Académique Documents

Professionnel Documents

Culture Documents

Kiln Area Learning Report

Transféré par

AbasiemekaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kiln Area Learning Report

Transféré par

AbasiemekaDroits d'auteur :

Formats disponibles

LEARNING REPORT

Safety Considerations

Mass Flow

Major Systems

Kiln Feed Extraction

Dedusting

Preheating/Pre-Calcining

Pyro-processing

Cooling

Insulation

Fuel

Blowers

Transport

Plant Air

Auxiliaries

Kiln Camera

Gas Analyzers

Air blasters

Interlocks

Routine Activities

Inspections

Housekeeping

De-blocking

Cleaning kiln camera

Emptying pan conveyor dust tray

Poking (kiln backend, burner rhino

horn)

PRESENTATION OUTLINE

Hazards:

Hot surfaces/environment

Fire

Heights

Gas handling

Oil handling

Noise

Others

Mitigation:

PPE: Hard hat, coverall, safety

shoes, hand gloves, eye goggles

are standard PPE in UniCem. Area

specific requirements include

thermal suit, ear muff.

Equipment: Fire extinguishers,

Housekeeping.

Safety Considerations

Safety Procedures:

Risk assessment, hot work permit, work at height & fall hazard risk assessment,

confined space permit, scaffold request

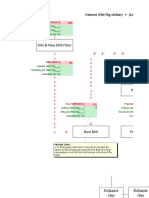

Mass Flow

Material, Gas, Dust

Material Flow

X X X X X X X

2

3

4

5

CF Silo

K K

L.O.W.

Bin

B B

Mixing

Vessel

Kiln

G

C

a

l

c

i

n

e

r

Cooler

X

Clinker

Silo

Gas Flow

X X X X X X X

2

3

4

5

CF Silo

K K

L.O.W.

Bin

B B

Mixing

Vessel

Kiln

G

C

a

l

c

i

n

e

r

Cooler

X

Clinker

Silo

Dust Reclamation Flow

X X X X X X X

2

3

4

5

CF Silo

K K

L.O.W.

Bin

B B

Mixing

Vessel

Kiln

G

C

a

l

c

i

n

e

r

Cooler

X

Clinker

Silo

Major Systems

Kiln Feed Extraction, Preheating/Pre-Calcining, Pyro-processing, Cooling,

Insulation, Fuel, Blowers, Transport, Plant Air & Water

Kiln Feed System

X X X X X X X

CF Silo

K K

L.O.W. Bin

B B

Mixing Vessel

1. Extraction gates:

- 7 in number

- Operate according to a predetermined sequence to extract material from

the CF-Silo at different rates. This is key to CF-Silo homogenization

- Pneumatically actuated

2. Extraction air-slides

3. Aeration system & patches:

- Responsible for fluidization of material

- 42 aeration patches

- Fed by blowers 341BL300, 305, 310 (for extraction) and 351BL110, 111 (for

LOW)

4. Mixing tank

5. Butterfly valves

6. Loss-of-Weight bin:

- Allows for accurate metering of kiln feed flow

- 3 load cells

- Operates by using control parameters to open/close the Kiln feed flow

control gates to achieve flow set-point

7. Kiln feed control gates

8. Air-slide 300

9. Air-lift 351AL340:

- Powered by 6 blowers 351BL342 to 347

- Operating pressure range (420 480)mbar

Dedusting

X X X X X X X

CF Silo

K K

L.O.W. Bin

B B

Mixing Vessel

1.

- 7 in number

- Operate according to a predetermined sequence to extract material from

the CF-Silo at different rates. This is key to CF-Silo homogenization

- Pneumatically actuated

2. Extraction air-slides

3. Aeration system & patches:

- Responsible for fluidization of material

- 42 aeration patches

- Fed by blowers 341BL300, 305, 310 (for extraction) and 351BL110, 111 (for

LOW)

4. Mixing tank

5. Butterfly valves

6. Loss-of-Weight bin:

- Allows for accurate metering of kiln feed flow

- 3 load cells

- Operates by using control parameters to open/close the Kiln feed flow

control gates to achieve flow set-point

7. Kiln feed control gates

8. Air-slide 300

9. Air-lift 351AL340:

- Powered by 6 blowers 351BL342 to 347

- Operating pressure range (420 480)mbar

Kiln Feed System

X X X X X X X

CF Silo

K K

L.O.W. Bin

B B

Mixing Vessel

1. Extraction gates

2. Extraction air-slides

3. Mixing tank

4. Butterfly valves

5. Loss-of-Weight bin

6. Kiln feed control gates

7. Air-slide 300

8. Air-lift

Refractories

X X X X X X X

CF Silo

K K

L.O.W. Bin

B B

Mixing Vessel

1. Extraction gates

2. Extraction air-slides

3. Mixing tank

4. Butterfly valves

5. Loss-of-Weight bin

6. Kiln feed control gates

7. Air-slide 300

8. Air-lift

Refractories

1. Exist as shaped and castable

2. Insulate vessel walls from thermal mechanical and chemical shock

1. Bricks

- Used exclusively in the kiln.

- Kiln process zones determine required properties

Refractories

Auxiliaries

Kiln Camera, Gas Analyzers, Air blasters

Kiln Main Burner System

Operation

Oil lance

Material Transport

Transport Process Diagram

Considerations

Material

Kiln feed; Fine, Sometimes moist (GCT outlet)

Clinker; Coarse lumps, hot.

Kiln Area Transport Equipment

Air Slides

Air Lift

Screw Conveyors

Drag Chains

Pan Conveyor

Bucket elevator

Vous aimerez peut-être aussi

- Coal Mill Ball Interlocks-V0.0Document11 pagesCoal Mill Ball Interlocks-V0.0Junaid MazharPas encore d'évaluation

- Kiln Control and OperationDocument56 pagesKiln Control and OperationLe Hoang100% (1)

- CoolerDocument10 pagesCoolerbudiPas encore d'évaluation

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiPas encore d'évaluation

- 3 CementDocument22 pages3 CementnecdetdalgicPas encore d'évaluation

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharPas encore d'évaluation

- Kiln Inlet Risk AssessmentDocument2 pagesKiln Inlet Risk AssessmentmunatsiPas encore d'évaluation

- Raw MixDocument96 pagesRaw Mixshannu826826Pas encore d'évaluation

- Dinesh Agrawal: Dry-ProcessDocument19 pagesDinesh Agrawal: Dry-ProcessSantanu PachhalPas encore d'évaluation

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani aminePas encore d'évaluation

- Mill ProcessDocument6 pagesMill ProcesskamjulajayPas encore d'évaluation

- Process Measurements ScheduleDocument25 pagesProcess Measurements ScheduleShivesh RanjanPas encore d'évaluation

- EKO BESTWAY PROJECT - PPSXDocument22 pagesEKO BESTWAY PROJECT - PPSXJunaid MazharPas encore d'évaluation

- Plant Location: Preheater Feed Preheater String - Calciner TypeDocument33 pagesPlant Location: Preheater Feed Preheater String - Calciner TypeDilnesa EjiguPas encore d'évaluation

- Ball Charge DesignDocument12 pagesBall Charge DesignPaulo VidasPas encore d'évaluation

- Cement Kiln Pyro BalanceDocument44 pagesCement Kiln Pyro BalanceirfanPas encore d'évaluation

- 1 Heat BalanceDocument4 pages1 Heat BalanceKiran Veerubhotla100% (1)

- PR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkDocument6 pagesPR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkJuan Nacimba NacimbaPas encore d'évaluation

- Knowledge Sharing Training On Grinding Operation by Alok VermaDocument29 pagesKnowledge Sharing Training On Grinding Operation by Alok VermaBir SinghPas encore d'évaluation

- Pyroprocessing: Dr. Ari Diana SusantiDocument27 pagesPyroprocessing: Dr. Ari Diana SusantiTitan Titanovsky KoraagPas encore d'évaluation

- Solid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversityDocument36 pagesSolid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversitysreePas encore d'évaluation

- Optimization of Kiln Plants: Activities and Technical DetailsDocument10 pagesOptimization of Kiln Plants: Activities and Technical DetailsPaulo VidasPas encore d'évaluation

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcPas encore d'évaluation

- Grinding Media ConsumptionDocument9 pagesGrinding Media ConsumptionMuhammadPas encore d'évaluation

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDocument5 pagesUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditPas encore d'évaluation

- Calcined ClayDocument3 pagesCalcined ClaytimothyPas encore d'évaluation

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099Pas encore d'évaluation

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- Mod 7Document47 pagesMod 7mkpq100% (1)

- Pyro-Processing System - MASS & GAS FLOWDocument1 pagePyro-Processing System - MASS & GAS FLOWVijay BhanPas encore d'évaluation

- Process Control IEEE Eml RDocument40 pagesProcess Control IEEE Eml RFran JimenezPas encore d'évaluation

- Process Audit in Cement IndustryDocument64 pagesProcess Audit in Cement IndustryNITITN ASNANIPas encore d'évaluation

- Coal Drying (Dry Basis)Document9 pagesCoal Drying (Dry Basis)billyPas encore d'évaluation

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriPas encore d'évaluation

- Measurements of The Quality of Cement Produced From Looped LimestoneDocument30 pagesMeasurements of The Quality of Cement Produced From Looped LimestoneCharlie Dean100% (1)

- HT-2.2 RMR Heat Belance 5 Stage T17 M7,9Document1 pageHT-2.2 RMR Heat Belance 5 Stage T17 M7,9GiequatPas encore d'évaluation

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084Pas encore d'évaluation

- 04 - Combustion and 10 Golden RulesDocument30 pages04 - Combustion and 10 Golden RulesAfqan B-vPas encore d'évaluation

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanPas encore d'évaluation

- Department of Chemical EngineeringDocument19 pagesDepartment of Chemical EngineeringPandia RajanPas encore d'évaluation

- Cpi CoolersDocument47 pagesCpi CoolersRobert BrownPas encore d'évaluation

- Process - Operation - Optimization of The ETA Cooler - MugherDocument138 pagesProcess - Operation - Optimization of The ETA Cooler - Mugherzewdu dechasaPas encore d'évaluation

- KHD Suspension PreheaterDocument3 pagesKHD Suspension PreheaterTamer FathyPas encore d'évaluation

- Burning DashboardDocument3 pagesBurning DashboardMehmet C100% (1)

- Kiln TrippingDocument13 pagesKiln Tripping7atemmohPas encore d'évaluation

- Plant InvesticationDocument3 pagesPlant InvesticationirfanPas encore d'évaluation

- Coal Preparation: Chris HoltDocument24 pagesCoal Preparation: Chris HoltAhmed ElbehairyPas encore d'évaluation

- Process Control of LURM MillDocument6 pagesProcess Control of LURM Millimam janiPas encore d'évaluation

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationDilnesa EjiguPas encore d'évaluation

- 043 Grinding PDFDocument11 pages043 Grinding PDFbkchoudhury1993Pas encore d'évaluation

- BurnersDocument19 pagesBurnerssameh ibrahemPas encore d'évaluation

- Ball Mill OptimiztionDocument8 pagesBall Mill OptimiztionShakil AhmadPas encore d'évaluation

- PE Pyroprocessing Day 4 Volatilisation Balance Calculation: June 2004Document18 pagesPE Pyroprocessing Day 4 Volatilisation Balance Calculation: June 2004recaiPas encore d'évaluation

- NOx Reduction PDFDocument7 pagesNOx Reduction PDFfahimulehsanPas encore d'évaluation

- Anaerobic ChamberDocument24 pagesAnaerobic ChamberDip MajumderPas encore d'évaluation

- F43-Obajana Line 3-PM-04 - Clinker ProductionDocument109 pagesF43-Obajana Line 3-PM-04 - Clinker ProductionYhane Hermann BackPas encore d'évaluation

- C&I in CFBC-1Document25 pagesC&I in CFBC-1Prudhvi RajPas encore d'évaluation

- ILC Kiln Manual Ed1 PDFDocument70 pagesILC Kiln Manual Ed1 PDFBùi Hắc Hải100% (4)

- Diverter Damper Systems - BrochureDocument8 pagesDiverter Damper Systems - Brochuregionizz100% (1)

- AlkylationDocument50 pagesAlkylationGaurav Lunawat100% (1)

- Guidelines On n200 Billion Refinancing ManufactcturingDocument8 pagesGuidelines On n200 Billion Refinancing ManufactcturingAbasiemekaPas encore d'évaluation

- Inspection Route ScheduleDocument10 pagesInspection Route ScheduleAbasiemekaPas encore d'évaluation

- Dear Colleagues,: 1. 331CV303 Missing Bolt Replaced by MechanicalDocument1 pageDear Colleagues,: 1. 331CV303 Missing Bolt Replaced by MechanicalAbasiemekaPas encore d'évaluation

- Guidelines On n200 Billion Refinancing ManufactcturingDocument8 pagesGuidelines On n200 Billion Refinancing ManufactcturingAbasiemekaPas encore d'évaluation

- Production Graduate Engineers ExpectationsDocument1 pageProduction Graduate Engineers ExpectationsAbasiemekaPas encore d'évaluation

- Re: Blue Rose WaterDocument1 pageRe: Blue Rose WaterAbasiemekaPas encore d'évaluation

- Monthly Production Meeting MinutesDocument4 pagesMonthly Production Meeting MinutesAbasiemekaPas encore d'évaluation

- Internet Banking - Transfer ReceiptDocument1 pageInternet Banking - Transfer ReceiptAbasiemekaPas encore d'évaluation

- Kiln Log Sheet Sched 20140520 A Day DailyDocument47 pagesKiln Log Sheet Sched 20140520 A Day DailyAbasiemekaPas encore d'évaluation

- HBL Mfamosing 16 04 2013 V Dar-Sab-JoyDocument115 pagesHBL Mfamosing 16 04 2013 V Dar-Sab-JoyAbasiemekaPas encore d'évaluation

- Chevron AdvertDocument2 pagesChevron AdvertAbasiemekaPas encore d'évaluation

- Gmail - IELTS Test ConfirmationDocument2 pagesGmail - IELTS Test ConfirmationAbasiemekaPas encore d'évaluation

- Sensor Location Measuring Range/ideal ValueDocument1 pageSensor Location Measuring Range/ideal ValueAbasiemekaPas encore d'évaluation

- Unicem Cement Factory Access Control Policy/Procedure Rev.01Document5 pagesUnicem Cement Factory Access Control Policy/Procedure Rev.01AbasiemekaPas encore d'évaluation

- UAC AdvertDocument1 pageUAC AdvertAbasiemekaPas encore d'évaluation

- Risk Assessment - Cleaning of Bucket Elevator BoothDocument2 pagesRisk Assessment - Cleaning of Bucket Elevator BoothAbasiemekaPas encore d'évaluation

- Internal and External - Store KeeperDocument2 pagesInternal and External - Store KeeperAbasiemekaPas encore d'évaluation

- VACANCY - Electrical InspectorDocument2 pagesVACANCY - Electrical InspectorAbasiemekaPas encore d'évaluation

- Internal and External - Store AttendantDocument2 pagesInternal and External - Store AttendantAbasiemekaPas encore d'évaluation

- VACANCY - Operations AnalystDocument2 pagesVACANCY - Operations AnalystAbasiemekaPas encore d'évaluation

- VACANCY - Senior Automation EngineerDocument2 pagesVACANCY - Senior Automation EngineerAbasiemekaPas encore d'évaluation

- Analysis of A Telnet Session Hijack Via Spoofed MAC AddressesDocument10 pagesAnalysis of A Telnet Session Hijack Via Spoofed MAC AddressesstephenrajPas encore d'évaluation

- Raw Mill Patroller Checklist Route 1Document5 pagesRaw Mill Patroller Checklist Route 1AbasiemekaPas encore d'évaluation

- Risk Assessment - Loading of CBS Hopper Using Pay-LoaderDocument2 pagesRisk Assessment - Loading of CBS Hopper Using Pay-LoaderAbasiemekaPas encore d'évaluation

- Jewellery PolicyDocument2 pagesJewellery PolicyAbasiemekaPas encore d'évaluation

- Subject: Unicem Computer Auctioning Exercise: Assets Disposal CommitteeDocument1 pageSubject: Unicem Computer Auctioning Exercise: Assets Disposal CommitteeAbasiemekaPas encore d'évaluation

- Problem 468 - Project EulerDocument1 pageProblem 468 - Project EulerAbasiemekaPas encore d'évaluation

- Chevron AdvertDocument2 pagesChevron AdvertAbasiemekaPas encore d'évaluation

- 2014 Football World Cup Match ScheduleDocument0 page2014 Football World Cup Match ScheduleBadr Naseem100% (1)

- HBS - Zara Fast Fashion Case Write UpDocument4 pagesHBS - Zara Fast Fashion Case Write Upaaronhwalton100% (1)

- Articles About Social Issues - Whiter SkinDocument9 pagesArticles About Social Issues - Whiter Skinf aPas encore d'évaluation

- A Review On Different Yogas Used in The Management of Mandali Damsa Vrana W.S.R. To KriyakaumudiDocument11 pagesA Review On Different Yogas Used in The Management of Mandali Damsa Vrana W.S.R. To KriyakaumudiTiya TiwariPas encore d'évaluation

- 30xa 100t PDFDocument162 pages30xa 100t PDFleung ka kitPas encore d'évaluation

- Keira Knightley: Jump To Navigation Jump To SearchDocument12 pagesKeira Knightley: Jump To Navigation Jump To SearchCrina LupuPas encore d'évaluation

- Drill Bit Classifier 2004 PDFDocument15 pagesDrill Bit Classifier 2004 PDFgustavoemir0% (2)

- About TableauDocument22 pagesAbout TableauTarun Sharma67% (3)

- Cross System Create Supplier ProcessDocument14 pagesCross System Create Supplier ProcesssakthiroboticPas encore d'évaluation

- Buy Wholesale China Popular Outdoor Football Boot For Teenagers Casual High Quality Soccer Shoes FG Ag Graffiti Style & FootballDocument1 pageBuy Wholesale China Popular Outdoor Football Boot For Teenagers Casual High Quality Soccer Shoes FG Ag Graffiti Style & Footballjcdc9chh8dPas encore d'évaluation

- Data Analyst Chapter 3Document20 pagesData Analyst Chapter 3Andi Annisa DianputriPas encore d'évaluation

- SLHT Grade 7 CSS Week 5 Without Answer KeyDocument6 pagesSLHT Grade 7 CSS Week 5 Without Answer KeyprinceyahwePas encore d'évaluation

- Wind LoadingDocument18 pagesWind LoadingStephen Ogalo100% (1)

- Volleyball Unit PlanDocument4 pagesVolleyball Unit Planapi-214597204Pas encore d'évaluation

- Celestino vs. CIRDocument6 pagesCelestino vs. CIRchristopher d. balubayanPas encore d'évaluation

- Massey Ferguson MF7600 Technician Workshop ManualDocument798 pagesMassey Ferguson MF7600 Technician Workshop Manualgavcin100% (5)

- C305 - QTO Workshop PDFDocument90 pagesC305 - QTO Workshop PDFJason SecretPas encore d'évaluation

- KirbyDocument3 pagesKirbyNorhassanah UtosabuayanPas encore d'évaluation

- 3S Why SandhyavandanDocument49 pages3S Why SandhyavandanvivektonapiPas encore d'évaluation

- Appendicitis Case StudyDocument6 pagesAppendicitis Case StudyKimxi Chiu LimPas encore d'évaluation

- 2005 Warehouse Benchmark in GR PTDocument59 pages2005 Warehouse Benchmark in GR PTMarco Antonio Oliveira NevesPas encore d'évaluation

- Biography of Anna HazareDocument4 pagesBiography of Anna HazareGenesis FirstPas encore d'évaluation

- Castle CrashesDocument21 pagesCastle Crasheswicked wolfPas encore d'évaluation

- Auburn Bsci ThesisDocument5 pagesAuburn Bsci Thesisafksaplhfowdff100% (1)

- Exam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)Document10 pagesExam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)SadishPas encore d'évaluation

- Marketing Measurement Done RightDocument16 pagesMarketing Measurement Done RightWasim Ullah0% (1)

- CR-805 Retransfer PrinterDocument2 pagesCR-805 Retransfer PrinterBolivio FelizPas encore d'évaluation

- Esp8285 Datasheet enDocument29 pagesEsp8285 Datasheet enJohn GreenPas encore d'évaluation

- Memo ALS Literacy MappingDocument4 pagesMemo ALS Literacy MappingJEPH BACULINAPas encore d'évaluation

- Loan Agreement: Acceleration ClauseDocument2 pagesLoan Agreement: Acceleration ClauseSomething SuspiciousPas encore d'évaluation

- Maven MCQDocument55 pagesMaven MCQANNAPUREDDY ANIL KUMAR REDDY CSEPas encore d'évaluation