Académique Documents

Professionnel Documents

Culture Documents

Chapter 2 Crystal Structure

Transféré par

Renu SekaranCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 2 Crystal Structure

Transféré par

Renu SekaranDroits d'auteur :

Formats disponibles

Chapter 3

Crystal Structure and

Noncrystalline Structure

Learning objectives

Describe what crystalline and noncrystalline materials

are

Draw unit cells for face-centered cubic (FCC), body-

centered cubic (BCC) and hexagonal close-packed

(HCP) crystal structures

Derive the relationships between unit cell edge length

and atomic radius for FCC and BCC crystal structures

Compute the densities for metals having FCC and BCC

structures

Write the designation for atom position, direction indices

and Miller indices for cubic crystals

Classify various types of crystalline imperfections (point

defect, linear defect and planar defect)

Crystalline and Amorphous

Structure

Most of engineering materials are

crystalline atoms are arranged in a

regular and repeating manner

Metals are crystalline

Minerals such as celestite (SrSo

4

),

amethyst (SiO

2

), alloys and some ceramic

materials are also crystalline

Amorphous without form, or non-

crystalline such as polymers, glasses and

some metals

Rare due to poor packing (only Po has this structure)

Simple cubic (SC)

Face-centered cubic (FCC)

Isolated unit cell Hard-sphere unit cell Atomic-site unit cell

Face-centered cubic (FCC)

Relationship between the

lattice constant, a, and

the atomic radius, R.

Typical metals: -Fe, Al, Ni,

Cu, Ag, Pt, Au

Body-centered cubic (BCC)

Isolated unit cell Hard-sphere unit cell Atomic-site unit cell

Body-centered cubic (BCC)

Relationship between the

lattice constant, a, and the

atomic radius, R.

Typical metals: -Fe, V, Cr,

Mo, W

Hexagonal close-packed (HCP)

Relationship between edge length and atomic radius : a = 2R

Typical metals: Be, Mg, -Ti, Zn, Zr

Isolated unit cell Hard-sphere unit cell Atomic-site unit cell

R

Atoms/unit cell

Unit cell c ontains:

6 x 1/2 + 8 x 1/8

= 4 atoms/unit cell

Unit cell c ontains:

1 + 8 x 1/8

= 2 atoms/unit cell

SC

BCC FCC

Unit cell contains:

8 Corners x 1/8

= 1 atom/unit cell

a

R=0.5a

a

a

Metals density

1. Copper is an fcc metal with an atomic

radius of 0.128 nm. Calculate the density

of copper. Atomic mass of copper is

63.55 g/mol.

2. Tungsten is a bcc metal with an atomic

radius of 0.137 nm. Calculate the density

of tungsten. Atomic mass of tungsten is

183.85 g/mol

5

Atomic packing factor (APF)

fraction of unit-cell volume occupied by

atoms

Calculate the APF for the BCC and FCC unit cell,

assuming the atoms to be hard spheres.

13

Theoretical Density, r

where n = number of atoms/unit cell

A = atomic weight

V

C

= Volume of unit cell = a

3

for cubic

N

A

= Avogadros number

= 6.022 x 10

23

atoms/mol

Density = r =

V

C

N

A

n A

r =

Cell Unit of Volume Total

Cell Unit in Atoms of Mass

Space lattice and unit cell

Crystalline structure regular

and repeating

Unit cell structural unit that

is repeated by translation in

forming a crystalline structure

Lattice constants length of a

unit cell edge and/or angle

between crystallographic

axes

Seven Crystal

Systems

Unique unit cell

shapes that can

be stacked

together to fill 3-D

space

14 Bravais Lattices

Lattice points theoretical points arranged periodically in 3-D space

Lattice positions

Atom positions in a

BCC unit cell

Directions in the unit cells: Miller indices is a notation

system in crystallography for planes and directions in

crystal

Shorthand notation

1. determine the coordinates of two points

2. subtract the coordinates of the tail from the head

3. Clear fraction and reduce the results to lowest

integers

4. Enclose the number in a brackets [ ]. If negative sign

is produced, represent the negative sign with a bar over

the number

Lattice direction

Lattice planes Miller indices

1. Identify the points at which the plane intercepts

2. Take receprocal of these inetercepts

3. Clear fractions

4. Enclose the number in a brackets , no comma [ ]. If negative

sign is produced, represent the negative sign with a bar over the

number

21

Crystallographic Planes

z

x

y

a b

c

4. Miller Indices (110)

example a b c

z

x

y

a b

c

4. Miller Indices (100)

1. Intercepts 1 1

2. Reciprocals

1/1 1/1 1/

1 1 0

3. Reduction 1 1 0

1. Intercepts 1/2

2. Reciprocals 1/ 1/ 1/

2 0 0

3. Reduction 2 0 0

example a b c

22

Crystallographic Planes

z

x

y

a b

c

4. Miller Indices (634)

example

1. Intercepts 1/2 1 3/4

a b c

2. Reciprocals

1/ 1/1 1/

2 1 4/3

3. Reduction 6 3 4

(001) (010),

Family of Planes {hkl}

(100), (010), (001), Ex: {100} = (100),

Single crystal : A material formed by the growth of a crystal nucleus without

secondary nucleation or impingement on other crystals; a regular three-

dimensional structure extends throughout the material

Polycrystalline materials are solids that are composed of many crystallites of

varying size and orientation. The variation in direction can be random (called

random texture) or directed, possibly due to growth and processing conditions.

Anisotropy: Is the property being directionally dependent

Modulus of Iron:

[100]= 125 MPa

[110]= 210 Mpa

[111]= 272 MPa

Isotropic: Substances in which measured properties are independent of

direction. Example; Tungsten , modulus is 384 in all direction [100], [110],

[111].

25

X-Rays to Determine Crystal Structure

X-ray

intensity

(from

detector)

q

q

c

d =

n l

2 sin q

c

Measurement of

critical angle, q

c

,

allows computation of

planar spacing, d.

Incoming X-rays diffract from crystal planes.

Adapted from Fig. 3.37,

Callister & Rethwisch 3e.

reflections must

be in phase for

a detectable signal

spacing

between

planes

d

q

l

q

extra

distance

travelled

by wave 2

26

X-Ray Diffraction Pattern

Adapted from Fig. 3.20, Callister 5e.

(110)

(200)

(211)

z

x

y

a

b

c

Diffraction angle 2q

Diffraction pattern for polycrystalline -iron (BCC)

I

n

t

e

n

s

i

t

y

(

r

e

l

a

t

i

v

e

)

z

x

y

a

b

c

z

x

y

a

b

c

27

Vacancy atoms

Interstitial atoms

Substitutional atoms

Point defects

Types of Imperfections

Dislocations

Line defects

Grain Boundaries

Area defects

28

Vacancies:

-vacant atomic sites in a structure which is produced when an

atom is missing from a normal sites.

-Produced at high temperature or by radiation damage

-At room temp few vacancies are present, but this number

increases exponentially as we increase temp.

n

v

-=n exp (-Q/RT)

n

v

is the number of vacancies per m

3

n is the number of lattice points per m

3

Q is the energy required to produce vacancy

R is gas constant and T temp (K)

Point Defects in Metals

Vacancy

distortion

of planes

29

Interstitial defects is produced when an extra atom is

inserted into the lattice structure.

-Present as impurities

-Once introduced, the number of interstitial atom in the

structure remains the same even the temperature is

changed.

Fig. 5.11, Callister & Rethwisch 3e.

self-

interstitial

distortion

of planes

31

Point Defects in Polymers

Defects due in part to chain packing errors and impurities such

as chain ends and side chains

Adapted from Fig. 5.7,

Callister & Rethwisch 3e.

Adapted from Fig. 5.7,

Callister & Rethwisch 3e.

32

Line Defects (Dislocations)

Are one-dimensional defects around which atoms are

misaligned

Produced during solidification or deformation

Edge dislocation:

extra half-plane of atoms inserted in a crystal structure

Screw dislocation:

spiral planar ramp resulting from shear deformation

33

Fig. 5.8, Callister & Rethwisch 3e.

Edge Dislocation

34

Edge, Screw, and Mixed

Dislocations

Adapted from Fig. 5.10, Callister & Rethwisch 3e.

Edge

Screw

Mixed

Significance of dislocations

Slip: The process by which a dislocation

moves and cause a material to deform is

called slip

Higher the number of slip system easy to

material deform.

Dislocation move to the closed pack

direction

There are certain no of slip system for crystal:

FCC=12

BCC=48

HCP=3 or higher (depend on temperature),

thats some materials shows DBTT (ductile

brittle transition temperature)

Surface defects:

Grain boundaries- boundary between two grain having

different crystallographic orientation

-small grain gives higher strength

Twin boundary produces during annealing

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- MWG Product 11.0, X PG-PRODUCT-1021-EnDocument941 pagesMWG Product 11.0, X PG-PRODUCT-1021-EnKuncen Server (Yurielle's M-Chan)Pas encore d'évaluation

- For Section A, Write Your Answer in The Answer Sheet Provided in Page 12Document12 pagesFor Section A, Write Your Answer in The Answer Sheet Provided in Page 12Renu SekaranPas encore d'évaluation

- Wesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksDocument8 pagesWesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksRenu SekaranPas encore d'évaluation

- Cell As A Unit of LifeDocument40 pagesCell As A Unit of LifeRenu SekaranPas encore d'évaluation

- Science Form 1Document15 pagesScience Form 1Renu SekaranPas encore d'évaluation

- Lesson Plan (Subject: SCIENCE)Document3 pagesLesson Plan (Subject: SCIENCE)Renu SekaranPas encore d'évaluation

- Lesson Plan Format 24-2 (Opal)Document3 pagesLesson Plan Format 24-2 (Opal)Renu SekaranPas encore d'évaluation

- Lesson Plan Format 27-1 (Opal)Document4 pagesLesson Plan Format 27-1 (Opal)Renu SekaranPas encore d'évaluation

- Intensive 4 Page 4Document1 pageIntensive 4 Page 4Renu SekaranPas encore d'évaluation

- Lesson Plan (Subject: SCIENCE)Document2 pagesLesson Plan (Subject: SCIENCE)Renu SekaranPas encore d'évaluation

- Lesson Plan Format 27-1Document4 pagesLesson Plan Format 27-1Renu SekaranPas encore d'évaluation

- Intensive 4 Page 2Document1 pageIntensive 4 Page 2Renu SekaranPas encore d'évaluation

- Intensive 3 Page 2Document1 pageIntensive 3 Page 2Renu SekaranPas encore d'évaluation

- E E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfDocument1 pageE E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfRenu SekaranPas encore d'évaluation

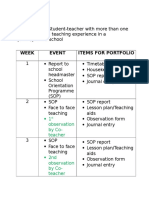

- MODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherDocument4 pagesMODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherRenu SekaranPas encore d'évaluation

- 1 PGDIPEDU (UAB) MyVLE Practicum SlideDocument17 pages1 PGDIPEDU (UAB) MyVLE Practicum SlideRenu SekaranPas encore d'évaluation

- Form 2 - Page 1Document1 pageForm 2 - Page 1Renu SekaranPas encore d'évaluation

- MODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherDocument4 pagesMODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherRenu SekaranPas encore d'évaluation

- Chapter 2b Molecular Diffusion in LiquidDocument12 pagesChapter 2b Molecular Diffusion in LiquidRenu SekaranPas encore d'évaluation

- Form 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Document8 pagesForm 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Renu SekaranPas encore d'évaluation

- Kids Can 5 - SyllabusDocument1 pageKids Can 5 - SyllabusAlejandra100% (2)

- Iso Iec Fdis 14763-3 - 2014Document32 pagesIso Iec Fdis 14763-3 - 2014alferedPas encore d'évaluation

- Queue Tree - Mutiple Wan Interfaces - What Should Be The Parent - MikroTikDocument25 pagesQueue Tree - Mutiple Wan Interfaces - What Should Be The Parent - MikroTikTony CervantesPas encore d'évaluation

- AdadasdDocument6 pagesAdadasdABHIROOP KPas encore d'évaluation

- Qabar Ki Pehli RaatDocument37 pagesQabar Ki Pehli RaatmadaniislamPas encore d'évaluation

- Wikibooks - Windows ProgrammingDocument120 pagesWikibooks - Windows Programmingmhardware100% (1)

- ABB-S4C+Rapid 4 - 0 - 100Document1 036 pagesABB-S4C+Rapid 4 - 0 - 100Eduard Lupus Lobo100% (1)

- 7613 TST5329 FP Ict4ll14Document3 pages7613 TST5329 FP Ict4ll14Lorena LisandraPas encore d'évaluation

- Keyboard Shortcuts - Mac GuidesDocument7 pagesKeyboard Shortcuts - Mac Guideserwinmiranda20033Pas encore d'évaluation

- Class 24: Case Study: Building A Simple Postfix Calculator: Introduction To Computation and Problem SolvingDocument16 pagesClass 24: Case Study: Building A Simple Postfix Calculator: Introduction To Computation and Problem SolvingyekychPas encore d'évaluation

- BotanicsDocument108 pagesBotanicsNalog RaznoPas encore d'évaluation

- Marcus Katz - Tarosophy Squared - Recovering The Spiritual Dignity of Tarot-Forge Press (2021)Document681 pagesMarcus Katz - Tarosophy Squared - Recovering The Spiritual Dignity of Tarot-Forge Press (2021)Gei Khristine100% (11)

- Homiletics An Introductory OverviewDocument11 pagesHomiletics An Introductory OverviewwilsonPas encore d'évaluation

- Utmconversions1Document14 pagesUtmconversions1K.k. SaraswatPas encore d'évaluation

- Funeral Games in Honor of Arthur Vincent LourieDocument321 pagesFuneral Games in Honor of Arthur Vincent LourieManuel CoitoPas encore d'évaluation

- 2FA Authentication For ABAP StackDocument3 pages2FA Authentication For ABAP StackAdrianPas encore d'évaluation

- Coding Assignment From XoxodayDocument2 pagesCoding Assignment From XoxodayKESHAV TYAGIPas encore d'évaluation

- ChödDocument5 pagesChödrangdroll dzogchenrimePas encore d'évaluation

- Presentation DW DMDocument132 pagesPresentation DW DMDinesh GokuladasPas encore d'évaluation

- 1.differential EquationsDocument13 pages1.differential EquationsAbhishek SakatPas encore d'évaluation

- Week 4 - Matthews & Yip (2009) Contact Induced GrammaticalizationDocument30 pagesWeek 4 - Matthews & Yip (2009) Contact Induced GrammaticalizationcolormemoPas encore d'évaluation

- QC Welding Inspector Interview Questions & Answers: Search For Jobs..Document1 pageQC Welding Inspector Interview Questions & Answers: Search For Jobs..kokaanilkumarPas encore d'évaluation

- Statement of The Problem/Objective: LessonDocument8 pagesStatement of The Problem/Objective: LessonPrincess ZamoraPas encore d'évaluation

- Critique PaperDocument1 pageCritique PaperNoemi Jane AmbonPas encore d'évaluation

- Project Based Learning Report On: Event Management System Using CDocument28 pagesProject Based Learning Report On: Event Management System Using CAniket BhoknalPas encore d'évaluation

- XTSC RMDocument1 461 pagesXTSC RM王佳旭Pas encore d'évaluation

- Onject Oriented ProgrammingDocument16 pagesOnject Oriented ProgrammingDeepak MalusarePas encore d'évaluation

- Grad Student Resume Doc XDocument1 pageGrad Student Resume Doc Xappie yhunazcaPas encore d'évaluation

- Spring Mass Dumper Project ReportDocument6 pagesSpring Mass Dumper Project Reportking of captainPas encore d'évaluation