187498993Pas encore d'évaluation

- Wound BallisticsDocument897 pagesWound Ballisticsintense4dislike100% (3)

- 7-24-1973 Buffalo Hunter (U) 1970-1972Document61 pages7-24-1973 Buffalo Hunter (U) 1970-1972Robert Vale100% (1)

- Kazachiy PolkDocument21 pagesKazachiy PolkFran BejaranoPas encore d'évaluation

- Beginners Guide To Piracy 2.1Document55 pagesBeginners Guide To Piracy 2.1Carlos KoulatsisPas encore d'évaluation

- E.R. Johnson - American Military Transport Aircraft Since 1925 (2013)Document489 pagesE.R. Johnson - American Military Transport Aircraft Since 1925 (2013)Stotza95% (20)

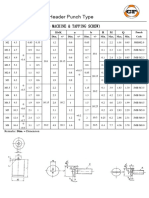

- Header Punch Standards (JIS-2nd Punch)Document9 pagesHeader Punch Standards (JIS-2nd Punch)nikesh singhPas encore d'évaluation

- MS HSS AC Unit 6 Chapter 15 Early AmericasDocument28 pagesMS HSS AC Unit 6 Chapter 15 Early AmericasJestony MatillaPas encore d'évaluation

- Wwi PDFDocument20 pagesWwi PDFRavi GadgilPas encore d'évaluation

- The Exercise of The Pardoning Power in The PhilippinesDocument15 pagesThe Exercise of The Pardoning Power in The PhilippinesSoc SaballaPas encore d'évaluation

- Triumph of The Will Wiki PDFDocument13 pagesTriumph of The Will Wiki PDFBilly NousisPas encore d'évaluation

- Pakistan External Affairs Pakistan's Relations With Its Neighbors (India, China, Afghanistan, Russia)Document2 pagesPakistan External Affairs Pakistan's Relations With Its Neighbors (India, China, Afghanistan, Russia)Mutiba RazzaqPas encore d'évaluation

- Dtic Ada096424 PDFDocument670 pagesDtic Ada096424 PDFBeefcakesMcGeePas encore d'évaluation

- El Presidente Movie ReviewDocument4 pagesEl Presidente Movie ReviewJames Roi Dela CruzPas encore d'évaluation

- Crack!+ #7 Adventure The Shadow of AvesnesDocument12 pagesCrack!+ #7 Adventure The Shadow of Avesnesmaxox96126Pas encore d'évaluation

- Buçaco OoBDocument9 pagesBuçaco OoBDMPas encore d'évaluation

- China As "Victim"? The Opium War That Wasn't (WPS 136) Harry G. Gelber.Document10 pagesChina As "Victim"? The Opium War That Wasn't (WPS 136) Harry G. Gelber.Minda de Gunzburg Center for European Studies at Harvard UniversityPas encore d'évaluation

- U. S. Naval Forces Vietnam Monthly Historical Summary Oct 1970Document81 pagesU. S. Naval Forces Vietnam Monthly Historical Summary Oct 1970Robert ValePas encore d'évaluation

- Sarvai PapannaDocument3 pagesSarvai Papannarajtanniru0% (1)

- Cheyenne and Arapaho Tribes: Oklahoma Indian Tribe Education GuideDocument11 pagesCheyenne and Arapaho Tribes: Oklahoma Indian Tribe Education GuideErich von MansteinPas encore d'évaluation

- Worship and War Sacred Space in Byzantine Military ReligionDocument71 pagesWorship and War Sacred Space in Byzantine Military ReligionSan PPas encore d'évaluation

- KarnadDocument10 pagesKarnadAdithya NarayanPas encore d'évaluation

- Albrecht Von Urach - The Secret of Japan's Strength PDFDocument11 pagesAlbrecht Von Urach - The Secret of Japan's Strength PDFMihai AdrianPas encore d'évaluation

- Jacob-The Essence of European Culture. The Evidence of Hans-Jürgen SyberbergDocument19 pagesJacob-The Essence of European Culture. The Evidence of Hans-Jürgen SyberbergJaime Luis Zapata GarciaPas encore d'évaluation