Académique Documents

Professionnel Documents

Culture Documents

L1-Well Life Cycle - Done 19jan

Transféré par

mirzafarhath0 évaluation0% ont trouvé ce document utile (0 vote)

57 vues31 pageswell

Titre original

L1-Well Life Cycle- Done 19jan

Copyright

© © All Rights Reserved

Formats disponibles

PPTX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentwell

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

57 vues31 pagesL1-Well Life Cycle - Done 19jan

Transféré par

mirzafarhathwell

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PPTX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 31

Well Lifecycle &

Drilling Process Overview

Arun Singh Chandel- Assistant Professor

B.Tech. (Chemical Engineering)

MS (Oil and Gas Engineering), United Kingdom

aschandel@ddn.upes.ac.in

COES

So just where does Oil Come from?

WEATHERING & EROSION

of igneous, sedimentary and

metamorphic rocks

TRANSPORT OF DEBRIS

by wind, running water, etc.., and

DEPOSITION in the sea

SUBSIDENCE

accompanied by compression and

cementation of loose sediments

FOLDING & UPLIFTING

accompanied by volcanic activity and

igneous intrusions

ERA SYSTEM AGE (approx.) millions of years

QUATERNARY Recent

Pleistocene

0

0.01

CAENOZOIC or TERTIARY Pliocene

Miocene

Oligocene

Eocene

Palaeocene

2

7

26

38

54

MESOZOIC or SECONDARY Cretaceous

Jurassic

Triassic

65

136

195

PALAEOZOIC or PRIMARY Permian

Carboniferous

Devonian

Silurian

Ordovician

Cambrian

225

280

345

395

440

500

AZOIC or ARCHAEAN Pre-Cambrian

Origin of Earth from -

570

4500

Just how long has it been there?

Oil in place

How much Oil?

Rock Matrix

Pore Space

(Porosity)

But

Pore space without

communication is

no good. We need

..

Permeability

Porosity

is expressed as a %

of pore space vs.

total rock volume

Drilling Process Overview Stage 1:

Geological Survey

Geological data is gathered and

interpreted by geophysicists and

geologists looking at where,

when, and at what depth there

could be hydrocarbons in place

Initially by using ...Seismic data

Subsurface formations are mapped

by measuring the time taken for

acoustic pulses generated in the

earth to return to the surface after

reflection or refraction from

interfaces between geological

formations with different physical

properties

Drilling Process Overview Stage 2:

Cost Estimation (AFE)

From this initial information

costs are estimated to

prepare an AFE (Application

for Expenditure) for

submission to management

Drilling Process Overview Stage 3:

Well Planning

Drilling engineers start the

process of designing the

well in conjunction with the

geologists, reservoir

engineers and well

completion specialists

Well Planning Consists of Things Like..

Rig Selection

Permits & Legislative compliance

Blow Out Prevention

Casing Design

Mud Programme

Solids Control Systems

Drill Bit Options

Directional Drilling Requirements

Logging (evaluation) Programme

Completion Requirements

HS&E (Health, Safety & Environmental) Aspects

... To name but a few...

Drilling Process Overview Stage 4:

Well Construction

The next stage is the

construction of the well

using drilling equipment

suitable for the pressure

and hazards expected

Well Types

Wildcat: Little or no previous drilling exploration activity in the area

Exploratory: Geological target selection based on seismic data, and geological

modelling i.e. no previous drilling in the prospective horizon

Appraisal: Delineates the reservoirs boundaries, usually drilled after the

exploratory discoveries

Producers: Drilling into a known reservoir

Infill: Drilling in known productive portions of the reservoir that have

not been properly drained. This is usually done later in the life of

the reservoir

Re-entry: Existing well re-entered to deepen, side-track, complete, or re-

complete

Drill Bits are used to cut / crush the rock

Roller Cone

PDC

These are made-up to heavy large diameter series

of tubes, collectively called...

... the Bottom Hole Assembly BHA

Drill Collar

Connection

Hevi-Wate Drill Pipe

Stabilizer

Drilling fluids: Mud - has to:

cool and lubricate the bit, drillstring, and to clean the bottom of

the hole

carry cuttings to surface

remove cuttings from the mud at surface minimise possible

subsequent formation damage

control formation pressures and to maintain hole integrity

assist in well logging operations

minimise corrosion of the drillstring, casing and tubing, minimise

contamination problems

minimise torque, drag and pipe sticking propensities, improve

drilling rate

Carry

Cuttings

to

Surface

Reduce

Rotational

Torque

Form

Filter

Cake

Stabilize

Formation

Lubricate

Drill Bit

Liner

Casing ... protects the newly drilled hole

Intermediate

Casing

Surface

Casing

Main functions of casing strings

Consolidate unstable formations that have just been drilled

through

Contain any pressures that may be encountered

Separate any different pressure regimes

Provide structural support for the BOPs and diverters

Protect sensitive formations from contamination

Provide a suitable environment for installation of production

or testing equipment such as packers, downhole valves,

tubing, liner hangers etc.

Packer

Production

Tubing

Production

Fluids

Casing String

Christmas

Tree

When a well has been

drilled and cased it

must now be

Completed in order

to produce the

hydrocarbons residing

in the reservoir

Completions

Modern completions

Drilling process overview Stage 5:

Well Maintenance

Once the well has been completed

and is flowing for commercial

purposes, it has to be maintained

with occasional intervention work for

replacement of worn parts e.g.

leaking down-hole safety valves, and

to gather pressure and temperature

information for reservoir

management

Produced Oil can be processed and stored ready for tankering in

Floating Production, Storage and Offloading (FPSO) Vessels

Or... By subsea pipelines etc...

.... Monitoring ....

Detailed reservoir models

and simulations are

constantly updated as new

development-drilling data

becomes available

enabling effective Field

Management

Drilling process overview Stage 6:

Abandonment

Abandonment - this is the stage when the reservoir is depleted

and seabed or land is returned to its natural environment

A well is abandoned when it reaches the end of its useful life or is

a dry hole.

The casing and other equipment is removed and salvaged.

Cement plugs are placed in the borehole to prevent migration of

fluids between the different formations.

The surface is reclaimed and returned to natural environment.

How an Oil Company is Generally Structured

Oil Company

(or Well operator)

Drilling Engineering Formation Evaluation Accounts Operations Reservoir Engineering Production Engineering Geology

Drilling Superintendent

Wells in Progress

How a Drilling Contractor is Generally Structured

Drilling Contractor

Accounts Rig Manager Rig Design & Maintenance

Tool Pusher Rig 1

Driller

Derrickman

Rig Crew

Tool Pusher Rig 2 (etc.

Driller

Derrickman

Rig Crew

Drilling Service companies

Drilling Service Companies

Drilling Fluids Drilling Cements

Directional Drilling Casing Running

Formation Evaluation Mud Logging

Drilling Bits Tool Rental

Well Completion Equipment Many others .....etc.

Further Reading

MIs Drilling Fluids Engineering Manual Chapter 1

Introduction

http://science.howstuffworks.com/oil-drilling.htm/printable

http://science.howstuffworks.com/oil-refining.htm/printable

http://www.glossary.oilfield.slb.com/Default.cfm

Vous aimerez peut-être aussi

- Well Control OpenDocument311 pagesWell Control OpenRobert Verret100% (1)

- Drill String Design & BHA DesignDocument115 pagesDrill String Design & BHA DesignUsama Bin Sabir97% (79)

- RatioDocument41 pagesRatioNaresh SainiPas encore d'évaluation

- ProbontrainDocument20 pagesProbontrainKoushik DasPas encore d'évaluation

- Drygasdownchoke - XLS: This Spreadsheet Calculates Downstream Pressure at Choke For Dry GasesDocument2 pagesDrygasdownchoke - XLS: This Spreadsheet Calculates Downstream Pressure at Choke For Dry Gasesmath62210Pas encore d'évaluation

- The Hydrogen Energy Transition (2004) Daniel SperlingDocument261 pagesThe Hydrogen Energy Transition (2004) Daniel SperlingmirzafarhathPas encore d'évaluation

- Practical Well Planning and Drilling Manual by Steve DevereuxDocument57 pagesPractical Well Planning and Drilling Manual by Steve Devereuxherikugis83% (6)

- Design of Heat ExchangersDocument20 pagesDesign of Heat ExchangersSudhir JadhavPas encore d'évaluation

- Shell& Tube Heat ExchangerDocument57 pagesShell& Tube Heat ExchangermirzafarhathPas encore d'évaluation

- 2.global Trends in Oil IndustryDocument52 pages2.global Trends in Oil IndustrymirzafarhathPas encore d'évaluation

- Kessler Et Al. 2010 JASPDocument29 pagesKessler Et Al. 2010 JASPmirzafarhathPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Paper 1 - 2017 EETDocument10 pagesPaper 1 - 2017 EETRayPas encore d'évaluation

- Chapter 2: Static Routing: Instructor MaterialsDocument63 pagesChapter 2: Static Routing: Instructor MaterialsAhmad Mustafa AbimayuPas encore d'évaluation

- Internet Intranet ExtranetDocument28 pagesInternet Intranet ExtranetAmeya Patil100% (1)

- Plea Agreement of ThomasbergDocument10 pagesPlea Agreement of ThomasbergSal CoastPas encore d'évaluation

- QP02Document11 pagesQP02zakwanmustafa0% (1)

- Experiment No 9 - Part1Document38 pagesExperiment No 9 - Part1Nipun GosaiPas encore d'évaluation

- BloodDocument22 pagesBloodGodd LlikePas encore d'évaluation

- Patient Care Malaysia 2014 BrochureDocument8 pagesPatient Care Malaysia 2014 Brochureamilyn307Pas encore d'évaluation

- Template For Public BiddingDocument3 pagesTemplate For Public BiddingFederico DomingoPas encore d'évaluation

- Geography Cba PowerpointDocument10 pagesGeography Cba Powerpointapi-489088076Pas encore d'évaluation

- Rachel Mitchell Task 1Document1 003 pagesRachel Mitchell Task 1nazmul HasanPas encore d'évaluation

- List of TCP and UDP Port NumbersDocument44 pagesList of TCP and UDP Port NumbersElvis JavierPas encore d'évaluation

- Genetic Engineering AssignmentDocument20 pagesGenetic Engineering AssignmentAcyl Chloride HaripremPas encore d'évaluation

- Attachment I - Instructions To Bidders - EEPNL EEPN (OE) L QA QC PDFDocument24 pagesAttachment I - Instructions To Bidders - EEPNL EEPN (OE) L QA QC PDFMathias OnosemuodePas encore d'évaluation

- ExSchutzkatalog Englisch 1Document61 pagesExSchutzkatalog Englisch 1marius_brkt6284Pas encore d'évaluation

- E2 Lab 2 8 2 InstructorDocument10 pagesE2 Lab 2 8 2 InstructorOkta WijayaPas encore d'évaluation

- VTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFDocument176 pagesVTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFIbrahim AwadPas encore d'évaluation

- Data Sheet Speaker StrobeDocument4 pagesData Sheet Speaker StrobeAneesh ConstantinePas encore d'évaluation

- APUS Court Cases: Escobedo V IllinoisDocument4 pagesAPUS Court Cases: Escobedo V Illinoisapi-3709436100% (1)

- Project Report On Design of Road IntersectionDocument15 pagesProject Report On Design of Road IntersectionJohn MalkinPas encore d'évaluation

- CV HariDocument4 pagesCV HariselvaaaPas encore d'évaluation

- 5th Year PES Mrs - Hamdoud Research Methodology 2Document3 pages5th Year PES Mrs - Hamdoud Research Methodology 2Rami DouakPas encore d'évaluation

- Case Study: Meera P NairDocument9 pagesCase Study: Meera P Nairnanditha menonPas encore d'évaluation

- Mechanical FPD P.sanchezDocument9 pagesMechanical FPD P.sanchezHailley DensonPas encore d'évaluation

- Geometric Driver Components Serial Copy: Topsolid'WoodDocument22 pagesGeometric Driver Components Serial Copy: Topsolid'Wooddrine100% (1)

- Evaluating The Procurement Strategy Adopted in The Scottish Holyrood Parliament Building ProjectDocument13 pagesEvaluating The Procurement Strategy Adopted in The Scottish Holyrood Parliament Building ProjectNnamdi Eze100% (4)

- Leyson vs. OmbudsmanDocument12 pagesLeyson vs. OmbudsmanDNAAPas encore d'évaluation

- C28x WorkshopDocument400 pagesC28x WorkshopMarcio De Andrade VogtPas encore d'évaluation

- Service Manual JLG 1055 S-N01600727600Document566 pagesService Manual JLG 1055 S-N01600727600RAPID EQUIPMENT RENTAL67% (6)

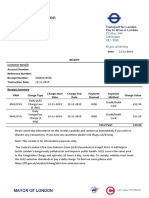

- Transport For London Pay To Drive in London: PO Box 344 Darlington Dl1 9qe TFL - Gov.uk/drivingDocument1 pageTransport For London Pay To Drive in London: PO Box 344 Darlington Dl1 9qe TFL - Gov.uk/drivingDanyy MaciucPas encore d'évaluation