Académique Documents

Professionnel Documents

Culture Documents

Soldering Iron

Transféré par

HilaryValdezRamosCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Soldering Iron

Transféré par

HilaryValdezRamosDroits d'auteur :

Formats disponibles

Mary Grace V.

Ramos

Carla Camille C. Closa

GAS TORCH SOLDERING IRON WITH

ADJUSTABLE: A TECHNICAL

FEASIBILITY STUDY

STATEMENT OF THE PROBLEM

Poor power supply can cause several

black out or power interruption.

Electricity tools or equipment cant be

used in this kind of situation.

When users are working in a dimly lit

setting.

OBJECTIVES OF THE STUDY

To design and construct the soldering electronics

equipment;

To design and construct soldering iron powered by a

gas;

To design and construct a gas torch soldering iron with

adjustable light;

To develop the gas torch soldering iron with adjustable

light would be helpful in case of emergency like power

interruption.

To construct it out of locally available materials

To test and evaluate the performance of the

equipment through testing; and

To determine the cost of the development

SIGNIFICANCE OF THE STUDY

To the student, it serves as a new project for the

electronics shop expose to a production type of

job that is similar in the field of technology

To the technician, to know the efficiency using

Gas Torch Soldering Iron other than the usual

soldering Iron

To the society, the use of Gas Torch Soldering

Iron is an option in case of electricity emergency

SCOPE AND LIMITATION

Focused on the design, construction, test and

evaluation of a Gas Torch Soldering Iron with

Adjustable Light.

Light limited only to the soldering in case of dark

operation can last at least 16 hours in use, because it

is only battery operated.

The availability of the equipment is reliable enough

when some unexpected situation arises.

It is technically feasible due to the fact that its design is

simple and construction is available in the market.

RELATED STUDIES

In the study conducted by, Esguerra, Dela Cruz, and

Bautistas (2006) study entitled A Improvised Rechargeable

Soldering Iron: A Technical Feasibility Study, the proponents

improved the iron to be rechargeable. It can power up using

charger and switch. On the other hand, Garcia and Nons

(2006) study entitled Digital Soldering Iron Controller with

Thermometer: A feasibility Study, produced a new design

equipped with a thermometer so it can control, if not totally,

cases of overheating.

SYNTHESIS

The related studies that says further was the

basis of the researcher. It is noticeable through

that nobody has attempted to produce a soldering

iron with built-in light source with it to make

soldering more convenient.

MATERIALS

Soldering tip- A hand tool consisting of a handle fixed to a

copper tip that is heated, electrically or in a flame, and used to

melt and apply solder.

Adjustment knob- controls the flow of gas.

Filter valve- Regulate the flow of gases

Orifice-also used to release the gas.

Panasonic ultra-heavy duty 9v- It is used as a source of

L.E.D light in the gas torch soldering iron.

L.E.D light 3v-are used in any place that needs a bright light

Battery holder- compartments that accepts a battery or

batteries.

Multi-fill adaptor- Serve as reloading station of the butane

gas fuel.

Gas Cylinder- Serve as storage of butane gas.

Solid Wire- use to hold the adjustable of the gas soldering

iron.

Shielded wires and Magnetic wire- use for the

connection of the battery holder and the LED light.

Soldering Torch-used to melt and apply solder

Gooseneck-. It is used to connect the cylinder gas to the

gas soldering iron.

TOOLS

Side cutting pliers- Pliers with cutting jaws at an angle

to the handles to permit cutting off wires close to

terminals.

Hack saw- A hacksaw is a fine-toothed saw, originally

and principally for cutting metal or plastic.

Screw driver- It serves to loosen and tightens screw.

Hand drill- a small portable drill held and operated by

hand. It used to drill tubes.

METHODS

Designing

Lay out

Cutting

assembly

SAMPLE DESIGN

ISOMETRIC VIEW OF GAS TORCH SOLDERING IRON WITH ADJUSTABLE LIGHT

EXPLODED VIEW OF GAS TORCH SOLDERING IRON WITH ADJUSTABLE

LIGHT

ORTHOGRAPHIC VIEW OG GAS TORCH SOLDERING IRON WITH ADJUSTABLE LIGHT

REFERENCE

Malvino, Albert, Bates David J. 2007, Electronic Principles,

the McGraw-Hill Companies, New York 7

th

Edition.

Neamen, Donald A. 2007, Micro Electronics Circuit Analysis and

Design,

the McGraw-Hill Companies, New York 3

rd

Edition.

Bautista, Richard H., Mark G. Dela Cruz, and Mart V.

Esquerra, 2006,

Rechargeable Soldering Iron: A Technical Feasibility

Study

Cavite State University-Rosario

Buisel, Apollo Bryan F. and Cherrry Maty Enriquez, 2009

Soldering Station: A Technical feasibility Study

Cavite State university

Vous aimerez peut-être aussi

- Tle Eim10 Q4 M4Document11 pagesTle Eim10 Q4 M4Ramil ObraPas encore d'évaluation

- 7 Steps Oxygen Sensor MTE THOMSON1Document9 pages7 Steps Oxygen Sensor MTE THOMSON12791957100% (1)

- Electrical Tools and EquipmentDocument26 pagesElectrical Tools and EquipmentNathan SantiagoPas encore d'évaluation

- YALE (C809 CUSHION) GLC030VX LIFT TRUCK Service Repair Manual PDFDocument21 pagesYALE (C809 CUSHION) GLC030VX LIFT TRUCK Service Repair Manual PDFhfjsjekmmdPas encore d'évaluation

- Foam Tank Installation Inspection ReportDocument13 pagesFoam Tank Installation Inspection ReportspazzbgtPas encore d'évaluation

- Chapter 10 - Fuel SystemsDocument87 pagesChapter 10 - Fuel SystemsKHAWAJA ZOHAIR NADEEM100% (1)

- Lda 450Document48 pagesLda 450Mirza Smailbegovic67% (3)

- Water Chiller SystemDocument19 pagesWater Chiller SystemAlok kumar92% (24)

- STIHL FS 91 91 R Owners Instruction ManualDocument116 pagesSTIHL FS 91 91 R Owners Instruction ManualJessPas encore d'évaluation

- EIM 12 Q1 Module 1 Mr. Hercules Marcos Sr.Document15 pagesEIM 12 Q1 Module 1 Mr. Hercules Marcos Sr.Robert kite ClementePas encore d'évaluation

- Pda Mechatro - Handbook 070226Document40 pagesPda Mechatro - Handbook 070226Paul Galvez100% (6)

- Hands-On BOP Workshop: Authors: Jaap Peetsold and Anton GreeffDocument8 pagesHands-On BOP Workshop: Authors: Jaap Peetsold and Anton GreeffKaleem UllahPas encore d'évaluation

- g11 Module ResistorDocument6 pagesg11 Module ResistorHarold Vernon MartinezPas encore d'évaluation

- Petron Fuel Supply AgreementDocument6 pagesPetron Fuel Supply AgreementMichael Garcia100% (4)

- EIM GRADE 12module4 New For StudentDocument17 pagesEIM GRADE 12module4 New For StudentSheridan Diente0% (1)

- q4 Ia Eim 11 Week 2Document4 pagesq4 Ia Eim 11 Week 2Harold Vernon MartinezPas encore d'évaluation

- Incandescent Lamp Classification, Installation ProcedureDocument19 pagesIncandescent Lamp Classification, Installation ProcedureMa Cecelia Borja50% (4)

- Activity 1 PCB Etching and EngravingDocument3 pagesActivity 1 PCB Etching and EngravingRyana Camille Roldan100% (1)

- Part3 Icho 11 15 PDFDocument124 pagesPart3 Icho 11 15 PDFManuel GuilhermePas encore d'évaluation

- 3rd Week Grade 11 EIM Activity SheetsDocument9 pages3rd Week Grade 11 EIM Activity SheetsLEO ANDREW san juanPas encore d'évaluation

- Bauer Junior IIDocument2 pagesBauer Junior IIHerbert M JuntakPas encore d'évaluation

- Class 4 EoowDocument74 pagesClass 4 EoowRyan Cardoza0% (1)

- Components of A CCTV SystemDocument15 pagesComponents of A CCTV Systemricky100% (1)

- Electrical Installation and Maintenance NC IiDocument25 pagesElectrical Installation and Maintenance NC Iiallanjules100% (1)

- Eulogio " Amang" Rodriguez Institute of Science and TechnologyDocument53 pagesEulogio " Amang" Rodriguez Institute of Science and TechnologyJohana MedallaPas encore d'évaluation

- Final ThesisDocument29 pagesFinal ThesisHilaryValdezRamos75% (4)

- Eim-Definition, Carreer OpportunitiesDocument21 pagesEim-Definition, Carreer OpportunitiesRodel de GuzmanPas encore d'évaluation

- Electrical Tools, Eq, Sup and MatDocument14 pagesElectrical Tools, Eq, Sup and MatXylene Lariosa-Labayan100% (2)

- Computer Hardware Servicing: Materials, Tools, Equipment and Testing DevicesDocument34 pagesComputer Hardware Servicing: Materials, Tools, Equipment and Testing DevicesAliyah Place50% (2)

- Electrical Installation and MaintenanceDocument5 pagesElectrical Installation and MaintenanceIvy Jannen PitogoPas encore d'évaluation

- Grade 12 - Media and Information Literacy - Q1 - W6Document5 pagesGrade 12 - Media and Information Literacy - Q1 - W6White SilencePas encore d'évaluation

- Automated Energy Saving Fan ThesisDocument66 pagesAutomated Energy Saving Fan ThesisDarwin BalangonPas encore d'évaluation

- EIM SP Power and Hydrolic Tools PDFDocument4 pagesEIM SP Power and Hydrolic Tools PDFrotsacreijav66666Pas encore d'évaluation

- EIM Front FDocument5 pagesEIM Front FAnjelou BonbonPas encore d'évaluation

- Open Wiring On InsulatorsDocument7 pagesOpen Wiring On InsulatorslouiePas encore d'évaluation

- Night Switch RogerDocument6 pagesNight Switch RogerNikoPas encore d'évaluation

- Module 1 (The Electric Circuits)Document11 pagesModule 1 (The Electric Circuits)Xavier Vincent VisayaPas encore d'évaluation

- Assessment of Electrical Safety Beliefs and Practices: A Case StudyDocument6 pagesAssessment of Electrical Safety Beliefs and Practices: A Case StudyARMANDO SORIANOPas encore d'évaluation

- Grade 12 Electronic Product Assembly and Servicing NCIIDocument3 pagesGrade 12 Electronic Product Assembly and Servicing NCIIMary Grace Dolotallas RiveraPas encore d'évaluation

- Manuel S. Enverga University Foundation Candelaria, Inc.: Periodical Examination - JanuaryDocument2 pagesManuel S. Enverga University Foundation Candelaria, Inc.: Periodical Examination - JanuaryZyriece CamillePas encore d'évaluation

- Research CapstoneDocument21 pagesResearch Capstonemarilou biolPas encore d'évaluation

- Using Properly Tools and Equipment Ninstallation and MaintenanceDocument12 pagesUsing Properly Tools and Equipment Ninstallation and MaintenanceRose Marie QuintanaPas encore d'évaluation

- Module 1 PDFDocument16 pagesModule 1 PDFJanix MagbanuaPas encore d'évaluation

- DIY Automatic Alcohol Dispenser No Arduino NeededDocument16 pagesDIY Automatic Alcohol Dispenser No Arduino NeededLuigi Ceda100% (1)

- Electronic Products Assembly and Servicing Ncii Competency-Based Learning Materials List of CompetenciesDocument33 pagesElectronic Products Assembly and Servicing Ncii Competency-Based Learning Materials List of Competenciesneil jovert ortostePas encore d'évaluation

- New Application in Generating Business IdeaDocument14 pagesNew Application in Generating Business Ideaedilberto perezPas encore d'évaluation

- 3.4.2 Cable Crimping and TestingDocument3 pages3.4.2 Cable Crimping and TestingRidzuan WrPas encore d'évaluation

- Tle Project-Night SwitchDocument2 pagesTle Project-Night SwitchDan FelixPas encore d'évaluation

- Feasibility Study On Viand Preference of Students in Naga National High SchoolDocument26 pagesFeasibility Study On Viand Preference of Students in Naga National High SchoolRina Mae Sismar Lawi-anPas encore d'évaluation

- TLEDocument4 pagesTLEAnonymous NcLnsmyEZPas encore d'évaluation

- Measuring ToolsDocument27 pagesMeasuring ToolsROWEL T. REYESPas encore d'évaluation

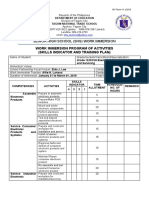

- Senior High School (SHS) Work Immersion: Work Immersion Program of Activities (Skills Indicator and Training Plan)Document2 pagesSenior High School (SHS) Work Immersion: Work Immersion Program of Activities (Skills Indicator and Training Plan)Alfie Lariosa100% (1)

- 3 Way and 4 Way Switches WorksheetDocument2 pages3 Way and 4 Way Switches WorksheetMinor100% (1)

- CSS 11 - Module 3 - CSS 11 - Module 3 - Wires and Cables, ToolsDocument12 pagesCSS 11 - Module 3 - CSS 11 - Module 3 - Wires and Cables, ToolsJoyPas encore d'évaluation

- Benthel Test Question in EimDocument3 pagesBenthel Test Question in EimMHar TrazonaPas encore d'évaluation

- Weng-Tools Finallll - Docx Feb28Document3 pagesWeng-Tools Finallll - Docx Feb28Juldan Belen OrdestaPas encore d'évaluation

- Eim 12Document3 pagesEim 12Shyr R Palm100% (1)

- Using ICT in Developing 21st Century SkillsICT in The 21st Century SkillsDocument5 pagesUsing ICT in Developing 21st Century SkillsICT in The 21st Century SkillsMariel Marfa UnatoPas encore d'évaluation

- Electric FanDocument38 pagesElectric FanKirby Morales67% (3)

- Chapter 1 Intro To ElectricityDocument14 pagesChapter 1 Intro To ElectricityRia Bariso100% (1)

- The Multitester HandoutsDocument19 pagesThe Multitester HandoutsBien MedinaPas encore d'évaluation

- ResumeDocument7 pagesResumemaykee01Pas encore d'évaluation

- Ports and CablesDocument12 pagesPorts and CablesAngelyn Lingatong100% (2)

- Activity Sheet Flexible Armored CableDocument3 pagesActivity Sheet Flexible Armored CableMarife Culaba100% (4)

- COC 1 - Computer Systems Servicing Presentation by Horacio N. Aceveda JRDocument92 pagesCOC 1 - Computer Systems Servicing Presentation by Horacio N. Aceveda JRRufino Allapitan GuiyabPas encore d'évaluation

- Entrepreneurship: Environmental Factors and Sources of OpportunitiesDocument15 pagesEntrepreneurship: Environmental Factors and Sources of OpportunitiesSyrine Myles SullivanPas encore d'évaluation

- Lesson Plan Grade 9 Basic Precaustions When Using A Flat IronDocument5 pagesLesson Plan Grade 9 Basic Precaustions When Using A Flat IronJessa Capuchino100% (2)

- EIM 5 Lesson 2Document41 pagesEIM 5 Lesson 2Victor RosalesPas encore d'évaluation

- Empowerment Technologies Contextualized Online Search and Research Skills / Developing Ict Content For Specific PurposesDocument3 pagesEmpowerment Technologies Contextualized Online Search and Research Skills / Developing Ict Content For Specific PurposesHannah MajadoPas encore d'évaluation

- Mig Welding Literature ReviewDocument8 pagesMig Welding Literature Reviewklbndecnd100% (1)

- Pin BrazingDocument2 pagesPin BrazingGlennSymingtonPas encore d'évaluation

- Syllabus For The Trade of Wireman: Week No:1Document43 pagesSyllabus For The Trade of Wireman: Week No:1Mohammed Abdul KaderPas encore d'évaluation

- Jan05 Tubulars p22 23Document2 pagesJan05 Tubulars p22 23abegarza1Pas encore d'évaluation

- Multiphase Flow Through Centrifugal PumpsDocument0 pageMultiphase Flow Through Centrifugal PumpsOrlando RojasPas encore d'évaluation

- Improving Turnarounds and Operations With Online CleaningDocument7 pagesImproving Turnarounds and Operations With Online CleaningMarvin Mendez GonzalesPas encore d'évaluation

- Level Switch Msi 96003421Document6 pagesLevel Switch Msi 96003421Sanyi48Pas encore d'évaluation

- Bissell Little Green Carpet Cleaner 1400CDocument12 pagesBissell Little Green Carpet Cleaner 1400CmarabskyPas encore d'évaluation

- Muskat EvingerDocument14 pagesMuskat EvingerChristian PradaPas encore d'évaluation

- Externally Fired Microturbine FlyerDocument1 pageExternally Fired Microturbine FlyerPaulFerry100% (1)

- Actron Catalog PDFDocument20 pagesActron Catalog PDFJorge OsorioPas encore d'évaluation

- Basic RefineryDocument17 pagesBasic RefineryKhairatun NisaPas encore d'évaluation

- Model P400P3Document1 pageModel P400P3lilirenePas encore d'évaluation

- 204 Operator Manual 2004Document141 pages204 Operator Manual 2004Jesus AguinagaPas encore d'évaluation

- Audi Power To Gas News (Media)Document3 pagesAudi Power To Gas News (Media)asmecsiPas encore d'évaluation

- Operation and Maintenance Manual: Panel Mount PRO/portionerDocument32 pagesOperation and Maintenance Manual: Panel Mount PRO/portionerAAR143Pas encore d'évaluation

- 101401-7321 - Isuzu Şampi̇yonDocument4 pages101401-7321 - Isuzu Şampi̇yonBaytolgaPas encore d'évaluation

- Articol Evolutie OffshoreDocument17 pagesArticol Evolutie OffshoreAna MariaPas encore d'évaluation

- Omegas Prezentacija 01Document20 pagesOmegas Prezentacija 01Predrag Djordjevic100% (1)

- Generator Set Data Sheet 2000 KW ContinousDocument4 pagesGenerator Set Data Sheet 2000 KW Continousricva_rjPas encore d'évaluation

- Tpd1357e1 PDFDocument68 pagesTpd1357e1 PDFAndres Lema100% (1)