Académique Documents

Professionnel Documents

Culture Documents

DNV

Transféré par

Muhammad Yahdiman0 évaluation0% ont trouvé ce document utile (0 vote)

273 vues34 pagesdetnorske veritas

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentdetnorske veritas

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

273 vues34 pagesDNV

Transféré par

Muhammad Yahdimandetnorske veritas

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 34

Standard For

Certification No. 2.7-1

DET NORKSE VERITAS

General

SCOPE

design,

Manufacture,

testing,

certification, and

periodic Inspection.

The Intention is that offshore containers shall meet

the following requirements :

Be safe with regard to:

oLives

oEnvironment

oHazard to vessel/installation

General

SCOPE

Be suitable for repeated use trough choice of :

oMaterial

oProtection

oEase of repair and maintenance

General

Relationship with othe standard, codes and

regulation

The International Maritime Organization (IMO)

ISO Standard Freight Containers (ISO Containers)

European Standard EN 12079

Standard for Certification 2.7-2- Offshore service

containers

Units of Transportation Offshore Regulation for

Lifting Appliances

General

Definition

Offshore Container

Freight Container

Units for

transportation

Offshore

Permanent Equipment

Primary Structure

Secondary Structure

Prototype

Owner

Lifting Set

Assembly Secured

Shackle

Approval and Certification

Procedures

Offshore containers designed, manufactured, tested

and marked in compliance with the following

requirements may be certified by Det Norske

Veritas

Certification steps:

Design review

Inspection and testing of prototype

Production inspection and testing

Issuance of certificates

Approval and Certification

Procedures

DNV type approvals are listed in DNV Exchange

on DNVs web site : www.dnv.com.

On website included :

Approval to other standards

Documents for approval and information

Design Review

Approval and Certification

Procedures

Certification

Certification must be consist the following steps :

Survey

Testing and Inspection

Before production starts, DNV should verify the

qualifications of the manufacturer :

Procedure for individual (case by case) approval and

certification

Procedure for type approval and certification

Procedure for design assessment for type approval

and certification.

Material

Container requirement for material

Steel

Aluminium and

Non-metalic material

In this section, the references to detail requirements are

generally to EN standards or DNVs Rules for

Classification of Ships. Other recognized standards for

equivalent materials may also be used.

Material

Material Certificates

Materials used for construction of offshore containers shall be furnished

with documentation in accordance with Table 3-6.

Design

An offshore container shall have sufficient strength to allow

loading and unloading in open seas from a ship deck with a

sea state up to significant wave heights of 6 m

The required Design of a container :

Structural Design

Stability Againts tipping

Protruding parts and top protection

Design Temperature

Design

The required Strenght test of a container :

Allowable Stress

Load Distribution

Lifting Load

Impact Load

Minimum Material Thickness

Other Test

Other tests may be required. These shall be agreed in advance

with the Society. When applicable, the method of testing shall as

far as possible be in accordance with tests described in relevant

ISO standards for freight containers

Design

Example of other tests that may be required :

internal load on walls, doors or removable sides

30 tilt test

fork pocket lift test

internal restraint tests on tank containers.

Production

The manufacturer shall present a quality plan for

acceptance before production starts. Relevant

production documents shall also be presented for

acceptance before start of production.

production:

Step by step of production :

Primary and Secondary Structure

Production Testing

Production Documentation

Inspection and Certification

Marking

Safety Marking to clearly delineate their

perimeter, partycularly in poor light

Identification and Certification Markings

an unique identification to cross check on in-

service certification and shipping documentation

Information Marking to identificate about

gross mass, tare mass, and payload of container

Marking of lifting set to identificate

specification of lifting set

Other Marking additional owner information

marking such as owners name .etc

Plating Containers

Container shall be fitted with a data plate and a

inspection plate.

Contain of data plate :

Name of Manufacturer

Month/year of manufacturer

Manufacturers serial number

Maximum gross (Kg) at the design sling angle

Tare Mass (Kg)

Payload (Kg)

Dnv Certificate Number and DNV stamp

Design Temperature

Plating Containers

Container shall be fitted with a data plate and a

inspection plate.

Contain of Inspection Plate :

Owners Container number.

Owners name.

Date of last inspection.

Lifting Sets

General Requirement

The lifting set (chain or wire rope slings and

shackles) shall be specially designed for use on

offshore containers, and shall normally not be

removed from the container except for replacement

Approval and Certification lifting sets

Lifting sets and components shall be tested according

to the applicable standards.

Lifting Sets

Design of lifting sets

Four leg sling angle shall be rated as for three leg sling.

Normally the sling leg angle from vertical foe two and

four leg slings should be 45

o

, but smaller angel can be

used.

In no case shall a sling be designed with an angle of the

sling legs to the vertical larger than 45

o

Lifting Sets

Dimension and Strenght of lifting Sets

WLL

min

= Rating of Container * Enhancement Factor

If Rating of Container < 2000kg WLL

min

= 7.00 t

For intermediate container ratings, the working load limit

values may be interpolated

WLLmin = Minimum Required Working Load Limit (t)

Note : The Enhancement factor are only included in table 8-1 for information purposes.

They are only used for calculating the WLLmin values in the last coloum, and are not

necessary for any other calculation

Standard Lifting Sets

Four Leg Chain or wire rope

Sling With leg 45 to vertical are calculated as single legs.

Sling shall be selected from recogized standard for lifting

slings or from a DNV type approval certificate, and shall

have WLL at least as big as the WLL

min

from table 8-1.

Shackles

Non-Standard Lifting Sets

The Required Working Load Limit for Each component in

2 and 4 leg lifting sets can be determined from the formula :

Required WLL = WLL

min

/ (n x cos )

This Can be expressed in the following table.

WLLmin : as determined from table 8-1

: the angle of the sling leg to the vertical

Lifting Sets

Lifting Sets Componen

Chain Sling (EN 818-4 grade 8 or other recognize

standard)

Wire Rope Slings (EN 13414-1 or other recognized

standard)

Shackles (EN 13889 or EN 1677-1, or other recognised

standard)

Couplings (Couplings for mechanical assembly of slings

can be certified after special consideration)

Lifting Sets

Material

Steels shall comply with the material requirements of the

recognised standard, have good ductility at low

temperatures, and be able to withstand dynamic loads.

The impact test temperature shall be equal to the design

air temperature TD and the minimum average impact

energy shall be 42J.

The minimum average impact energy of the weld shall be

27J.

Lifting Sets

Certificates for Lifting sets and components

Sling Certificates

Components Certificates :

Chain

Shackles

Master link

Master link assembies

Coupling

Periodic Examination test and

repair

Inspection, test and repairs on containers

Schedule

Periodic Examination test and

repair

Inspection, test and repairs on containers

Visual Inspection

Markings

Welds

Pad eyes and lashing points

Structure

Door closures

Floor

Fork Pockets

Periodic Examination test and

repair

Inspection, test and repairs on lifting sets

Lifting sets shall be inspected at intervals not exeeding 1

year in accordance with the schedule listed in table 9-2

T: to indicate proof

load test, non-

destructive

examination, and

visual examination

VN: to indicate non-

destructive

examination and

visual examination

V : to indicate visual

examination only

Periodic Examination test and

repair

Inspection test and repair of lifting sets

Load Testing of chain sling legs

Non-Destructive examination of sling

components exept wire rope legs

Visual inspection of the lifting set

Chain and wire rope slings and components

Shackles

Marking of the lifting tag

Periodic Examination test and

repair

Inspection test and repair on tank containers

Offshore tank containers that are certified for

dangerous goods

according to the IMDG code are :

subject to 5-year periodic inspections and

tests,

and to intermediate 2.5-year periodic

inspections and tests

Periodic Examination test and

repair

Inspection Report

The inspection reports shall be attached to the

container certificate or be inserted in the As

Built dossier.

Appendix

Appendix

Appendix

Example of drop test

(Vertical Impact Test)

Vous aimerez peut-être aussi

- Cab&Chaissis ElectricalDocument323 pagesCab&Chaissis Electricaltipo3331100% (13)

- Pipe Fitting Symbol Guide Under 40 CharactersDocument5 pagesPipe Fitting Symbol Guide Under 40 CharactersErnalyn ValenciaPas encore d'évaluation

- Lifting ShacklesDocument8 pagesLifting Shacklesgechaves1Pas encore d'évaluation

- EG3409 Davit InspectionDocument10 pagesEG3409 Davit InspectionqaqcpipemanPas encore d'évaluation

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPOPas encore d'évaluation

- Pad Eye New ReleaseDocument10 pagesPad Eye New ReleaseEnrique BarajasPas encore d'évaluation

- Twenty Five Ton Padeye - SpreadsheetDocument4 pagesTwenty Five Ton Padeye - Spreadsheetoluomo1Pas encore d'évaluation

- Civil Service Exam Clerical Operations QuestionsDocument5 pagesCivil Service Exam Clerical Operations QuestionsJeniGatelaGatillo100% (3)

- DNV 2-7-3 2006Document22 pagesDNV 2-7-3 2006thanhhai66Pas encore d'évaluation

- Change APItoISODocument9 pagesChange APItoISOStephen KokoPas encore d'évaluation

- Pad Eye Calculation according to DNV 2.7-3Document9 pagesPad Eye Calculation according to DNV 2.7-3Jacek75% (4)

- SkyCiv Sample DNV 2 7 1 Design Report Example Integrated PDFDocument11 pagesSkyCiv Sample DNV 2 7 1 Design Report Example Integrated PDFCarlos Eduardo Alvarez SantiagoPas encore d'évaluation

- DNV2.7-1 Offshore ContainerDocument138 pagesDNV2.7-1 Offshore Containernewdao100% (1)

- Caodc RP 6.0 Inspection and Certification of BopDocument19 pagesCaodc RP 6.0 Inspection and Certification of BopEDWIN M.P0% (1)

- Shellliftingspecsops0055rev1 4Document125 pagesShellliftingspecsops0055rev1 4Marcos TadsioPas encore d'évaluation

- APPEA Guidelines For Liting Equipment Combined)Document101 pagesAPPEA Guidelines For Liting Equipment Combined)kunbasukiadi100% (1)

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- Chapter01 ShacklesDocument48 pagesChapter01 Shacklescalculus pussPas encore d'évaluation

- DerrickDocument17 pagesDerrickNigin Parambath100% (4)

- Mathcad - X 320016 30 22 PDFDocument1 pageMathcad - X 320016 30 22 PDFUmair LiaqatPas encore d'évaluation

- 11 DNV 2.7 3 Portable Offshore Units PDFDocument23 pages11 DNV 2.7 3 Portable Offshore Units PDFArgonauta_navegadorPas encore d'évaluation

- Design of Cargo Handling Baskets Step ChangeDocument27 pagesDesign of Cargo Handling Baskets Step ChangeSteve MorrisonPas encore d'évaluation

- DNV 2.7-1 Quick ReferenceDocument2 pagesDNV 2.7-1 Quick ReferenceengeniusPas encore d'évaluation

- 4 Design (Compatibility Mode) - tcm153-474863Document65 pages4 Design (Compatibility Mode) - tcm153-474863Gautam Vijay100% (2)

- DNV 2.7.1 2006Document60 pagesDNV 2.7.1 2006chiwankmattoPas encore d'évaluation

- Crosby ShackleDocument1 pageCrosby Shacklecaner_kurtoglu-1Pas encore d'évaluation

- DNV Os H205Document45 pagesDNV Os H205havona100% (1)

- Offshore Containers - DNV Standard 2-7!1!10071901Document60 pagesOffshore Containers - DNV Standard 2-7!1!10071901Luiz Magri100% (2)

- Examination Procedure For Runway Beam InspectionDocument6 pagesExamination Procedure For Runway Beam InspectionTrust EmmaPas encore d'évaluation

- New Hire WorkbookDocument40 pagesNew Hire WorkbookkPas encore d'évaluation

- DNV 2.22-Padeye TestingDocument2 pagesDNV 2.22-Padeye Testingepzilon1985Pas encore d'évaluation

- CCU Design and Handling GuidelinesDocument75 pagesCCU Design and Handling Guidelinesfahril100% (2)

- BS 5639Document7 pagesBS 5639Mohamed FaroukPas encore d'évaluation

- API Spec 8C - Specification For Drilling and Production Hoisting Equipment (PSL 1 and PSL 2)Document6 pagesAPI Spec 8C - Specification For Drilling and Production Hoisting Equipment (PSL 1 and PSL 2)hesam abbaszadehPas encore d'évaluation

- Har-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Document12 pagesHar-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Damar Budi LaksonoPas encore d'évaluation

- BS EN12079-1999 (Inspection and Testing of Offshore ContainerDocument32 pagesBS EN12079-1999 (Inspection and Testing of Offshore Containerjohnsonpinto100% (3)

- DNV 2.7 3 Portable Offshore Units OverviewDocument23 pagesDNV 2.7 3 Portable Offshore Units Overviewhelden50229881100% (4)

- InvoiceDocument1 pageInvoiceMuhammad YahdimanPas encore d'évaluation

- Tank Calibration:, Surveys & InspectionsDocument2 pagesTank Calibration:, Surveys & InspectionsIETqatarPas encore d'évaluation

- Offcon DNV Zorro SkidDocument7 pagesOffcon DNV Zorro SkidRAMSINGH CHAUHANPas encore d'évaluation

- Inspections Surveys and CertificatesDocument79 pagesInspections Surveys and CertificatesBhalchandra Chandakkar100% (1)

- Imo Circ 860 Guidelines For Offshore ContainersDocument6 pagesImo Circ 860 Guidelines For Offshore ContainersMohammed Abd El Rahman100% (2)

- Offshore Container (Generator Skid) Design Approval - 1Document14 pagesOffshore Container (Generator Skid) Design Approval - 1Stephen Koko100% (1)

- Certification Description Tcm4-29411Document12 pagesCertification Description Tcm4-29411bluesbankyPas encore d'évaluation

- Calculation Sheet for Lifting Set DNV 2.7-1Document3 pagesCalculation Sheet for Lifting Set DNV 2.7-1Nguyễn Quốc Phượng100% (1)

- Piping B31.3Document30 pagesPiping B31.3Tito Fernandez100% (2)

- DNV 2.7 2 Standard For Certification of Offshore Service Containers December 1995Document31 pagesDNV 2.7 2 Standard For Certification of Offshore Service Containers December 1995kingtohPas encore d'évaluation

- Ultrasonic Testing of Metal Pipe and Tubing: Standard Practice ForDocument11 pagesUltrasonic Testing of Metal Pipe and Tubing: Standard Practice ForBauyrzhanPas encore d'évaluation

- Offshore ContainersDocument40 pagesOffshore ContainerssalahjallaliPas encore d'évaluation

- Ovr IbDocument27 pagesOvr IbAriel CaresPas encore d'évaluation

- DNV ST E271 Offshore ContainersDocument107 pagesDNV ST E271 Offshore ContainersWantana RattaneePas encore d'évaluation

- BS en 12079-2 2006Document18 pagesBS en 12079-2 2006Carlos Roberto Ferreira JuniorPas encore d'évaluation

- DNV 2.7-2Document26 pagesDNV 2.7-2Timothy BabooramPas encore d'évaluation

- Swager Safety GuideDocument18 pagesSwager Safety GuideJason RobertsPas encore d'évaluation

- UD150L-40E Ope M501-E053GDocument164 pagesUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- Naseem & Son lifting manualDocument349 pagesNaseem & Son lifting manualSagar SharmaPas encore d'évaluation

- LR Energy Offshore Container Certification GuideDocument19 pagesLR Energy Offshore Container Certification GuidenamasralPas encore d'évaluation

- Daftar Tabel Berat BesiDocument21 pagesDaftar Tabel Berat BesiRamdani Hidayat100% (2)

- Schlage S-6800 ManualDocument32 pagesSchlage S-6800 Manualgeotechsoil1100% (1)

- Guidelines on Certification of ContainersDocument60 pagesGuidelines on Certification of ContainersSagar PanditPas encore d'évaluation

- Bridon Offshore ExplorationDocument44 pagesBridon Offshore ExplorationAthox QhurienPas encore d'évaluation

- Litewalk Steel GratingDocument2 pagesLitewalk Steel GratingDr Bugs TanPas encore d'évaluation

- Surface Safety Valve PsDocument2 pagesSurface Safety Valve PsDani JuandaPas encore d'évaluation

- Securing Straps & RatchetsDocument2 pagesSecuring Straps & RatchetsKhurram S. MuzammilPas encore d'évaluation

- Norsok G 001Document70 pagesNorsok G 001Grant HosiePas encore d'évaluation

- 04 Fab Install Stark Bogota 2019 8-5-19Document57 pages04 Fab Install Stark Bogota 2019 8-5-19DocimfernandezPas encore d'évaluation

- Quality Assurance Protocol-2Document1 pageQuality Assurance Protocol-2renjithv_4Pas encore d'évaluation

- Aboveground Storage Tank Inspection: On 25-26 June 2014Document44 pagesAboveground Storage Tank Inspection: On 25-26 June 2014iraprobotPas encore d'évaluation

- Catálogo Guindaste de Coluna DemagDocument72 pagesCatálogo Guindaste de Coluna Demag0842500% (1)

- Statutory Requirements On Pressure Vessels SystemsDocument42 pagesStatutory Requirements On Pressure Vessels Systemskashing_wongPas encore d'évaluation

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFDocument3 pagesITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanPas encore d'évaluation

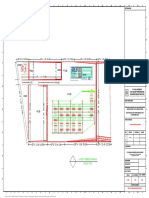

- Layout Dinding PenahanDocument1 pageLayout Dinding PenahanMuhammad YahdimanPas encore d'évaluation

- Barge Specification MSI 1Document11 pagesBarge Specification MSI 1Muhammad YahdimanPas encore d'évaluation

- Lampiran 1. Bagan Struktur PT. BUMA Site LATIDocument6 pagesLampiran 1. Bagan Struktur PT. BUMA Site LATIMuhammad YahdimanPas encore d'évaluation

- Class 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 charactersDocument2 pagesClass 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 characterskh88hmiPas encore d'évaluation

- Perhitungan Single BoxDocument114 pagesPerhitungan Single BoxRheiga DoremiPas encore d'évaluation

- Ges en SPC CC 0005 8Document24 pagesGes en SPC CC 0005 8Muhammad YahdimanPas encore d'évaluation

- Logo TotalDocument1 pageLogo TotalMuhammad YahdimanPas encore d'évaluation

- Soil and Rock InvestigationDocument3 pagesSoil and Rock InvestigationMuhammad YahdimanPas encore d'évaluation

- Blastroom PDFDocument4 pagesBlastroom PDFMuhammad YahdimanPas encore d'évaluation

- Standart Fitting Pipe 888888888888888Document6 pagesStandart Fitting Pipe 888888888888888Muhammad YahdimanPas encore d'évaluation

- Lift PlanDocument1 pageLift PlanJersson Ticona ZegarraPas encore d'évaluation

- Contoh CVDocument3 pagesContoh CVDzaky AhmadaPas encore d'évaluation

- StpamDocument1 pageStpamMuhammad YahdimanPas encore d'évaluation

- Strategic Highway Research Program Established New Superpave System for Asphalt MixturesDocument4 pagesStrategic Highway Research Program Established New Superpave System for Asphalt MixturesMuhammad YahdimanPas encore d'évaluation

- Daftar Alumni Jurusan Sipil UNHASDocument115 pagesDaftar Alumni Jurusan Sipil UNHASMuhammad Yahdiman100% (1)

- List of Reactive Chemicals - Guardian Environmental TechnologiesDocument69 pagesList of Reactive Chemicals - Guardian Environmental TechnologiesGuardian Environmental TechnologiesPas encore d'évaluation

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 pagesStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141Pas encore d'évaluation

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Document12 pagesPaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziPas encore d'évaluation

- MA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Document10 pagesMA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Sit LucasPas encore d'évaluation

- Felizardo C. Lipana National High SchoolDocument3 pagesFelizardo C. Lipana National High SchoolMelody LanuzaPas encore d'évaluation

- SBI Sample PaperDocument283 pagesSBI Sample Paperbeintouch1430% (1)

- Paper SizeDocument22 pagesPaper SizeAlfred Jimmy UchaPas encore d'évaluation

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDocument15 pagesComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikPas encore d'évaluation

- Grading System The Inconvenient Use of The Computing Grades in PortalDocument5 pagesGrading System The Inconvenient Use of The Computing Grades in PortalJm WhoooPas encore d'évaluation

- Ofper 1 Application For Seagoing AppointmentDocument4 pagesOfper 1 Application For Seagoing AppointmentNarayana ReddyPas encore d'évaluation

- SDS OU1060 IPeptideDocument6 pagesSDS OU1060 IPeptideSaowalak PhonseePas encore d'évaluation

- Key Fact Sheet (HBL FreedomAccount) - July 2019 PDFDocument1 pageKey Fact Sheet (HBL FreedomAccount) - July 2019 PDFBaD cHaUhDrYPas encore d'évaluation

- Induction ClassesDocument20 pagesInduction ClassesMichelle MarconiPas encore d'évaluation

- Consumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaDocument16 pagesConsumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaSundaravel ElangovanPas encore d'évaluation

- WindSonic GPA Manual Issue 20Document31 pagesWindSonic GPA Manual Issue 20stuartPas encore d'évaluation

- Srimanta Sankaradeva Universityof Health SciencesDocument3 pagesSrimanta Sankaradeva Universityof Health SciencesTemple RunPas encore d'évaluation

- Week 15 - Rams vs. VikingsDocument175 pagesWeek 15 - Rams vs. VikingsJMOTTUTNPas encore d'évaluation

- Maharashtra Auto Permit Winner ListDocument148 pagesMaharashtra Auto Permit Winner ListSadik Shaikh50% (2)

- Sinclair User 1 Apr 1982Document68 pagesSinclair User 1 Apr 1982JasonWhite99Pas encore d'évaluation

- Computer Networks Transmission Media: Dr. Mohammad AdlyDocument14 pagesComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Pas encore d'évaluation

- Paradigms of ManagementDocument2 pagesParadigms of ManagementLaura TicoiuPas encore d'évaluation

- 7 Aleksandar VladimirovDocument6 pages7 Aleksandar VladimirovDante FilhoPas encore d'évaluation

- Statistical Decision AnalysisDocument3 pagesStatistical Decision AnalysisTewfic SeidPas encore d'évaluation

- Exercise-01: JEE-PhysicsDocument52 pagesExercise-01: JEE-Physicsjk rPas encore d'évaluation